Main Methods Applied in Fertigation Technology

2016-01-12,,,,

, , , ,

1. Institute of Environment, Resource, Soil and Fertilizer, Zhejiang Academy of Agricultural Sciences, Hangzhou 310021, China; 2. Tonglu County Agricultural Technology Extension Center of Zhejiang Province, Hangzhou 311500, China; 3. Lanxi City Agricultural Technology Extension Center of Zhejiang Province, Jinhua 321100, China

1 Introduction

Fertigation technology is a new agricultural technology based on water saving irrigation system, combined with fertilization facility, and integrating water and fertilizer application, to realize water and fertilizer coupling. It mixes soluble solids or liquid fertilizer into fertilizer solution, then supplies the solution to crops in a well-distributed, fixed time, and fixed amount through pipeline and water spray according to soil moisture, nutrients, and water and fertilizer demand rules of crops. This technology not only saves labor cost and working time, but also increases fertilizer utilization efficiency, and the yield increase effect is significant[1-3], so it is favorable for improving quality of agricultural products[4]. In addition, it also avoids volatilization and loss due to excessive conventional fertilizer application, favorable for environmental protection[5]. In recent years, Zhejiang Province has allocated large funds to build considerable scale water saving irrigation projects. All areas also arranged funds for building water saving irrigation facilities, which energetically promotes extension and application of water saving irrigation technology and improvement of agricultural production modernization. However, since fertigation technology is highly comprehensive, it is a key technology for modern centralized agriculture[6]. Besides, compared with original irrigation and fertilizer method, this technology is quite different. Furthermore, people are still not clear about application of fertigation technology. In view of these, we will elaborate main issues in the extension and application of this technology according to achievements of projects we have undertaken and practical experience we accumulated.

2 Fertigation facility and application methods

2.1SelectionofirrigationsystemtypesFor fertigation technology, irrigation types include drip irrigation, micro spray, spray, underground drip irrigation, and infiltration irrigation,etc. Drip irrigation and micro spray are widely applied. Users can select irrigation types according to crops. Micro spray system is suitable for crops with crops with not obvious or dense plant spacing and row spacing, such as leaf vegetable planted in a big canopy, scallion, ginger, and garlic, and crops not vulnerable to plant diseases; drip irrigation system is suitable for crops with obvious or sparse plant spacing and row spacing, and crops vulnerable to humidity and plant diseases, such as solanaceous and melon crops. In greenhouses, because crops cultivated are changed frequently, if drip irrigation system and micro spray system are installed together, it will be very convenient for use. For example, in low temperature season or for crops suitable for drip irrigation system, it is preferred to adopt drip irrigation system, while in dry season or for crops suitable for micro spray system, it is convenient to use micro spray system. The micro spray system is able to perform fertigation, reduce temperature, increase moisture, regulate micro climate within the greenhouse, so as to realize excellent effect. Fruit tree fertigation mainly adopts drip irrigation, especially for fruit trees needing much water and fertilizer, such as grape vine, cherry, and kiwi fruit. For cash crops such as mulberry and tea trees, ornamental plant such as flowers and seedlings, forage grass, and other most field vegetables, and grain crops, spray irrigation is mainly employed. Spray irrigation can be combined with fertilization. If fermented liquid is sprayed, it is necessary to spray water to clean leaves.

2.2MainpointsforattentioninthedesignoffertigationsystemThe design of fertigation system should be stricter than that of simple irrigation system. However, there is still no corresponding design standard. Therefore, when designing the fertigation system with reference to design of water saving irrigation system, special attention should be paid to following two points. (i) Pipe diameter control. The pipe diameter should be designed according to irrigation control area, irrigation area, and irrigation intensity with the aid of hydraulic calculation formula. Nevertheless, for design of fertigation system, the pipe diameter design should consider reducing detention of fertilizer solution as much as possible. Under the premise of meeting the irrigation design standard and convenience in use, it is necessary to minimize pipe diameter, and do not increase the pipe diameter blindly during installation. (ii) Increasing the design uniformity. The higher uniformity will receive better result, because the effect of fertilizer and water on crop growth is greater than simple water irrigation. According to industrial standards formulated by the Ministry of Water Resources, the uniformity of micro spray system should reach 80%[7]. At present, there is still no design standard for uniformity of fertigation system, but uneven irrigation will reduce uniformity of crop growth under mutual interaction of water and fertilizer. If the overall uniformity for the effect of mutual interaction on crop growth is required to be higher than 80%, the uniformity of Fertigation system should reach 90%.

2.3Performanceandapplicationoffertigationfacility

2.3.1Fertilizer application facility. Differential pressure fertilizer tank: it is a fertilizer application facility through irrigated water flowing in the tank, dissolving and diluting fertilizer in the tank and bringing into irrigation pipeline. Large metal fertilizer tank can be installed at the head part, while small plastic fertilizer tank can be installed in the edge of the field. Before fertilizer application, firstly spray water 20-30 minutes, pour the dissolved and filtered fertilizer stock solution into the fertilizer tank. After the tank becomes full, regulate the pressure difference to keep normal fertilizer application speed, and add fertilizer after finishing application of fertilizer in the tank. The time for adding the fertilizer is calculated according to the following formula, and equivalent to the time taken for finishing 4 times of tank volume of the fertilizer solution.

T=4V/Q

whereTis the time for adding the fertilizer (h),Vis the tank volume (L), andQis the speed of solution (L/h).

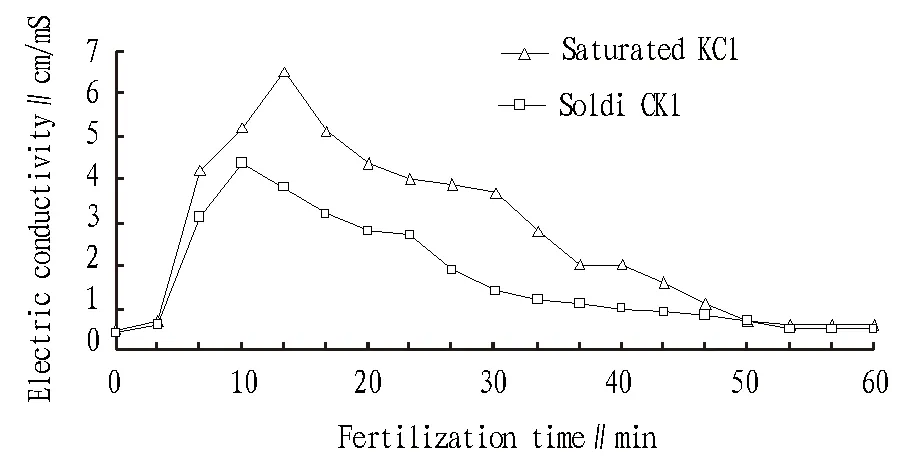

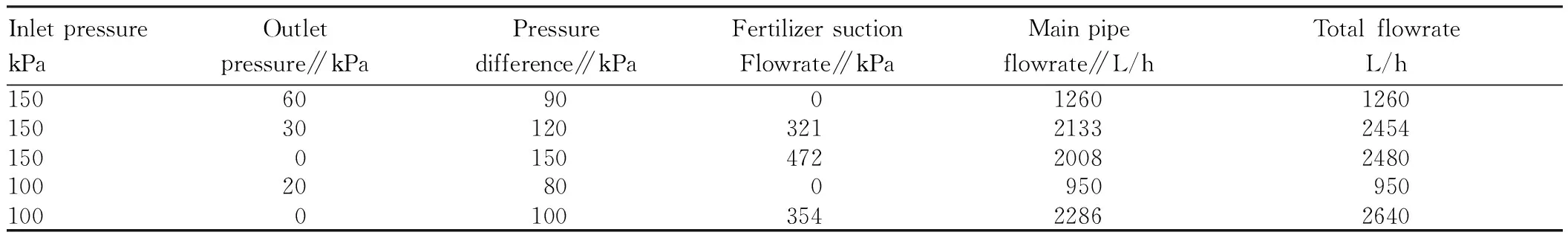

Fig. 1 depicts changes in electric conductivity with the irrigation time during the full dilution process of solid KCl and saturated KCl solution within the fertilizer tank. Finally, electric conductivity drops to zero fertilizer concentration. Venturi fertilization apparatus is a type of fertilization device with the aid of negative pressure suction of fertilizer through changes in pipe diameter of fertilization apparatus. Venturi fertilization apparatus is connected with valves in main pipe in parallel. After filtering the stock solution of fertilizer, pour it to a vessel, wrap the suction head of venture with filter screen, put into fertilizer solution, do not contact the vessel bottom, pour water 30 minutes, then open the valve on suction pipe and adjust valve on main pipe, adjust inlet and outlet pressure difference, to render the suction pipe to uniformly and stably absorb fertilizer solution. After completion of fertilization, continue to irrigate for more than 20 minutes. For venturi fertilization apparatus, it is recommended to adopt brands with high performance and low head loss. During use, keep the pressure difference; during installation, avoid gas leakage during installation and use. Venturi fertilization apparatus is generally installed in greenhouse or field end, to realize independent fertilization. Proportional fertilization apparatus: also called piston fertilization apparatus, absorbing high concentration solution (pesticide and fertilizer,etc) as per designed proportion through driving piston by water pressure. There are many specifications of proportional fertilization apparatus available, which should be equipped with irrigation facility and selected in accordance with specifications. Both serial connection and parallel connection are acceptable and generally installed in header supply pipeline.

Fig.1 Changes in solute concentration of fertilizer tank

2.3.2Filter equipment. Screen filter: a common filter device in fertigation. It directly intercepts impurities in water using the screen. It is suitable for filtering powder, sand and water scale, and can filter inorganic fertilizer impurities and undissolved particles, to remove suspensions and particles, and reduce system scale, thallose, and rusting corrosion. Simple screen filter is single layer screen, while automatic reverse washing filter has two layers of screen. Water enters the filter through inlet, the filter firstly filters large particles through rough filter element, then filters small particles through fine filter element, and finally clean water is discharged through outlet. In the process of automatic washing filtration, inner layer of screen gradually accumulates impurities, rendering a pressure difference between inner and outer layer of screen filter. When the pressure difference of screen filter reaches the preset value, it will start automatic washing process. There are many types of specifications for filter screen. For the drip irrigation system, 120-200 mesh screen is widely used. Laminated filter: cylindrical filter consisting of many plastic laminates carved with micron level grooves. In normal work, water flows through laminate, foreign matters will be intercepted in the laminate wall and grooves. It is a kind of three-dimensional filtration and has high filtration efficiency. Laminated filter has excellent filtration effect on organic foreign matters, especially fibrous organic foreign matters. It is often used together with screen filter. Sand filter: tank type filter using sand as filter medium, also three-dimensional filter, having strong sewage interception ability. In all filters, sand filter has highest effect of filtering organic and inorganic foreign matters in water. It can supply water without interruption. It is equipped with a sand filter tank with diameter of 0.35-1.2 m, 25-50 cm filter medium, and interface diameter 2"(50 mm) - 6"(150 mm) with flowrate of 5-17 m3/h. When organic substance content in water exceeds 10 mg/L, it is required to apply sand filter. In a combined filter, sand filter should be placed before the screen filter and laminated filter. Centrifugal filter: filter based on gravity and centrifugal force, to remove solid particles weightier than water. Water flows into centrifugal filter through inlet pipe, rotates and generates centrifugal force, pushes sand and solid particles with higher density, rendering sand and stone enter the sand collection tank. Clean water will flow out through outlet, to complete the separation of water and sand. The centrifugal filter is installed beside a well and pump station and used for separating sand and stone in water. When requirements of filter are met, the ability of separating 60-150 mesh sand can reach 92%-98%. As front-end filter system, it can be combined with other filters.

Table1Specificationofaventurifertilizationapparatus

InletpressurekPaOutletpressure∥kPaPressuredifference∥kPaFertilizersuctionFlowrate∥kPaMainpipeflowrate∥L/hTotalflowrateL/h1506090012601260150301203212133245415001504722008248010020800950950100010035422862640

Table2Specificationofanimportedproportionalfertilizationapparatus

Workingpressure∥barProportionaladjustmentrange∥%Waterflowratem3/hStocksolutionflowrate∥L/hInterfacedimension∥inWorkingtemperature∥℃0.3-6.00.5-5(1:200-1:20)3.0-10l0.02-1503/4"(25mm)5-40

2.3.3Control equipment. Variable frequency control: variable frequency controller is commonly used in fertigation system for agricultural parks and can keep constant water pressure when the water consumption is high. At present, agricultural production in China is mainly contractual management. Even large agricultural parks also have the problem of several family individual management, diversified crops, different one-time irrigation area, and not unified fertigation. Through variable frequency control, irrigation and fertilization become simple and convenient. Automatic monitoring and control: in modern agricultural parks with high management level, it is feasible to install water manure information collection and intelligent control system. Through sensor, it promptly senses soil moisture and monitors parameters such as pH and EC of fertilizer solution, combines intelligent control software, realizes guidance and control of fertigation, to realize the effect of high efficient fertilization, and automatic control can significantly save labor[8].

3 Main points and methods of fertigation technology

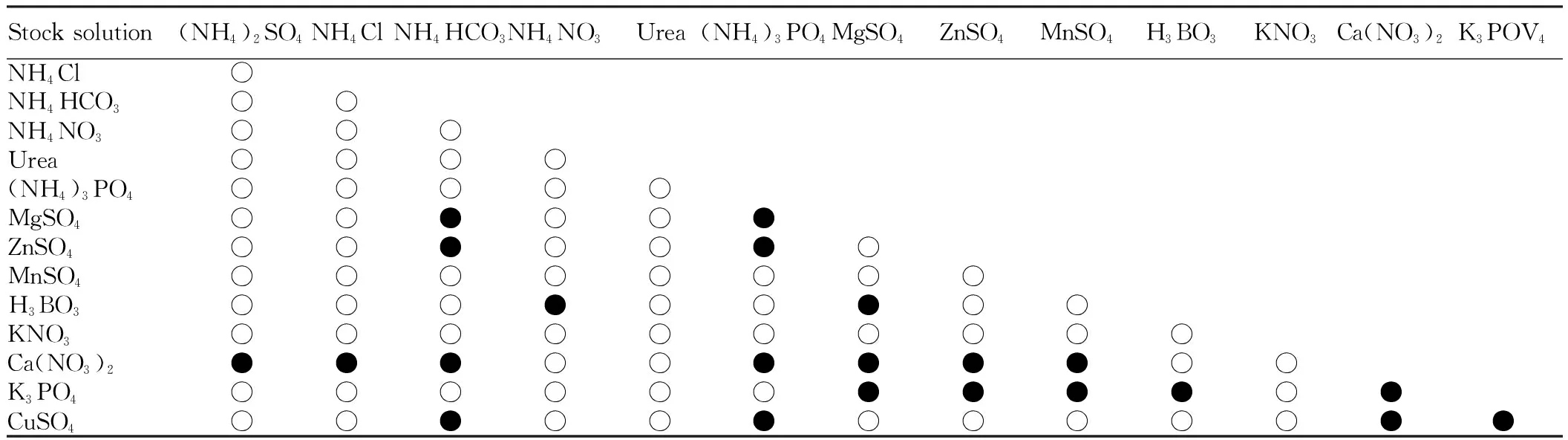

3.1FertilizerselectionandmixingFertilizer suitable for fertigation system includes liquid fertilizer, solid soluble fertilizer, liquid biological fertilizer, and fermented fertilizer filtrate. Commonly used fertilizer includes solid water-soluble fertilizer, single element manure, dual element fertilizer and compound fertilizer, such as urea, ammonium bicarbonate, ammonium chloride, ammonium sulfate, ammonium nitrate, calcium, KH2PO4, potassium chloride (preferably white), potassium nitrate, di-ammonium phosphate (DAP) and mono-ammonium phosphate (industrial grade), water-soluble sulfate and water-soluble K2SO4. Water soluble fertilizer features benefits of full nutrients, high utilization ratio, and designing formula according to nutrient demand characteristics of crop growth, but the selected fertilizer must conform to agricultural industrial standard[9-12]. Fermented liquid is excellent base fluid for mixing water soluble fertilizer and can be directly applied in irrigation. Besides, fermented liquid contains full nutrient and rich organic matters like humic acid[13]. Through reasonable selection of delivery ways, fermented liquid can be used well[14]and can reduce pollution. Fertilizer used for fertigation should have excellent quality. At normal temperature, the content of undissolved matter should be below 5%, and fertilizer should have benefits of high nutrient concentration, fertilizer effect, high stability, high compatibility, and low corrosion, and should not generate sedimentation when mixed with other fertilizer (Table 3).

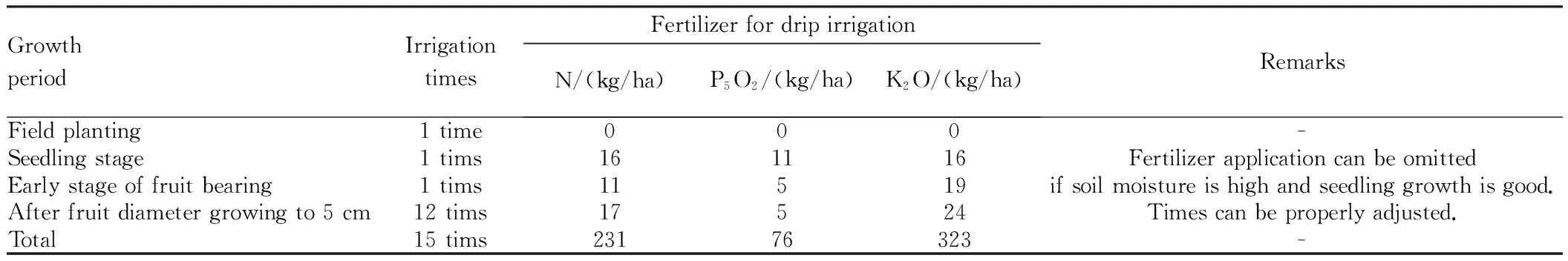

3.2FertilizationcalculationandmethodsFertigation amount can be calculated according to the target yield of crops (the average yield of local vegetable in last 3 years plus 30% increase) and nutrient demands in different soil fertility and different growth stage. Take tomato as an example, according to target yield calculation method recommended by the FAO, 1000 kg tomato fruit needs 2.8-4.5 kg N, 0.5-1.0 kg P2O5, and 3.9-5.0 kg K2O[15]. In Table 4, the target yield is 10 t/ha, an application case of drip irrigation fertilization calculated as per medium nutrient demand of target yield on the basis of base manure 25 t/ha, organic fertilizer, Ca, Mg, and P fertilizer 500 kg/ha, urea, and KCl 225 kg/ha, excluding soil nutrient supply (calculated as per testing soil for formulated fertilization). At the seedling stage, tomatoes need little fertilizer. After transplantation, field planting water should be fully irrigated and fertilizer may not be applied. After field planting, depending on soil moisture, little water soluble fertilizer may be added. Later, restrain the growth of seedlings and do not irrigate water, till the first fruit expands and irrigate water one time according to soil moisture. After the first fruit expands to 5 cm, conduct drip irrigation one time in 7-10 days. For autumn tomatoes, it will last to the end of November and beginning of December. Later, the temperature drops, greenhouse should be sealed, and the irrigation and fertilization are controlled according to soil moisture, to prevent excessive high humidity within the greenhouse. For spring tomatoes, drip irrigation will last until the autumn harvest, and at this time, fertilizer should be reduced. N fertilizer gradually increases with plant growth. From the first fruit growing to 5 cm to the busy harvest season, the fertilizer demand is the highest. In the middle period of harvest, the fertilizer demand declines. P fertilizer demand is higher in seedling stage. Later, P fertilizer demand becomes lower, thus stable supply is acceptable. K element is important for fruit growth. K demand is mainly after bearing fruit. In fact, the demand of tomato for K element is higher than N element. Ca and Mg are also major elements for tomato fruit growth. Ca absorption curve of tomato is similar to N absorption, and Mg absorption is about a half of P absorption[16]. For other crops, fertigation design should be made according to target yield, nutrient demand and soil fertility. For calculating fertilizer demand in drip irrigation, the fertilizer utilization ratio is converted as per 20%-30% increase.

Table3ListoffertilizersforFertigation

Stocksolution(NH4)2SO4NH4ClNH4HCO3NH4NO3Urea(NH4)3PO4MgSO4ZnSO4MnSO4H3BO3KNO3Ca(NO3)2K3POV4NH4Cl○NH4HCO3○○NH4NO3○○○Urea○○○○(NH4)3PO4○○○○○MgSO4○○●○○●ZnSO4○○●○○●○MnSO4○○○○○○○○H3BO3○○○●○○●○○KNO3○○○○○○○○○○Ca(NO3)2●●●○○●●●●○○K3PO4○○○○○○●●●●○●CuSO4○○●○○●○○○○○●●

Note: ○ denotes compatible and ● denotes incompatible.

Table4ReferencelistforFertigationofgreenhousetomato

GrowthperiodIrrigationtimesFertilizerfordripirrigationN/(kg/ha)P5O2/(kg/ha)K2O/(kg/ha)RemarksFieldplanting1time000-Seedlingstage1tims161116FertilizerapplicationcanbeomittedEarlystageoffruitbearing1tims11519ifsoilmoistureishighandseedlinggrowthisgood.Afterfruitdiametergrowingto5cm12tims17524Timescanbeproperlyadjusted.Total15tims23176323-

3.3FertigationmethodsA technical principle for fertigation is little but many times of irrigation and fertilizer. This principle conforms to characteristics of root system constantly absorbing nutrients. Using this principle, it is able to reduce fertilizer loss. Following matters should be considered when applying water soluble fertilizer. (i) Fertilizer solution should be mixed as required, especially when the water quality is not good, to prevent fertilizer component reacting with substances in water. (ii) The concentration of fertilizer solution should be in the range of 0.1%-0.4%, varied with soil moisture and crops. For vegetable, the concentration should be lower; for fruit trees, the concentration should be higher. When soil is dry, the concentration can be lower; when the soil is moist, the concentration can be higher. (iii) Fertilizer application time should be noticed. In fine days with high temperature, fertilizer should be applied before 10 am and after 4 pm, to avoid direct sunshine; for outdoor cultivation, it is required to avoid fertilization during rainy days, especially for spraying foliar fertilizer, to avoid fertilizer loss. (iv) For water soluble fertilizer in drip irrigation, it is recommended to drip clean water firstly, and do no apply fertilizer until pipeline is full of water. After completion of fertilizer application, clean water should be dripped for 20-30 minutes, and residual fertilizer solution in pipeline should be emptied. (v) When irrigating water for roots or spraying foliar fertilizer, it is required to avoid mixing acid fertilizer with alkaline pesticide and mixing alkaline fertilizer with acid pesticide. (vi) In southern moist areas, soil is often too wet, which will influence drip irrigation fertilization. Thus, it is recommended to reduce soil moisture through placing high ridges and opening drainage. (vii) In areas with saline and alkaline soil, it is required to take notice of the drip irrigation pipe, and do not make wet peak push salt to root system of crops.

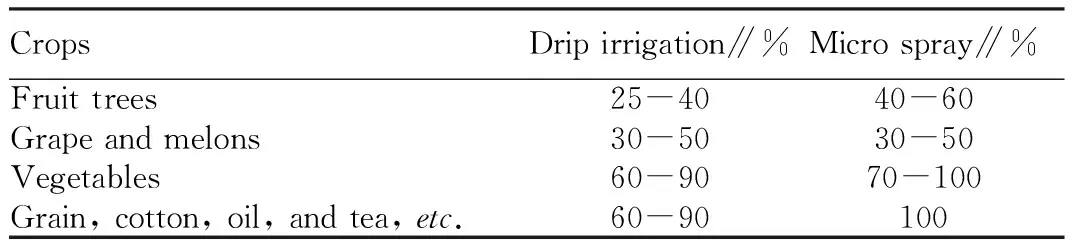

3.4SoilmoisturecontrolIn most cases, micro spray is local irrigation and it limits water and fertilizer in crop root system, so it changes traditional soil watering method to crop watering method. The percentage of wetted soil area is the ratio of wetted soil volume to planned soil volume for root system[6]. Different crop varieties need different percentage of wetted soil area, as listed in Table 5. In the early stage of crop growth, this percentage may adopt the lower limit; with the crop growth and root system expansion, it can gradually increase to the upper limit. For example, at the early stage of growth, tomato root system is mainly distributed in 0-30 cm; later, it can expand to 0-50 cm. Thus, wetting layer of drip plan and the percentage of wetted soil area should be increased accordingly. Crop growth needs proper soil moisture. Different crops need different soil moisture. For most crops, the field moisture capacity should be kept higher than 70%-80%, but too moist soil is also harmful to crops. With the aid of hand feeling, it is able to judge whether the soil moisture is suitable. Usually, loam should become soil ball and it will not fall apart when slightly tossing; clay soil should be able to become strips when rubbing with hands.

Table5Designedpercentageofwettedsoilareaformicrospray

CropsDripirrigation∥%Microspray∥%Fruittrees25-4040-60Grapeandmelons30-5030-50Vegetables60-9070-100Grain,cotton,oil,andtea,etc.60-90100

4 Conclusions

Fertigation technology is a comprehensive technology. It needs learning application knowledge of facilities and fertigation. Especially, due to influence of many factors, there are still no sufficient and pertinent fundamental data for determining water and fertilizer application of different crops. It needs a long period of research and practice to accumulate experience. However, with the extension of integration water and fertilizer technology, it is expected to obtain better effect than conventional fertilization and irrigation through strengthening construction of management and technical service system. Besides, it is expected to greatly promote improvement of agricultural modernization and make great contribution to strategic objective of "five water treatment" in Zhejiang Province.

[1] LIU JQ, ZHANG Q. On the application effect of water-fertilizer integrated technology in the tomato[J].Journal of Zhejiang Agricultural Sciences,2014 (11):1702,1705.(in Chinese).

[2] XING YY, ZHANG FC, ZHANG Y,etal. Irrigation and fertilization coupling of drip irrigation under plastic film promotes tomato’s nutrient uptake and growth[J].Transactions of the Chinese Society of Agricultural Engineering,2014 (21):70-80.(in Chinese).

[3] LIN AD, HUANG YF, HUANG PS. Study on the technology of drip-fertigation to winter-planting potato in Guangdong[J].Guangdong Agricultural Sciences,2012 (7):46-47.(in Chinese).

[4] CHEN G, GAO CG, ZHANG XL,etal. Study on technology of irrigation combined with fertilization for watermelon in greenhouse[J].Shandong Agricultural Sciences,2013 (8):103-105,109.(in Chinese).

[5] XIA LZ, HAN QZ, XIANG L. On the countermeasures of water-fertilizer integrated management in the citrus garden of the Three Gorges Reservoir Region[J].Agro-Environment and Development,2012 (6):12-15.(in Chinese).

[6] ZHANG CL, DENG LS. Water-fertilizer integrated technology[M].Beijing: China Agriculture Press,2012:13,126-127.(in Chinese).

[7] SL 103-95,on the technical manual of micro-irrigation engineering technology[S].(in Chinese).

[8] WEI K, AN JQ, JIA Y,etal. Irrigation system of constant pressure control based on ZigBee technology[J].Journal of Gansu Agricultural University, 2013 (5):146-150.(in Chinese).

[9] NY 1107-2010,water-soluble fertilizers containing macroelements[S].(in Chinese).

[10] NY 1429-2010,water-soluble fertilizers containing amino acid[S].(in Chinese).

[11] NY 1107-2010,water-soluble fertilizers containing humic acid[S].(in Chinese).

[12] NY 1428-2010,water-soluble fertilizers containing microelements[S].(in Chinese).

[13] LUO LP, ZHANG MX, SHAN SD. Progress in research on biogas slurry fertilizer[J].Journal of Zhejiang Agricultural Sciences, 2009(5):977-978,983.(in Chinese).

[14] CHEN XJ, JIANG LN, XI H, et al. Discussion on biogas slurry digestion and utilization of farmland in agricultural engineering[J].Journal of Zhejiang Agricultural Sciences,2011 (1):132-135.(in Chinese).

[15] YU LY, HE CH, MA MK,etal. On the test of fertilizer for target yield method of tomato[J].Vegetables,2005 (12):40-41.(in Chinese).

[16] MA GR. On the manual of vegetable fertilization[M].Beijing: China Agriculture Press,2003:90-91.(in Chinese).

杂志排行

Asian Agricultural Research的其它文章

- How to Improve the Teaching Quality of Plant Physiology?

- Overview of Ecological Toxicity of Potassium Chlorate Pollution

- Path Choice of Rural Land Transfer in China

- A Study on the Reform of China’s Agricultural Administration System

- The Application of Acidic Electrolyzed Water to Grape Cultivation in the Southern Regions

- Recent Advance in Division of Carbohydrate and Protein Fractions of Ruminant Feed and Their Metabolism in Digestive Tract