Impact of fluid properties on the injection process in a common-rail direct injection system

2015-10-29JunxingHOUJianweiLIUZhenhuaWENYuanpengLIUZhiqiangJIANGXinqiQIAO

Jun-xing HOU, Jian-wei LIU, Zhen-hua WEN,Yuan-peng LIU, Zhi-qiang JIANG, Xin-qi QIAO

(1School of Mechatronics Engineering, Zhengzhou Institute of Aeronautical Industry Management, Zhengzhou 450015, China)(2Key Laboratory for Power Machinery and Engineering of M. O. E, Shanghai Jiao Tong University, Shanghai 200240, China)

Impact of fluid properties on the injection process in a common-rail direct injection system

Jun-xing HOU1*, Jian-wei LIU1, Zhen-hua WEN1,Yuan-peng LIU1, Zhi-qiang JIANG1, Xin-qi QIAO2

(1SchoolofMechatronicsEngineering,ZhengzhouInstituteofAeronauticalIndustryManagement,Zhengzhou450015,China)(2KeyLaboratoryforPowerMachineryandEngineeringofM.O.E,ShanghaiJiaoTongUniversity,Shanghai200240,China)

In this paper, the injection rates and fuel line pressure of DME and diesel are measured. The effects of fluid properties on the injection characteristics in a common rail injection system are investigated. The results show that the injection timing of DME begins and ends later than that of diesel due to larger compressibility. The peak injection rates of DME and diesel are similar. The injection quantity of DME is larger than that of diesel, while its injection energy is lower. Compared to diesel, the fluctuation amplitude of DME during injection is smaller, and the duration is longer.

Fluid properties, DME, Diesel, Injection

1 Introduction

Due to the challenge of energy crisis and environmental pollution, clean alternative fuels for engine application are becoming increasingly important [1]. DME is an excellent and efficient alternative fuel for diesel engines [2-3]. It can be produced by de-hydrogenation of methanol or direct conversion from synthesis gas. Compared to diesel fuel, DME has advantages of low boiling point, high cetane number, high oxygen content and no carbon-to-carbon bonds. Diesel engines fueled with DME can realize high thermal efficiency, low combustion noise, low emissions and smoke-free combustion. Fuel injection is very important to combustion and emission formation of the engine. Due to different fluid properties of DME and diesel, the fuel delivery and injection systems of diesel engines are needed to be modified when fueled with DME [4]. Studies of injection of DME have been carried out on conventional pump-line-nozzle injection system. The effects of bulk modulus on compression work was verified by Sorenson et al.[5], and it is found out that due to lower bulk modulus and lower density of DME, more compression work is needed for DME pump. Egnell [6] studied the needle lift characteristics in injectors and reported that DME gives slower needle lift speed than diesel fuels. Common rail system has more advantages than conventional pump-line-nozzle injection system, and is regarded as the trend of fuel delivery system in diesel engines. Due to the different physical and chemical properties of DME and diesel, the features of injection and flow in the fuel line and common-rail system for DME and diesel are different. However, few researchers focus on the effect of fuel properties of DME on the injection characteristics in the common rail system.

In this paper, the dynamic behavior during the injection process of DME and diesel in a common-rail injection system are experimentally studied. The effects of fuel properties, rail pressure and energizing time on injection rate and instantaneous line pressure evolution in the fuel line are experimentally analyzed.

2 Experimental apparatus and method

Experiments were conducted on a fuel injection system test bench. The fuel injection system for DME consists of a fuel tank, a filter, a low-pressure supply pump, an injection pump, a common-rail, an injector, a fuel line and an electronic control unit. As DME has a high vapor pressure in the environmental situations, the low-pressure supply pump to pressurize DME or blend fuels at 1.6 MPa to prevent vapor lock in the fuel system. Rail pressure and energizing time are controlled by the computer connected to the electronic control unit. Test nozzle orifice number × diameter is 7 × 0.17 mm with 17 MPa opening pressure. In the experiments, the rail pressure is 40 MPa and 60 MPa, and energizing time is 1.2 ms and 1.6 ms, respectively.

The schematics diagram of fuel injection rate measuring system is shown in Fig. 1.

Fig. 1 Schematics diagram of fuel injection rate mea-suring system

The injection measurement apparatus includes a line pressure sensor at the injector inlet, a charge amplify, a Bosch tube, a pressure sensor at Bosch tube, a charge amplifier, and a current probe and data acquisition equipment. Sampled signals include line pressures at the rail outlet and at the injector inlet injector current, and injection rate and injector current. The line pressure at the injector inlet is acquired with a pressure sensor and a charge amplifier. The fuel injection rate measuring system includes an injector, a pressure sensor, a charge amplifier and a Bosch Tube Meter. The fuel is injected into a tube filled with fuel, and the ambient pressure within the tube is kept at 2 MPa during the fuel injection process. The pressure varies with time due to fuel flows in the tube, and it is acquired by a pressure sensor and charge amplifier. Afterwards, the injection rate is calculated based on the pressure wave. The injector current is acquired by the current probe. All of sampled signals are recorded by the data acquisition equipment. Sampling frequency was 50 kHz. The pressure data of 50 consecutive cycles are sampled and recorded.

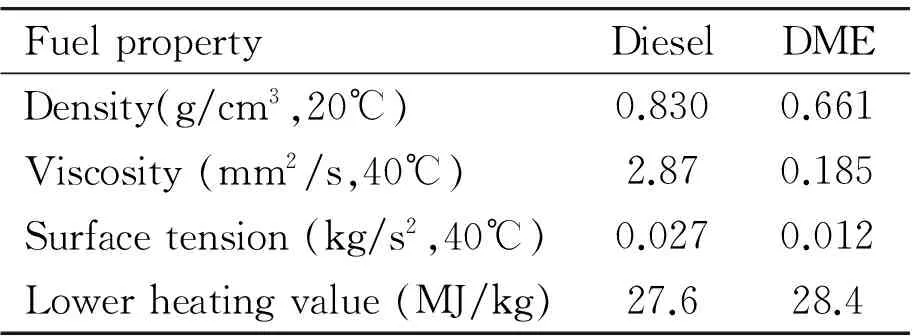

The fluid properties of DME and diesel are shown in Table 1.

Table 1 Properties of DME and diesel fuel

FuelpropertyDieselDMEDensity(g/cm3,20℃)0.8300.661Viscosity(mm2/s,40℃)2.870.185Surfacetension(kg/s2,40℃)0.0270.012Lowerheatingvalue(MJ/kg)27.628.4

3 Results and discussions

3.1Effectoffluidpropertiesoninjectionprocess

The effects of fluid properties on injection rate are shown in Fig. 2. In the experiment, rail pressure is 40 MPa and 60 MPa, respectively. And energizing time is 1.2 ms and 1.6 ms, respectively. It can be seen clearly that compared to diesel, the injection of DME starts and ends later, and the injection duration is prolonged significantly, but the peak injection rate is almost unchanged. With the rail pressure increasing from 40 MPa to 60 MPa, the early change rate of injection rate with time and peak injection rate increases. With the energizing time increased from 1.2 ms to 1.6 ms, the start of injection and peak injection rate remain almost unchanged.

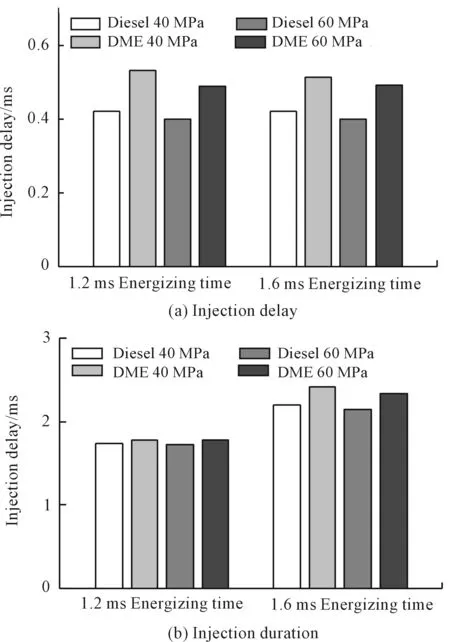

Fig. 3 shows the effects of fluid properties on injection delay and injection duration. Because of the low density, elastic module and viscosity, DME has higher compressibility than that of diesel. Therefore, compared to diesel fuels, the injection delay for DME increases and the actual injection duration is longer than that of diesel fuel at the same condition. It means that with the same energizing time and rail pressure, DME fuels show a longer injection duration than that of diesel fuels. With the increase of rail pressure, the injection delay and the injection duration decreases. Because the increased rail pressure causes higher needle valve opening and closing velocity, the needle valve can completely open and close in a shorter time. It indicates that the high rail pressure causes high injection velocity at the early stage of injection duration.

Fig. 2 Effect of fluid properties on fuel injection rate

Fig.3 Effect of fluid properties on injection delay and injection duration

Fig. 4 shows the effects of fluid properties on injection quantity and injection energy per cycle. The injection quantity of DME is larger than that of diesel with all testing conditions, because the injection duration of DME is longer than that of diesel. For the same fuel, the increased rail pressure leads to higher cycle injection quantity and injection energy. With the energizing time increased from 1.2 ms to 1.6 ms, the injection duration extends, and the injection quantity and energy increases obviously due to the extension of valve opening duration. However, because the lower heating value of DME is about 65% of that of diesel, the injection energy of DME is smaller than that of diesel. To acquire the same engine power output, the energizing time of DME needs to be extends.

Fig.4 Effect of fluid properties on injection quantity and injection energy

3.2Effectoffluidpropertiesonlinepressurefluctuations

The pressure wave propagation phenomena in line during and after the injection process are investigated. The line pressure fluctuation at the injector inlet is illustrated in Fig. 5. The energizing time is 1.6 ms and the rail pressure is 60 MPa. The curves of line pressure at the injector inlet for DME and diesel blends are similar. When injection begins, line pressure first decreases and then increases to a peak. After that, it begins to fluctuate, and the fluctuation decays gradually due to the friction resistance between fuel and tube. The pressure fluctuation amplitude of DME is smaller than that of diesel during injection, and the duration is longer. The viscosity, bulk modulus and density of DME and those of diesel are different, which cause the variation of the line pressures fluctuation.

Fig.5 Effect of fluid properties on line pressure fluctuation

4 Conclusions

In this paper, the effects of fluid properties on injection process and instantaneous line pressure evolution are investigated. The conclusions are listed as follows.

1) Compared to diesel, the injection of DME starts and ends later due to larger compressibility, the injection duration prolongs significantly, and the peak injection rate is almost unchanged.

2) With the increase of rail pressure, the early change rate of injection and peak injection rate increase. With the increased energizing time, the injection start and peak injection rate remain unchanged, but the injection duration increases.

3) The injection quantity of DME is larger than that of diesel, but its injection energy is lower than that of diesel. To acquire the same engine power output, the energizing time of DME needs to be extends.

4) Compared to diesel, the pressure fluctuation amplitude of DME during injection is smaller, but its duration is longer.

Acknowledgements

This paper is supported by the Aeronautical Science Foundation of China (2013ZB55003), Innovation Scientists and Technicians Troop Construction Projects and Talents of Henan Province (134200510024), Program of University Youth Key Teacher of Henan Province (2014GGJS-104), and the Tackle-Program of S&T Committee of Henan Province (132102210287), China.

[1]Han D, Ickes A M, Assanis D N, et al. Attainment and load extension of high-efficiency premixed low-temperature combustion with dieseline in a compression ignition engine [J]. Energy & Fuels, 2010, 24: 3517-3525.

[2]Hou J, Wen Z, Jiang Z, et al. Study on combustion and emissions of a turbocharged compression ignition engine fueled with dimethyl ether and biodiesel blends [J]. Journal of the Energy Institute, 2014, 87: 102-113.

[3]Arcoumanis C, Bae C, Crookes R, et al. The potential of dimethyl ether (DME) as an alternative fuel for compression-ignition engines: A review [J]. Fuel, 2008, 87: 1014-1030.

[4]Hou J, Wen Z, Jiang Z, et al. Effects of premixed ratio on combustion characteristics of a homogeneous charge compression ignition-direct injection engine fueled with dimethyl ether [J]. Journal of Renewable and Sustainable Energy, 2014, 6(1): 013106-9.

[5]Sorenson S C, Glensvig M, Abata D L. Dimetyl ether in diesel fuel injection systems [R]. SAE Technical Paper, 1998, 981159.

[6]Egnell R. Comparison of heat release and NOx formation in a DI diesel engine running on DME and diesel fuel [R]. SAE Technical Paper, 2001, 2001-01-0651.

10.3969/j.issn.1001-3881.2015.24.021 Document code: A

TK421.42

流体物性对高压共轨系统喷射过程的影响研究

侯军兴1*,刘建伟1,文振华1,刘元朋1,蒋志强1,乔信起2

1.郑州航空工业管理学院 机电工程学院, 郑州450015 2.上海交通大学 动力机械及工程教育部重点实验室, 上海200240

测量了二甲醚和柴油的喷射率和油管压力,研究了流体物性对高压共轨喷油过程的影响。研究结果表明:由于二甲醚的可压缩性比柴油大,导致其喷油始点、喷油终点均比柴油晚。两种燃料的最大喷油速率接近。与柴油相比,二甲醚的循环喷油量较大,循环喷油能量较小。油管压力波动幅值较小,但波动持续期较长。

流体物性;二甲醚;柴油;喷射

13 January 2015; revised 9 April 2015;

Jun-xing HOU, Lecturer.

E-mail: houjunxing@126.com

accepted 12 May 2015

Hydromechatronics Engineering

http://jdy.qks.cqut.edu.cn

E-mail: jdygcyw@126.com

猜你喜欢

杂志排行

机床与液压的其它文章

- The design of control system applied in artificial grass tufting machine adopting servomotors

- Research on active suspension control strategy based on fuzzy PID control

- Automobile magnetorheological damper multi-objective optimization analysis

- Co-simulation and consumption analysis of wheel loader on negative loading condition

- Influence of the underlap in the poppet valve on its performance

- Comprehensive reliability evaluation of foreign high-end gantry machining Center