多变的样式:膨胀金属板建筑

2015-03-02学生组SuperBoysMichaelBarracloughMatthewLeGriceJoseParejaDanielOvalleCostal

学生组:SuperBoys (Michael Barraclough, Matthew Le Grice, Jose Pareja, Daniel Ovalle Costal)

导师: Robert Stuart-Smith

工作室技术顾问:Tyson Hosmer

多变的样式:膨胀金属板建筑

学生组:SuperBoys (Michael Barraclough, Matthew Le Grice, Jose Pareja, Daniel Ovalle Costal)

导师: Robert Stuart-Smith

工作室技术顾问:Tyson Hosmer

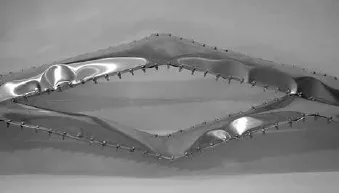

金属薄片预制构件 sheet metal fabricated components

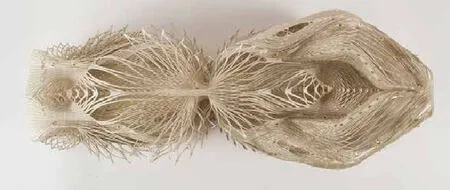

切割文件模板 cutting template

最终生成形态resultant geometry

模型:最终的形态是通过连接平面穿孔薄板之间的对应点生成models: form is generated through pinching of machine perforated flat sheets

本项目研究基于这一认识,即今后50年内计划建造的建筑物比人类在整个文明史中所建造的建筑物总和都要多。这说明,如果建筑行业要降低其在全球能源消耗和碳排放量中所占的50%比例,而不是像目前预计那样继续增加,就必须按照环保理念进行大规模、快速建造施工。膨胀金属板建筑是一项关于金属平板建筑的研究,旨在避免许多生产阶段中的材料浪费。金属平板由机器切割,并在场外焊接到扁平的预制件上。通过这个过程,能够将一种有效的构筑物运至现场,然后使这种构筑物膨胀,形成一个三维管状部件,并利用可重复使用的脚手架将这些部件拉伸成形。该项目涉及材料工艺、切割、膨胀和装配的实物原型。此外还开发了一款数字化软件,该软件能够生成设计,模拟搭建过程,并将几何结构整理成平板截面,导出能够直接在数控机床上进行加工的切割文件。该项目推测了这种建筑技术在密集低层住宅中的应用,作为一种能够嵌入现有城市结构中的网络化建筑类型,这种设计达到了高效生产工艺的复杂效果和独特美感,与其他现有建筑技术相比,能够节省大量材料。

-- PREFABRICATION --PROTEAN PATTERN: INFLATED SHEET METAL ARCHITECTURE

STUDENTS: SUPERBOYS: MICHAEL BARRACLOUGH, MATTHEW LE GRICE, JOSE PAREJA, DANIEL OVALLE COSTAL

SUPERVISOR: ROBERT STUART-SMITH

STUDIO TECHNICAL CONSULTANT: TYSON HOSMER

This project arose from the recognition that more building construction is set to be built in the next 50 years than has ever has been constructed in the entire history of civilisation. This suggests the need for rapid construction on a large scale, yet undertaken with environmental sustainable ideas if construction is to reduce its share of 50% of world energy consumption and carbon emissions rather than rise as is currently predicted. Inflated Sheet Metal Architecture is a research into flat sheet metal construction aims to eliminate material waste at many stages of production. Flat sheet metal is machine cut and welded into flat prefabricated elements off-site. This process enables an efficient transport volume to be delivered to site where it is then inflated to create a tubular cross-section in three-dimensional parts which are stretched into shape using a reusable scaffold. The project involved physical prototypes of the material process, cutting, inflating and assembling. A digital software was also developed that enabled designs to be generated, their erection process simulated, and their geometry rationalised into flat sheet sections and exported as cutting files that could be directly fabricated on cnc machines. The project speculated this use for dense low-rise housing as a networked building typology that could be inserted into existing urban fabric. The design gains much intricacy and a unique aesthetic from an efficient production process that substantially reduces material waste compared to alternative existing building technologies.

低层高密度建筑方案 low-rise high-density housing proposal

互锁公寓缩放模型 scale model of interlocking apartments