Characteristics of serrated chip formation in high speed machining Ti6Al4V

2014-09-06QibiaoYANGPengCHENDazhangYOUZhanqiangLIU

Qi-biao YANG, Peng CHEN, Da-zhang YOU, Zhan-qiang LIU

1School of Mechanical Engineering, Hubei University of Technology, Wuhan 430068, China;2School of Mechanical Engineering, Shandong University, Jinan 250061, China

Characteristics of serrated chip formation in high speed machining Ti6Al4V

Qi-biao YANG† 1, Peng CHEN1, Da-zhang YOU1, Zhan-qiang LIU2

1School of Mechanical Engineering, Hubei University of Technology, Wuhan 430068, China;2School of Mechanical Engineering, Shandong University, Jinan 250061, China

Abstract:A deep understanding of the generation and characteristics of serrated chip formation can obtain some practical advices of controlling this type chip in engineering applications. The characteristics of serrated chip including the frequency of serration, the degree of segmentation and the space of adiabatic shear band are comprehensively investigated in this paper. Experiments of high speed milling Ti6Al4V were performed. The investigated material is Ti6Al4V since it is prone to form serrated chip in machining process. The chips of Ti6Al4V under different cutting speeds and feed per tooth were collected during machining. After inlay and polishing process for the collected chips, the chip morphology could be observed by VHX-600 ESO digital microscope. The expressions of the frequency of serration, the degree of segmentation and the space of adiabatic shear band were determined through microcosmic observation. The results show that the space of adiabatic shear band gets decreased with the increase of cutting speed and the feed per tooth. On the contrary, the frequency of serration will get increased with the increase of the cutting speed and it will get decreased with the increase of the feed per tooth. The increase of cutting speed or the feed per tooth could intensify the degree of chip segmentation. The degree of segmentation can be used as the criterion of ordinary cutting, high speed cutting and ultra high speed cutting.

Key words:Serrated chip, High speed machining, Adiabatic shear band, Ti6Al4V

1.Introduction

Ti6Al4V is a kind of difficult-to-cut material due to the low thermal conductivity and low elastic modulus. It is prone to form serrated chip in high speed machining Ti6Al4V. This phenomenon may lead to high-frequency fluctuations of cutting force, accelerate the wear rate of cutting tool, reduce the machined surface quality and the machining accuracy[1]. Therefore, it is necessary to study the mechanism of serrated chip formation during high speed machining process. The study of the characterization of serrated chip is conducive to a correct understanding of serrated chip formation mechanism. Through orthogonal cutting Ti6Al4V, it was found that the shear band width and the space of shear band were determined by micrographic observations[2]. Due to the difference between the deformation of the serrated chip and that of the continuous chip, the shear strain and rate of shear strain have been used to characterize the serrated chip[3-7]. Zhu et al regarded the deformation internal length and thermal internal length as the characteristics of the serrated chips[8]. It was found that the deformation of internal length arising from the strain gradient is about two orders of magnitude greater than the thermal internal length for the typical steel considered. Schulz and Abele[9] used the degree of segmentation to characterize the serrated chip of high speed machining aluminum alloy 7075. The results showed that the degree of segmentation will get increased with the increase of cutting speed and the feed per tooth.

In this paper, the space of adiabatic shear band, the frequency of serration and the degree of segmentation were used to characterize the serrated chip. The experiments of high speed machining Ti6Al4V were performed. Some results of the investigation of the cutting speed and the feed per tooth influence into chip formation were presented as well.

2.Experiment work

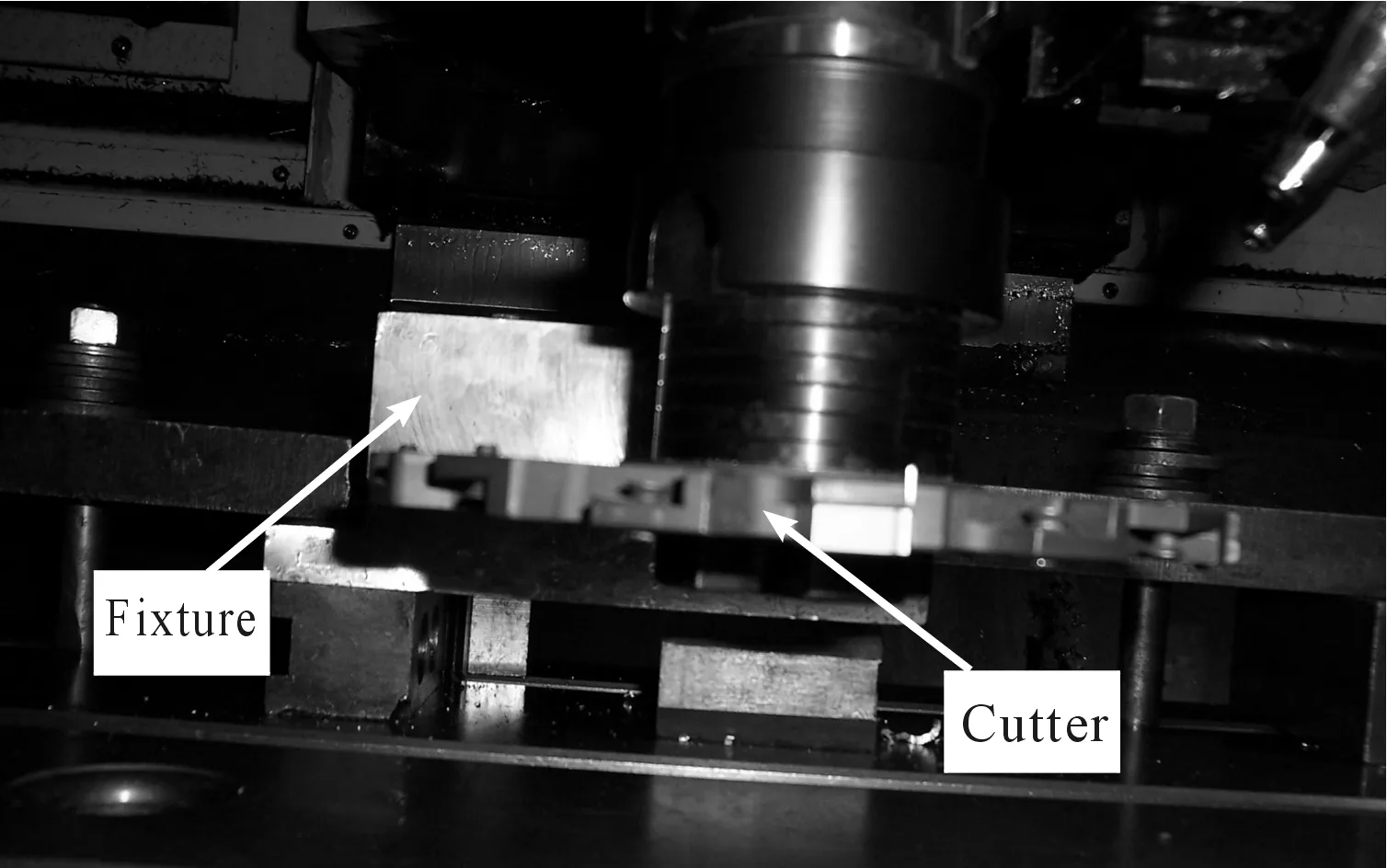

The high speed cutting experiment was performed on a DAEWOO ACE-V500 vertical machining center. A 90° SN slot milling cutter (Kennametal, 4.96164-210) was used in the cutting experiment with coated carbide (KC725M) inserts whose type is SNHX12L5PZTNGP. The experiment setup was shown in Figure 1. The chemical composition of Ti6Al4V was presented in Table 1. Ti6Al4V was machined at the cutting speeds of 50, 100, 200, 400, 600, 800, 1 000, 1 300,1 800 m/min while the feed per tooth is 0.1 mm/z and the feed per tooth of 0.02, 0.04, 0.06, 0.08, 0.10, 0.10, 0.14 , 0.16 mm/z when the cutting speed is 200 m/min. The cutting depth is a constant, i.e., 2 mm.

Figure 1.Experiment setup

The chips of Ti6Al4V with different cutting speeds and feed per tooth have been collected after machining process. After inlay and polishing process, the chips were observed by VHX-600 ESO digital microscope.

Table 1.Chemical composition of Ti6Al4V

3.Characterization of serrated chip

In order to describe the basic geometry characteristics of the serrated chip, the chips could be expressed as the space of adiabatic shear band, the frequency of serration and the degree of segmentation.

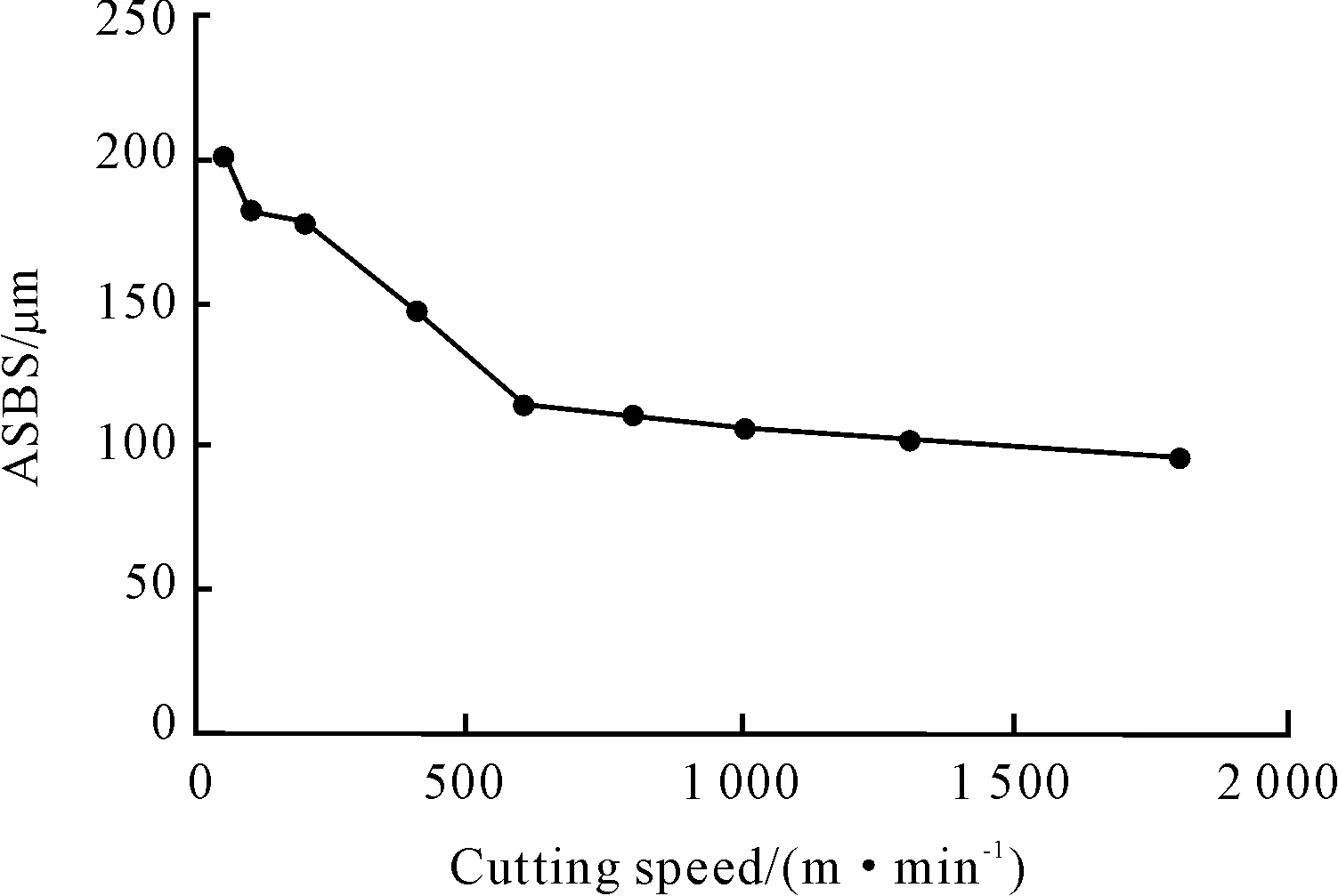

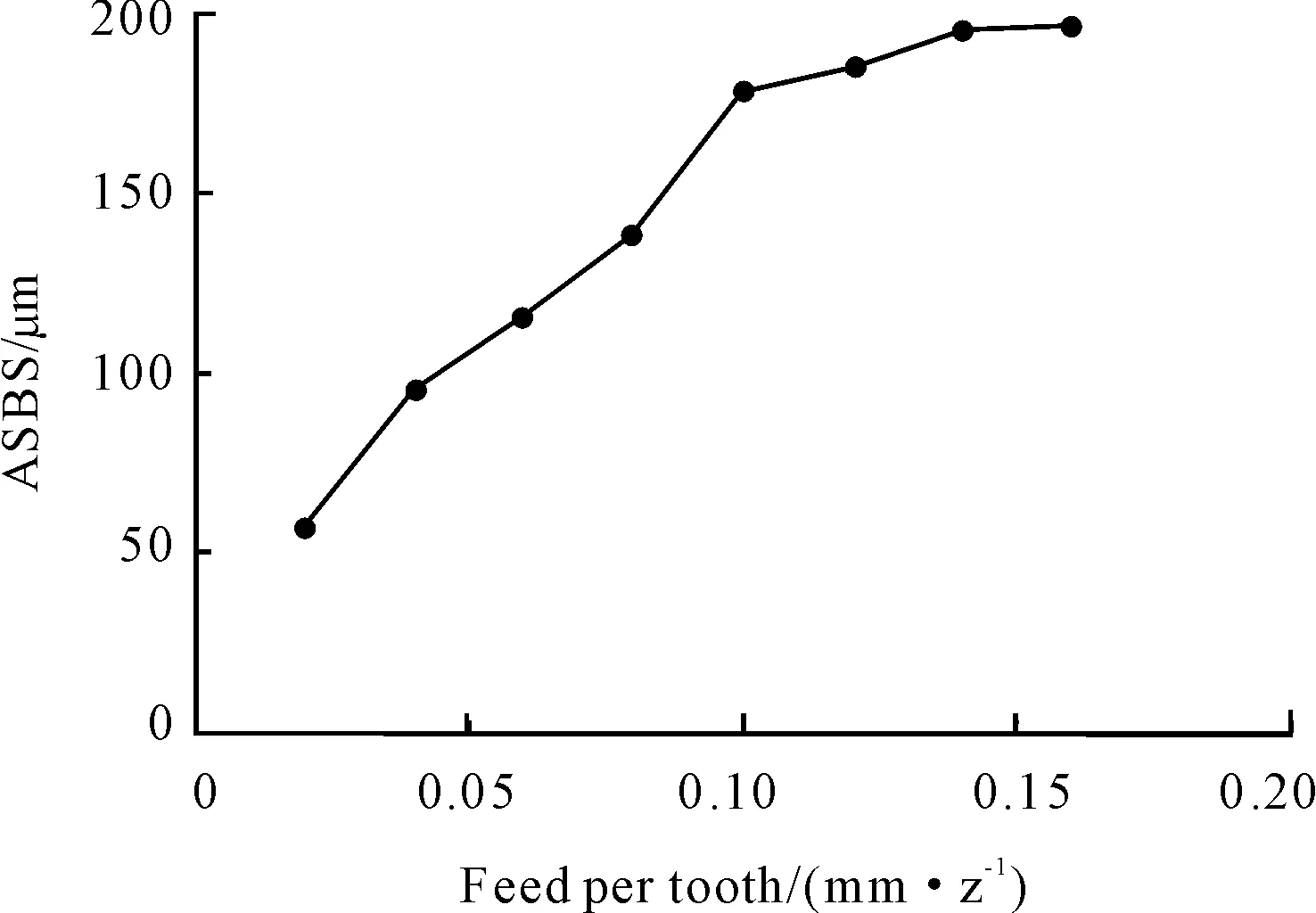

The space of adiabatic shear band (ASBS) at different cutting speeds and feed per tooth were presented in Figure 2 and Figure 3. It was found that the space of adiabatic shear band gets decreased with the increase of the cutting speed and increased with the increase of the feed per tooth.

Figure 2.ASBS at different cutting speeds (V=50~1 800 m/min, fz=0.1 mm/z)

Figure 3.ASBS at different feed per tooth (V=200 m/min, fz=0.02~0.16 mm)

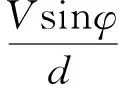

The frequency of serration was the number of segments produced per unit time. Therefore, the frequency of serrationfcan be defined as the number of shear bands produced per unit time. The frequency of serration could be expressed as follows.

(1)

Where,Vis the cutting speed,φis the shear angle anddis the space of adiabatic shear band. The shear angle could be expressed as equation (2).

(2)

Where,ξis the deformation coefficient, andγ0is the tool rake angle which is 0° in the experiment.The results show that with the increase of cutting speed, the deformation coefficient will be ultimately close to 1 for the workpiece of titanium alloy[10]. Therefore, the shear angle could be approximately equal to 45°. Submit the values of the cutting speed, the shear angle and the space of adiabatic shear band into equation (1), the frequency of serration under different conditions could be obtained.

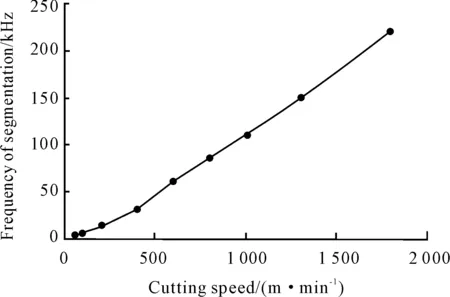

Figure 4 showed the varied of the frequency of serrationfunder different cutting speeds at the feed per tooth of 0.1 mm/z. It can be found thatfincreases with the increase of cutting speed when the feed per tooth is 0.1 mm/z. The frequency of serrationfvaries from 2.9 kHz to 221.0 kHz. The frequency of serrationfunder different feed per tooth at the cutting speed of 200 m/min was shown in Figure 5. This is consistent with those of thesis[2, 11]. It could be seen that the variation tendency offis opposite to that of the cutting speed in accordance with thesis[12]. The cutting speed will accelerate the fluctuation of high speed machining. It can be expected that the cutting speed will accelerate the tool wear or breakage.

Figure 4.Frequency of serration (V=50~1 800 m/min, fz=0.1 mm/z)

Figure 5.Frequency of serration (V=200 m/min, fz=0.02~0.16mm)

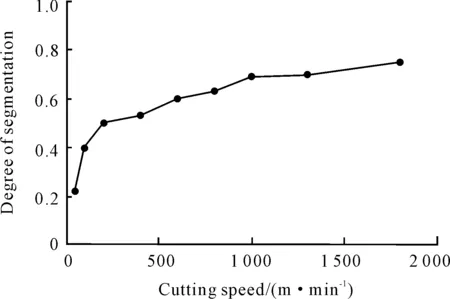

The chip segmentation was characterized by the degree of segmentation as defined in equation (3)[9].

Gs=(h1-h2)/h1

(3)

Where,Gsis the degree of segmentation,h1is the maximum of the serrated chip andh2is the height of the continuous part of the serrated chip, as shown in Figure 6.

Figure 6.Micrograph of the serrated chip

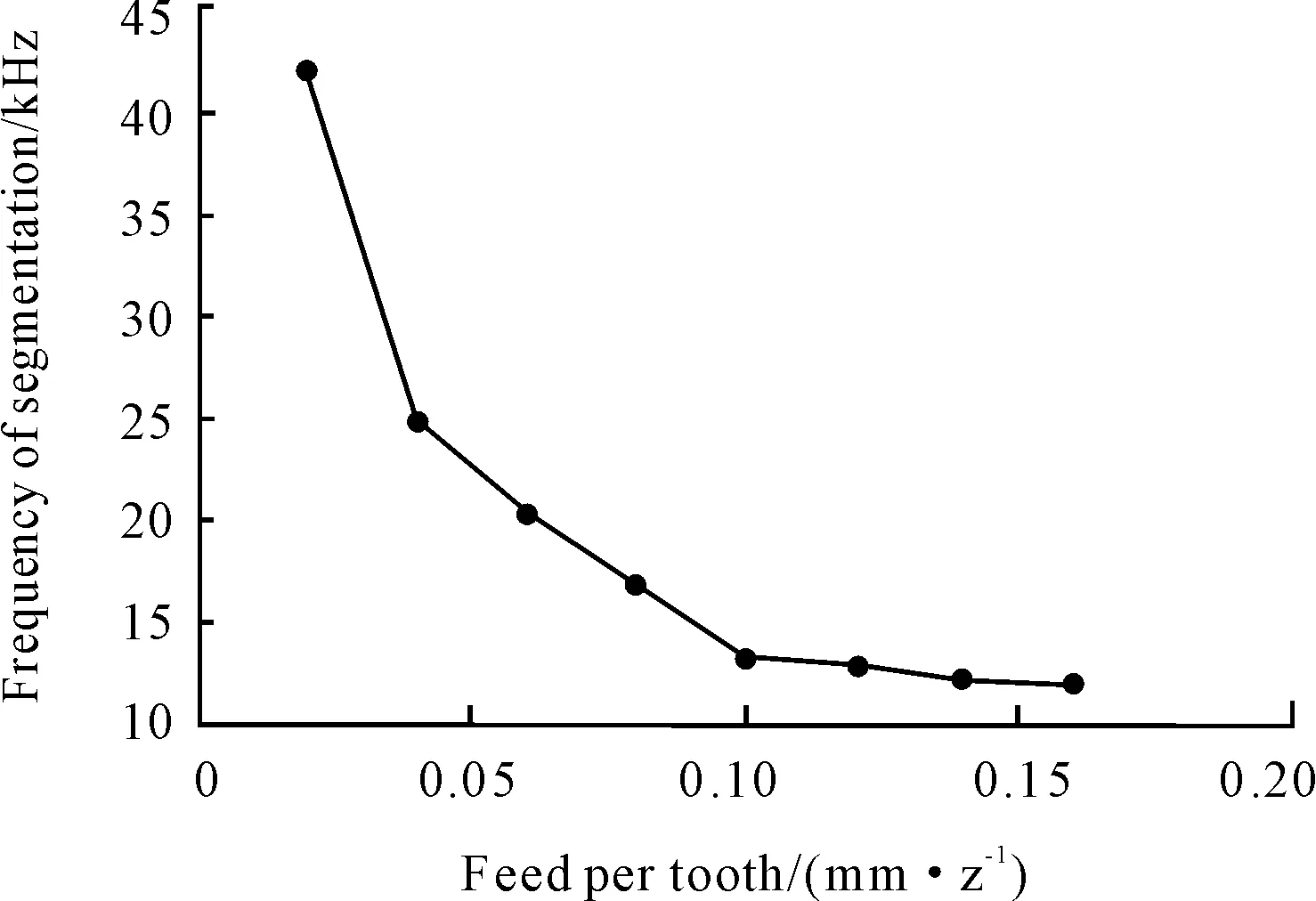

Sinceh1≥h2≥0, it can be indicated that 0≤Gs≤1 from equation (3). Ifh1=h2, thenGs=0. In this case, the type of chips is continuous. Ifh2=0, thenGs=1. In this case, the type of chips is segmented. Therefore, the value ofGscould be regarded as a criterion of the type of chips. If it is assumed that the continuous chip produced by ordinary cutting, the serrated chip produced by high speed cutting and the segmented chip produced by ultra high speed cutting, theGscan be expressed as a criterion of the ordinary cutting, the high speed cutting and the ultra high speed cutting .

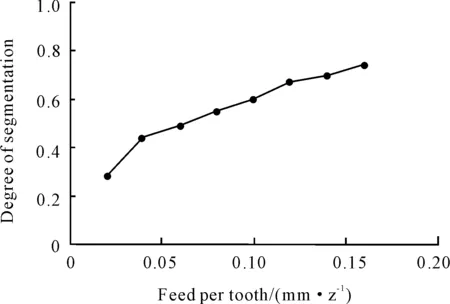

All measurements of the chip segmentation were carried out starting at the thicker end of the serrated chip for 10 neighboring segments. The degree of segmentation under different cutting conditions was shown in Figure 7 and Figure 8. It could be found that 0 From Figure 7 it can be found that the increase of cutting speed will promote the chip segmentation. With the cutting speed increasing, the rate of shear strain get increased and the cutting temperature in primary shear zone get increased since the cutting heat is difficult to diffuse due to the short time period of chip deformation. Therefore, these two reasons will accelerate the chip segmentation. It is quite clear that the increase of the feed per tooth promotes the chip segmentation from Figure 8. As the feed per tooth increases, the rate of shear strain get decreased due to the increase of the shear zone width .This may suppress the chip segmentation. However, the compressive stress in primary shear zone gets increased with the increase of the feed per tooth. This phenomenon will promote the chip segmentation. The combined effect of the rate of shear strain and the compressive stress will promote the chip segmentation. Figure 7.Degree of segmentation (V=50~1 800 m/min, fz=0.1 mm/z) Figure 8.Degree of segmentation (V=200 m/min, fz=0.02~0.16 mm) The characterization of serrated chip in high speed machining Ti6Al4V was defined as the space of adiabatic shear band, the frequency of serration and the degree of segmentation. Through high speed machining Ti6Al4V, the chips under different conditions have been collected. It was found that the space of adiabatic shear band gets decreased with the increase of the cutting speed and gets increased with the increase of the feed per tooth. The frequency of serration gets increased with the increase of the cutting speed and gets decreased with the increase of the feed per tooth. The degree of segmentation could be used as a criterion of ordinary cutting, high speed cutting and ultra high speed cutting. The degree of segmentationGsgets increased with the increase of the cutting speed and the feed per tooth. [1]Ai X. Technology of high speed cutting[M]. Beijing: National Defense Industrial Press, 2003:264-266. [2]Molinari A, Musquar C, Sutter G. Adiabatic shear banding in high speed machining of Ti-6Al-4V: experiments and modeling[J]. International Journal of Plasticity, 2002, 18(4):443-459. [3]Turley D M, Doyle E D. Calculation of shear strains in chip formation in Titanium[J]. Materials Science and Engineering, 1982, 55(1):45-48. [4]Matthew C, Gerry B. Characterization of chip formation during orthogonal cutting of titanium alloy Ti-6Al-4V[J]. CIRP Journal of Manufacturing Science and Technology, 2008, 1(2):81~85. [5]Matthew C, Gerry B. Dynamics of chip formation during orthogonal cutting of titanium alloy Ti-6Al-4V[J].CIRP Annals-Manufacturing Technology, 2008, 57(1):93-96. [6]He N, Lee T C, Lau W S, et al. Assessment of deformation of shear localized chip in high speed machining[J].Journal of Materials processing technology, 2002, 129(1-3): 101-104. [7]Duan C Z, Wang M J, Pang J Z, et al. A calculational model of shear strain and strain rate within shear band in a serrated chip formed during high speed machining[J]. Journal of Materials Processing Technology, 2006, 178(1-3):274-277. [8]Zhu H T, Zbib H M, Aifantis E C. On the role of strain gradients in adiabatic shear banding[J]. Acta Mechanical, 1995(111):111-124. [9]Schulz H, Abele E, Sahm A .Materials aspects of chip formation in HSC machining[J]. CIRP Annals-Manufacturing Technology, 2001, 50(1):45-48. [10]Komanduri R, Von Turkovich B F. New observations on the mechanism of chip formation when machining titanium alloys[J]. Wear, 1981, 69(2):179-188. [12]Morehead M D, Huang Y, Luo J. Chip morphology characterization and modeling in machining hardened 52100 steels[J]. Machining Science and Technology, 2007 (11):335-354. (Continued from 78 page) DOI:10.3969/j.issn.1001-3881.2014.06.014 Received: 2013-11-05 † Qi-biao YANG, E-MAIL:qibiaoy@aliyun.com

4.Conclusion

References

杂志排行

机床与液压的其它文章

- Control of EPS with regulating factor

- Numerical simulation of the double suction balance type screw compressor working process*

- Cam profile optimization design of variable cycle reciprocating piston engine*

- A Sort of fusion control strategy for uncertainty complex process with large time lag*

- Influence of salt fog test on the performance of the composite coating on avionics cases

- Flow field CFD analysis of axial flow blood pump*