煎炸次数对大豆油及薯条脂质中极性组分的影响

2016-03-21冯红霞隋晓楠齐宝坤王中江江连洲曹文明

冯红霞,李 杨※,隋晓楠,齐宝坤,王中江,江连洲,曹文明

(1.东北农业大学食品学院,哈尔滨 150030; 2.上海粮食科学研究所,上海 200136)

煎炸次数对大豆油及薯条脂质中极性组分的影响

冯红霞1,李杨1※,隋晓楠1,齐宝坤1,王中江1,江连洲1,曹文明2

(1.东北农业大学食品学院,哈尔滨 150030;2.上海粮食科学研究所,上海 200136)

摘要:采用中压快速制备型色谱-高效体积排阻色谱技术,探索了煎炸次数对大豆油及薯条表面所吸附油脂中极性化合物总量(total polar compounds,TPC)及其组分的影响。结果表明,煎炸薯条后剩余的大豆油中的TPC总量随着煎炸次数的增加而是逐渐增加,而薯条表面所吸附油脂中的TPC含量也随之逐渐增加;同时,煎炸次数的增加,显著改变了极性组分氧化甘油三酯寡聚物(oxidized triglyceride oligomers,TGO)、氧化甘油三酯二聚物(oxidized triglyceride dimers,TGD)、氧化甘油三酯单体(oxidized triglyceride monomers,ox-TG)在大豆油中的分布,而甘油二酯(diacylglycerols,DG)的含量增加缓慢,游离脂肪酸和甾醇(free fatty acids and sterols,FFA & sterols)和其他未知小分子化合物的含量呈现波动性变化。煎炸次数严重影响了大豆油和薯条表面所吸附油脂中的TPC及其组分分布,也在一定程度上影响了薯条的健康价值。

关键词:油脂;食品加工;氧化;煎炸次数;薯条;极性组分;高效体积排阻色谱;氧化甘油三酯寡聚物;氧化甘油三酯二聚物

冯红霞,李杨,隋晓楠,齐宝坤,王中江,江连洲,曹文明. 煎炸次数对大豆油及薯条脂质中极性组分的影响[J]. 农业工程学报,2016,32(3):309-314.doi:10.11975/j.issn.1002-6819.2016.03.044http://www.tcsae.org

Feng Hongxia, Li Yang, Sui Xiaonan, Qi Baokun, Wang Zhongjiang, Jiang Lianzhou, Cao Wenming. Effect of frying cycles on polar components in soybean oil and l absorbed lipids of fried potatoes[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(3): 309-314. (in Chinese with English abstract)

Email:fenghongxia914@163.com

Email:liyanghuangyu@163.com

0 引 言

由于在煎炸过程中,油脂在大气氧、食物中的水分以及高温之间的相互作用下发生聚合、氧化和水解等显著反应而导致了极性化合物的生成[1]。极性化合物能够较全面的反映油脂在加热和煎炸食品时的劣变程度[2],因此其含量的测定也被认为是评价加热油品质的最值得信赖的方法[3-4],并被广泛用来评价煎炸油的品质[5]。

在煎炸过程中煎炸油的极性物质含量随煎炸时间而增加,同时煎炸油中对健康有害的成分含量增加。在油炸食品过程中,极性化合物能够粘附在食品上,不仅会对食品的外表皮厚度、感官特性、微观结构和质构特性等品质特性造成影响[6-7],食用后在人体内逐渐蓄积的极性化合物会引起许多不良反应,甚至引发人体细胞发生癌变[8]。蔡文辞[9]分析评价了煎炸油中总极性化合物的细胞毒性,发现随着极性化合物浓度和作用时间的增加,细胞的生长抑制作用显著增加、细胞的形态发生变化,同时细胞凋亡率增大。刘元法等[10]研究了极性化合物的致突变性,发现煎炸油中分离出的极性物质对鼠伤寒沙门氏菌的致基因突变作用较强。国外文献中也有有关极性化合物导致基因突变、染色体突变从而诱发癌症如乳腺癌、结肠癌等相关报道[11-14]。这些研究表明极性化合物对人类健康存在一定的威胁。

近年来,人们对煎炸油中极性化合物的分离测定方法[8,15-17]、以及煎炸条件对其含量的影响[18-19]等方面进行了较详细的研究并取得了一定的进展。此外,高效体积排阻色谱技术(high performance size-exclusion chromatography,HPSEC)[20-21]的引入,使得中国对极性化合物的分析不再停留在其总质量上,它可以实现对极性化合物组分,包括氧化甘油三酯寡聚物(oxidized triglyceride oligomers,TGO)、氧化甘油三酯二聚物(oxidized triglyceride dimers,TGD)、氧化甘油三酯单体(oxidized triglyceride monomers,ox-TG)、甘油二酯(diacylglycerols,DG)以及游离脂肪酸和甾醇(free fatty acids and sterols,FFA &Sterols)等的分离测定。而且,随着研究的深入,发现同浓度的氧化甘油三酯对细胞的毒性最大,氧化甘油三酯二聚物次之,总极性化合物的细胞毒性最小[9],而TGD与TGO细胞毒性差异不明显[12]。由于国内外关于煎炸的试验大多集中于煎炸食物后油脂的理化特性,包括极性化合物总量的测定,缺少对煎炸后油脂中极性化合物具体组分的分析,同时,针对煎炸后食物脂质中极性化合物及其组分的变化也缺乏相关报道。因此,本文主要研究煎炸次数对大豆油及薯条表面所吸收油脂中的极性化合物总量的影响,并利用高效体积排阻色谱技术分析测定薯条对极性化合物组分的吸收情况。

1 材料与方法

1.1材料与仪器

大豆油(九三非转基因一级)市售;冷冻薯条 市售;;石油醚(30~60℃沸程)、乙醚、丙酮分析纯;四氢呋喃色谱纯。

3 L不锈钢单缸油炸锅(广东友田家用电器有限公司);真空旋转蒸发器(上海申胜生物科技有限公司);DZF-6050型真空干燥箱(上海一恒科技有限公司);FA2004型电子分析天平(上海舜宇恒平科学仪器有限公司);Waters2695型高效液相色谱仪、2414型示差折光检测器、Styragel HR高分辨率体积排阻色谱柱(内径7.8 mm,长300 mm)(美国Waters公司);食用油极性组分快速制备型柱层析系统(EOPC PFC SYSTEM)、Flash中压纯化制备柱(长11 cm,直径2.1 cm)(天津博纳艾杰尔科技有限公司)。

1.2试验方法

1.2.1煎炸试验

2 L油倒入煎炸锅,预热至180℃,保持30 min。每批薯条添加量200 g,(薯条/油质量体积比=1:10),煎炸时间7 min,间隔时间8 min,1次循环时间为15 min。连续煎炸30次,中间无新油添加。次日补充200 mL新油后再煎炸30次。每隔10次进行取样,移取20 mL煎炸油,冷却至室温后收集于试管,并密封保存于−20℃冰箱。同时所煎炸后的薯条立即进行脂质的提取。

1.2.2油炸薯条表面吸附油脂的提取

新鲜薯条及煎炸后薯条中脂质的提取参考文献[22]的方法。煎炸后的薯条用200 mL石油醚混合搅拌1~2 s,将薯条表面吸附的油脂溶解于石油醚中,之后将混合溶剂置于真空旋转容器中,在真空度0.1 MPa、温度45 ℃下蒸发溶剂,并在45 ℃真空烘箱中加热0.5 h挥干溶剂,所得样品即为油炸薯条表面所吸附的油脂,密封保存置于−20 ℃冰箱内。

1.2.3油样中极性化合物的分离制备

油样中极性化合物的分离制备参考文献[20]的方法。Flash中压纯化制备柱链接于快速中压制备型柱层析系统,并用A相洗脱液(石油醚︰乙醚体积比=87︰13)润洗10 min,流速25 mL/min。称取1 g左右(精确至0.0001 g)油样(m)于10 mL烧杯,用5 mL石油醚溶解油脂样品,用少量石油醚冲洗烧杯,制成上样液并用注射器加入Flash中压制备柱,继续使用A相洗脱液洗脱油样中的非极性化合物,洗脱时间为20 min,流速25 mL/min;之后采用B相洗脱液(乙醚︰丙酮体积比=40︰60)洗脱并收集油脂中的极性化合物于已称质量(m0)的干净烧瓶内,在1.2.2旋转蒸发条件下挥发溶剂得到极性化合物,称质量(m1)。每个样品重复测定3次。总极性化合物(TPC)含量的计算方法如下:

1.2.4HPSEC测定极性化合物组分分布

将1.2.3节制备的极性化合物用四氢呋喃溶液进行溶解,制成质量体积比1%四氢呋喃溶液,并用0.22 μm滤膜过滤至1.5 mL进样瓶。色谱柱、进样条件以及油脂中各类极性组分(TGO、TGD、ox-TG、DAG、FFA等)相对含量计算方法均按文献报道方法[20]。每个样品重复测定3次。

1.3数据统计分析

油脂极性物组分的HPSEC色谱数据由美国Waters公司的Waters Empower 2液相色谱数据处理软件自动生成;利用SPSS 16.0中的单因素方差分析试验数据,计算其均值及其标准差,并进行Turkey多重比较分析不同水平值变量间的差异显著性(P<0.05)。

2 结果与分析

2.1煎炸次数对大豆油及薯条表面吸收油脂中总极性化合物含量的影响

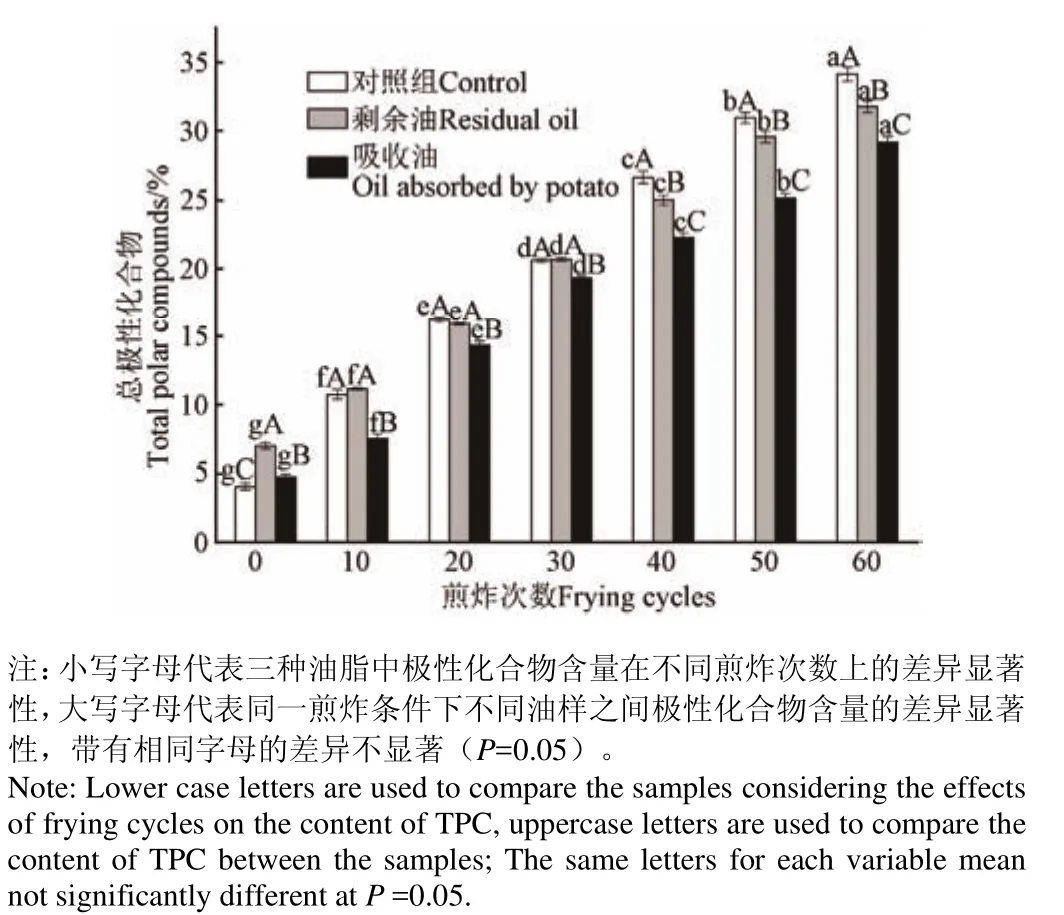

在本论文中,没有薯条添加而加热的大豆油称为对照组,煎炸薯条后剩余的大豆油称为剩余油,薯条表面所吸附的油脂称为吸收油。由快速中压制备型柱层析系统从以上3种油脂样品分离制备的总极性化合物(TPC)以及它们随着煎炸次数的变化如图1所示。

图1 煎炸次数对各油样中总极性化合物含量的影响Fig.1 Effect of frying cycles on content of TPC from samples

新鲜大豆油中TPC质量分数为1.59%,这是由于毛油在精炼过程中受高温、水分等的影响,易发生氧化酸败,形成聚合物、甘油二酯、游离脂肪酸等[23]。而在新鲜薯条中提取的油脂中无TPC的检出。在煎炸过程中,由于空气、水分、高温等条件的影响,甘油三酯分子开始氧化降解,形成初级氧化产物、次级氧化产物,其中挥发性产物随着水蒸气而挥发,非挥发性产物则留在油脂中,造成油脂中极性产物也开始增加[24]。由图1可知,3种油脂样品,包括对照组、剩余油、吸收油中的TPC含量都是随着煎炸次数的增加而显著(P<0.05)增加,表明持续增加的煎炸次数加剧了油脂的氧化裂变反应,产生了大量的极性化合物。这与文献中的结果相一致,随着反复煎炸试验的实施,葵花籽油中的TPC含量显著(P<0.05)增加[1]。在1~30次煎炸过程中,对照组与剩余油之间的TPC含量差异不显著(P>0.05),在40~60次煎炸过程中,对照组中的TPC含量显著高于剩余油中的TPC含量,可能是由于在煎炸薯条过程中所产生的美拉德反应产物,对油脂氧化反应具有一定的抑制作用[25],降低了极性化合物的生成速率。而在整个煎炸过程中,剩余油中的TPC含量显著高于吸收油中的TPC含量(P <0.05)。这是由于煎炸过程中,随着反复煎炸次数的增加,大豆油中的降解反应加剧,反应产物增加,造成大豆油中TPC含量显著增加,而薯条所吸附的油脂中TPC含量随着大豆油中TPC含量的增加而增加[26]。Atanu利用热聚合棕榈油煎炸法式土豆条时发现,当土豆条的含水率在52.03%~76.07%时,其表面所吸收油脂中的TPC含量显著高于剩余油脂的TPC含量,当其含水率为10.14%时,剩余油中的TPC含量高于土豆条表面所吸收油脂中的TPC含量,但两者之间的TPC含量差异不显著(P>0.05)。而煎炸的鱼肉脂质中的TPC低于剩余油脂中的TPC[27]。

2.2煎炸次数对煎炸油脂及食物脂质中极性化合物组分含量的影响

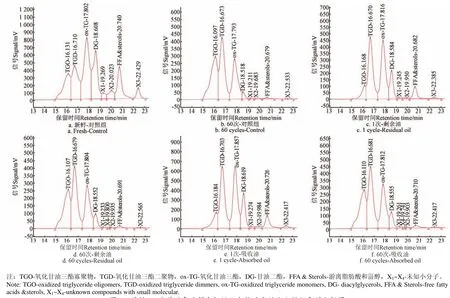

对于1.2.3中分离制备的TPC,进一步使用高效体积排阻色谱技术(HPSEC)分析其组分。根据相对分子质量大小,HPSEC可将TPC分离为氧化甘油三酯寡聚物(TGO)、氧化甘油三酯二聚物(TGD)、氧化甘油三酯单体(ox-TG)、甘油二酯(DG)、游离脂肪酸与甾醇(FFA & sterols)等,其中还有一些相对分子质量较小的未知物(X1、X2、X3等)。由于FFA & sterols相对分子质量较接近,无法实现两者之间的分离。

新鲜大豆油、煎炸1次后的剩余油和吸收油以及煎炸60次后的对照组、剩余油和吸收油中所分离得到的总极性化合物的HPSEC分析结果如图2所示。由图2可知,煎炸60次后,对照组、剩余油、吸收油中TGO和TGD 在TPC中的相对含量大量增加,而DAG和FFA & sterols 在TPC中的相对含量含量大幅度降低,这个现象与前人的研究结果相一致[26,28],表明随着煎炸次数的增加,油脂中的聚合反应加剧,水解反应减弱。由于HPSEC操作方法的差异,PÉREZ-CAMINO等未能将TGP分离为TGO 和TGD。由于TGD和TGO含有改变的酰基基团,可影响油脂的营养价值[26-27],因此需要对其在煎炸油及食物脂质中进行定量分析。采用峰面积归一化法定量分析各组分在TPC中的相对含量,同时根据油样中的TPC含量,计算各组分在油脂中的相对含量(%),结果如表1和表2。

图2 煎炸60次前后各油样中极性化合物的高效体积排阻色谱分析图Fig.2 High performance size-exclusion chromatography analysis of TPC from each oil sample before and after frying for 60 cycles

表1 煎炸次数对油脂中氧化甘油三酯聚合物和氧化甘油三酯含量的影响Table 1 Effect of frying cycles on content of oxidized triglyceride polymers and oxidized triglyceride monomers

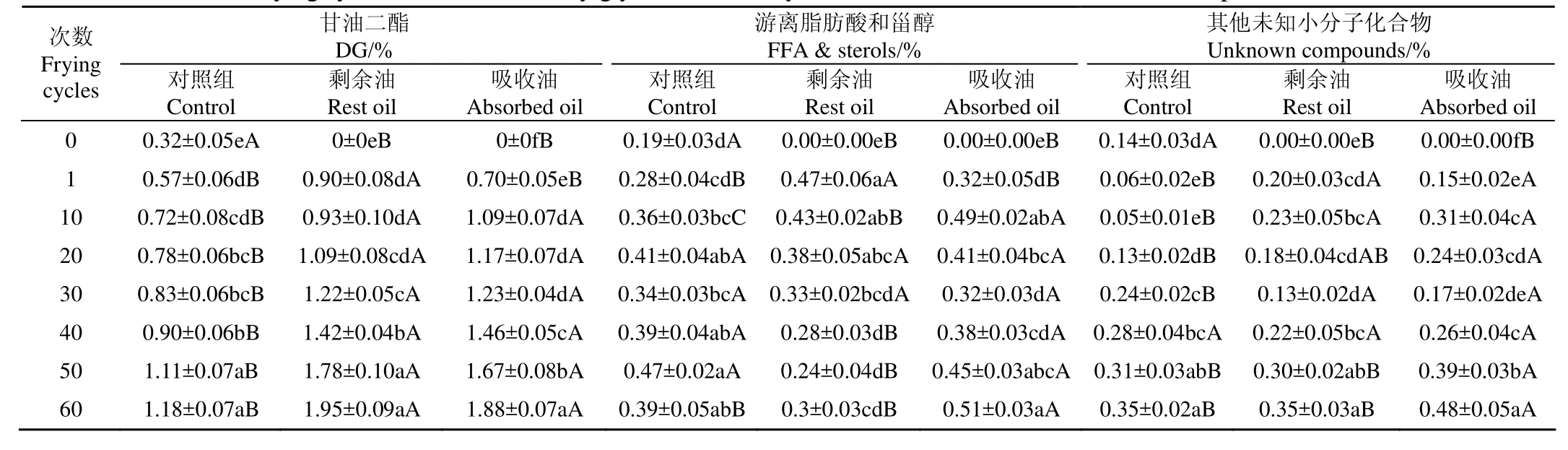

表2 煎炸次数对油脂中甘油二酯、游离脂肪酸、甾醇及其他未知小分子化合物含量的影响Table 2 Effect of frying cycles on content of diacylglycerols, free fatty acids & sterols, and some unknown compounds with small molecular

由表1可知,3种油样中的TGO、TGD和ox-TG含量随着煎炸次数的增加而显著增加的,这是由于在连续的煎炸过程中,油脂中的聚合反应和氧化反应逐渐占据主导地位,使得油脂氧化产物中的聚合物和氧化产物含量增加[24]。由差异显著性分析可知,TGO、TGD和ox-TG在吸收油中的含量低于它们在剩余油中的含量,表明煎炸次数会显著影响薯条对大豆油中的TGO、TGD和ox-TG的吸收性。与对照组相比,剩余油中的TGO含量较低,一方面煎炸油脂中TGD比TGO更容易形成,另一方面可能是由于煎炸薯条过程中,水分的引入抑制了TGP的形成并降低了它的含量[28]。对于TGD而言,在煎炸1次后,它在剩余油中的含量显著高于对照组中的含量,而在连续煎炸至30次时,它在2种油样中的含量之间的差异不显著(P>0.05),这可能是由于随着煎炸次数的连续增加,TGD在连续增加的同时,也会参与TGO的形成,导致TGD增加缓慢。对于同一油样而言,在相同的煎炸条件下,TGD的含量低于TGO的含量,这也证实了油脂中的聚合反应是从两分子化合物到多分子化合物逐级结合的[23]。Susana 等将油样中的脂肪酸进行甲酯化,之后利用硅胶柱层析分离极性脂肪酸甲酯与非极性脂肪酸甲酯,最后采用HPSEC分析极性脂肪酸甲酯的组成,发现脂肪酸二聚物(fatty acid dimmers,FAD)与脂肪酸寡聚物(fatty acid oligomers,FAO)的比率(FAD/FAO)显著高于未进行甲酯化处理所得到氧化甘油三酯二聚物与氧化甘油三酯寡聚物的比例(TGD/TGO),这一事实提供了在三聚体和更高寡聚甘油三酯结构上联合二聚体的证据[29]。当继续煎炸至60次时,由于在深度煎炸过程中,TGD的增加速率显著大于其消耗速率,使得TGD在2种油样中的含量之间存在显著性差异(P<0.05)。在同一煎炸条件下,吸收油中TGD的含量高于ox-TG的含量,而ox-TG的含量高于TGO,表明薯条对这3种极性组分的吸收强度依次为TGD>ox-TG>TGO。同时,我们也发现,当煎炸次数从10增加到30次时,对照组中的ox-TG含量与剩余油中的ox-TG含量不存在显著差异;而当继续煎炸时,对照组中的ox-TG含量显著高于剩余油中的ox-TG含量。这可能是由于在更剧烈的煎炸条件下,ox-TG参与了其他反应,降低了它本身的含量。Tommaso等也发现碱炼后ox-TG变化不显著(P>0.05),而经脱色、脱臭处理后油脂中的ox-TG大量减少,认为在此阶段,ox-TG的消耗速率大于它的生成速率[24]。

由表2可知,对照组、剩余油和吸收油中的DG和其他未知小分子化合物含量随着煎炸次数的增加而缓慢增加,FFA & sterols的变化具有一定的波动性,但其波动范围较小(0.19%~0.49%)。剩余油和吸收油中的DG含量之间的差异不显著(P>0.05),两者的DG含量都显著高于对照组中的DG含量,这是由于DG分子质量较小,薯条对其具有良好的吸收性。这个结果与前人的研究结果相一致[30]。此外,吸收油中的FFA & sterols含量显著(P<0.05)高于它在剩余油中的含量。在Camino的研究中,当薯条在橄榄油中煎炸时,其表面所吸收油脂中的FFA含量高于剩余橄榄油中的FFA含量,当它在葵花籽油中煎炸时,其表面所吸收油脂中的FFA含量低于剩余葵花籽油中的FFA含量,因此,FFA含量在吸收油中的含量受油脂种类的影响[26]。随着煎炸次数的增加,3种油脂中的未知小分子化合物种类增多,但由于现有分离技术的限制,未能鉴定此类化合物的种类,猜测可能是由于脂肪酸长链断裂所形成的甘油等小分子化合物,需要进一步的分析研究。尽管文献中指出水解产物对食物的营养价值没有不利的影响,而且在深度煎炸过程中,由水解反应而产生的FFA含量是非常少的,不足以影响食物的品质[23],但也有文献中认为一定浓度DAG和FFA会对油脂产生促氧化作用[31-32]。因此,在煎炸过程中,也需要关注油脂及食物脂质中的DG和FFA浓度。

3 结 论

通过研究煎炸次数对大豆油和薯条表面所吸收油脂中极性化合物的影响,结论如下:

1)煎炸次数的增加,会显著增加剩余油和吸收油中的总极性化合物含量;

2)煎炸次数的增加,会显著改变极性组分,尤其是氧化甘油三酯寡聚物、氧化甘油三酯二聚物和氧化甘油三酯在剩余油和吸收油中的分布;

3)随着煎炸次数的增加,油脂中的降解产物种类增加;

4)由于甘油二酯和游离脂肪酸是脂质代谢中的起始化合物,聚合物和氧化甘油三酯含有改变的酰基基团,会改变油脂的营养价值,为了饮食健康,需要严格控制煎炸次数。

[参考文献]

[1] Farhoosh R, Tavassoli-Kafrani M H. Polar compounds distribution of sunflower oil as affected by unsaponifiable matters of Bene hull oil (BHO) and tertiary-butylhydroquinone (TBHQ) during deep-frying[J]. Food Chemistry, 2010, 122(1): 381-385.

[2] Caponio F, Giarnetti M, Summo C, et al. A comparative study on oxidative and hydrolytic stability of monovarietal extra virgin olive oil in bakery products[J]. Food Research International, 2013, 54(2): 1995-2000.

[3] Farhoosh R, Pazhouhanmehr S. Relative contribution of compositional parameters to the primary and secondary oxidation of canola oil[J]. Food Chemistry, 2009, 114(3): 1002-1006.

[4] Farhoosh R, Khodaparast M H H, SHARIF A, et al. Olive oil oxidation: Rejection points in terms of polar, conjugated diene, and carbonyl values[J]. Food Chemistry, 2012, 131(4): 1385-1390.

[5] Gil B, Cho Y J, Yoon S H. Rapid determination of polar compounds in frying fats and oils using image analysis[J]. LWT-Food Science and Technology, 2004, 37(6): 657-661.

[6] 邓云,吴颖,杨铭铎,等. 煎炸油中产生的极性成分对食品微观结构和质构的影响[J]. 农业工程学报,2004,20(6):160-164. Deng Yun, Wu Ying, Yang Mingduo, et al. Effects of polar components in frying oil on microstructure and texture of fried food[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2004, 20(6): 160-164. (in Chinese with English abstract)

[7] 邓云,杨铭铎,李健,等. 油炸中油脂极性成分的产生对食品品质的影响[J]. 华南理工大学学报:自然科学版,2004,32(6):49-54. Deng Yun, Yang Mingduo, Li Jian, et al. Influence of the polar components produced in oil on food quality during deep-frying[J]. Journal of South China University of Technology: Natural Science Edition, 2004, 32(6): 49-54. (in Chinese with English abstract)

[8] 李昌模. 薄层色谱法测定油脂中极性化合物含量[J]. 中国油脂,2007,32(11):77-79. Li Jianmo. Determination of polar compounds in edible oil by thin – layer chromatography[J]. China Oils and Fats, 2007, 32(11): 77-79. (in Chinese with English abstract)

[9] 蔡文辞. 煎炸油中极性物质的分析及其细胞毒性评价[D].无锡:江南大学,2014. Cai Wenci. Analysis and Cytotoxicity Evaluation of Polar Components in Frying Oil[D]. Wuxi: Jiangnan University, 2014. (in Chinese with English abstract)

[10] 陈雅琼,张铁英,陈元,等. 煎炸老油对小鼠重要脏器的影响[J]. 中国油脂,2014,39(12):38-41. Chen Yaqiong, Zhang Tieying, Chen Yuan, et al. Effect of deep fried oil on important organs of mice[J]. China Oils and Fats, 2014, 39(12): 38-41. (in Chinese with English abstract)

[11] Indart A, Viana M, Clap S S, et al. Clastogenic and cytotoxic effects of lipid peroxidation products generated in culinary oils submitted to thermal stress[J]. Food and Chemical Toxicology, 2007, 45(10): 1963-1967.

[12] Cao Wenming, Wang Xiang, Zhang Weiyun, et al. Toxic effects of triacylglycerol polymer on macrophages in vitro [J]. Eur J Lipid Sci Technol, 2013, 115(7): 756-763.

[13] Lim J, Kim Y S, Kim S H, et al. Triglyceride enhances susceptibility to TNF-α-induced cell death in THP-1 cells[J]. Genes & Genomics, 2013, 36(1): 87-93.

[14] Huang Chinfang, Lin Yushun, Chiang Zongcian, et al. Oxidized frying oil and its polar fraction fed to pregnant mice are teratogenic and alter mRNA expressions of vitamin A metabolism genes in the liver of dams and their fetuses[J]. The Journal of Nutritional Biochemistry, 2014, 25(5): 549-556.

[15] 邓云,杨铭铎,李健,等. 煎炸油脂中极性成分的色谱分析[J]. 食品与发酵工业,2006,32(5):127-130. Deng Yun, Yang Mingduo, Li Jian, et al. Analysis for polar components and polymers in the deep-frying oil[J]. Food and Fermentation Industries, 2006, 32(5): 127-130. (in Chinese with English abstract)

[16] 李浩南,邹勇,张彩,等. 煎炸油脂中极性组分检测方法 [J].粮食与油脂,2006(5):18-21. Li Haonan, Zhou Yong, Zhang Cai, et al. Determination methods of polar compounds in frying fats and oils[J]. Cereals & Oils, 2006(5): 18-21. (in Chinese with English abstract)

[17] 穆昭,刘元法,王兴国. 煎炸油加热后极性物质色谱分析[J].食品工业科技,2008,29(9):118-121. Mu Zhao, Liu Yuanfa, Wang Xingguo. Study on polar components of heated frying oil using liquid chromatography[J]. Science and Technology of Food Industry, 2008, 29(9): 118-121. (in Chinese with English abstract)

[18] 周雅琳,周令国,李智,等. 影响煎炸油中极性化合物生成因素的研究[J]. 中国粮油学报,2010,25(3):50-53. Zhou Yalin, Zhou Lingguo, Li Zhi, et al. Influencing factors for polar compounds created in oil during deep-frying[J]. Journal of the Chinese Creaeals and Oils Association, 2010, 25(3): 50-53. (in Chinese with English abstract)

[19] 黄苏萍,徐咏薇. 影响煎炸油中极性组分生成因素的实验研究[J]. 中国卫生检验杂志,2000,10(4):417-418. Huang Suping, Xu Yongwei. The study of influencing factors for polar components formed in frying oil[J]. Chinese Journal of Health Laboratory Technology, 2000, 10(4): 417-418. (in Chinese with English abstract)

[20] 曹文明,薛斌,王文高,等. 高效体积排阻色谱测定油脂中氧化甘油三酯聚合物[J]. 中国油脂,2011,36(10):57-59. Cao Wenming, Xuebin, Wang Wengao, et al. Determination of oxidized triglycerides polymers by high performance sizeexclusion chromatography[J]. China Oils and Fats, 2011, 36(10): 57-59. (in Chinese with English abstract)

[21] 曹文明,薛斌,陈凤香,等. 食用植物油与餐厨废油脂中三酰甘油氧化聚合物含量的研究[J]. 中国粮油学报,2012,27(11):96-99. Cao Wenming, Xuebin, Chen Fengxiang, et al. Research of content of oxidized triacylglycerol polymers both in edible vegetable oils and in waste cooking oils[J]. Journal of the Chinese Creaeals and Oils Association, 2012, 27(11): 96-99. (in Chinese with English abstract)

[22] Al-Khusaibi M, Niranjan K. The Impact of blanching and high-pressure pretreatments on oil uptake of fried potato slices[J]. Food Bioprocess Technol, 2012, 5(6): 2392-2400. [23] Gomes T, Caponio F, Durante V, et al. The amounts of oxidized and oligopolymeric triacylglycerols in refined olive oil as a function of crude oil oxidative level[J]. LWT-Food Science and Technology, 2012, 45(2): 186-190.

[24] Fritsch C W. Measurements of frying fat deterioration: A brief review[J]. Journal of the American Oil Chemists’Society, 1981, 58(3): 272-274.

[25] Marmesat S, Mancha M, Ruiz-M Ndez M V, et al. Performance of sunflower oil with high levels of oleic and palmitic acids during industrial frying of almonds, peanuts, and sunflower seeds[J]. J Am Oil Chem Soc, 2005, 82(7): 505-510.

[26] Pérez-Camino M C, Márquez-Ruiz G, Ruiz-Méndez M V, et al. Lipid changes during frying of frozen prefried foods[J]. Journal of Food Science, 1991, 56(6): 1644-1647.

[27] Arroyo R, Cuesta C, Garrido-Polonio C, et al. High-performance size-exclusion chromatographic studies on polar components formed in sunflower oil used for frying[J]. Journal of the American Oil Chemists Society, 1992, 69(6): 557-563.

[28] Abidi S L, Kim I H, Rennick K A. Determination of nonvolatile components of heated soybean oils separated with high-efficiency mixed-bed polystyrene/divinylbenzene columns[J]. J Am Oil Chem Soc, 1999, 76(8): 939-944.

[29] Marmesat S, Morales A, Velasco J, et al. Influence of fatty acid composition on chemical changes in blends of sunflower oils during thermoxidation and frying[J]. Food Chemistry, 2012, 135(4): 2333-2339.

[30] Garrido-Polonio M C, S Nchez-Muniz F J, Arroro R, et al. Small scale frying of potatoes in sunflower oil: thermoxidative alteration of the fat content in the fried product[J]. Z Ernährungswiss, 1994, 33(4): 267-276.

[31] Caponio F, Paradiso V M, Bilancia M T, et al. Diacylglycerol isomers in extra virgin olive oil: Effect of different storage conditions[J]. Food Chem, 2013, 140(4): 772-776.

[32] Paradiso V M, Gomes T, Nasti R, et al. Effects of free fatty acids on the oxidative processes in purified olive oil [J]. Food Research International, 2010, 43(5): 1389-1394.

Effect of frying cycles on polar components in soybean oil and absorbed lipids of fried potatoes

Feng Hongxia1, Li Yang1※, Sui Xiaonan1, Qi Baokun1, Wang Zhongjiang1, Jiang Lianzhou1,Cao Wenming2

(1. College of Food Science, Northeast Agricultural University, Harbin 150030, China; 2. Shanghai Grain Science Research Institute, Shanghai 200136, China)

Abstract:Frying is a traditional and popular processing method for the food preparation throughout the world. Frying can not only confer good flavor and color, but also generate many kinds of reaction products, affecting the quality of the oil and the food. A lot of published literatures focused on the quality of the frying oil. However, for direct consumption, the quality of the fried food affects human’s health and safety, and thus addressing the study on the quality of the fried food is needed. As we all know, the content of total polar compound (TPC) is one of the most valid and objective criteria for the evaluation of deterioration of oils during deep frying. Thus, in this study, our research was mainly focused on the content and composition of polar compounds in the lipids absorbed on the surface of fried food during deep frying. Preparative flash chromatography, as a convenient and fast way, was adopted to separate polar compounds from the oil and the absorbed lipids of fried food. The obtained polar compound was further analyzed by high performance size-exclusion chromatography to determine its main compositions. The results indicated that the contents of TPC from both the fried oil and the absorbed lipid of fried food were gradually increasing with the number of frying times. No significant difference of TPC content between the rest oil of treatments and the sample of control was observed for the number of frying times of 1-30 (the heated oil without adding French fries was the control). However, TPC content of the control was significantly higher than that of the rest oil of treatments for the number of frying times of 40-60, indicating that the addition of potatoes to a certain extent could help inhibit the formation of polar compounds. In addition, frying times significantly changed the distribution of polar components, which were oxidized triglyceride oligomers (TGO), oxidized triglyceride dimers (TGD), oxidized triglyceride monomers (ox-TG), diacylglycerols (DG), free fatty acids and sterols (FFA & sterols), and some unknown compounds with small molecule, not only in the frying oil but also in the absorbed lipid of fried food. The contents of TGO, TGD and ox-TG in samples of the control, the rest oil of treatments, and the absorbed lipid of fried food were significantly (P<0.05) increasing with the number of frying times. But under the same condition, the contents of TGO, TGD and ox-TG in the absorbed lipid of fried food were much lower than those in the rest oil of treatment, while the difference of the contents of TGO, TGD and ox-TG between the control and the treatment was affected by the number of frying times. On the other hands, a little change was observed in the content of DG and FFA & sterols of all the samples for the frying times of 60. More kinds of unknown compounds with small molecule were generated with the increase of frying times. In conclusion, the content and the composition of TPC in the frying oil and the absorbed oil of fried potatoes are seriously affected by frying times. And in some extent, the health value of the fried potatoes is also influenced. Taking into account of the potential threat of polar compounds to human health, the frying times must be strictly controlled.

Keywords:oils and fats; food processing; oxidation; frying cycles; potatoes; polar compounds; high performance size-exclusion chromatography; oxidized triglyceride oligomers; oxidized triglyceride dimers

通信作者:※李杨,男,黑龙江人,博士,硕士生导师,研究方向:粮食、油脂及植物蛋白工程。哈尔滨东北农业大学食品学院,150030。

作者简介:冯红霞,女,河南人,博士生,研究方向:粮食、油脂及植物蛋白工程。哈尔滨东北农业大学食品学院,150030。

基金项目:东北农业大学研究生科技创新项目(yjscx14058);国家自然科学基金重点项目(31430067);黑龙江省自然科学基金项目重点项目(ZD201302);黑龙江省教育厅科学技术研究项目面上项目(12531049);黑龙江省博士后科研启动金项目(LBH-Q13018)。

收稿日期:2014-07-25

修订日期:2015-11-16

中图分类号:TS221;TQ646

文献标志码:A

文章编号:1002-6819(2016)-03-0309-06

doi:10.11975/j.issn.1002-6819.2016.03.044 10.11975/j.issn.1002-6819.2016.03.044http://www.tcsae.org