Variation of chemical composition of high strength low alloy steels with different groove sizes in multi-pass conventional and pulsed current gas metal arc weld depositions

2015-11-01DEVAKUMARANANANTHAPADMANABANGHOSH

K.DEVAKUMARAN*,M.R.ANANTHAPADMANABAN,P.K.GHOSH

aWelding Research Institute,Bharat Heavy Electrical Limited,Trichy 620014,Tamil Nadu,India

bDepartment of Mechanical Engineering,M.A.M College of Engineering and Technology,Siruganur,Trichy 621 105,Tamil Nadu,India

cDepartment of Metallurgical&Materials Engineering,Indian Institute of Technology Roorkee,Roorkee 247 667,India

Variation of chemical composition of high strength low alloy steels with different groove sizes in multi-pass conventional and pulsed current gas metal arc weld depositions

K.DEVAKUMARANa,*,M.R.ANANTHAPADMANABANb,1,P.K.GHOSHc,2

aWelding Research Institute,Bharat Heavy Electrical Limited,Trichy 620014,Tamil Nadu,India

bDepartment of Mechanical Engineering,M.A.M College of Engineering and Technology,Siruganur,Trichy 621 105,Tamil Nadu,India

cDepartment of Metallurgical&Materials Engineering,Indian Institute of Technology Roorkee,Roorkee 247 667,India

25 mm thick micro-alloyed HSLA steel plate is welded by multi-pass GMAW and P-GMAW processes using conventional V-groove and suitably designed narrow gap with 20 mm(NG-20)and 13 mm(NG-13)groove openings.The variation of weld metal chemistry in the multi pass GMA and P-GMA weld depositions are studied by spark emission spectroscopy.It is observed that the narrow groove GMA weld joint shows significant variation of weld metal chemistry compared to the conventional V-groove GMA weld joint since the dilution of base metal extends from the deposit adjacent to groove wall to weld center through dissolution by fusion and solid state diffusion.Further,it is noticed that a high rate of metal deposition along with high velocity of droplet transfer in P-GMAW process enhances the dilution of weld deposit and accordingly varies the chemical composition in multi-pass P-GMAweld deposit.Lower angle of attack to the groove wall surface along with low heat input in NG-13 weld groove minimizes the effect of dissolution by fusion and solid state diffusion from the deposit adjacent to groove wall to weld center.This results in more uniform properties of NG-13 P-GMA weld in comparison to those of NG-20 and CG welds.

Pulsed current;Narrow gap;Weld metal chemistry

1.Introduction

The micro-alloyed high strength low alloy(HSLA)steels are widely used in engineering applications because of their relatively low cost,moderate strength and very good toughness and fatigue strength,together with their ability to be readily welded.Arc welding,including shielded metal arc welding(SMAW),gas metal arc welding(GMAW)andsubmerged arc welding(SAW),is widely used in fabrication of various components of the HSLA steel.Due to several merits of producing comparatively cleaner and continuous weld deposition with automation,the GMAW process is becoming widely popular,especially for welding of structural membersusedinpower,transportationanddefense industries.

It is often found that the heterogeneity of weld metal chemical composition,especially for multi-pass welding of thick sections,gives the different weld joint properties primarily due to the repetitive influence of subsequent weld passes on thermal cycles and the dilution of base metal[1,2]. The most significant changes in the properties of weld joints are due to adverse development of residual stress,microstructure and corrosion resistance,etc[2].In case ofconventional GMAW process,it is not always possible to maintain the chemical composition of the weld deposit within a desired level with respect to its influence on thermal and mechanical effects primarily due to limited operating parameters such as welding current,arc voltage and welding speed,which is used to determine the heat input of the process[3]. The pulsed current gas metal arc welding(P-GMAW)process instead of the conventional GMAW process may be more useful due to its ability to precisely control the geometry of weld deposit dictated by appropriate selection of pulse parameters[4,5]and also operate at low heat input in producing a sound weld joint[6,7].However,the involvement of large number of pulse current parameters in P-GMAW,including peak current(Ip),base current(Ib),pulse on-time(Tp),pulse off-time(Tb)and pulse frequency(f),introduces a certain degree of complexity in controlling the process for desired welding.It is reported that the complexity of the process primarily arising due to the criticality in selection of pulse parameters can be solved by correlating the weld characteristics with a summarized influence of pulse parameters defined by a dimensionless factorɸ=(Ib/Ip)× fTb,where Tbis expressed as[(1/f)-Tp][8,9].Lots of research work has been done and reported in reference to the P-GMAW arc and metal transfer dictating thermal behavior and its influence on various characteristics of ferrous and non-ferrous materials weld joints[10-13],but the chemical heterogeneity of multi-pass weld deposit has been not reported.

http://dx.doi.org/10.1016/j.dt.2014.11.001

2214-9147/Copyright©2015,China Ordnance Society.Production and hosting by Elsevier B.V.All rights reserved.

Thus,the present work has been carried out to investigate the effects of GMA and P-GMA welding parameters in the case of different groove sizes on the variation in the chemical composition of multi-pass weld deposit of 25 mm thick HSLA steel plate.The changing mechanism of its chemical composition during multi-pass weld deposition in the case of different groove design and welding parameters were discussed.A systematic understanding of these aspects may be beneficial in using GMAW process to produce desired weld quality.

2.Experiment

2.1.Welding

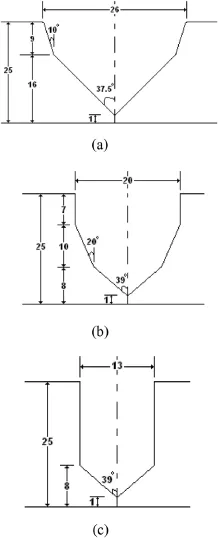

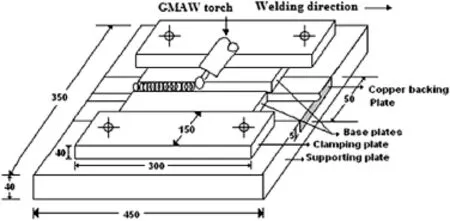

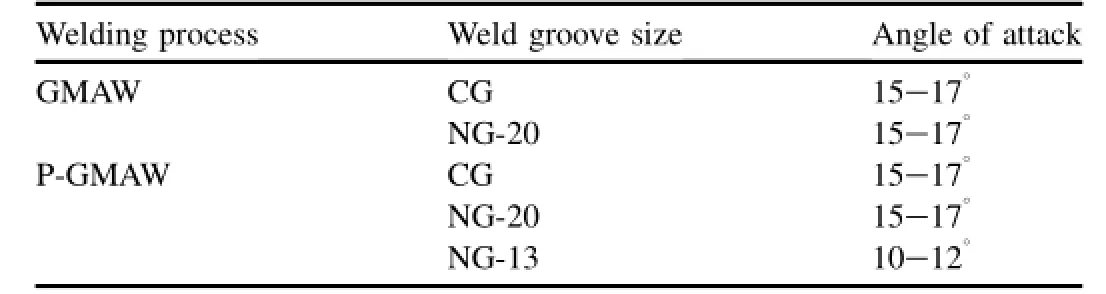

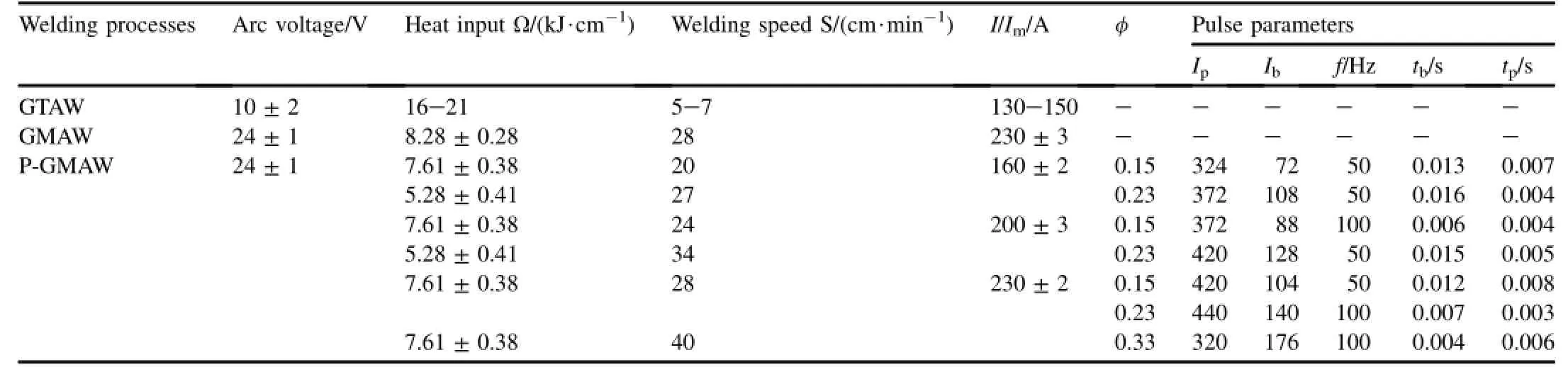

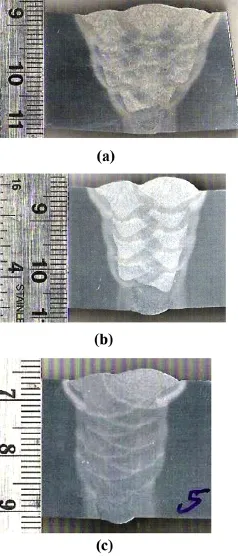

The 25 mm thick plate of controlled rolled micro-alloyed high strength low alloy(HSLA)steel of SAILMA 410HI/ SA543 having chemical composition given in Table 1 were used in this work.250 mm×100 mm plates were butt welded by multi-pass and multi-seam deposition techniques using conventional V-groove(CG)as per AWS specification[15]and a suitably designed narrow groove with 20 and 13 mm groove openings,designated by(NG-20)and(NG-13),respectively,as shown in Fig.1.The plates were welded by autogenous gas tungsten arc welding(GTAW)root pass,followed by GTAW filling pass and subsequent filling pass,in the process of continuous current gas metal arc welding(GMAW)or pulsed current gas metal arc welding(P-GMAW).The GTAW was carried out using a water cooled torch with 7 mm diameter gas nozzle and 3.2 mm diameter with 2%thoriated tungsten electrode(AWS:5.12 EWTh-2)under the shielding of 99.95%pure commercial argon at a flow rate of 18 l/min. The GMAW and P-GMAW passes were carried out by using 1.2 mm diameter mild steel filler wire of specification AWS/ SFA 5.18 ER-70S-6.The shielding gas used for experimentation is argon(98.95%)at a flow rate of 17-18 l/min.Direct current electrode positive(DCEP)polarity is used with an electrode extension of 14-15 mm.The chemical composition of filler wires given by the supplier is also given in Table 1. The plates was weld using semi-automatic welding with mechanized torch travel.Prior to welding the plates were preheated at about 125-130°C for 60 s,and the inter-pass temperature during welding was maintained in the range from 150°C to 300°C.The welding was carried out by arranging the groove plates without root gap.The root was supported by a copper backing plate fitted in a thick mild supporting steel plate of a fixture,as shown in Fig.2.Prior to weld deposition,the base plates were thoroughly cleaned to remove the excess oxide layer and any dirt or grease adhering to the faying surface.The angles between the electrode/filler and the groove wall under different welding processes and groove size are given in Table 2.The P-GMA weld deposition under different weld groove sizes was carried out at two different levels of heat input(Ω)by varying φ within the range from 0.15 to 0.33.During welding all the conventional welding parameters were recorded with WMS 4000 software installed in a computer,and the pulse parameters were recorded with the help of a transient recorder appropriately connected to the electrical circuit of the welding power source. The welding parameters used in the preparation of GMA and P-GMA weld joints are shown in Table 3.A multi-pass and multi-layer welding procedure was adopted for preparation of weld joints.

2.2.Chemical analysis

The chemical analysis of the weld joints under different weldingprocesses,groovetypeandparameterswerecarriedoutby using spark emission optical spectroscopy with a spot of 3mmdiameteronsolidspecimens.Theanalysiswasperformed on weld metal at two different locations on the polished transversesection of theweld joint.The two locations on weld metal are defined along its central axis parallel to the edge of plate surface within 10 mm below from its top side(Location-T)and 6-15 mm above from its bottom side(Location-B)of the weld metal,as shown in Fig.3.In the case of conventional GMAW process,NG-13 with the smallest possible groove size is not analyzed because the weld joint does not meet the required quality in reference to the absence of defect in it.

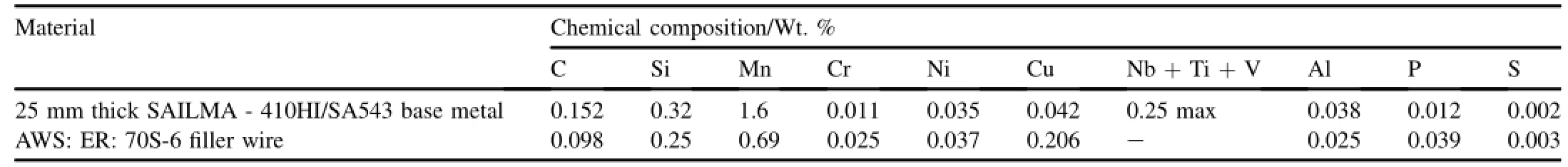

Table 1 Chemical compositions of base and filler materials.

2.3.Microstructure

Fig.1.Schematic diagram.(a)Conventional V-groove(CG),(b)20 mm width narrow groove(NG-20),(c)13 mm width narrow groove(NG-13).

Fig.2.Schematic diagram of fixture.

The microstructures of base metal and weld deposits of GMA and P-GMA weld joints having different groove sizes were studied under optical microscope.The sample was prepared as per metallographic procedure and etched with alcoholic solution of 2%HNO3.

尽管做了最充分的心理准备,可是当秦川如期死去,艾莉还是感觉整个世界离她而去。她抱着秦川的头,亲吻着秦川布满皱纹的嘴唇,她求秦川不要走不要走。她惊叹自己竟然有着如此之多的眼泪。

3.Result and discussions

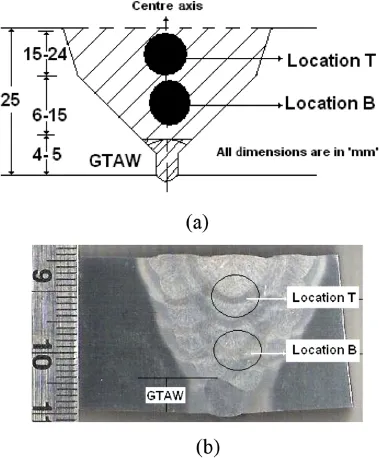

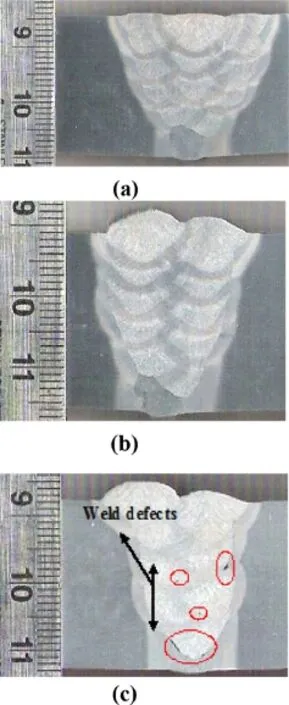

The variation behaviors of chemical composition in multipass GMA weld deposition under different groove designs were analyzed at a given heat input of 8.28±0.28 kJ/cm.In the case of multi pass P-GMA weld deposition under different groove designs,the variation behaviors of chemical composition were also analyzed by variation of factor φ and mean current(Im)under different heat inputs(Ω).The typical macrographs of conventional and pulsed current GMA weld joints are shown in Figs.4 and 5,respectively.

3.1.Chemical composition of GMA weld under different weld groove sizes

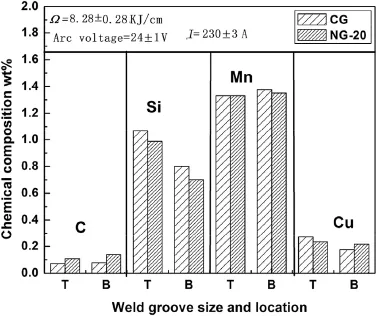

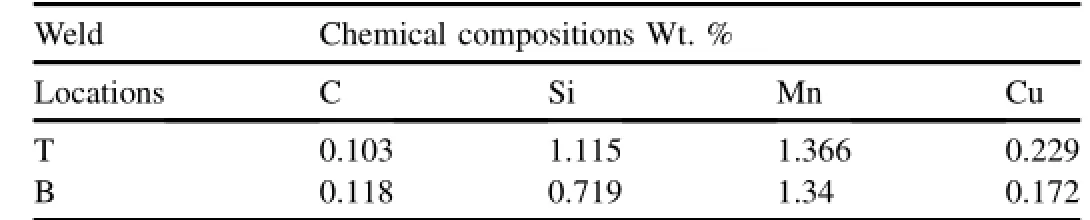

The chemical compositions at the different locations of weld deposit in the CG and NG-20 weld joints are shown in Fig.6.It is observed that the NG-20 weld joint has a higher carbon(C)content but lower silicon(Si),manganese(Mn)and copper(Cu)contents at the different locations of welds in comparison with CG weld joint.It may be because the effect of dilution in NG-20 narrow groove weld significantly extendsfrom the deposit adjacent to groove wall to the weld center through dissolution by fusion and solid state diffusion.However,the Fig.6 shows that the location-B of the weld has relatively higher C and Mn contents but lower Si and Cu contents than that the location-T has due to multi-pass weld deposition.

Table 2 Angles of attack between electrode/filler and groove wall under different welding processes and groove sizes.

Table 3 Welding parameters used in weld joint studies under different welding processes and groove type.

3.2.Chemical composition of P-GMA weld under different weld groove sizes

3.2.1.Conventional V-groove

Fig.3.Schematic diagram and macrophotograph showing the measurement of chemical composition at two different locations on weld metal.

The chemical compositions at different locations of PGMAweld deposit in the CG weld joint at a given arc voltage(V),mean current(Im),φ and heat input(Ω)are shown in Table 4.It has been observed that C content at any location of the weld deposit in CG P-GMAweld joint is about 30%higher than that of CG GMA weld joint and the changes in other elements are insignificant in it.In general,the axial spray metal transfer produces higher weld fumes than pulsed spray metal transfer[16].It indicates that the loss of elements(mainly C,Si and Mn)from the arc cavern is relatively higherin GMAW process than that in P-GMAW process.In addition to above high rate of metal deposition along with high velocity of droplet transfer in P-GMAW process the dilution of weld deposit is also enhanced[14],which may also play an important role in enhancing the C content in P-GMA weld. Table 4 further shows that C content is higher and Si content is lower at the location-B in comparison to those at the location-T,and other elements show insignificant variation in it.

Fig.4.Typical macrographs of conventional GMA weld joints.(a)Conventional V-groove(CG),(b)Narrow groove with 20 mm groove width(NG-20),(c)Narrow groove with 13 mm groove width(NG-13).

Fig.5.Typical macrographs of pulsed current GMA weld joints.(a)Conventional V-groove(CG),(b)Narrow groove with 20 mm groove width(NG-20),(c)Narrow groove with 13 mm groove width(NG-13).

3.2.2.Narrow groove with 20 mm groove width(NG-20)

Fig.6.The effect of weld groove size on chemical composition at different locations of GMAweld deposit for I=230±3A and Ω=8.28±0.28 kJ/cm.

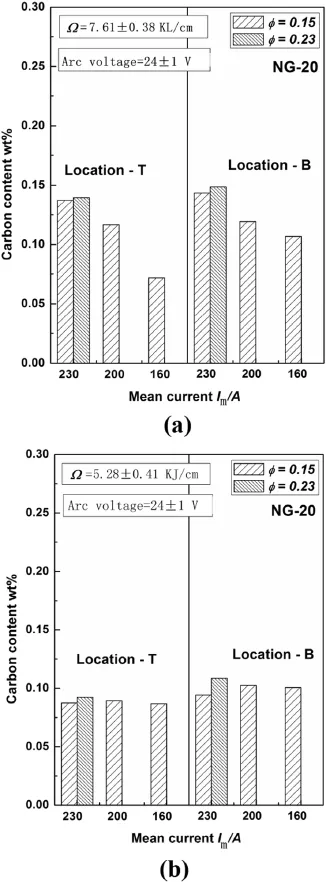

Fig.7 shows the effects of Imand φ on C contents at different locations of NG-20 P-GMA weld joints under two different heat inputs(Ω)of 7.61 and 5.28 kJ/cm at a given arc voltage(V)and φ=0.15 and 0.23.The Si,Mn and Cu contents are shown in Figs.8-10,respectively.It is also found that the C contents of NG-20 P-GMA weld joints at the locations B and Tof weld are about 20-25%higher than that of the CG P-GMA weld joint due to reduction in groove width,which is in agreement to those observed in NG-20 GMAweld joint(Fig.6).However,the Fig.7 shows that the C content at the location-B is higher than that at the location-T due to the effect of dilution in location-B in narrow groove weld in the case of different pulse parameters and Ω.It is also interestingly observed that,at a given Imof 230A,the C content at any locations of the weld increases with the increase in Ω and φ due to the increase in total heat transferred to the weld pool(QT)per unit length and projected arc diameter[11,12]respectively,which may give rise to more melting of base plate.On the other hand,it was reported that more fumes were generated when the angle of attack to groove wall surface and Ω were decreased by increasing the welding speed[16].In view of this,it is well understood that the final chemical composition of weld not only depends on the chemical compositions of electrode and base metal,but also depends on welding parameter and weld groove size.Fig.7 further depicts that,the decrease of Imfrom 230A to 160A decreases the C content significantly at both the locations of weld at 7.61 kJ/ cm due to the lower area of weld deposits and weld pool temperature(TWP),but C content shows an insignificant variation in it at 5.28 kJ/cm because of low TWP.

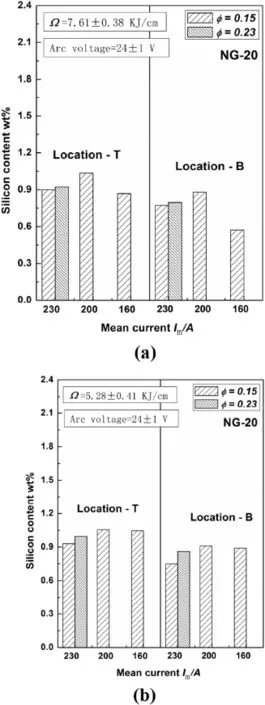

As in case of carbon,the Si contents at different locations of weld are also correlated to the factorφ,Imand Ω,as shown in Fig.8.It has been observed that the Si contents at two different locations of the weld increase significantly with the increase of φ due to the increase of projected arc diameter[10,13]at any Ω of relatively low and high levels in the order of 5.28±0.41 and 7.61±0.38 kJ/cm and a given Im,resulting in large melting of base metal.However,Fig.8 also shows that,at a given φ at both the locations of weld,the Si contents are insignificantlyvaried with the increase of Ω from 5.5 to 7.61 kJ/cm,but they are appreciably enhanced with the decrease of Imfrom 230 to 200,and they decrease with the further decrease of Im.Such variations of Si contents as a function of Imand Ω are primarily attributed to the combined influence of heat transfer on the weld pool and fume formation rate from arc cavern.

Table 4 Chemical compositions at different locations of CG P-GMA weld joint.

Fig.7.Effects of Imand φ on Wt.%of C contents at two different locations of NG-20 P-GMA weld joints prepared at different Ω.(a)7.61±0.38 kJ/cm,(b)5.28±0.41 kJ/cm.

Fig.8.Effects of Imand φ on Wt.%of Si contents at two different locations of NG-20 P-GMAweld joints prepared at different Ω.(a)7.61±0.38 kJ/cm,(b)5.28±0.41 kJ/cm.

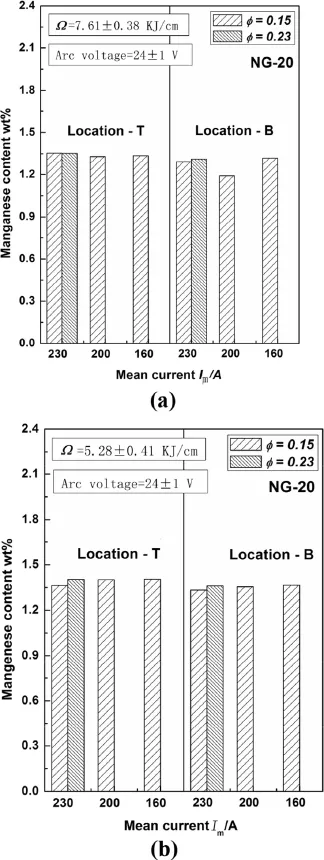

Fig.9.Effects of Imand φ on Wt.%of Mn contents at two different locations of NG-20 P-GMA weld joints prepared at different Ω.(a)7.61±0.38 kJ/cm,(b)5.28±0.41 kJ/cm.

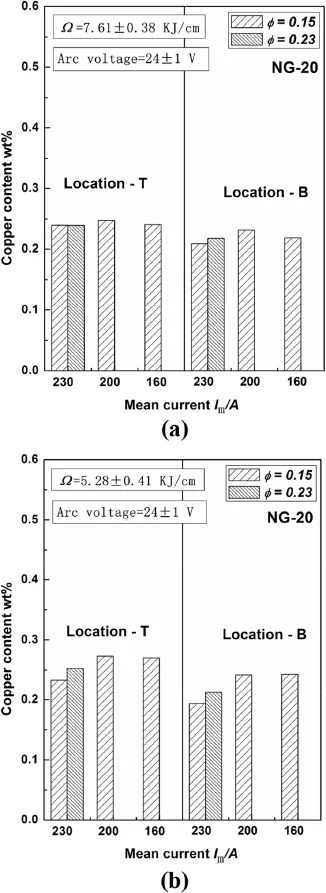

As in case of C and Si,the Mn and Cu contents at different locations of weld are also correlated to the factorφ,Imand Ω, as shown in Figs.9 and 10,respectively.It has been observed that the variations of Mn and Cu contents at both the locations of weld with the changes in φ,Imand Ω were not evident.

Fig.10.Effects of Imand φ on Wt.%of Cu contents at two different locations of NG-20 P-GMA weld joints prepared at different Ω.(a)7.61±0.38 kJ/cm,(b)5.28±0.41 kJ/cm.

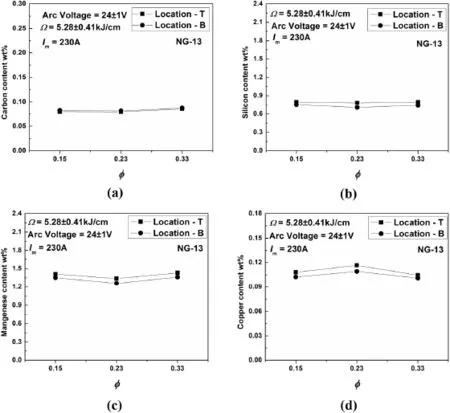

3.2.3.Narrow groove with 13 mm groove width(NG-13)

The effects of φ on C,Si,Mn and Cu contents at different locationsofNG-13P-GMA weldjointat230Aand 5.28±0.41 kJ/cm are shown in Fig.11.It has been observed Ccontent is lower but Si and Mn contents are insignificantly varied at any location of NG-13 P-GMA weld as compared to the NG-20 P-GMAweld.The lowering of C content in NG-13 P-GMA weld primarily happened due to lower angle of attack against the groove wall surface along with low Ω minimizes the effect of dissolution by fusion and solid state diffusion from the deposit adjacent to groove wall to weld center and also enhances the fume formation rate because of wider contact area of arc exposed to groove wall surface,resulting in a significant amount of element loss from arc cavern.In addition to above decrease of Ω with the increase of welding speed,the fume formation rate is also enhanced[16],which may also play an important role for decrease of C content in NG-13 PGMA weld.In this regard,for the given electrode chemical compositions,the change in weld groove size by varying groove angle provides a more efficient way to control the chemical composition of weld,and also play a favorable role in weld properties and microstructure.However,Fig.11 further shows the insignificant variation of the chemical compositions at both the locations of weld depicts,which indicates that the properties of the weld are more uniform in comparison to those of NG-20 and CG welds.Fig.11(d)shows that the Cu contents at different locations of NG-13 PGMAweld are comparatively lower than those of CG P-GMA and NG-20 P-GMA welds due to higher fume generation rate. However,the influence of φ on the chemical compositions at different locations of NG-13 weld shows an insignificant variation in it.In this regard,all the phenomena regarding the influence of pulse parameters and groove size on chemical compositions of P-GMA weld should be studied further in detail with the help of other experimental technique,like XRD,SEM-EDAX,etc.

In the last few decades,the control of weld fumes in arc welding is a challenging task as the inhalable metal fumes pose a potential health hazard to the human body.In view of the above observations,the significant role of pulse parameters of P-GMAW process may give wider possibility to control the weld fumes.However,the study on fume generation rate under different pulse parameters and weld groove sizes of P-GMAW process is beyond the scope of the present work,but it should be studied further in detail.

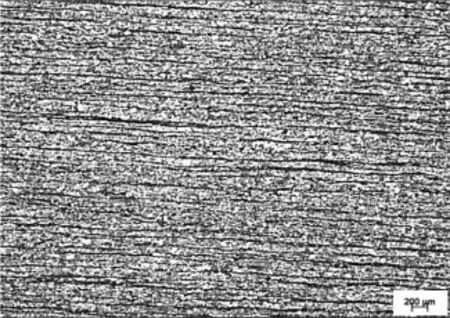

3.3.Microstructure

The typical microstructure of 25 mm thick plate of microalloyed HSLA(SAILMA-350HI/SA533 grade)steel and its transverse direction are shown in Fig.12.The microstructure of base metal has been primarily found to consist of ferrite and pearlite along with the lamination of matrix typical of rolled structure.Due to the addition of micro alloying elements Ti,V,and Nb,the average grain size is around 18±3 μm and are comparatively finer than those observed in commonly used structural steel(24±3 μm)[17].

Fig.11.Effect of φ on Wt.%of C,Si,Mn and Cu contents in NG-13 P-GMA weld joints at 5.28±0.41 kJ/cm(a)C,(b)Si,(c)Mn,(d)Cu.

Fig.12.Typical microstructure of base metal.

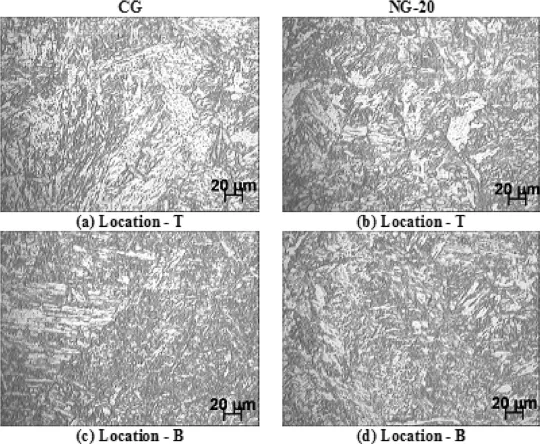

The significant change in the chemical composition of weld deposit with the change in welding processes and groove design should also influence its microstructure.Thus,it may be interesting to study the microstructure of weld deposits. The typical microstructures of CG and NG-20 GMA weld joints at two different locations of the weld deposit are shown in Fig.13.It is observed that,in comparison to the CG GMA weld,the NG-20 weld shows a larger amount of pearlites and a lower fraction of pro-eutectoid ferrite due to variation of chemical composition as explained earlier.The typical microstructures of CG,NG-20 and NG-13 P-GMAweld joints at two different locations of the weld deposit are in Fig.14.It is also observed that the microstructures of P-GMA weld deposits have the same features as those of the GMA weld deposits.However,relatively low thermal impact in P-GMAW weld shows a large proportion of ferrite in the matrix in comparison to the GMA welds.Further,it has been observed that the microstructure of NG-13 P-GMAweld deposits at two different locations show insignificant variation due to uniformly distributed chemistry in the weld deposits as explained earlier.

4.Conclusions

The present study provides a basic understanding of the effect of welding processes and groove size on variation of weld metal chemical composition in multi-pass weld deposition of HSLA steel.The observations on various critical aspects of GMA and P-GMAW processes may be primarily concluded as follows.

1)Due to multi-pass GMA weld deposition,the chemical composition of weld metal is not uniform throughout the welding process,irrespective of change in groove size.

2)The use of P-GMAW process enhances the dilution of weld deposit.Further,it is observed that,the NG-13 PGMA weld joint shows the uniform properties throughout the multi-pass weld deposition due to lower angle of attack against the groove wall surface along with low heat input.

Fig.13.Typical microstructures of conventional GMA weld deposits.

Fig.14.Typical microstructures of pulsed current GMA weld deposits.

3)Finally,it is concluded that,for a given electrode chemical compositions,the change in weld groove size by varying groove angle provides a more efficient way to control the chemical composition of weld plays a favorable role in weld properties.Thus it may be considered further to characterize the microstructure of weld deposits.

Acknowledgment

The authors thankfully acknowledge the Indian Institute of Technology Roorkee(IITR),India for supporting to the research work.

[1]Linnert G.Welding metallurgy.4th ed.,vol.1.Miami,Florida:American Welding Society;1994.

[2]Kou Sindo.Welding metallurgy.New York:John Wiley and Sons;1987.

[3]Messler Jr Robert W.Principles of welding.New York:John Wiley and Sons;1999.

[4]Ghosh PK,Gupta SR,Randhawa HS.Characteristics and criticality of bead on plate deposition in pulsed current vertical-up GMAWof steel.Int J Join Mater 1999;11(4):99-110.

[5]Ghosh PK,Gupta SR,Randhawa HS.Characteristics of a pulsed-current,verticalupgasmetalarcweldinsteel.MetalTransA 2000;31A:2247-59.

[6]Praveen P,Yarlagadda PKDV,Kang MJ.Advancements in pulse gas metal arc welding.J Mater Process Technol 2000;164-165:1113-9.

[7]Rajasekaran S,Kulkarni SD,Mallya UD,Chaturvedi RC.Droplet detachment and plate fusion characteristics in pulsed current gas metal arc welding.Weld J 1998;6:254s-68s.

[8]Ghosh PK.Decide pulse parameters for desired properties of pulsed current GMAW weld.In:International welding conference(IWC-99)on welding and allied technology”challenges in 21st century,”New Delhi;1999:Feb.15-17.p.18-28.

[9]Ghosh PK,Dorn L,Goecke SF.Universality of co-relationships among pulse parameters for different MIG welding power sources.Int J Join Mater 2000;13(2):40-7.

[10]Ghosh PK,Dorn L,Devakumaran K,Hofmann F.Pulsed current gas metal arc welding under different shielding and pulse parameters;part-1: arc characteristics.ISIJ Int 2009;49(2):251-60.

[11]Ghosh PK,Goyal VK,Dhiman HK,Kumar M.Thermal and metal transfer behaviour in pulsed current GMA weld deposition of Al-Mg alloy.Sci Technol Weld Join 2006;11(2):232-42.

[12]Ghosh PK,Dorn L,Hubner M,Goyal VK.Arc characteristics and behaviour of metal transfer in pulsed current GMAwelding of aluminium alloy.J Mater Process Technol 2007;194:163-75.

[13]Ghosh PK,Dorn L,Kulkarni S,Hoffmann F.Arc characteristics and behaviour of metal transfer in pulsed current GMA welding of stainless steel.J Material Process Technol 2008;209:1262-74.

[14]Kulkarni SG.Narrow gap pulse current gas metal arc welding of thick wall 304LN stainless steel pipe[Ph.D.Thesis].2008.IIT Roorkee,India.

[15]Welding handbook,welding technology.8th Ed.vol.1.American Welding Society;1987.

[16]Dennis John,H,Peter JH,Redding CAJ,Andrew DW.A model for prediction of fume formation rate in gas metal arc welding,globular and spray modes,DCelectrodepositive,vol.45(2).PergamonPress;2001.p.105-13.

[17]Tamura I,Sekine Hiroshi,Tanaka Tomo,Ouchi Chiaki.Thermo-mechanical processing of high strength low alloy steels.Butterworth&Co. Metals Handbook;1988.

11 September 2014;revised 13 November 2014;accepted 24 November 2014

Available online 20 February 2015

.Tel.:+91 9443689943.

E-mail addresses:devakumaran@bheltry.co.in(K.DEVAKUMARAN),mrpadmanaban@yahoo.com(M.R.ANANTHAPADMANABAN),prakgfmt@ gmail.com,prakgfmt@iitr.ernet.in(P.K.GHOSH).

Peer review under responsibility of China Ordnance Society.

1Tel.:+91 9488090838.

2Tel.:+91 1332 285699.

Copyright©2015,China Ordnance Society.Production and hosting by Elsevier B.V.All rights reserved.

杂志排行

Defence Technology的其它文章

- Inspection of aluminum alloys by a multi-frequency eddy current method

- 2D and 3D milled surface roughness of high volume fraction SiCp/Al composites

- Determination of penetration depth at high velocity impact using finite element method and artificial neural network tools

- Microstructure and pitting corrosion resistance of AA2219 Al-Cu alloy friction stir welds-Effect of tool profile

- Theoretical study of BTF/TNA cocrystal:Effects of hydrostatic pressure and temperature

- Friction stir surfacing of cast A356 aluminium-silicon alloy with boron carbide and molybdenum disulphide powders