钢渣硅肥硅素释放规律及其影响因素研究

2015-06-15宁东峰宋阿琳梁永超

宁东峰, 宋阿琳, 梁永超,3*

(1 中国农业科学院农田灌溉研究所, 农业部作物需水与调控重点实验室, 河南新乡 453002;2 中国农业科学院农业资源与农业区划研究所, 北京 100081; 3 浙江大学环境与资源学院, 浙江杭州 310058)

钢渣硅肥硅素释放规律及其影响因素研究

宁东峰1, 2, 宋阿琳2, 梁永超2,3*

(1 中国农业科学院农田灌溉研究所, 农业部作物需水与调控重点实验室, 河南新乡 453002;2 中国农业科学院农业资源与农业区划研究所, 北京 100081; 3 浙江大学环境与资源学院, 浙江杭州 310058)

【目的】钢渣是缓释硅钙肥原料,钢渣中硅素释放受钢渣自身性能和外界环境条件等因素影响,本文设置了钢渣冷却方式、钢渣粒径、培养介质和培养温度四种因子,研究钢渣中硅素释放规律及其影响因素,为钢渣硅钙肥合理施用提供理论依据。【方法】选用粉末状水淬渣(S1)、粒状水淬渣(S2)和空气冷却粒状钢渣(S3)为研究对象,分别设置在土壤水溶液以及纯蒸馏水中培养97天,并设置 35℃和25℃两个培养温度。定期离心取上清液,取样后补充水分继续培养,直至培养结束。【结果】钢渣在土壤溶液中培养,第一天的硅素释放主要由钢渣冷却方式决定,而在以后的培养过程中主要受温度的影响,其次为钢渣粒径;硅素累积释放量与时间的关系可以用幂函数方程y=kxm来拟合;35℃培养97天后,S1、S2与S3钢渣硅的溶出率(累积硅释放量与有效硅的比例)分别为37.3%、 30.3%与27.3%;在25℃培养下,S1、S2与S3钢渣硅的溶出率分别为14.3%、7.9%与10.2%。钢渣在纯蒸馏水的培养中,第一天钢渣硅释放主要受温度的影响,而在以后的培养过程中主要受钢渣粒径的影响,温度和钢渣冷却方式对其影响甚微;硅素累积释放量与时间的关系可以用线性方程y=ax+b来拟合;在35℃,S1、S2与S3钢渣硅的溶出率分别为0.22%、0.16%与0.16%。在25℃培养下,S1、S2与S3钢渣硅的溶出率分别为0.17%、 0.13%与0.14%。钢渣在土壤溶液培养,25℃培养67天,加入钢渣提高了土壤浸提液的pH值,但之后与CK基本相同;在35℃培养下,加入钢渣的土壤浸提液pH值总体都要显著高于CK处理。纯水培养介质中,两种温度培养下,在同一阶段S1浸提液的pH和EC值都要显著高于S2和S3,温度对pH和EC的影响不显著。【结论】钢渣硅素释放规律主要受培养介质和温度的影响,粒径有一定的影响。在土壤溶液中钢渣硅素释放显著高于在蒸馏水中,35℃比25℃更有利于硅素的释放,粉末状比粒状更有利于硅素的释放。由此认为,钢渣作为硅钙肥在大田施用时,将钢渣磨细做成粉末状产品,施用时随翻耕埋入土壤,初春采用保温措施等都有利于提高钢渣中硅的利用效率。

钢渣; 培养; 温度; 粒径; 冷却方式; 硅释放

1 材料与方法

1.1 供试材料

试验选用三种钢渣, 粉末状水淬渣(鞍钢, 编号S1),过2 mm筛的颗粒状水淬渣(首钢,编号S2)和气缓慢冷却颗粒状钢渣(过2 mm筛,武钢,编号S3)。三种钢渣详细化学性质见表1。

表1 钢渣基础化学特性

1.2 试验设计

1.2.1 水浸泡法 (水培法) 准确称取钢渣2.00 g置于50 mL塑料离心管中,加25 mL蒸馏水,加盖摇匀,每份钢渣重复8次,分为两批,分别于25℃与35℃恒温培养箱培养。在培养的第1、4、7、12、17、27、37、47、57、67、82和97 d取样。取样法为3000 r/min离心15 min,倾倒出全部上清液,离心管中新加入25 mL蒸馏水,加盖摇匀后继续培养,直至培养结束。浸提液保存于-20℃冰箱中,培养结束后统一测定浸提液中硅含量与pH、EC值。

1.2.2 土壤溶液培养法(土培法) 试验选用的土壤为红壤性水稻土,土壤有效SiO2含量为94.2 mg/kg,pH值为5.76,EC值为75 μs/cm。准确称取过l mm筛的5.00 g风干土样和0.100 g钢渣于100 mL的塑料离心管中,充分混匀后加入50 mL的蒸馏水,另设不加钢渣土样为空白,每个处理重复8次。分为两批分别在25℃、35℃下恒温培养。在培养的第1、4、7、12、17、27、37、47、57、67、82和97 d取样。取样方法为3000 r/min离心20 min,倾倒出全部上清液,离心管中新加入50 mL蒸馏水,加盖摇匀继续培养,直至培养结束。浸提液统一保存于-20℃冰箱中,培养结束后统一测定浸提液中硅含量与pH、EC值。

1.3 测定项目与方法

1.3.1 测定方法 pH采用Sartorins PB-10 pH计测定,电导率采用雷磁DDS-307电导率仪测定。浸提液硅测定: 取5 mL 浸提液,采用硅钼蓝比色法测定[13]。水培钢渣硅素释放速率[mg/(kg·d)]= n天钢渣硅素累计释放量(mg/kg)/n(n为培养天数)。土培钢渣硅素释放速率[mg/(kg·d)]= [ n天(钢渣+土壤) 硅素累积释放量-n天土壤硅素累积释放量](mg/kg)/n(n为培养天数)。水培钢渣有效硅素溶出率(%)=钢渣总硅素累积释放量/钢渣中有效硅含量×100。土培钢渣有效硅溶出率(%)=[(钢渣+土壤)总硅素累积释放量-土壤硅素总累积释放量]/钢渣中有效硅含量*100。

1.3.2 数据分析

试验数据用Microsoft Excel和SPSS 18.0软件进行分析,采用LSD法进行差异显著性比较,用Origin 8.0 软件作图。

2 结果与分析

2.1 钢渣硅素释放速率及影响因素分析

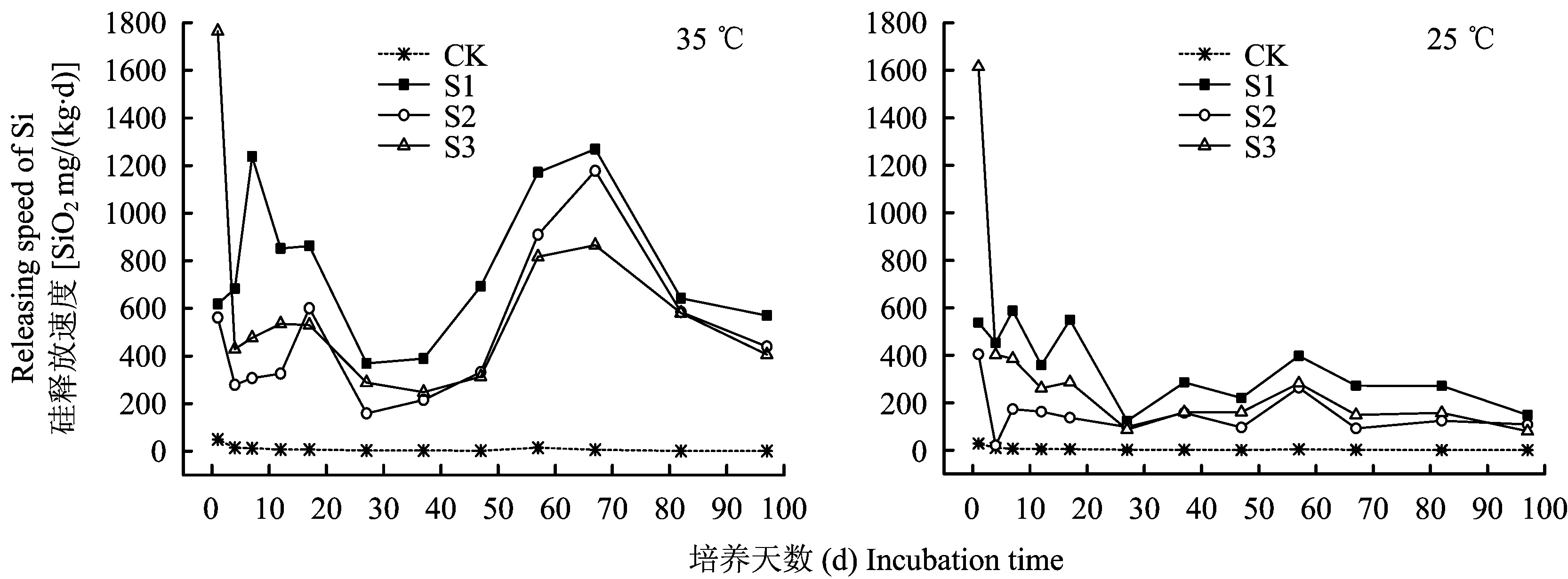

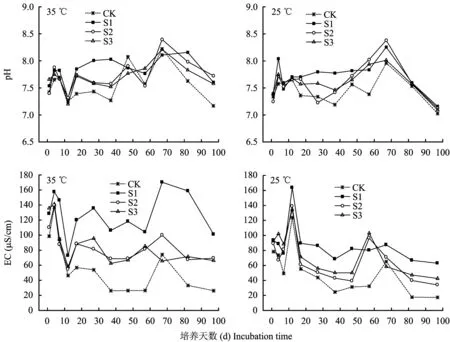

图1 土壤溶液培养钢渣硅素释放规律Fig.1 Si releasing dynamics of different slags under soil suspension incubation

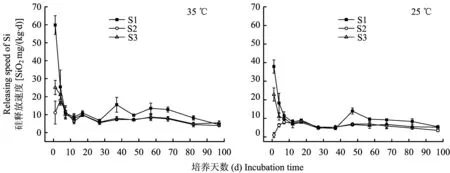

图2 水浸提培养钢渣硅素释放规律Fig.2 Si releasing dynamics of different kinds of slag in water incubation

2.2 钢渣培养中浸提液pH 和EC的变化

2.3 钢渣累积释放量变化以及释放动力学方程

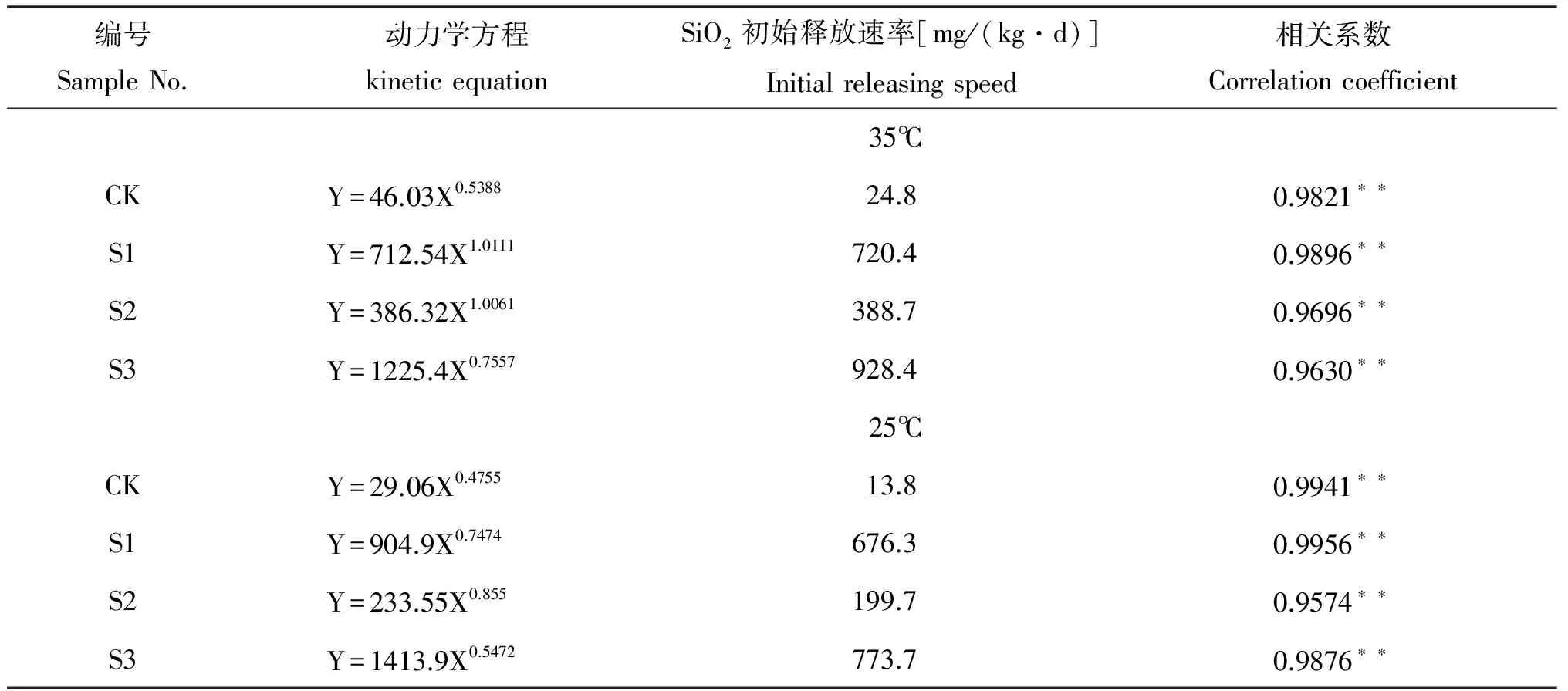

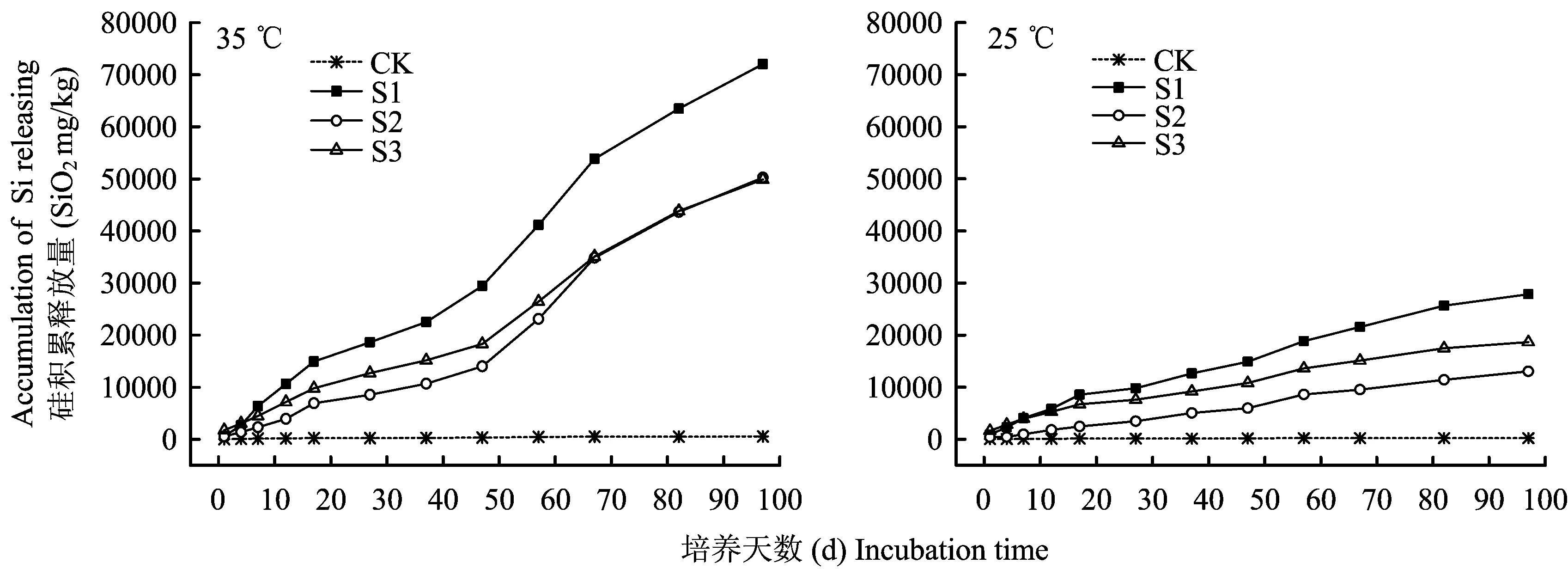

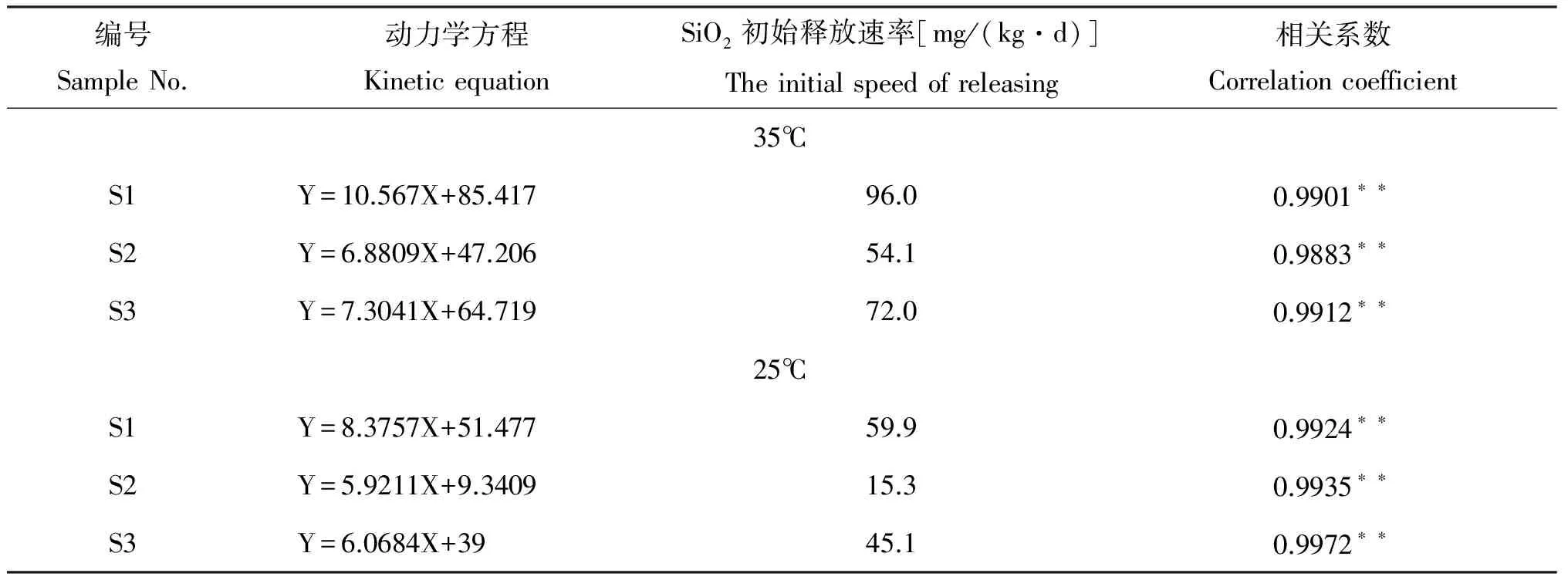

图5为钢渣在土壤水溶液培养中硅素累积释放量随时间的变化。硅素累积释放量与时间的关系可以用幂函数方程y=kxm来拟合[14](表2)。式中,y为土壤或钢渣硅素累积释放量(SiO2mg/kg);x为时间(d);k为常数,相当于x = 1时硅素累积释放量[SiO2mg/(kg·d)],其表征硅素释放速率的大小;m 为土壤硅素释放速率变化系数,决定着土壤硅素释放动力学曲线的形状。由表2知,土壤(CK)以及3种钢渣硅素累计释放量与时间的幂函数拟合方程,相关系数都达到了0.95以上的极显著水平。对幂函数求微分,则dy/dx=km·xm-1。当x=1时,dy/dx=km,即km相当于钢渣或土壤的硅素初始释放速率。由表2知,土壤本身硅素释放拟合方程,参数k、m以及km值都要低于3种钢渣硅素释放拟合方程参数值。3种钢渣在同一温度下比较,k值的大小顺序为S3>S1>S2;m值的大小顺序为S1≈S2>S3,km的值得大小顺序为S3>S1>S2。温度对钢渣及土壤(CK)硅素释放量都有显著的影响,同一处理其k、m以及km值,在35℃培养下都要显著高于25℃培养结果。25℃培养条件下,CK、S1、S2与S3的硅素最终累积释放量,分别为其在35℃培养下的45.2%、 38.8%、 26.0%与37.4%。

表2 土壤悬浮液中不同钢渣硅素的释放动力学方程及参数

注(Note): **—P<0.01

图3 土壤培养浸提液pH和EC变化Fig.3 The pH and EC values in soil leaching solutions in soil suspension incubation method

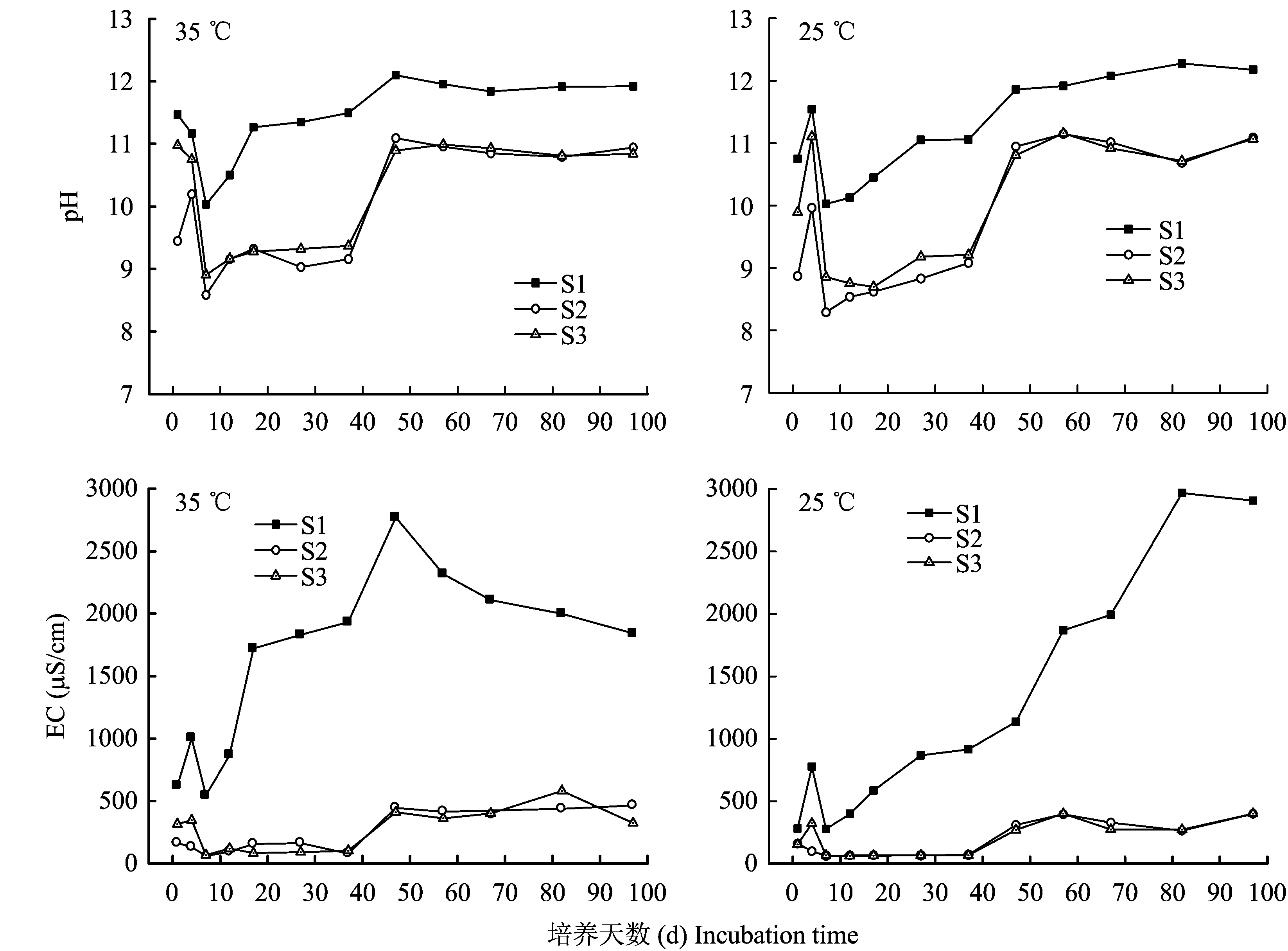

图4 浸提液pH和EC变化(水培养法)Fig.4 The pH and EC values in leaching solution of slags using water incubation method

图5 钢渣硅素累积释放量(土壤培养法)Fig.5 Accumulation of silicon released from different slags by soil suspension incubation method

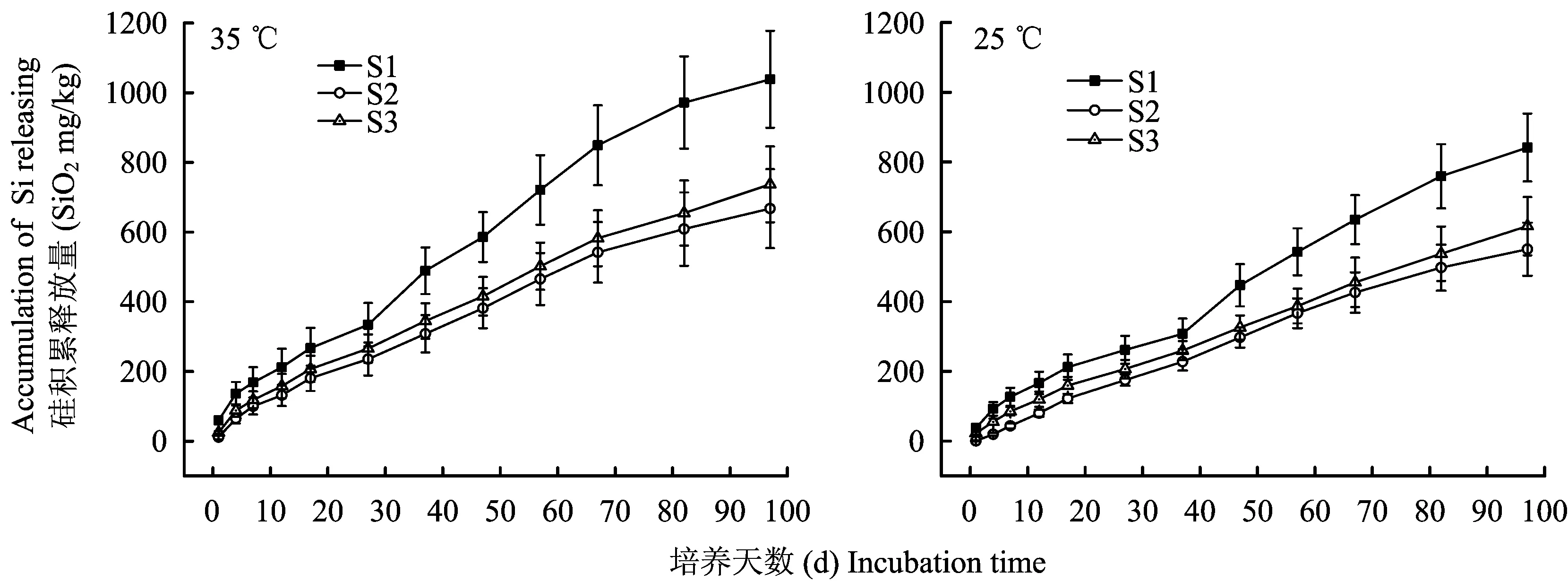

图6为水浸提钢渣中硅素累积释放量随时间的变化。水浸提钢渣硅素累积释放量与时间的关系可以用线性方程y=ax+b来拟合(表3)。式中y为钢渣硅素累积释放量(SiO2mg/kg);x为时间(d);a与b为常数,a+b的值为x = 1时硅素累积释放量[SiO2, mg/(kg·d)],其表征硅素初始释放速率的大小。由表3知,三种钢渣硅素累计释放量与时间的线性拟合方程,相关系数都达到了0.99以上的极显著水平。在同一温度下比较,a值以及a+b值的大小顺序均为S1>S3>S2。同一处理,在35℃培养下a值以及a+b值均高于25℃。在25℃培养条件下,S1、S2与S3的钢渣硅素最终累积释放量,分别为其在35℃培养下的81.0%、82.4%和83.6%。

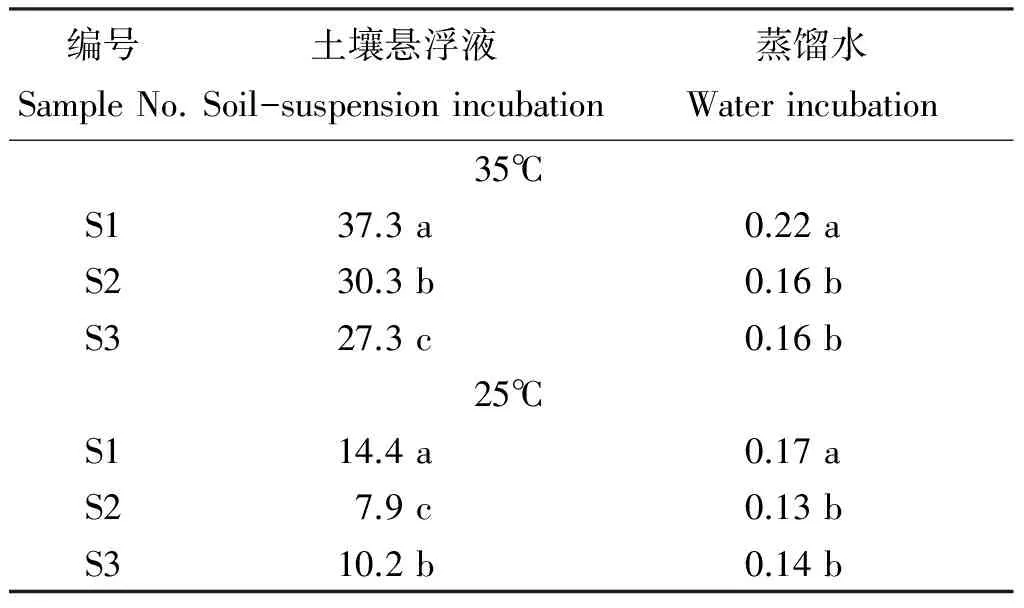

表4为两种培养方式下,钢渣在第97天的培养中硅素总释放量与钢渣中有效硅含量(0.5 mol/L HCl) 的百分比。结果表明,在土壤溶液培养中, 35℃培养下,S1、 S2与S3钢渣硅的溶出率分别为37.3%、30.3%与27.3%,3种钢渣溶出率差异显著;在25℃培养下,S1、S2与S3钢渣硅的溶出率分别为14.3%、7.9%与10.2%,相互间差异显著。在水介质培养中,35℃培养下,S1、S2与S3钢渣硅的溶出率分别为0.22%、0.16%与0.16%,S1与其他两种处理差异显著,S2与S3无显著差异;在25℃培养下,S1、S2与S3钢渣硅的溶出率分别为0.17%、0.13% 与0.14%,S1与其他两种处理差异显著,S2与S3无显著差异。同一温度下,同一种钢渣在水介质中硅溶出率显著低于在土壤溶液介质中,说明土壤溶液介质可促进钢渣中硅的释放。在土壤培养条件下,提高温度可显著促进钢渣中硅的释放,S2受温度影响最明显,而在水培条件下,温度对钢渣硅素释放影响较弱。

图6 水浸提培养钢渣硅素累积释放量Fig.6 Cumulative silicon from different kinds of slag in water incubation

编号SampleNo.动力学方程KineticequationSiO2初始释放速率[mg/(kg·d)]Theinitialspeedofreleasing相关系数Correlationcoefficient35℃S1Y=10.567X+85.41796.00.9901∗∗S2Y=6.8809X+47.20654.10.9883∗∗S3Y=7.3041X+64.71972.00.9912∗∗25℃S1Y=8.3757X+51.47759.90.9924∗∗S2Y=5.9211X+9.340915.30.9935∗∗S3Y=6.0684X+3945.10.9972∗∗

注(Note): **—P<0.01.

表4 不同培养液钢渣硅素溶出率(%)

注(Note): 数据值为每个处理3个重复的平均值 Data are means of three replicates; 不同字母表示同一季水稻不同处理间差异达5%显著水平 Mean values followed by different letters in the same season are significantly different at the 5% level.

3 讨论

钢渣是一种缓释硅肥,在我国及日本等国家,钢渣中有效硅的含量通常以0.5 mol/L HCl浸提结果作为评价标准[15-17],但是这种测定方法并不能精确地表明钢渣中植物有效硅含量[16-18]。钢渣中硅的植物有效性受其本身因素(如组成成分、冷却方式、粒径大小等)和环境因素(如外界介质、温度等)影响。本文选用3种有效硅含量(0.5 mol/L HCl测定)相近,其他性质不同的钢渣为研究对象,包括粉末状水淬渣(S1)、粒状水淬渣(S2)和空气缓慢冷却粒状钢渣(S3),分别设置在土壤水溶液以及蒸馏水中培养,并且设置 35℃和25℃两个培养温度,以期研究钢渣中硅的释放规律及影响因素。

研究结果表明,在土壤水溶液浸提培养中,空气缓慢冷却钢渣(S3)的初始释放速率显著高于水淬渣(S1和S2),而温度和粒径对第一天的释放速率没有显著影响。Takahashi[19]研究结果同样表明慢速冷却的钢渣中植物有效性硅的含量要大于在水中快速冷却的钢渣。在以后的培养过程中温度对钢渣硅素的释放影响最大,其次为钢渣粒径,而钢渣冷却方式影响甚微。钢渣累积释放量随时间的变化可以用幂函数方程很好的拟合,通过方程参数k、m,室以及km值的比较,得到与上述相同的结论。3种钢渣在土壤溶液介质中培养97天后,S1、S2与S3的钢渣硅的溶出率,35℃下分别为37.3%、30.3%与27.3%, 25℃下分别为14.3%、7.9%与10.2%。S2在35℃时的释放量大于S3,而在低温时结果相反。表明,高温更有利于水淬渣的硅素释放。97天的培养时间可以代表水稻移栽至收获期的天数,在这一过程中,钢渣中硅素释放量在35℃仅占有效硅含量的30%左右。所以,钢渣中硅在下一季水稻中仍可发挥余效。

在蒸馏水培养介质中与土壤水溶液培养的结果表现并不完全一致,钢渣硅素累积释放量要显著低于在土壤溶液介质中释放量。结果说明,高温更有利于水淬渣硅的释放,在同一温度下,粒径对钢渣硅的释放大于冷却方式。在培养7天以后,释放速率只存在小幅的波动,而且35℃和25℃的释放速率基本相近。结果表明,在水培条件下,温度对钢渣硅的释放影响甚微,这与土壤溶液培养结果不一。分析认为在土壤介质中,35℃的条件下促进了土壤中硅酸盐细菌等微生物的活性,从而间接的提高了钢渣中硅的释放。

土壤溶液培养介质中,25℃培养下,前67天加入钢渣提高了土壤浸提液中的pH值,但后期与CK基本相同。但在35℃培养下,加入钢渣的土壤浸提液pH值一直都要显著高于CK处理。两种温度培养下,加入钢渣都显著提高了土壤浸提液的EC值,而且粉末状钢渣(S1)土壤浸提液的EC要高于其他两种钢渣,而且高温对其提高也更显著。纯水培养介质中,两种温度培养下,在同一阶段S1浸提液的pH和EC值都要显著高于S2和S3,而温度对pH和EC的影响不显著。

4 结论

在土壤溶液培养介质中,钢渣的硅素释放主要由温度因子决定,35℃比25℃更有利于硅素的释放; 次要影响因子为钢渣粒径,粉末状比粒状更有利于硅素的释放。在纯水的培养介质中,钢渣硅的释放主要影响因子为钢渣粒径,温度和钢渣冷却方式对其影响甚微。由此认为,钢渣作为硅钙肥在大田施用时,将钢渣磨细做成粉末状产品,在施用时随翻耕埋入土壤,以及在初春采用保温措施等都有利于提高钢渣中硅的利用效率。

[1] http://www.worldsteel.org/media-centre/press-releases/2012/12-2012-crude-steel html.

[2] 李灿华, 吴江红, 汪晖, 等. 从资源属性看我国钢渣资源化利用[J]. 重钢技术,2011,54(1): 12-15. Li C H, Wu J H, W Hetal. Study on the technology of recycling steel slag with the theory for the attributes of the natural resources in China[J]. Cisc Technology, 2011, 54 (1): 12-15.

[3] 程绪想,杨全兵.钢渣的综合利用[J]. 粉煤灰综合利用,2010, 5: 45-49. Chen X X, Yang Q B. The comprehensive utilization of steel slag[J]. Fly Ash Comprehensive Utilization, 2010, 5: 45-49.

[4] Shen H T, Forssberg E. An overview of recovery of metals from slags[J]. Waste Management, 2003(10), 23: 933-949.

[5] Geiseler J. Use of steelworks slag in Europe[J]. Waste Management, 1996, 16(3): 59-63.

[6] 吴志宏,邹宗树,王承智.转炉钢渣在农业生产中的再利用[J]. 矿产综合利用, 2005, (6): 25-28. Wu Z H, Zou Z S, Wang C Z. Application of converter slags in agriculture[J]. Multipurpose Utilization of Mineral Resource, 2005, (6): 25-28.

[7] Tsakiridis P E, Papadimitriou G D, Tsivilis Setal. Utilization of steel slag for Portland cement clinker production[J]. Journal of Hazardous Materials, 2008, 152: 805-811.

[8] Wang H, Li C, Liang Y C. Agricultural utilization of silicon in China[A]. Datnoff L E, Snyder G H, Korndörfer G H. Silicon in agriculture [C]. Amsterdam: Elsevier, 2001. 343-358.

[9] Ma J F, Takahashi E. Soil, fertilizer, and plant silicon research in Japan[M]. Amsterdam: Elsevier, 2002, 52-59.

[10] Datnoff L E, Deren C W, Snyder G H. Silicon fertilization for disease management of rice in Florida[J]. Crop Protection, 1997, 16: 525-531.

[11] Seebold K W, Kucharek T A, Datnoff L Eetal. The influence of silicon on components of resistance to blast in susceptible, partially resistant, and resistant cultivars of rice[J]. Phytopathology, 2001, 91: 63-69.

[12] Cha W, Kim J, Choi H.Evaluation of steel slag for organic and inorganic removals in soil aquifer treatment[J]. Water Research, 2006, 40: 1034-1042.

[13] 刘鸣达, 张玉龙, 李军, 等. 施用钢渣对水稻土硅素肥力的影响[J]. 土壤与环境,2001,10(3): 220-223. Liu M D, Zhang Y L, Li Jetal. Effects of slag application on silicon fertility in paddy soil[J]. Soil Environmental Science, 2001, 10 (3): 220-223.

[14] 刘鸣达, 张玉龙, 孟祥富, 等. 应用硅素释放动力学方程评价水稻土供硅能力[J]. 土壤通报, 2006, 37(1): 107-110. Liu M D, Zhang Y L, Meng X Fetal. Evaluation of silicon supplying capacity of paddy soil by silicon liberation dynamics equation[J]. Chinese Journal of Soil Science, 2006, 37 (1): 107-110.

[15] 李春花, 周卫, 荣向农. 硅肥中有效SiO2分析方法的标准化研究[J]. 磷肥与复肥, 2004, 19(4): 60-61. Li C H, Zhou W, Rong X N. Standardization of analytical method for available SiO2in silicon containing fertilizer[J]. Phosphate & Compound Fertilizer, 2004, 19 (4): 60-61.

[16] Kato N, Owa N. Dissolution of slag fertilizers in a paddy soil and Si uptake by rice plant[J]. Soil Science and Plant Nutrition, 1997a, 43: 329-341.

[17] Kato N, Owa N. Evaluation of Si availability in slag fertilizers by an extraction method using a cation exchange resin[J]. Soil Science and Plant Nutrition, 1997b, 43: 351-359.

[18] Buck G B, Korndorfer G H, Datnoff L E. Extractors for estimating plant available silicon from potential silicon fertilizer sources[J]. Journal of Plant Nutrition, 2011, 34: 272-282.

[19] Takahashi K. Effects of slags on the growth and the silicon uptake by rice plants and the available silicates in paddy soils[J]. Bulletin Shikoku Agricultural Experiment Station, 1981, 38: 75-114.

Si-releasing character of slag-based silicon fertilizer and impact factors

NING Dong-feng1,2, SONG A-lin2, LIANG Yong-chao2,3*

(1InstituteofFarmlandIrrigationResearch,ChineseAcademyofAgriculturalSciences/MinistryofAgricultureKeyLaboratoryofCropWaterUseandRegulation,Xinxiang,Henan453002,China;2AgriculturalResourcesandRegionalPlanningInstitute,ChineseAcademyofAgriculturalScience,Beijing100081,China;3CollegeofEnvironmental&ResourceSciences,ZhejiangUniversity,Hangzhou, 310058,China)

【Objectives】 The release character of Si form the slag-based Si fertilizer affects the efficiency of Si fertilizer, which might be governed by the cooling process and granular size of slag. So the study on the Si-release characters of slag-based Si-fertilizers will provide basis for their field application. 【Methods】 Three different types of steel slag, including S1 (in powder form, water-cooling), S2 (in granular form, water-cooling), and S3 (in granular form, air-cooling) with identically available Si content, were used for incubation trial in both soil suspension and distilled water media at 35℃ and 25℃. Leaching solutions were collected through centrifugation at regular intervals. After centrifugation, samples were added with quantitative amount of water and incubated sequentially till the trial end.【Results】 In the soil suspension-incubation experiment, the rate of Si released from slag in the first day was mainly influenced by slag cooling process, but was impacted principally by temperature and granular size of slag as the experiment later on. The relationship between the cumulative Si release and time could be expressed with the exponential equation: y=kxm. After 97 days of soil incubation, the Si-releasing percentage (the ratio of cumulative Si release to total available Si content) of S1, S2 and S3 were 37.3%, 30.3% and 27.3%, respectively, at 35℃, and 14.3%, 7.9% and 10.2% at 25℃. In distilled water-incubation experiment, the first day release of Si was mainly influenced by temperature, afterwards principally by granular size of slag, never by slag cooling process. The relationship between the cumulative Si release and incubation time could be expressed with linear equation (y=ax+b). After 97 days incubation in water, the Si-releasing percentages of S1, S2 and S3 were 0.22%, 0.16% and 0.16%, respectively, at 35℃, and 0.17%, 0.13% and 0.14% at 25℃. In the soil suspension-incubation experiment, the pH values of leaching solutions from the soils added with steel slag were increased in the first 67 days incubation period, then their pH values were kept similar with CK at 25℃, but the pH values of treatments were always higher than that of CK throughout the whole incubation period at 35℃.In the distilled water-incubation experiment, pH and EC of S1 were significantly higher than those of S2 and S3 within the same incubation period, temperature did not show much impact on pH and EC.【Conclusions】 Si-releasing characteristic of slag was principally influenced by incubation medium and temperature, followed by particle size of slag. Si-releasing rate was significantly higher in the soil-incubation condition than in the distilled water-incubation condition. High temperature and fine particles are good for the release of Si. Therefore, steel slag is recommended to be completely pulverized before application into soil.

steel slag fertilizer; incubation; temperature; particle size; cooling process; silicon-release

2014-01-20 接受日期: 2014-09-12

国家“十二·五”科技支撑计划 “钢渣农业资源化利用技术研究与示范”(2013BAB03B02); 国家自然基金“秸秆还田对我国南方典型水稻土壤硅素释放过程影响的定量研究”(41301310)资助。

宁东峰(1985—),女,山东泰安人,博士研究生,主要从事植物营养生理学与废弃物资源利用研究。 E-mail: smile_0808@163.com * 通信作者 E-mail: liangyongchao@caas.cn

S143.7+1

A

1008-505X(2015)02-0500-09