Formulation development and characterization of cellulose acetate nitrate based propellants for improved insensitive munitions properties

2014-02-09ThelmMANNINGJeffreyWYCKOFFCrltonADAMEugeneROZUMOVKennethKLINGAMANVirlPANCHALJosephLAQUIDARAMikeFAIRJohnBOLOGNINIKeithLUHMANNSteveVELARDEChristineKNOTTStephniePIRAINOKevinBOYD

Thelm MANNING*,Jeffrey WYCKOFFCrlton ADAMEugene ROZUMOVKenneth KLINGAMANVirl PANCHALJoseph LAQUIDARAMike FAIRJohn BOLOGNINIKeith LUHMANNSteve VELARDE,Christine KNOTT,Stephnie M.PIRAINO,Kevin BOYD

aUS Army RDECOM ARDEC,Picatinny Arsenal,NJ,USA

bAlliiant Tech ATK,RAFPRD AAP,VA,USA

cNaval Surface Warhead Center,Indian Head,MD,USA

dArmy Research Laboratory,Aberdeen Proving Ground,MD,USA

1.Introduction

Researchers at U.S.Army Armament Research,Development and Engineering Center(ARDEC),through a cooperative agreement with the Japanese Defense Agency(JDA)on March 24,2000 have extensively studied CAN based gun propellants.The ultimate goal was to develop a high performance,low vulnerability(LOVA)propellant for future artillery charge systems[1-3].One of the objectives of the cooperative effort was to develop CAN based formulations that met or exceeded those of the baseline M30A1 propellant.These include energy content,flame temperature,erosion,low vulnerability,and ballistic performance from-35°C to+65°C.All the CAN based formulations evaluated had energy values equal to or greater than M30A1.The filler level for the CAN based formulation was kept to a lower level.Since the chemical structure of CAN is similar to the chemical structure of NC,the conventional gun propellant process was used to fabricate these three CAN based formulations and the reference M30A1 propellant.Interior ballistic calculations were conducted to optimize the grain configurations and to predict the pressures and velocities in the 30 mm ballistic gun test fixture.The CAN based formulation delivered the best performance in the 30 mm ballistic test(+5%at hot and+6%at cold)relative to the M30A1 formulation.In terms of the performance goal,the CAN based formulations demonstrated variety of subscale tests to determine its sensitivity and performance characteristics.Then we scaled up to demonstrate its potential in indirect fire gun propellants and assessed its sensitivity towards fragment impact in its final configuration.

2.Experiments

2.1.Synthesis of CAN

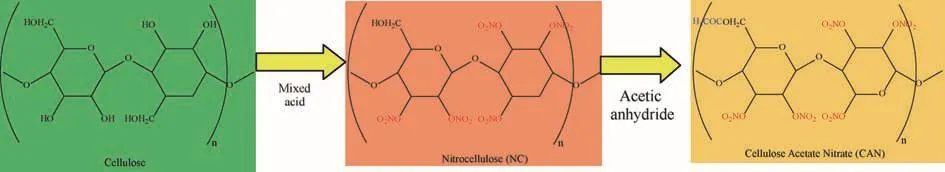

The basic synthesis of CAN[1]has been known for many years.In essence,nitrocellulose(NC)is reacted with acetic anhydride in the presence of an inert solvent and an acid catalyst.The reagents and solvent are then removed by washing(Fig.1).marked improvement over the baseline formulations that utilized NC as a binder.

Fig.1.The traditional route to CAN.

In addition to the temperature performance tests,LOVA assessment tests were conducted.To confirm LOVA characteristics,the bullet impact test,fragment impact test,fast cookoff test,and shaped charge jet impact test were conducted[4].Results of these tests demonstrated that the CAN based propellant formulations exhibited reduced sensitivity to all of these threats relative to the baseline M30A1 propellant.

The alternative synthetic route is to reverse the order of esterification of the cellulose as in Fig.2.The partial acetylation of cellulose is very well known and understood.In the early days of cellulose derivatization it was found much more difficult to do more than partially acetylate.This reaction has been conducted on a laboratory and industrial scale to give a very low cost product that retains the fibrous properties of the original cellulose just as NC does.This partial acetylation leaves sufficient free hydroxyl groups capable of undergoing nitration and producing CAN.

Fig.2.The optimal route to CAN.

The overall objective of this current project was to develop a CAN based propellant for the 105 mm artillery charge that demonstrated better IM response towards fragment impact threats than the current M1 propellant employed in the M67 propelling charge for 105 mm gun systems.This effort consisted of two phases:subscale and full scale.First we synthesized CAN and processed it into an insensitive propellant.This propellant was examined by a

2.2.Propellant development and characterization

Under Phase I of the project,the CAN based formulations were developed utilizing insensitive energetic solid fillers and high-nitrogen modifiers,in place of nitramines.Thermochemical properties for these formulations were calculated using the CHEETAH 6.0 thermodynamic code for a gun propellant run at a loading density of 0.2 g/cc.Auto-ignition temperature was determined via differential scanning calorimetry[5].Critical diameter[6],HFCI[7],impact sensitivity[8],friction sensitivity[9],and electrostatic discharge[10]were performed as described elsewhere.

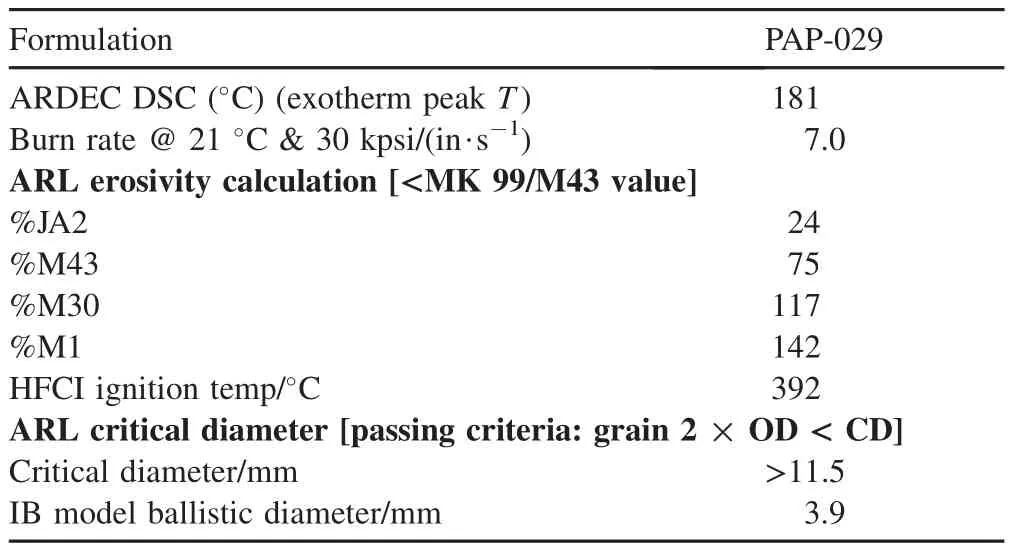

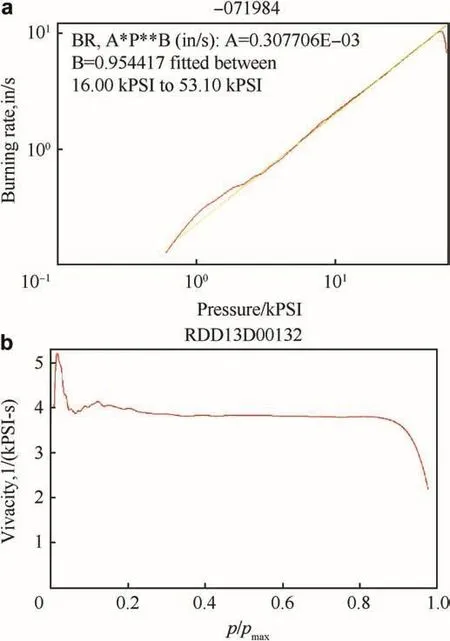

Burn rates were determined by closed bomb analysis.The closed bomb was a 200 cc vessel filled to a 0.2 g/cc loading density with single perforated grains.Using the data obtained from this test,the burn rate can be predicted as in equation(1),wherein P is the pressure in the chamber,αis the burn rate coefficient,andβis the burn rate pressure exponent.[11]

This burn rate was then used in the Interior Ballistic High Velocity Gun version 2(IBHVG2)code to model ballistic performance.This code was utilized to determine the ballistic grain geometry and web dimensions needed for 105 mm gun firings.

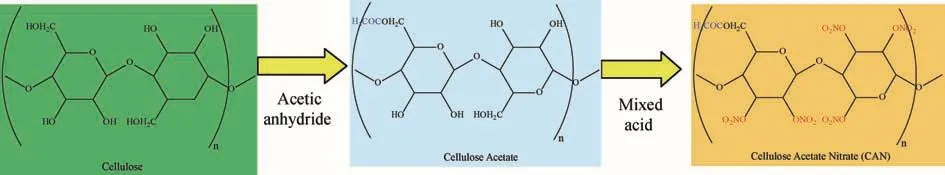

For the ballistic performance test,PAP-029 Propellant ARDEC Lot RDD13F-00136 was used.Since PAP-029 has never been fired and its ballistic behavior is unknown in the gun,a seven perforated configuration was selected based on the IBHVG2 predictions.ARDEC manufactured 85 pounds of seven perforated PAP-029 shown in Fig.3a.Two configurations of the M1 propellant currently used are shown in Fig.3b and c.In Fig.3b,a single perforation LOT RAD11C-071984 is shown and in Fig.3c,a seven perforation LOT RAD11C-071984 is presented.These were used in all large scale ballistic performance and sensitivity tests.

2.3.Ballistic performance

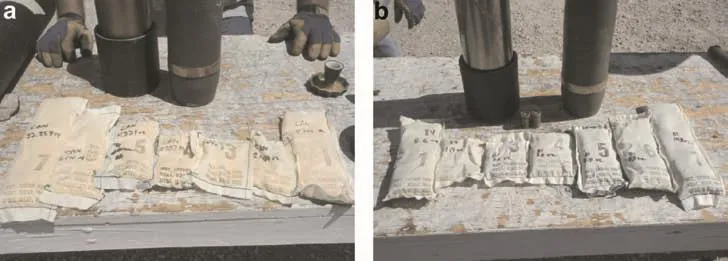

The PAP-029 CAN based propellant and the M1 propellant were loaded,assembled and packed in the M67 and M14B4 propelling cartridge case as shown in Fig.4.This was in preparation for the charge weight establishments and charge verification tests.All the M14B4 cartridge cases were drilled to accommodate the pressure transducers.All the M1 projectiles were wax- filled.In addition,a correspondingly drilled cannon and breech block to collect pressure data for all rounds fired was employed.The howitzer quadrant elevation was set to approximately 800 mils(45°)for maximum range as shown in Fig.5.

The purpose of the charge weight assessment and propellant uniformity tests were to establish charge weights for the final ballistic evaluation of PAP-029 CAN propellant without over-pressurizing the gun.Data was collected to evaluate the propellant in terms of muzzle velocity,and maximum chamber pressure as determined by both pressure transducers and crusher gauges.

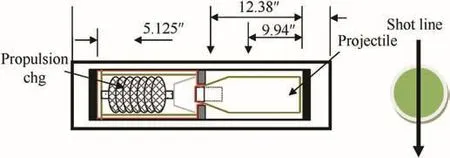

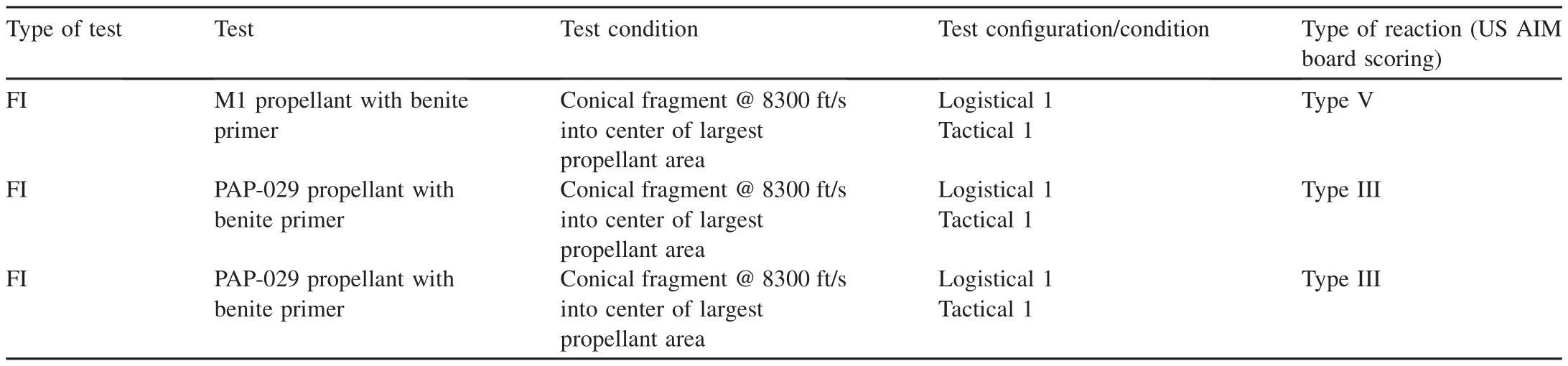

2.4.Fragment impact test

Fragment impact tests determine the sensitivity of energetic rounds to high speed fragments via the severity of their response as defined by the U.S.Army IM Board(AIMB).Responses are characterized by type in which the most severe is a Type I indicating detonation of the material,to least severe being a Type V.In this test,a 0.5-inch milled steel conical fragment traveling at a velocity of approximately 8300 ft/s is launched at the center of the most energetic portion of the round[12].Instrumentation consists of blast overpressure gauges and witness plates[13-15].

Fig.3.(a)PAP-029 in seven perforated grain geometry ARDEC LOT RDD13F-00136.(b)M1 seven perforated geometry LOT RAD11C-071981.(c)M1 propellant in single perforated geometry LOT RAD11C-071984.

Fig.4.(a)PAP-029 propellant bags for zone 7.(b)M1 propellant bags for zone 7.

Fig.5.105 mm howitzer quadrant elevation set for maximum range.

Besides the propellant,there was also an igniter in this projectile.The igniter used in this test was benite,M28E2,Lot No.LS 09G003S839,and 15 unbroken benite strands were used per round.The projectile in these tests was a 33 lb inert projectile so that the only energetic material being examined in this test case was the propellant.The use of a high explosive containing projectile could mask the role of the propellant in fragment impact response.All tests were conducted using the 105 mm projectile and M14B4 cartridge case packaged in a PA117 container with PA55 fiber tube shown in Fig.6.The shot-line configuration is shown in Fig.7 wherein it is shown that the fragment will impact the propelling charges 5.125′′above the base of the propelling charge container.

Fig.6.105 mm projectile and M14B4 cartridge case packaged in a PA117 container with PA55 fiber tube.

Fig.7.Fragment impact test shot-line location.

3.Results and discussion

After the processing parameters were established,a CAN formulation designated PAP-029 was produced.Unlike M1,PAP-029 contained no dinitrotoluene(DNT)or dibutyl phthalate(DBP)in the propellant compositions.DNT is a known carcinogen[16]and DBP is known to be toxic[17].Their exclusion from the formulation makes PAP-029 safer to handle and process.The calculated thermo-chemical properties of PAP-029 are listed in Table 2.The currently fielded propellant,M1,was used as the baseline to compare whether the thermo-chemical properties such as the impetus,and flame temperature can maintain the system requirements.PAP-029 has a much higher energy density and impetus when compared to the M1 propellant while not producing an exceedingly high flame temperature.Higher flame temperatures have been shown to increase barrel erosion[18].

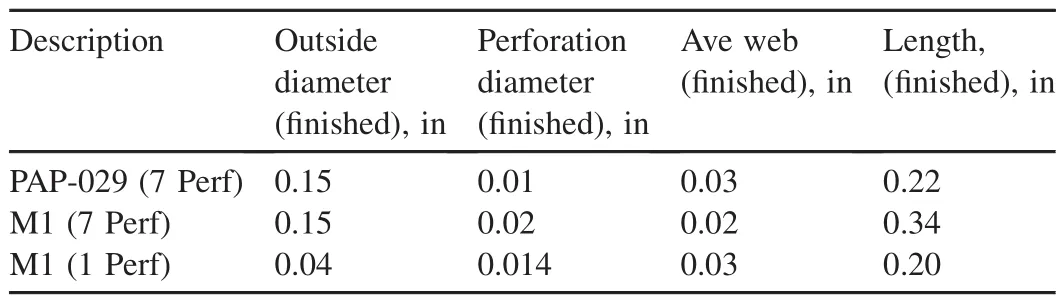

Table 1Finished grain dimensions.

Table 2Thermo-chemical properties of CAN based PAP-029.[19].

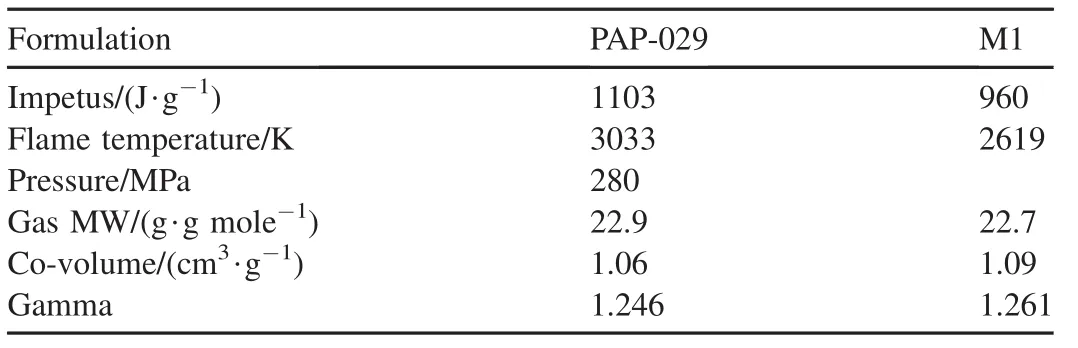

PAP-029 was then characterized via a battery of small scale analytical tests which results are presented in Table 3.DSC analysis demonstrated that PAP-029's thermal decomposition temperature occurs between that of JA2 and MK 99.PAP-029's burn rate is twice that of M1 as determined by closed bomb.The erosion potential of PAP-029,while higher than those of M1 and M30 is less than those of M43 and JA2.HFCI results are better than JA2 and M30.The measured burn rate was then used to calculate the ballistic diameter of the grains necessary for 105 mm gun applications.This diameter was more than twice as small as the critical diameter for PAP-029,indicating it is safe to be employed in M67 propelling charges.PAP-029 also exhibited the overall best mechanical properties.This is undoubtedly due to the high concentration of CAN and good plasticization[19].

Table 3CAN formulation properties[19].

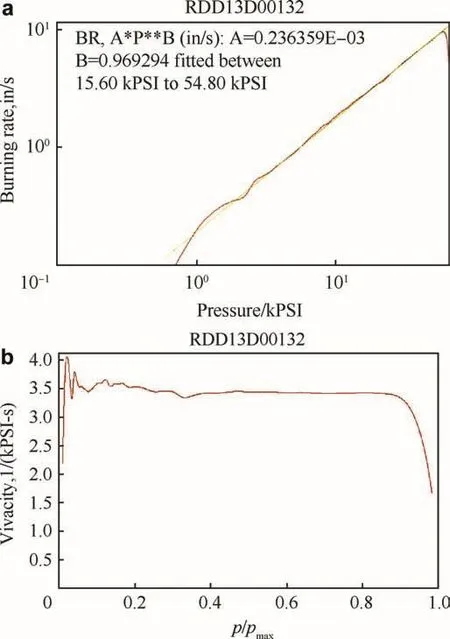

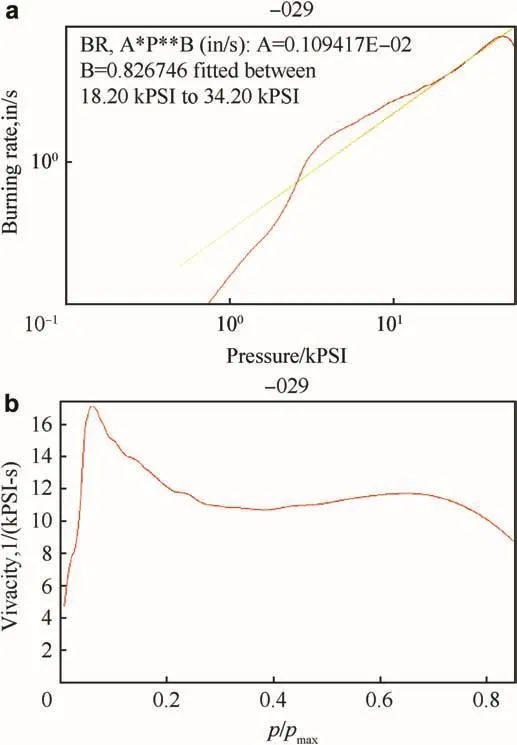

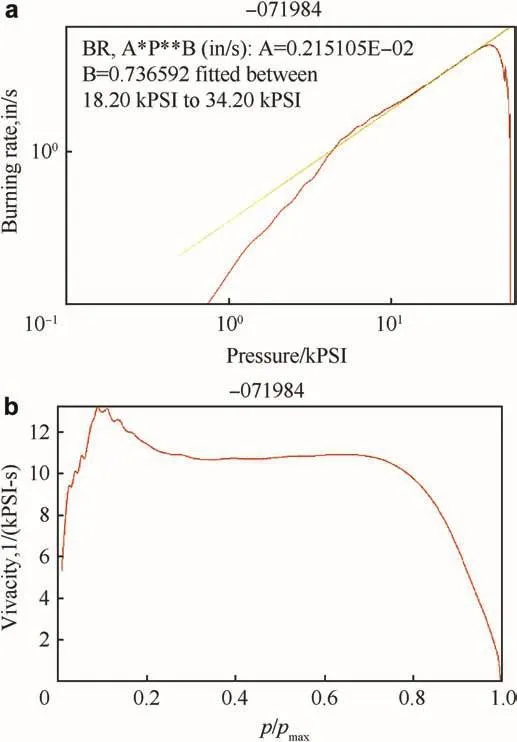

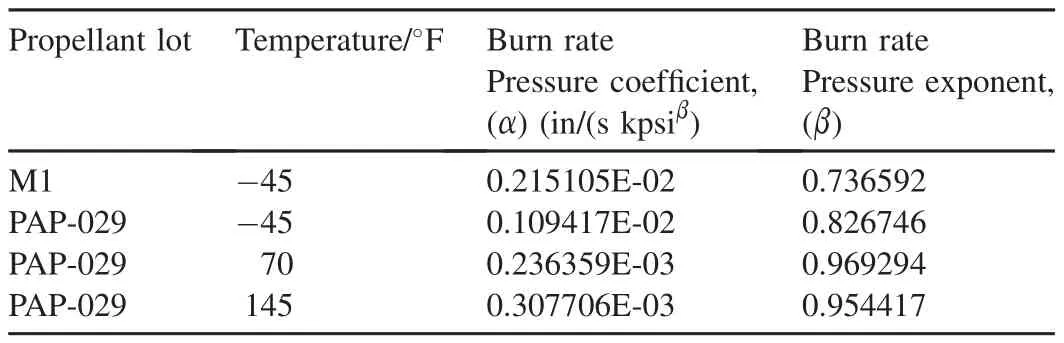

Once we examined PAP-029 for its sub-scale characteristics,we further employed closed bomb analysis across a broad temperature range on the actual grains to be fired in the 105 mm gun.This was performed in order to ensure that the propellant will perform as expected in its final con figuration.Figs.8-10 show the burn rates and vivacity curves of the PAP-029 at 145°F,70°F,and-45°F,respectively.Fig.11 shows the burn rates and vivacity curve of the M1 at-45°F.

PAP-029 propellant exhibits a comparable burn rate and vivacity curve behavior especially at-45°F with M1 propellant.The vivacity curves of PAP-029 followed the form function of a seven perforated geometry just like the M1 propellant.The burn rates and vivacity curves provided confidence that it was safe to fire PAP-029 in the 105 mm gun at cold temperatures without causing significant damage to the 105 mm gun barrel.The pressure exponents and pressure coefficients are shown in Table 4.The pressure exponent for the M1 propellant is lower than those of PAP-029 propellant at cold temperature.

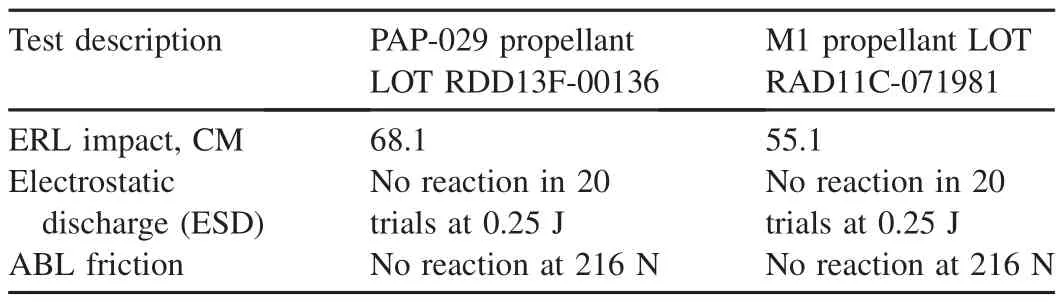

Small scale sensitivity testing was also conducted for both the PAP-029 and M1 propellant as shown in Table 5.PAP-029 propellant has a higher impact value as compared to the M1 propellant indicating it is less sensitive towards impact threats,but has the same ESD and friction values.

3.1.Ballistic performance test

The ultimate objective of this test program was to develop a propelling charge system that meets the ballistics requirements of the 105-mm Howitzer ammunition,using CAN Propellant.The specific objectives of this test were to:

Fig.8.a:Burn rates of PAP-029 at 145°F.b:Vivacity curve of PAP-029 at 145°F.

·Complete charge establishment and charge verification testing to compare PAP-029 CAN propellant to the current M1 single-and multi-perforated propellant.

·Determine the zone seven charge weight for the CAN propellant.

·Collect muzzle velocity and pressure data from each round if red in order to compare the CAN and M1 propellants at zone 7.

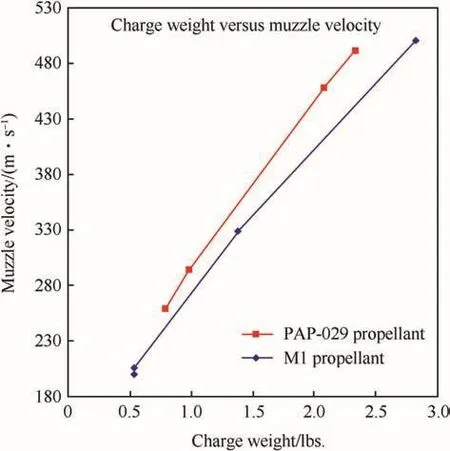

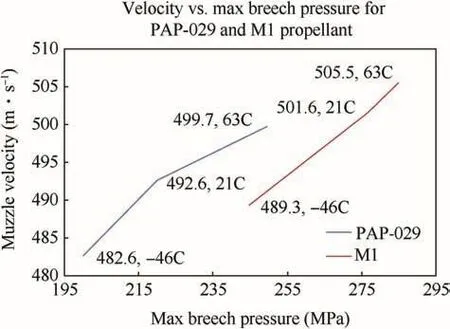

The results of the charge establishments are shown in Fig.12.PAP-029 had slightly higher muzzle velocities at all charge weights than the M1 baseline indicating its performance should be slightly better than that of M1 propelling charge.

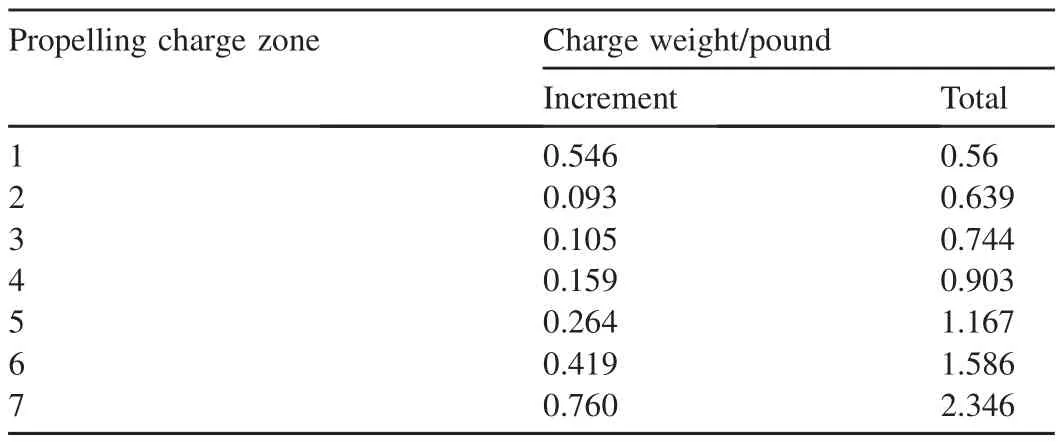

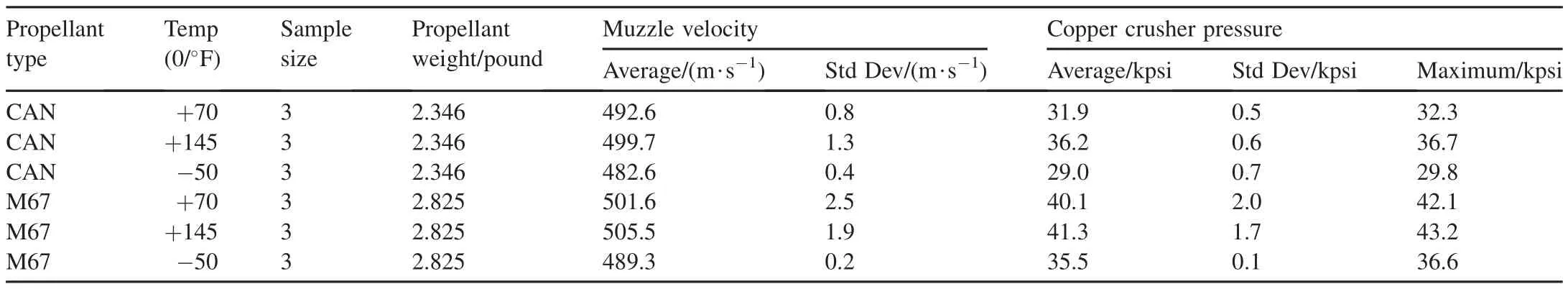

Table 6 displays new charge weights based on the results of the charge establishment firing.For the remainder of the test,PAP-029 and M1 were fired at zone 7 with PAP-029 having a total charge weight of 2.346 pounds.The results of the charge verification and temperature sensitivity summary are shown in Table 7 and plotted in Fig.13.PAP-029 velocities were slightly lower than that of M1,but this was due to the reduced charge weight for PAP-029.By increasing the charge weight of the PAP-029,the velocity and pressure could easily match that of the higher charge weight M1.This data also indicates that PAP-029 is a more efficient propellant than the M67 used in the M1 propelling charge owing to the significantly lower pressures observed.Finally,the temperature sensitivity of PAP-029 was comparable to the M1.

Fig.9.a:Burn rates of PAP-029 at 70°F.b:Vivacity curve of PAP-029 at 70°F.

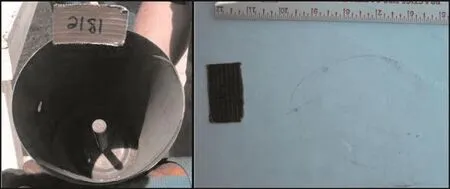

After each gun firing,the cartridge cases were examined for residue.Figs.14 and 15 show samples of PAP-029 CAN propellant and the M1 propellant cartridge cases.Also shown is the corresponding residue after gun firings.PAP-029 had no residue which indicated that the gun barrel would not need to be swabbed after each round when fired in the field.

3.2.Fragment impact test

With the ballistic performance of PAP-029 confirmed,the fragment impact IM test was then performed on PAP-029 and M1 in an effort to achieve a Type IV response or better.The fragment impact test results are summarized in Table 8.PAP-029 had a Type III response,while M1 had a Type V response,indicating that PAP-029 is much more susceptible to fragment impact than M1.It is theorized that all the factors listed below contributed to more rapid flame-spread and gas generation during the early phase of the event,which in turn led to a more violent response for the PAP-029.

Fig.10.a:Burn rates of PAP-029 at-45°F.b:Vivacity curve of PAP-029 at-45°F.

·PAP-029 was more energetic;therefore,it had a higher energy density and was more likely to yield a more energetic reaction than the M1.

·PAP-029 had a burn rate twice that of the M1 propellant.The higher burn rate for the PAP-029 likely caused a greater pressurization of the charge during the fragment impact test,thus producing a more violent response.

·The plasticizers used in PAP-029(TEGDN&TMETN)are not known for insensitivity,and may have contributed to the poor fragment impact results.

· PAP-029 is formulated with ground RDX(>5-micron).The RDX may have contributed to the FI sensitivity.

·PAP-029 had poorer mechanical properties relative to the M1 propellant[19].The relationship between mechanical properties and reduced sensitivity with respect to IM is not well understood.M1 exhibited a higher failure stress across the temperatures tested,which may have contributed to the less violent reactions over PAP-029.

Fig.11.a:Burn rates of M1 at-45 °F.b:Vivacity curve of M1 at-45 °F.

Table 4PAP-029 AND M1 propellant:burn rates,pressure coefficients,and pressure exponents from closed bomb testing.

Table 5Small scale sensitivity test results for PAP-029 and M1 propellants.

Fig.12.Results of the charge establishments for the PAP-029 propellant.

Table 6Charge verification CAN propellant charge weights.

·PAP-029 had a lower packing density due to the lower charge weight used.It is unclear whether a lower packing density is beneficial or not,as a lower packing density translates to a decreased energy per unit volume,which should be advantageous for IM.

·The distribution of propellant in the increment bags and the filled bags within the case may have influenced the fragment impact test results.

4.Summary,conclusions and recommendations

CAN was synthesized and incorporated into propellant formulation PAP-029.Small scale analyses all confirmed that the CAN based PAP-029 was comparable or better in terms of sensitivity and thermal properties than the M1 propellant utilized in the M67 propelling charge.The results of the charge verification tests indicated that the PAP-029 CAN based propellant was more ballistically efficient as compared to the M1 propellant.PAP-029 delivered higher muzzle velocities at lower breech pressures as compared to the baseline M1 propellant.Furthermore,PAP-029 propellant did not produce any residue,while the M1 propellant did.The PAP-029 propellantis safer to manufacture since it doesn't contain toxic and carcinogenic ingredients like DNT and DBP.One drawback in this effort was the Type III response achieved in fragment impact for PAP-029.An interesting serendipitous discovery was found in the Type V(burn reaction)response of the M1 baseline propellant FI test results which we were not looking for.The use of the benite primer may have resulted in the M1 propellant being an insensitive propellant worthy of further investigation for the 105 mm Howitzer IM solution.This highlights the importance of the primer compositions in affecting IM response,since M1 tested with the standard primer consisting of black powder,never achieved a Type V response previously.

Table 7Charge verification and temperature sensitivity summary.

Fig.13.Comparison of the muzzle velocity versus the maximum breech pressure.

Fig.14.Sample CAN cartridge case and no residue after firing.

Fig.15.Sample M1 cartridge case and residue after firing.

Table 8Summary of fragment impact tests.

Legends

Std Dev standard deviation

kpsi thousand pounds per square inch

We thank the Joint Insensitive Munitions Technology Program,Munitions Area Technology Group,Large Caliber Gun Propellant(JIMTP MATG V LCGP),for their funding of this effort.We would like to thank the ARDEC Processing Plant Team members for the manufacture of the PAP-029 CAN based propellant.We thank the Radford Army Ammunition Plant for the scaled-up synthesis of CAN.We thank Army Research Laboratories for performing the mechanical properties,HFCI,and critical diameter tests,as well as the erosivity predictions.We thank Yuma Test Center for performing the 105 mm gun firings.

[1]Carignan YP,Bobinski J.Cellulose nitrate-acetate mixed esters.Technical Report 3105;June 1964.

[2]Method for producing acetylated pyroxylin.U.S.Patent 6,417,345;July 9,2002.

[3]Low vulnerability gun propellant for artillery cooperative project;August 7,2003.Technical Report.

[4]MIL-STD-2105B.

[5]Harris J.Thermochim Acta 1976;14:183-99.

[6]Department of Defense.Ammunition and explosives hazard classification procedures,unconfined critical diameter test.TB 700-2;2009.p.59.

[7]Law HC,Rocchio JJ.The hot fragment conductive ignition test:a means of evaluating propellant vulnerability to spall.1981 JANNAF Combustion Meeting;October 1981.

[8]STANAG 4489 Ed.1.Explosives,impact sensitivity tests.

[9]STANAG 4487.Explosives,friction sensitivity tests.

[10]MIL-STD-1751A Method 1032,Electrostatic discharge sensitivity test(ARDEC(Picatinny Arsenal)method);11 December 2001.

[11]STANAG 4115.Definition and determination of ballistic properties of gun propellants.

[12]Mil-Std-2105D.

[13]DeMella Dominick,Ackerman Edwin.NLOS Cannon Artillery Division,105Mm Artillery Weapon System Reference Data Book.US Army RDECOM ARDEC,Armament Engineering&Technology Center,Munitions Systems&Technology Directorate,NLOS Cannon Artillery Division,Picatinny Arsenal,NJ.

[14]Final hazard classification(FHC)&insensitive munitions(IM)test plan for 105 mm high explosive artillery cartridge,M1 IM,Dr.Pail Lu;June 2011.

[15]Memorandum for Program Manager Combat Ammunition Systems(PMCAS),Dr.Thelma G.Manning,US Army Insensitive Munitions Board(AIMB).Review of the fragment impact test plan for 105mm high explosive artillery cartridge,M1 M67 and PAP-029 CAN propellant.August 2013.Mr.Brian E.Krzewinski,Chair,US Army Insensitive Munitions Board,17 July 2013.

[16]New Jersey Department of Health and Services.Hazardous substance fact sheet,dinitrotoluene;June 1998.CAS Number 606-20-2.

[17]Memorandum for Associate Executive and Director,Directorate of Health Sciences,United States Consumer Product Safety Commission.Toxicity review of di-n-butyl phthalate;April 7,2010.

[18]Lawton B.Wear 251;2001.pp.827-38.

[19]Manning Thelma,Wyckoff Jeffrey,Piraino Stephanie,et al.Characterization and development of CAN based propellant,phase I,60th JPM/9th Modeling and Simulation/7th Liquid Propulsion/6th Spacecraft Propulsion Joint Subcommittee Meeting Joint Army-Navy-NASA-Air Force(JANNAF),Cheyenne Mountain Conference Center 29 April-2 May,2013.

杂志排行

Defence Technology的其它文章

- Shock tube design for high intensity blast waves for laboratory testing of armor and combat materiel

- A passive method to stabilize an airborne vehicle

- Experimental investigation of a cook-off temperature in a hot barrel

- Deconsolidation and combustion performance of thermally consolidated propellants deterred by multi-layers coating

- Burning characteristics of microcellular combustible objects

- Dynamic analysis of a guided projectile during engraving process