Study of nano-nitramine explosives:preparation,sensitivity and application

2014-02-09JieLIUWeiJIANGQingYANGJianSONGGaziHAOFengshengLI

Jie LIU,Wei JIANG,Qing YANG,Jian SONG,Ga-zi HAO,Feng-sheng LI*

National Special Superfine Powder Engineering Research Center of China,Nanjing University of Science and Technology,Nanjing 210094,China

1.Introduction

The brisant nitramine explosives(Hexahydro-1,3,5-trinitro-1,3,5-triazine (RDX), octahydro-1,3,5,7-tetranitro-1,3,5,7-tetrazocine(HMX)and 2,4,6,8,10,12-hexanitro-2,4,6,8,10,12-hexaazaisowurtzitane(CL-20))have high detonation heat,detonation velocity and detonation pressure.They have been extensively used in plastic bonded explosives(PBXs)[1-6]and propellants[7-16].However,the micron-sized explosives are very sensitive,which seriously threatens the safety of the ammunitions.The reduction in sensitivity has become a research focus.The studies have shown that the sensitivities of nitramine explosives are affected obviously by the sizes and size distributions of the explosive particles[17-19].The sensitivities of explosives can be cut down effectively by reducing the particle sizes.If the nano-particles were obtained,the sensitivities would be greatly decreased[20-22].

As an inspiring fact,nano-RDX and nano-HMX,which are characterized by regular shapes and narrow size distributions,have been produced in batch using a wet ball mill,and the prepared nano-sized particles can be effectively extracted by freezing drying[23,24].Based on these experiences,nano-CL-20 had been successfully produced and effectively extracted.The sensitivities and explorative applications of the three nitramine explosives are researched in this paper.

2.Experimental

2.1.Sample preparation

2.1.1.Preparation of nano nitramine explosives

Micron-sized RDX and HMX,produced by Gansu Yinguang Chemical Industry Group Co.,Ltd of China,are separately suspended in a miscible liquid which is a mixture of deionized water,ethanol and isopropanol,with the volume ratio of 10:10:1.Micron-sized CL-20,produced by Qingyang Chemical Industry Corporation of China,is suspended in water containing 1%polyoxyethylene sorbitan oleate dehydration(Tween-80)as surfactant.Their mass concentrations are 15%.

The three nitramine explosives(RDX,HMX and CL-20)of 500-1000 g are processed at a time,respectively,and their suspensions are put into a bi-directional rotation mill[25],of which the axle and the barrel rotate reversely and simultaneously,for 6h,5 h and 4 h,respectively.The rotation speeds of axle and barrel are controlled in the range of 90-150 rpm and 60-90 rpm,respectively.The filling content of grinding media is controlled within 65%-70%.During pulverization,the machine is cooled down by the cycling water.The pulverized slurries are freezingly dried and the product yield is about 97%.

2.1.2.Preparation of PBX samples

The explosives are coated by slurry technique.The stirring speed is 600 rpm,the temperature of the water bath is 80°C,the binders are dissolved by ethyl acetate dropping in the range from 1 ml/min to 3 ml/min,and the ratios of water to material are 1:2.5 for micron-sized samples and 1:4 for nanosized samples.

RDX is coated with dinitrotoluene(DNT),polyvinyl acetate(PVAc)and stearic acid(SA).The mass percentage of RDX:DNT:PVAc:SA is 94.5:3:2:0.5.

HMX is coated with fluororubber Viton(F,a copolymer consisting of vinylidene fluoride and hexafluoropropylene),polymethyl methacrylate(PMMA)and wax.The mass percentage of HMX:F:PMMA:wax is 95:3:0.8:1.2.

2.2.Measuring instrument and apparatus

The Malvern Mastersizer Micro laser particle size analyzer is used to measure the particle size distributions of the explosives.The particle sizes and morphologies of the explosives are characterized using S-4800Ⅱ Scanning Electron Microscope (SEM) made by Hitachi High-Technologies Corporation.

2.3.Test of sensitivities and detonation velocities

2.3.1.Sensitivity test of pure nitramine explosives

The friction sensitivities are measured by sliding friction test at 3.92 MPa(RDX,HMX)and 2.45 MPa(CL-20).Fifty tests are carried out to obtain the mean explosion probability(P,%).

The impact sensitivities are measured by drop-hammer test and characterized by the characteristic heights(50%probability of initiation(H50)),which are statistically calculated by 25 effective test values obtained by using a 2.5 kg drophammer.

The small scale gap test(SSGT)is selected to measure the shock sensitivities.In this test,the booster charge is mad3e from RDX re fined by acetone,with a density of 1.48 g/cm,the gap material is polymethyl methacrylate polymer,and the acceptor charges have the densities of 1.63 g/cm3(RDX),1.71 g/cm3(HMX)and 1.80 g/cm3(CL-20),respectively.The inside diameter and length of charges are 5.10 mm and 5.45 mm,respectively.The gap thicknesses(δ)are calculated by 25 effective values.

2.3.2.Shock sensitivity tests of PBX samples

The shock sensitivities of PBX samples are measured by the gap tests.The inside diameter and length of booster charge,which is made of tetryl with the density of 1.55 g/cm3,are 40.0 mm and 25.4 mm,respectively.The gap material is cellulose triacetate.The inside diameter and length of the acceptor charges are 25.0 mm and 38.0 mm,respectively,with the densities of 1.63 g/cm3(RDX)and 1.71 g/cm3(HMX).The gap thicknesses(δ)are calculated by 25 effective values.

2.3.3.Detonation velocity tests

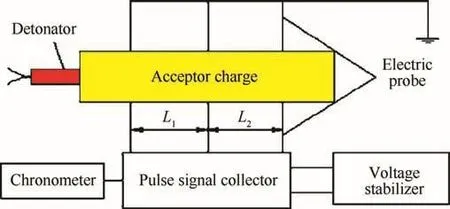

The detonation velocity is tested by ionized probe method,as shown in Fig.1.

JH-14,a PBX explosive,is made of RDX,fluororubber Viton(F)and graphite(G).The mass percentage of RDX:F:G is 96.5:3.0:0.5.

The inside diameter and length of booster charge,which is made of JH-14 with the density of 1.55 g/cm3,are 13.0 mm and 13.0 mm,respectively.The acceptor charges are made of as-prepared PBX samples(Section 2.1.2).The inside diameter and length of the acceptor charges are 10.0 mm and 10.0 mm,respectively,with the densities of 1.63 g/cm3(RDX)and 1.71 g/cm3(HMX).The detonation velocities are calculated by 5 effective values.

2.4.Symbols and abbreviations

M-:Micron-sized explosives;N-:Nano-sized explosives;

M-RDX:Micron-sized RDX;N-RDX:Nano-sized RDX;

M-HMX:Micron-sized HMX;N-HMX:Nano-sized HMX;

M-CL-20:Micron-sized CL-20;N-CL-20:Nano-sized CL-20.

P-M-:M-contained PBX samples;P-N-:N-contained PBX samples.

P-M-RDX:M-RDX-contained PBX sample;P-N-RDX:NRDX-contained PBX sample;P-M-HMX:M-HMX-contained PBX sample;P-N-HMX:N-HMX-contained PBX sample.

Fig.1.Schematic diagram of set-up for detonation velocity test.

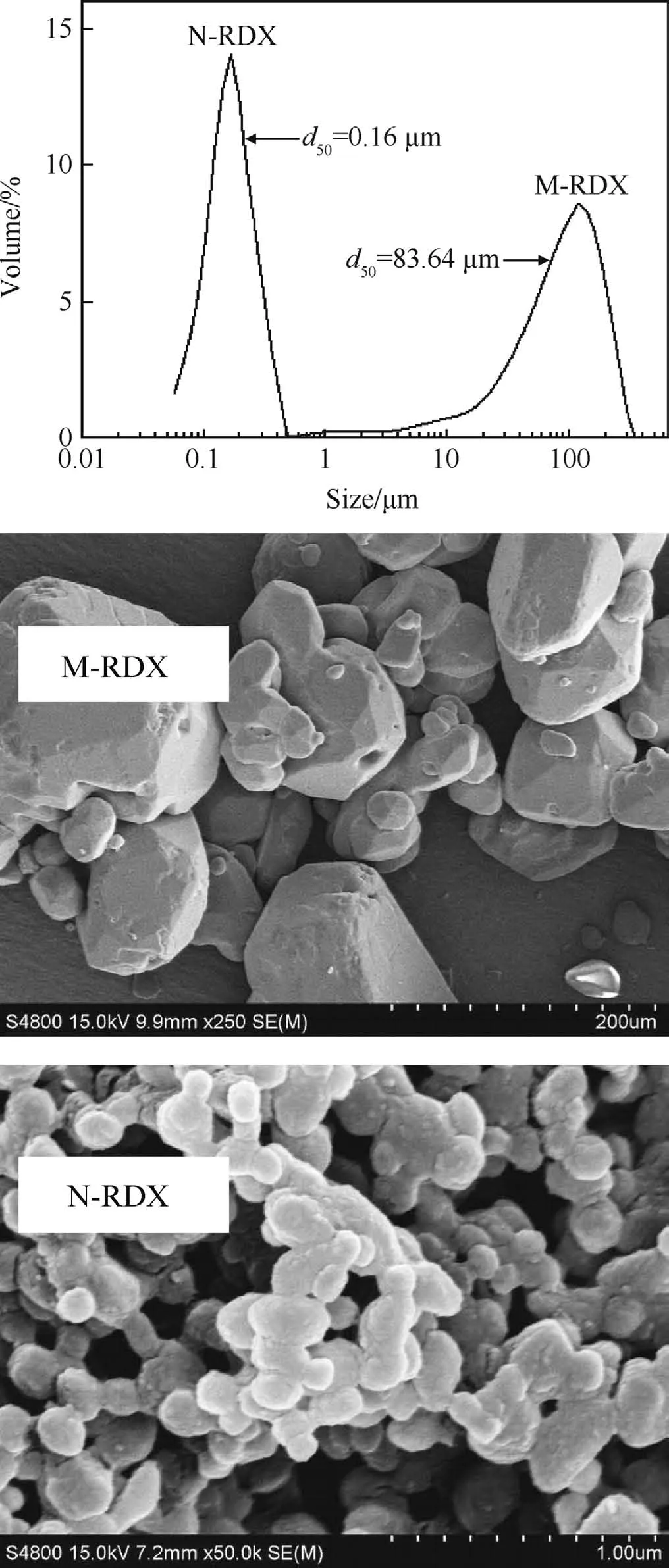

Fig.2.The size distributions and SEM images of RDX particles.

2.5.Variable calculation of sensitivities and detonation velocities

The variable of friction sensitivity is calculated as

The variable of impact sensitivity is calculated as

The variable of shock sensitivity is calculated as

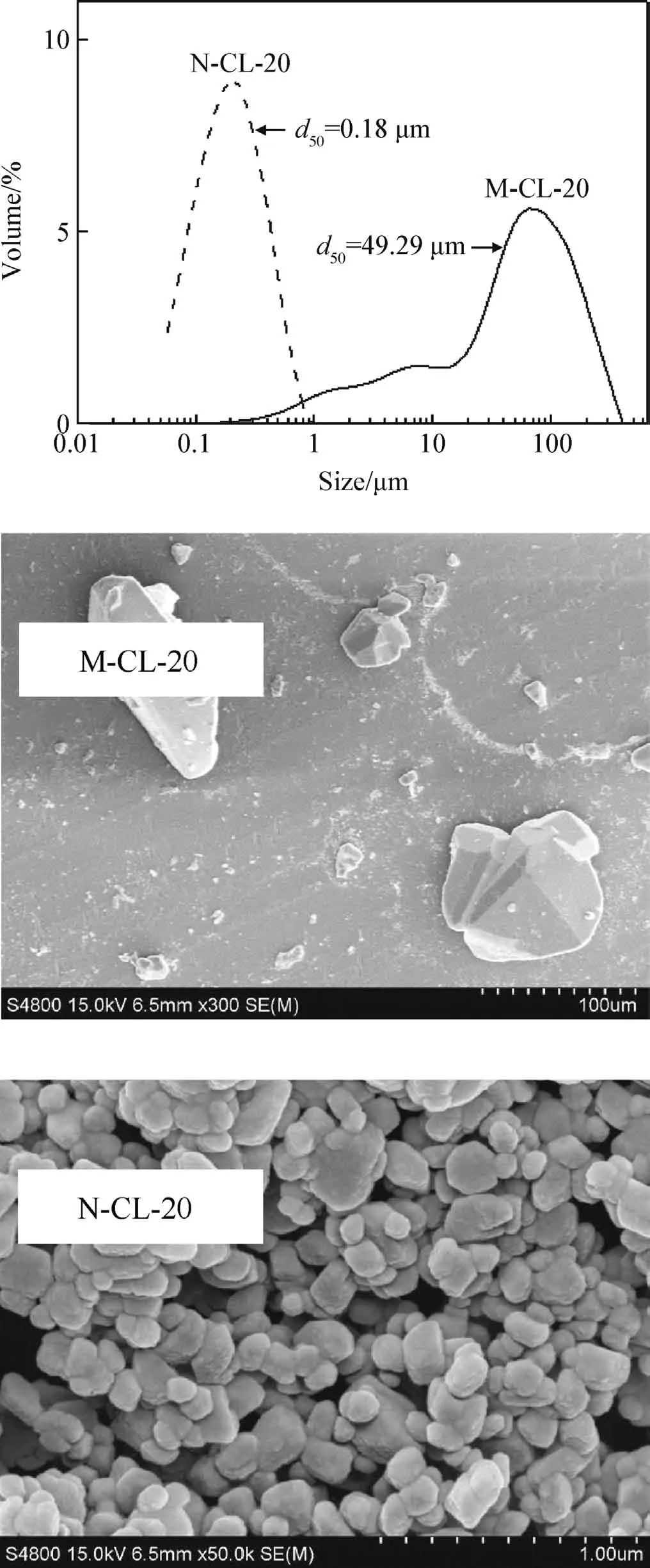

Fig.4.The size distributions and SEM images of CL-20 particles.

The variable of detonation velocity is calculated as

3.Results and discussion

3.1.Particle size distributions and SEM images

The particle size distributions and SEM images of explosives are shown in Figs.2-4.

As shown in Figs.2-4,the average particle sizes of micron-sized RDX,HMX andCL-20are83.64μm,120.36 μm and 49.29 μm with wide size distributions,and the average sizes of the nano-sized particles are 0.16 μm,0.16 μm and 0.18 μm with narrow size distributions,respectively.The micron-sized particles are polyhedral,irregular and heterogeneous,while the nano-sized particles are semi-spherical and homogeneous.

3.2.Sensitivities of pure nitramine explosives

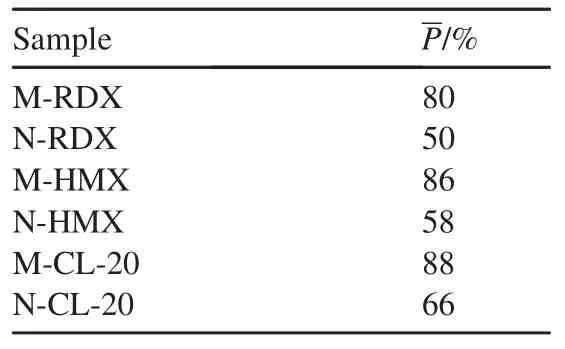

The friction,impact and shock sensitivities of pure RDX,HMX and CL-20 samples are listed in Tables 1-3.

As listed in Table 1,compared with the micron-sized samples(M-RDX,M-HMX and M-CL-20),the average explosion percentages of the nano-sized samples(N-RDX,NHMX and N-CL-20),which characterize the fiction sensitivities,are decreased by 30%,28%and 22%,respectively.

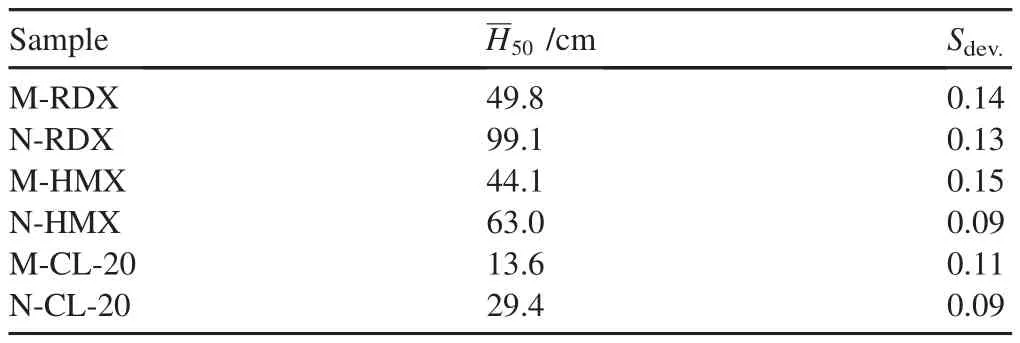

As listed in Table 2,the special heights of N-RDX,N-HMX and N-CL-20 are 49.3 cm,18.9 cm and 15.8 cm higher than those of the micron-sized samples,respectively.In other words,the impact sensitivities of the nano-sized samples are 99.0%,42.8%and 116.2%lower than those of the micron-sized samples,respectively.Additionally,the standard deviations(Sdev.)of the nano-sized samples are smaller than those of the micronsized samples,which means that the size and morphology of the particles are close to each other.As a result,the impact initiation probability of the samples is close to each other.

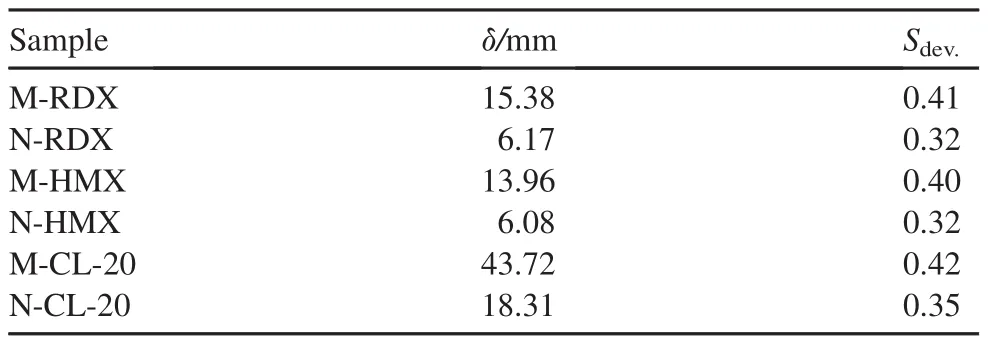

As listed in Table 3,compared with the micron-sized samples,the gap thicknesses(δ)of the nano-sized samplesare 9.21 mm,7.88 mm and 25.41 mm thinner,which means that the shock sensitivities of the nano-sized samples are decreased by 59.9%,56.4% and 58.1%,respectively.Furthermore,the standard deviations(Sdev.)of the nano-sized samples are smaller than those of the micron-sized samples,which states that the size and morphology of the particles are close to each other.As a result,the shock initiation probabilities of the samples are close to each other.

Table 1The friction sensitivities of RDX,HMX and CL-20.

Table 2The impact sensitivities of RDX,HMX and CL-20.

Table 3The shock sensitivities of RDX,HMX and CL-20.

3.3.Sensitivities of PBX samples

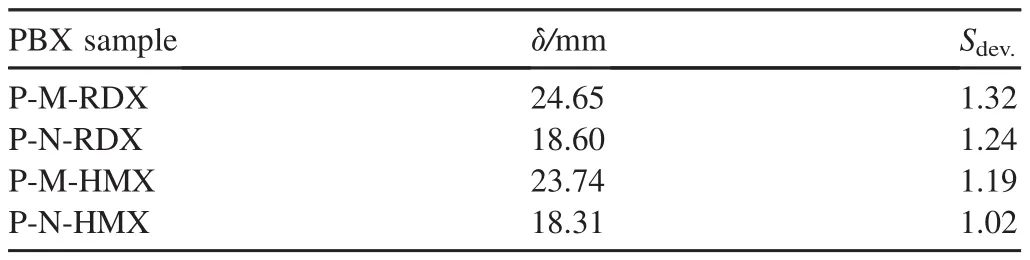

The shock sensitivities of PBX samples are listed in Table 4.

Table 4The shock sensitivities of PBX samples.

As listed in Table 4,when RDX and HMX are used in PBX,the gap thicknesses(δ)of P-N-RDX and P-N-HMX are 6.05 mm and 5.43 mm thinner than those of P-M-RDX and PM-HMX,which reflects the shock sensitivities of the nanosized particle-contained samples are 24.5%and 22.9%lower than those of the micron-sized particle-contained samples,respectively.What’s more,the standard deviations(Sdev.)of the nano-sized particle-contained samples are smaller than those of the micron-sized particle-contained samples,which implies that the size and morphology of the particles are close to each other.As a result,the shock initiation probabilities of PBX samples are close to each other.

3.4.Detonation velocities of PBX samples

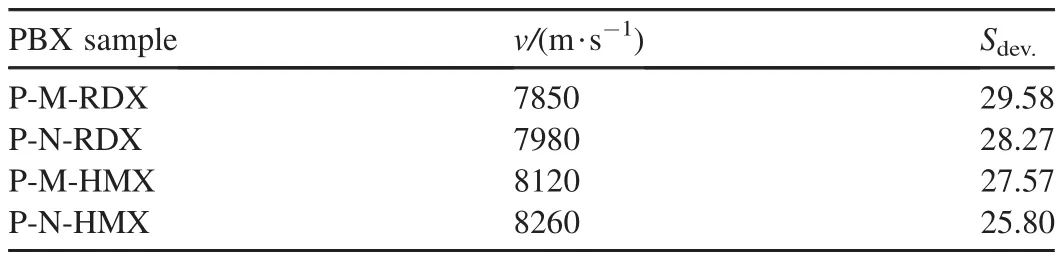

The detonation velocities of PBX samples are listed in Table 5.

As listed in Table 5,the detonation velocities of P-N-RDX and P-N-HMX are 130 m/s and 140 m/s higher than those of P-M-RDX and P-M-HMX when the densities are 1.63 g/cm3and 1.71 g/cm3,respectively.Compared with P-M-RDX and P-M-HMX,the detonation velocities of P-N-RDX and P-NHMX are enhanced 1.66%and 1.72%,respectively.Moreover,the standard deviations(Sdev.)of the nano-sized particlecontained samples are smaller than those of the micron-sized particle-contained samples.It can be concluded that the size and morphology of the particles are close to each other.As a result,the energy-release rates of the PBX samples are close to each other.

Table 5The detonation velocities of PBX samples.

4.Conclusions

Nano-sized nitramine explosives were successfully produced in batch using a bi-directional rotation mill,and the prepared nano-particles were effectively extracted by freezing drying.The product particles are semi-spherical with narrow size distributions.

Compared with the micron-sized RDX,HMX and CL-20,the friction,impact and shock sensitivities of the nano-sized explosives are apparently decreased.When RDX and HMX are used in PBX,the shock sensitivities of the nano-sized particle-contained samples are still obviously lower than those of the micron-sized particle-contained samples.After the micron-sized nitramine explosives are pulverized to be nanosized,the dislocations and occlusions in particles are almost disappeared and the particle surfaces are more regular,which would lead to the sharp diminution of hot-spot generating probability,so the sensitivities of nano-sized particles are apparently lower.

The detonation velocities of the nano-sized particle-contained samples are higher than those of the micron-sized particle-contained samples,which could be benefitted from the larger specific surface area of the nano-sized particles.It is promising to promote the applications of nano-nitramie explosives in PBXs and CMDBs so that some of their properties would be improved.

[1]Yan QL,Zeman S,Elbeih A.Recent advances in thermal analysis and stability evaluation of insensitive plastic bonded explosives(PBXs).Thermochim Acta 2012;537:1-12.

[2]Nouguez B,Mahe B,Vignaud PO.Cast PBX related technologies for IM shells and warheads.Sci Technol Energetic Mater 2009;70(5-6):135-9.

[3]Menikoff R.Comparison of constitutive models for plastic-bonded explosives.Combust Theory Model 2008;12(1):73-91.

[4]Jaidann M,Abou-Rachid H,Lafleur-Lambert X.Atomistic studies of RDX and FOX-7-based plastic-bonded explosives:molecular dynamics simulation.Procedia Comput Sci 2011;4:1177-85.

[5]Kumar AS,Rao VB,Sinha RK.Evaluation of plastic bonded explosive(PBX)formulations based on RDX,aluminum,and HTPB for underwater applications.Propell Explos Pyrotech 2010;35(4):359-64.

[6]Samudre SS,Nair UR,Gore GM.Studies on an improved plastic bonded explosive (PBX)forshaped charges.Propell Explos Pyrotech 2009;34(2):145-50.

[7]Zhang W,Fan XZ,Wei HJ.Application of nitramines coated with nitrocellulose in minimum signature isocyanate-cured propellants.Propell Explos Pyrotech 2008;33(4):279-85.

[8]Damse RS,Singh A,Singh H.High energy propellants for advanced gun ammunition based on RDX,GAP and TAGN compositions.Propell Explos Pyrotech 2007;32(1):52-60.

[9]Strunin VA,Nikolaeva LI.Combustion mechanism of RDX and HMX and possibilities of controlling the combustion characteristics of systems based on them.Combust Explos Shock Waves 2013;49(1):53-63.

[10]Landsem E,Jensen TL,Hansen FK.Neutral polymeric bonding agents(NPBA)and their use in smokeless composite rocket propellants based on HMX-GAP-BuNENA.Propell Explos Pyrotech 2012;37(5):581-91.

[11]Dubey R,Srivastava P,Kapoor IPS.Synthesis,characterization and catalytic behavior of Cu nanoparticles on the thermal decomposition of AP,HMX,NTO and composite solid propellants,part 83.Thermochim Acta 2012;549:102-9.

[12]Yan QL,Li XJ,Wang Y.Combustion mechanism of double-base propellant containing nitrogen heterocyclic nitroamines(I):the effect of heat and mass transfer to the burning characteristics.Combust Flame 2009;156(3):633-41.

[13]An CW,Li FS,Wang JY.Surface coating of nitroamine explosives and its effects on the performance of composite modified double-base propellants.J Propuls Power 2012;28(2):444-8.

[14]Xing XL,Zhao FQ,Ma SN.Thermal decomposition behavior,kinetics,and thermal hazard evaluation of CMDB propellant containing CL-20 by microcalorimetry.J Therm Analysis Calorim 2011;110(3):1451-5.

[15]Divekar CN,Sanghavi RR,Nair UR.Closed-vessel and thermal studies on triple-base gun propellants containing CL-20.J Propuls Power 2010;26(1):120-4.

[16]Xu SY,Zhao FQ,Yi JH.Thermal behavior and non-isothermal decomposition reaction kinetics of composite modified double base propellant containing CL-20.Acta Physico-Chimica Sin 2008;24(8):1371-7.

[17]Song XL,Li FS.Dependence of particle size and size distribution on mechanical sensitivity and thermal stability of hexahydro-1,3,5-trinitro-1,3,5-triazine.Def Sci J 2009;59(1):37-42.

[18]Song XL,Wang Y,An CW.Dependence of particle morphology and size on the mechanical sensitivity and thermal stability of octahydro-1,3,5,7-tetranitro-1,3,5,7-tetrazocine.J Hazard Mater 2008;159(2-3):222-9.

[19]Siviour CR,Gifford MJ,Walley SM.Particle size effects on the mechanical properties of a polymer bonded explosive.J Mater Sci 2004;39(4):1255-8.

[20]Liu J,Jiang W,Li FS.Preparation and study on nano octahydro-1,3,5,7-tetranitro-1,3,5,7-tetrazocine.Acta Armamentarii 2013;34(2):174-80[in Chinese].

[21]Liu J,Wang LX,Li Q.Preparation and characterization of insensitive nano RDX.Chin J Explos Propell 2012;35(6):46-50.

[22]Bayat Y,Zeynali V.Preparation and characterization of nano-CL-20 explosive.J Energetic Mater 2011;29(4):281-91.

[23]Liu J,Jiang W,Li FS.Effect of drying conditions on the particle size,dispersion state,and mechanical sensitivities of nano HMX.Propell Explos Pyrotech;2013.n/a-n/a.

[24]Liu J,Jiang W,Zeng JB.The effect of drying on the particle size and sensitivities of nano hexahydro-1,3,5-trinitro-1,3,5-triazine.Def Technol 2014;10(1):9-16.

[25]Li FS.Bi-directional rotation mill,Chinese Patent:ZL 200610096755.1 2006.

杂志排行

Defence Technology的其它文章

- Shock tube design for high intensity blast waves for laboratory testing of armor and combat materiel

- Formation of explosively formed penetrator with fins and its flight characteristics

- Experimental investigation of a cook-off temperature in a hot barrel

- Formulation development and characterization of cellulose acetate nitrate based propellants for improved insensitive munitions properties

- Deconsolidation and combustion performance of thermally consolidated propellants deterred by multi-layers coating

- Burning characteristics of microcellular combustible objects