马氏体转变(二十)

2014-01-10朱祖昌杨弋涛吴旭炜

朱祖昌,杨弋涛,吴旭炜,王 洪

(1.上海工程技术大学,上海 201620;2.上海大学,上海 200072;3.上海市机械制造工艺研究所有限公司,上海 200070)

7.3马氏体的韧性

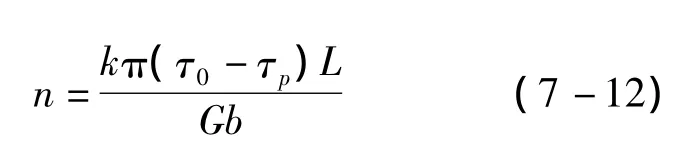

研究材料韧性,易于设想的是位错的塞积。在奥氏体晶体内一滑移面上Frank-Read位错源(简称F-R 源)受到切应力 τ0,当 τ0> τp,则位错源启动。形成的位错环先后在晶界处发生塞积,塞积位错数n[131]为

式中:k为系数,对螺位错k=1,对刃位错k=1-ν(ν为泊松比);τp为位错移动的摩擦力(称Peierls-Nabarro力),前已有指出;G为切变模量;b为布氏矢量;L为发生位错塞积的距离。一般认为F-R位错源在晶粒中心时,L=D/2,D为奥氏体晶粒直径。

由式(7-12)可知L(即D)减小,则塞积位错数n减小。

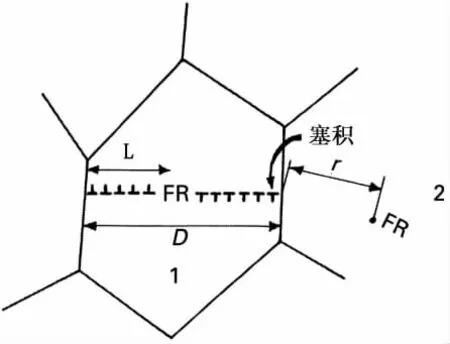

位错发生塞积后,塞积群的领先位错前端存在很大的应力集中τ,τ=nτ0,随n增加至一定程度,位错塞积会开启另一奥氏体晶粒中的F-R源产生位错运动的传播。按图7-9,距塞积位错前端r处的F-R源处受到的切应力τ为式中,β为与图中方向θ有关的系数。有文献表明,当 θ=70.53°(70°31')时,应力处于最大。显然L(D/2)减小,τ应力集中减小。为此,奥氏体晶粒细化,能减小塞积的位错数n和应力集中τ,亦即可以使材料承受更大的负荷。

图7-9 晶界位错发生塞积示意图Fig.7-9 Schematic of dislocation pile-up before grain boundary

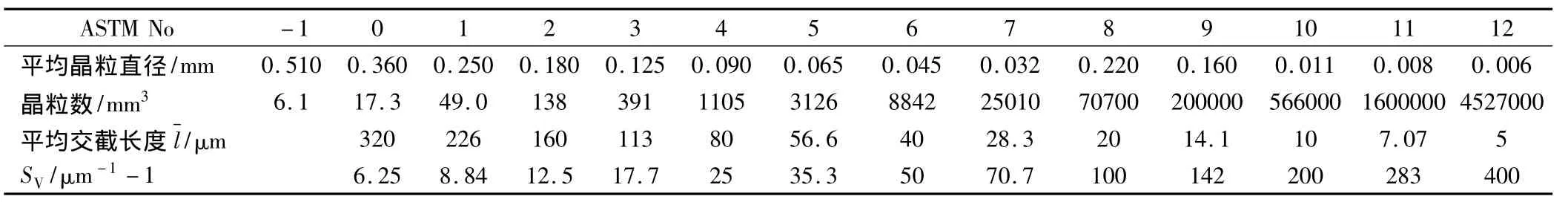

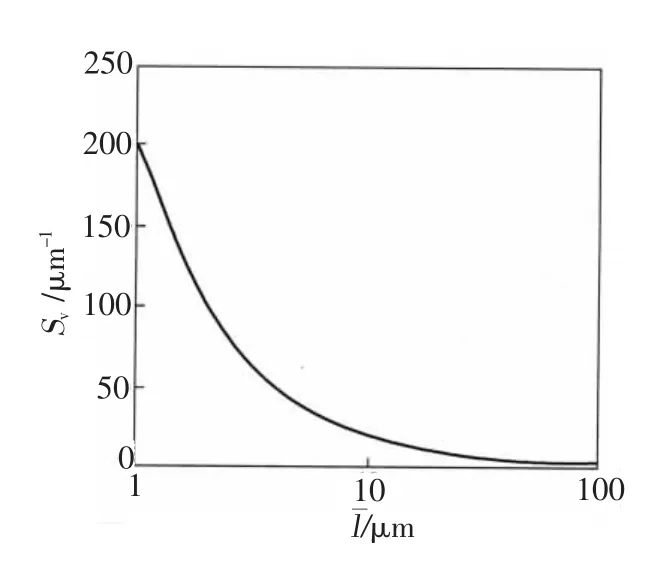

同时,尚要考虑晶粒细化后每单位体积中存在的奥氏体晶界表面积SV[132]。SV由测定的抛光表面上晶粒的平均截距长(μm)表示,其相应的变化示于表7-3和图7-10。当晶粒由20 μm细化至2 μm,SV约提高10倍。SV的提高将明显减小H、S、P、As和Sb等脆化杂质在晶界上的偏聚,即能使获得较洁净的晶界,那么材料的断裂机制随晶粒细化将会由沿晶界断裂变成穿晶断裂(在室温时),使材料的韧性提高。晶粒平均截距与晶粒直径随晶粒度增加而减小,它们之间的关系示于下表7-3中。

表7-3 晶粒度、晶粒直径、SV和晶粒平均截距的关系Table 7-3 Relationship of grain size,grain diameter,SV and grain mean intercept length

表7-3 晶粒度、晶粒直径、SV和晶粒平均截距的关系Table 7-3 Relationship of grain size,grain diameter,SV and grain mean intercept length

平均晶粒直径/mm 0.510 0.360 0.250 0.180 0.125 0.090 0.065 0.045 0.032 0.220 0.160 0.011 0.008 0.006晶粒数/mm3 6.1 17.3 49.0 138 391 1105 3126 8842 25010 70700 200000 566000 1600000 4527000平均交截长度l/μm 320 226 160 113 80 56.6 40 28.3 20 14.1 10 7.07 5 SV/μm-1 -1 6.25 8.84 12.5 17.7 25 35.3 50 70.7 100 142 200 283 400

图7-10 每单位体积中奥氏体晶界表面积SV和晶粒的平均截距长度的关系Fig.7-10 Relationship of grain boundary surface area per volume of austenite SVand mean intercept lengthl

图7-11 工业用42CrMo钢室温冲击断口组织(a、b)和高洁净42CrMoVNb钢-192℃冲击断口组织(c、d)Fig.7-11 Fractograph of impact samples tested at room temperature for commercial steel 42CrMo(a,b)and tested at-192 ℃ for high purity steel 42CrMoVNb(c,d)

图7-11(a)、7-11(b)表明了42CrMo钢淬火和400℃回火后于20℃的冲击断口组织,图7-11(c)、7-11(d)为高洁净42CrMoVNb钢淬火和600℃回火于-192℃的断口组织[132]。相应晶粒尺寸为22 μm(图 7-11(a))、4.7 μm(图 7-11(b))、8 μm(图 7-11(c))和2 μm(图7-11(d));相应冲击断口组织为沿晶断裂(图7-11(a)),其余的均为穿晶断裂,穿晶断裂具有高的韧性数值。可见一般的42CrMo钢奥氏体晶粒细化至4.7 μm使常温冲击韧性提高了;高洁净42CrMoVNb钢在8 μm时也已具有高的低温冲击韧性。可以推断:奥氏体晶粒的细化不仅能提高强度,而且能阻止沿晶界微裂纹的产生和扩展,从而也提高钢的韧性。这与Benerje等对AISI4340钢奥氏体晶粒尺寸在20~100 μm的结果相一致。

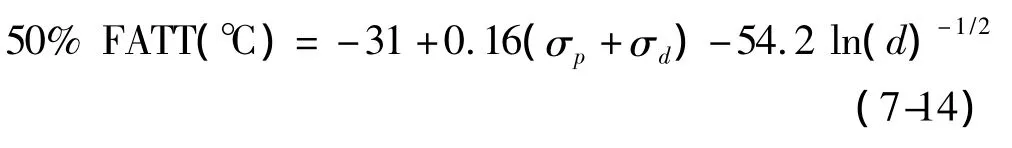

上面说明了奥氏体晶粒细化对韧性的影响。马氏体板条束细化的工作按Maropoules等分析的韧脆转折温度与板条束d的关系,其公式为

50%FATT为50%断裂形貌转折温度。显然,对强度贡献的σp和σd使韧性下降,束尺寸d的减小则有利于50%FATT的降低和韧性的提高。

还应该特别注意的是,钢中奥氏体晶粒尺寸细化也会改善马氏体钢的延迟断裂DF阻力。延迟断裂与钢的塑性变形相关联。在材料中含有氢,氢会促使位错的发射和运动,使材料即使在受到低于不含有氢时的临界应力条件下,就会在位错塞积区域内产生应力集中,并逐渐積累达到由于与氢交互作用引起降低原子结合强度值,从而使裂纹在含氢的局部区域内形核,最后产生延迟断裂。钢中奥氏体晶粒细化和晶界表面积SV的提高会减小晶界上氢的捕集量,明显减少马氏体钢的延迟断裂的发生。Tien计算了10 ppm含氢量当晶粒尺寸自100 μm细化至10 μm,氢覆盖区域从饱和条件减至1:10,从而有利于DF阻力的改进[132]。显然,对上述两种钢由于晶粒细化的延迟断裂DF阻力也得以改进。

7.4 马氏体亚结构对性能的影响

Thomas和Krauss已经提出,钢中合金组成元素通过对Ms的影响改变着马氏体的亚结构,从而影响它们的力学性能。Thomas更认为,含碳结构钢的韧性降低是与相变出现孪晶马氏体相关联的。一般地讲,钢中孪晶马氏体的出现除起一定的强化作用外,也降低韧性,已愈来愈被人们所接受。徐祖耀[5]指出,Fe基合金中随着碳及合金元素的增加,增加的孪晶马氏体有附加强化的作用,但使韧性下降。下面主要对Fe-Cr-C、Fe-Ni-C和 Fe-Mn-C或Fe-Mn-Ni-C合金作一些说明。

7.4.1 Fe-Cr-C 钢

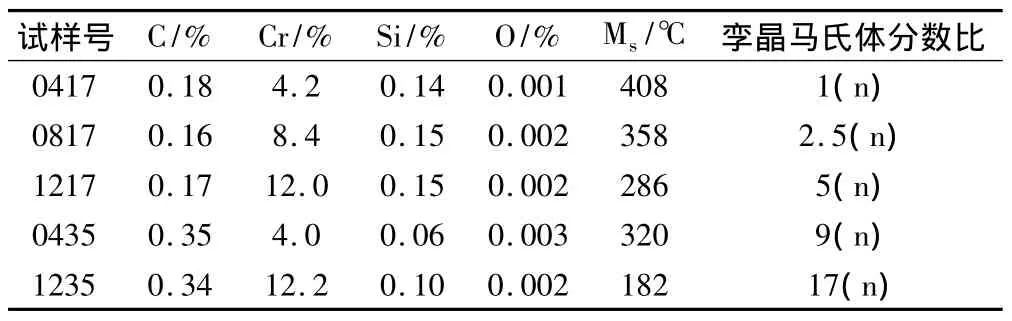

McMahon 和 Thomas[137]1973 年设计经济的韧性高强度Fe-Cr-C钢是十分有意义的。他们指出,Cr的固溶强化作用不明显,见图7-12(a),但会改变马氏体的亚结构,从而设计出淬火状态下的不同亚结构钢,钢的主要成分(质量分数)、Ms点和亚结构数量列于表7-4。钢的试样号与含Cr量和含碳量有关,孪晶马氏体分数n为0417合金的平均值,其它合金的孪晶马氏体数量为与0417合金的相对比值。

对含碳0.17%的3个合金,孪晶马氏体分数较少,其中0417的含Cr量较低,Ms点最高,马氏体亚结构基本上为位错;其他合金的含Cr量增加,孪晶马氏体量增多。对含碳0.35%的2个合金,孪晶马氏体数量增高相当多,其中1235含最高合金元素量,Ms点最低,孪晶马氏体分数比最高17(n)。合金的屈服强度、平面应变断裂韧性KIC和孪晶马氏体分数的关系示于图7-12。

图7-12 淬火态Fe-Cr-C钢力学性能和孪晶马氏体相对数量的关系Fig.7-12 Relations of mechanical properties vs twin martensitic relative number of as-quenched Fe-Cr-C steels

表7-4 几种Fe-Cr-C钢主要成分、Ms点和马氏体亚结构Table 7-4 The composition,Ms,and martensitic substructure ofsome Fe-Cr-C steels

由图7-12可知,含碳0.17%的3个合金钢,随着含Cr量增加,屈服强度保持不变,表明Cr不具有固溶强化作用;但随着含Cr量增加至12%时,KIC从80降至70。对含碳量为0.35%的2个钢,随含Cr量由4%增至12%,强度由1654 MPa提高至2067 MPa。这里的强化是由于孪晶马氏体数量增加所致,但是却使KIC从减至20。他们提出:出现孪晶马氏体的强化源于孪晶对位错运动的限制,但孪晶是bcc金属中裂纹的形核源,从而使KIC下降。为此,对未回火的马氏体组织如要获得高的韧性,应避免出现孪晶型马氏体。

由图7-12还可以明确:材料强度提高未必引起韧性的降低。以含4%Cr的0435试样为例,淬火态强度比1217(含12%Cr)试样的提高579 MPa,但具有相同的KIC值70。为此,可以通过调整碳和合金元素Cr的含量控制马氏体的亚结构,使强度提高和不降低韧性。Thomas等设计的0435钢与几个商用超高强度钢的比较示于图7-13,其淬火态的性能与18Ni型马氏体时效钢相当,在200℃回火后的性能更有所提高,更优于4340和300M钢,而且具有价格低和处理工艺方便的特点。这种思路为高强高韧钢的设计提供新途经。

7.4.2 Fe-Ni-C 钢

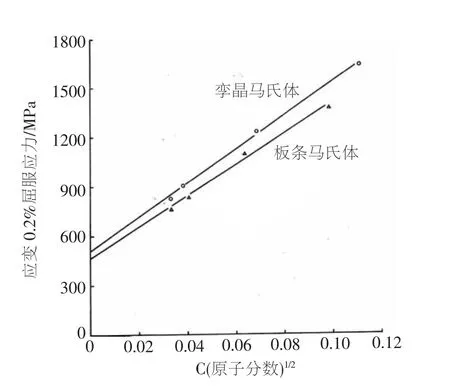

Chilton和 Kelly[138]1968年按马氏体亚结构形态和碳含量以及镍含量(对应于Ms差异)设计含24~32%Ni和不同含碳量的Fe-Ni-C合金,以获取位错型板条马氏体和孪晶型马氏体的组织;在室温进行拉伸和压缩试验,分别求得0.2%的拉伸屈服强度和压缩屈服强度与含碳量(原子分数)平方根之间的直线关系,示于图7-14和图7-15中;相应求得的拉伸应力的斜率为G/6.5~G/6(对孪晶马氏体)和G/7.5~ G/8.5(对板条马氏体),前者比后者略大。相应求得拉伸和压缩试验中孪晶马氏体较位错马氏体的高出值为1.31和1.08(图7-14中低碳范围的2个值取自Speich等的数据)。其它实验得到的值为1.25 ~ 1.28[5]。在低碳范围内两者的强度比则相差相当小,随含碳量增加,孪晶亚结构的强化有所增加。

图7-13 Fe-4Cr-0.35C钢与一些商用超高强度钢的拉伸强度和断裂韧性比较Fig.7-13 The comparison of tensile strength and fracture toughness for Fe-4Cr-0.35C steel with some commercial ultra high strength steels

图7-14 淬火态板条和孪晶马氏体0.2%拉伸屈服强度与含碳量(原子分数)平方根之间的直线关系Fig.7-14 0.2%Linear relationship between yield strength(in 0.2%tension)and the square root of carbon content(atomic fraction)for as-quenched lath and twinned martensites

图7-15 淬火态板条和孪晶马氏体0.2%压缩屈服强度与含碳原子分数平方根之间的直线关系Fig.7-15 Linear relationship between yield strength(in 0.2%compression)and the square root of carbon content(atomic fraction)for as-quenched lath and twinned martensites

Kelly等[139]按后文 Sleeswyk模型,设定 Fe-Ni-C钢中基体上的孪晶比为1:1,滑移面在基体上和孪晶中为{110},对孪晶马氏体中位错滑移运动的分切应力应用电子计算机进行模拟,结果预测孪晶马氏体的强度比位错马氏体的高1.05~1.20倍,与上述的实验测定值的比吻合。

7.4.3 Fe-Ni-Mn-C 钢

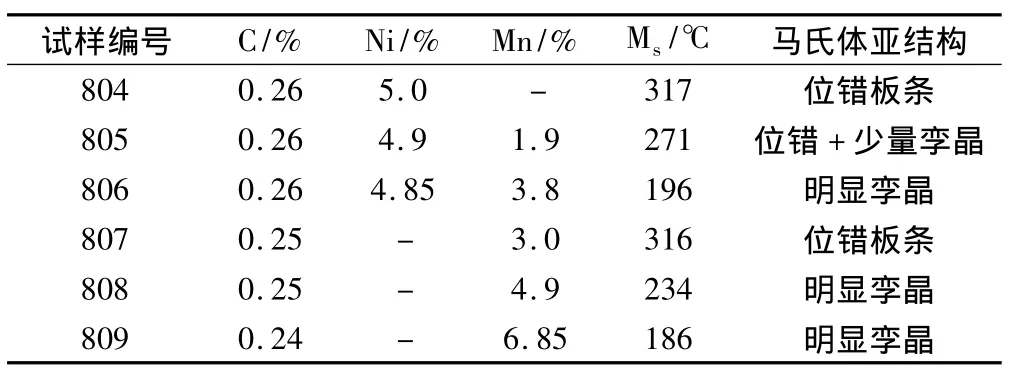

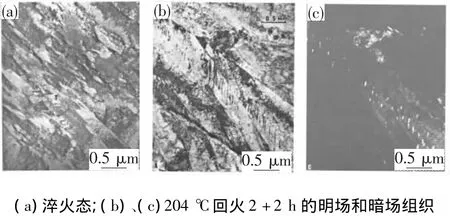

1970 年 Huang 和 Thomas[140]建立了关于回火Fe-Ni-Mn-C钢马氏体亚结构与力学性能之间的关系。在Fe-5Ni-C和Fe-C合金中增加Mn的量,Ms降低和增加孪晶马氏体数量列于下表7-5中。805合金的显微组织示于图7-16(a)中,在位错亚结构板条马氏体中偶尔出现一些孪晶马氏体。该合金在204℃(400°F)回火2+2 h后显示在板条束中出现的孪晶马氏体的孪晶交界面上出现碳化物析出,相应的明场和暗场组织示于图7-16(b)和图7-16(c)。

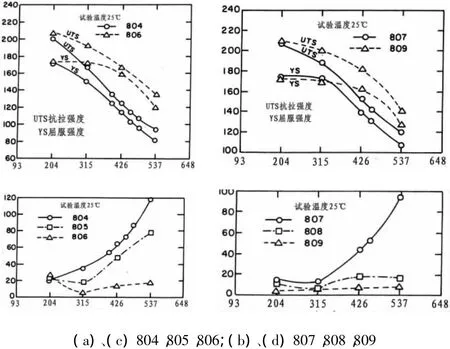

表7-5 Fe-Ni-Mn-C钢的组成,马氏体点和马氏体亚结构Table 7-5 The composition,Msand martensitic substructure of some Fe-Ni-Mn-C steels

图7-16 805合金的显微组织(a)as quenched;(b)、(c)bright and dark field for tempered at 204℃for 2+2 hFig.7-16 The microstructure of 805 alloy

含5%Ni的804、806钢的强度和804~806三种钢的CVN冲击能与不含Ni的807、809钢的强度和807~809三种钢的CVN冲击能分别示于图7-17(a)和(d)中(试验温度在25℃)。由图7-17(a)和(b)可见,在含Ni和不含Ni钢中分别加入3.8% 和6.85%Mn均使回火抗力增加,但均使CVN值迅速下降,见图7-17(c)和(d)。值得注意的是805合金中CVN的降低显然与出现碳化物析出有关。结果明显表明:孪晶马氏体具有较高的强度,但使韧性降低。

图7-17 Fe-Ni-Mn-C钢回火温度对强度和韧性的影响(a)、(c)804,805,806,(b)、(d)807,808,809Fig.7-17 The effect of tempering temperature on strength and toughness of some Fe-Ni-Mn-C steels

7.4.4 孪晶马氏体的强化作用和对韧性的降低

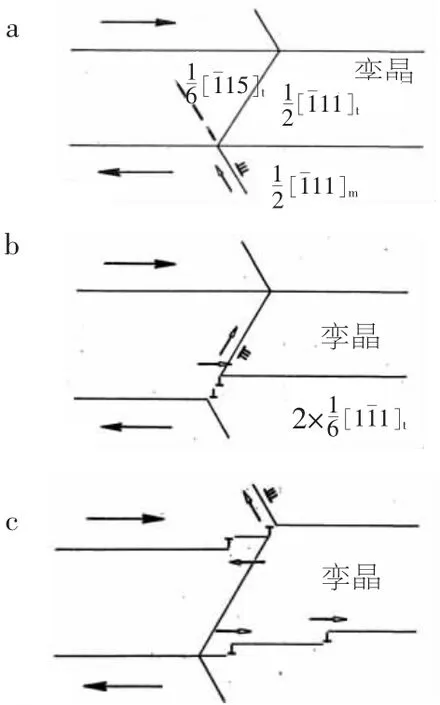

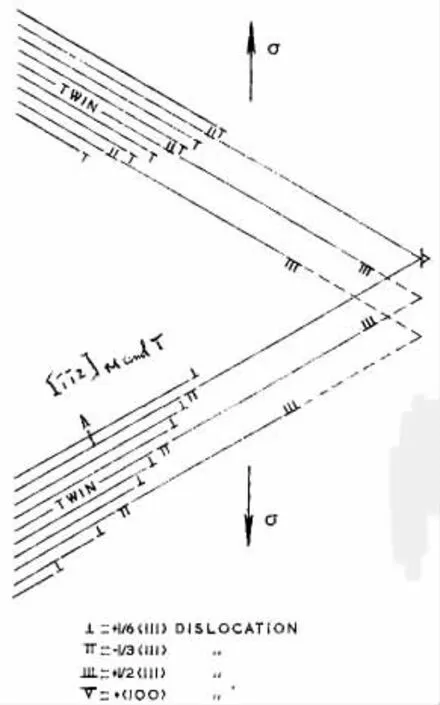

1961 年 Sleeswyk 和 Verbraak[141]提出了 bcc 金属中位错滑移和孪晶“掺合过程(incorporation)”模型,来说明孪晶阻止位错滑移起强化的效应。

bcc金属中,存在晶体学孪晶{112}<111>,通过晶体轴的转动的矩阵计算可以得出4个对应关系,其中(b)关系为,相应下标m和t为基体和孪晶。同时,孪晶界面上会存在一般孪晶位错和互补(complementary)孪晶位错,分别以符号┸、┰和表示,布氏矢量分别为

图7-18 滑移位错(布氏矢量为)滑移通过孪晶的过程(a→b→c)示意图Fig.7-18 The sequence(a→b→c)shows a slip dislocation traversing a twin band

Klems等[142]1976年作了 Fe马氏体的内耗测定,采用Ms<35℃(以免除自回火影响)的19种Fe-Ni-C合金淬至-196℃获得85%~95%的孪晶型{259}r惯习面马氏体显示160℃的内耗峰,与Fe-C合金在室温形成位错型{111}r或位错和孪晶型的{225}r马氏体在250℃出现的位错-间隙原子交互作用内耗峰成鲜明对照。他们提出,160℃内耗峰与碳原子在孪晶边界的应力诱发运动有关。

另外,与Fe-Ni-Mn-C合金400°F(204℃)回火出现孪晶交界面上碳化物析出能说明C偏聚在孪晶交界面现象。为此,对Fe-C合金,由于Ms点较高,在马氏体转变完成后再发生这种C的偏聚和甚至导致碳化物析出的现象在近室温时就可开始,导致增加孪晶马氏体脆性是难以避免的。

基于上述位错与孪晶掺合交互作用模型,Sleeswyk[143]又指出“分支(emissary)位错反应”模型:当近40个一般孪晶位错(┸)塞积,在每第三个{112}上按反应产生分支(emissary)位错,并发生滑移塞积;又按Cottrell位错反应(参见第二章)形成<100>立方位错,12个孪晶面上的分支位错交截,产生在bcc晶体解理面{100}晶带面上的裂纹形核,相应示意图为图7-19。成对分支位错的反应式为

作者还指出,这些反应中有些是在拉应力下发生的,将会成为解理裂纹源,从而就会使bcc金属的韧性降低。

图7-19 二套分支位错形成<100>立方位错的过程示意图Fig.7-19 Schematic of a sequence of forming a <100 > cube dislocation from two sets of emissary dislocations

8 结束语

21世纪占主导地位的结构材料仍然是钢铁材料。现在,没有一种材料能够全面代替钢铁。同时,现今社会的发展和经济建设仍需要新一代的钢铁材料。

马氏体转变是钢铁材料中最重要的一种相变,研究已愈来愈深入化。

主要参考 Nishiyama的“Martensitic Transformation”和徐祖耀的“马氏体相变与马氏体”;以及按上世纪80年代的两本“金属热处理原理”的思路和框架对近二三十年来研究马氏体转变中所拥现的大量著作和论文进行梳理、编辑、撰写;並按自己多年从事教学工作经验和要求选取基材,进行仔细切磋和精心编缀,这是我们写作本文的初衷,从中也使自己获得更多提高。但由于我们的水平有限,文章中难免会出现管窥之见和一定差错,祈求赐教和斧正。

[1] 冯端,师昌储,刘治国,材料科学导论[M].北京:化学工业出版社,2002.

[2] 冯端等.金属物理学;第二卷 相变[M].北京:科学出版社,1998.

[3] Aaronson HI,Enomoto M,Lee JK,Mechanisms of diffusional phase transformations in metals and alloys[M].CRC Press,Taylor& Francis Group,2010.

[4] Zlateva G,Martinova Z,Microstructure of Metals and Al-loys,An Atlas of Transmission Electron Microscopy Images[M].CRC Press,Taylor& Francis Group.2008.

[5] 徐祖耀.马氏体相变与马氏体[M].2版.北京:科学出版社,1999.

[6] The Institute of Metals,The Mechanism of Phase Transformations in Metals[M].London,1956.

[7] Porter DA,Easterling KE,Sherif MY.Phase Transformations in Metals and Alloys[M].3rded,CRC Press,Taylor&Francis Group,2009.

[8] Belin-Ferré E.Basics of Thermodynamics and Phase transitions in Complex Inter-metallics.[M].Book Series on Complex Metallic Alloys-Vol.1,World Scientific publishing Co.Pte.Ltd.,2008.

[9] Greninger AB,Troiano AR.The mechanism of martensite formation[J].Trans.AIME,1949,185:590.

[10] Nishiyama Z,Martensitic Transformation[M].Ed.Fine ME,Meshil M,Wayman CM.Academic Press,Inc.,New York,1978.(S.Sato等将日文译为英文).

[11]柴田晓申,村上俊夫,森户茂一,et al.レンズマルテンサィトのミドリブ[J].热处理,2009,49(4):179.

[12]森户茂一,岩见祐贵,古谷野有,et al.Fe-N合金ラスマルテンサィトの組織と結晶学[J].热处理,2009,49(3):89.

[13]陈景榕,李承基.金属和合金中的固态相变[M].北京:冶金工业出版社,1997.

[14]刘云旭,金属热处理原理[M].北京:机械工业出版社,1981.

[15] Durand-Charre M.La microstructure des aciers et des fonts[M].2003,英译本:Microstructure of steels and Cast I-rons,Springer,2004.

[16] Magee CL.The Nucleation of Martensite,in Phase Transformation[M].American Society for Metals,Metals Park,Ohio,1970.

[17] 邓永瑞.马氏体转变理论[M].北京:科学出版社,1993.

[18] Raghavan V,Cohen M.A nucleation model for martensitic transformations in Fe-base alloys[J].Acta Metallargica,1972,20,333 -338.

[19] Pfeiler W.Alloy Physics[M].A Comprehensive Reference,Wiley-VCH Verlag GmbH & Co,2009.

[20] Mills K,Vavis JR,et al.Metals Handbook[M].ASMMetals Park,Ohio,1985.

[21] Morito S,Tanaka H,Konishi R,et al.The morphology and crystallo-graphy of lath martensite in Fe-C alloys[J].Acta Materialia,2003,51:1789 -1799.

[22] Shibata S,Morito S,Furubara T,et al.Morphology and crystallography of martensite in Ferrous Alloys[R].International Conference on Solid-Solid Phase Transformations in Inorganic Materials(PTM2005),2005.

[23] Shibata S,Murakami T,Morito S,et al.The Origin of midrib in lenticular Martensite[J].Mater.Trans,JIM,2008,49(6):1242-1248.

[24]北原弘基,辻伸泰.FE-SEM/EBSP法による钢のマルテンサィト結晶学の解析[J].热处理,2010,50(3):186-193.

[25]戚正风.金属热处理原理[M].北京:机械工业出版社,1987.

[26]徐祖耀.铁基合金马氏体相变热力学[J].材料科学进展,1987,1(4):3 -11.

[27]徐祖耀,张鸿冰,罗守福.Fe-C合金Ms的热力学计算及马氏体相变驱动力[J].金属学报,1984,20(3):A151-161.

[28]朱祖昌,徐祖耀.淬火应力对钢中相变的影响[J].金属热处理学报,1988,9(2):45 -51.

[29]朱祖昌,梁碧玲,陈瑞兴,等.淬火空位对马氏体相变的影响[D].上海:上海交通大学,1964(未发表).

[30] Hsn TY(徐祖耀),Yan Lifab.J.Mater.Sci.1983,18:3213-3218.

[31] Banerjee S,Mnkhopadhyay P.Phase Transformations,Examples from Titanium and Zirconium Alloys[J].Elsevier,2007.

[32] Minfa Lin,Olson GB,Cohen M.Distributed-Activation Kinetics of Hetero-geneous Martensilic Nucleation[J].Metallurgical Transaction A,1992,23A:2987.

[33] Christion JW.The Theory of Transformation in Metal and Alloys,PartⅡ,Pergamon,Elsevier Science Ltd,2002.

[34]早川元造,玉木正纪.マルテンサィト变态温度の试料サイズ依存性より求めた核生成サィト密度[R].日本金属学会讲演概要,(第141回大会):2007,398.

[35] Murty VSR,et al.Structure and properties of engineering materials[M].Tata McGraw-Hill,2003.

[36] Cohen M.Martensitic Nucleation-Revisited[J].Materials Transaction,JIM,1992,33(3):178 -183.

[37] Olson GB,Cohen M.A perspective on martensitic nucleation[J].Ann.Rev.Mater.sic.,1981,11:1 -30.

[38] Ghosh G,Olson GB.Kinetics of F.C.C→B.C.C heterogeneous martensitic nucleation—1.the critical driving force for athermal nucleation[J].Acta Metal.Mater.1994,42(10):3361 -3370.

[39]冯瑞.金属物理学:第一卷 结构与缺陷[M].北京:科学出版社,1998.

[40] Cayron C,Barcelo F,Carlan Y de.The mechanisms of the fcc-bcc martensitic transformation revealed by pole figures[J].Acta materilia,2010,58:1395 -1402.

[41] He Y,Godet S,Jonas J.Observations of the Gibeon metrorite and the inverse Greninger-Troiano orientation relationship[J].J.Appl.Cryst.,2006,39:72 -81.

[42]Wayman CM.马氏体相变晶体学导论[M].陈业新,李箭,译.徐祖耀,校.长沙:中南大学出版社,1989.

[43] Bowles JS,Mackenzie JK.The crystallography of martensite transformation,I,II,III[J].Acta metallurgica,1954(2):129 -148,224 -234.

[44] Wechsler MS,Lieberman DS,Reed TA.On the theory of the formation of martensite[J].Trans.AIME,1953,197:1503-1515.

[45] Bhadeshia HKDH.Martensite in steels[R].http://www.msm.cam.ac.uk/phase-trans/2002/martensite.html.

[46] 徐祖耀.相变原理[M].北京:科学出版社,1988.

[47]王世道.铁基马氏体相变位移机制[J].自然科学进展,1994,4(6):726 -734.

[48]戚正风.固态金属中的扩散与相变[M].北京:机械工业出版社,1998.

[49]许长庆.铁基合金马氏体相变晶体学研究[D].天津:河北工业大学博士学位论文,2007.

[50]许长庆.马氏体相变Bowles-Mackenzie理论的简化计算[J].材料热处理学报,2007,27(3):137 -140.

[51] Kitahara H,Ueda M,Tsuji N,et al.Variant selection of plate martensite in Fe-28.5at%Ni alloy [J].Materials Science Forum,2006,512:117 -122.

[52] Keto M.Invariant-plane and invariant-line deformation criteria and their application to interface crystallography[J].Materials Transactions,JIM,1992,33(2):89 -96.

[53] Totten GE.Steel heat treatment,metallurgy and technology[M].CRC Press,Taylor & Francis Group,2007.

[54]石德轲.材料科学基础[M].2版.北京:机械工业出版社,2003.

[55] Brooks CR.Heat treatment structure and properties of nonferrous alloys[M].American Society for Metals,Metals Park,Ohio,1982.

[56]王心美,岳珠峰,王亚芳,等.NiTi合金的超弹性力学特性及其应用[M].北京:科学出版社,2009.

[57] Smoluchowski R,Mayer JE,Weyl WA.Phase transformations in solids[M].John WIley & Sons,Inc.New York,1951.

[58] Kelly PM.Crystallography of lath martensite in steel[J].Materials Transactions,JIM,1992,33(3):235 -242.

[59] Sandvik BPJ,Wayman CM.Characteristics of lath martensite Part 1,Crystallo-graphic and substructural features[J].Metallurgical Transactions A,1983,14A:809 -822.

[60] Sandvik BPJ,Wayman CM.Characteristics of lath martensite Part 2,The martensite-Austenite interface[J].ibid,823-834.

[61] Sandvik BPJ,Wayman CM.Characteristics of lath martensite Part 3,Some theoreti-cal considerations[J].ibid,835 -844.

[62]顾新福,张文征.马氏体相变晶体学的简易矢量分析方法[J].金属学报,2011,47(2):241-245.

[63] Ross NDH,Crocker AG.A generalized theory of martensite crystallography and its Application to transformations in steels[J].Acta metallurgica,1970,18:405 - 418.

[64] Wakasa K,Wayman CM.The relative orientation between adjacent martensite lathsin an Fe-20Ni-5Mn alloy[J].Scripta metallurgica,1980,14:261 -268.

[65] Acton AF,Bevis M.A generalized martensite crystallography theory[J].Materials Science and Engineering,1969/1970,5:29.

[66] Patterson RL,Wayman CM.The crystallography and growth of partially-twinned Martensite plates in Fe-Ni alloys[J].Acta metallurgica,1966,14:347 -369.

[67] Barsch G R.Landau theory of the displacive phase transformation in gold-cadmium and titanium-Nickel alloys[J].Materials Science Forum,2000,327/328:367 -376.

[68] Ren X,Taniwaki K,Otsuka K,et al.Elastic constants of Ti50Ni30Cu20 alloy prior to martensitic transformation[J].Philosophical Magazine A,1999,79(l):31 -41.

[69] Ren X,Otsuka K.The role of softening in elastic constant C44 in martensitic transformation[J].Scripta Materialia,1998,38(11):1669 -1675.

[70] Ren X,Miura N,Zhang J,et al.A comparative study of elastic constants of Ti-Ni-based alloys prior to martensitic transformation[J].Materials Science and Engineer,2001,A312:196-206.

[71] Shimizu K,Tadaki T.Recent studies on the precise crystal-structural analyses of martansitic transformation[J].Materials Transactions JIM,1992,33(3):165 -177.

[72]宫崎修一,佐久間俊雄,渉谷寿一.形状记忆合金の応用展開[M].シ-エムシ-株式会社,2006.

[73] Otsuka K,Ren X.physical metallurgy of Ti-Ni-based shape memory alloys[J].Progress in Materials Science,205,50(5):511 -678.

[74] Watanabe K.Magnetic properties of Clb-type Mn base compounds[J].Trans.JIM,1976,17:220 -225.

[75] Kudoh V,Tokonami M.Crystal structure of the martensite in Ti-49.2at%Ni alloy analyzed by the single crystal X-ray diffraction method[J].Acta Metall,1985,33(11):2049 -2056.

[76] Kubo H,Shimizu K.Crystal structure of Cu30Au25Zn45 martensite[J].Trans.JIM,1976,17:330 -338.

[77] Schroeder TA,Wayman CM.Pseudoelastic effects in Cu-Zn single crystals[J].Actc Metallurgia,1979,27:405 -417.

[78] Otsuka K,Sakamoto H,Shimizu K.Successive stress-induced martensitic Transfor-mations and associates transformation pseudoelasticity in Cu-Al-Ni alloys[J].Acta Metallurgica,1979,27:585 -601.

[79] Miyazaki S,Otsuka K.Development of shape memory alloys[J].ISIJ International,1989,29(8):353 -377.

[80] Sakamoto H,Shimizu K.Effect of heat treatment on thermally formed martensite phases in mono-crystalline Cu-Al-Ni shape memory alloy[J].ibid,1989,29(5):395 -404.

[81]宫崎修一.Ti-Ni系形状记忆合金の研究と開発経纬[J].まてりあ,2012,51(5):209 -215.

[82] Kagiwara S.Characteristic features of shape memory effects and related trans-formation behavior in Fe-based alloys[J].Materials Science and Engineering,1999,A273/275:67-88.

[83] Otsuka K,Ren X.Martensitic transformations in nonferrous shape memory alloys[J].ibid,1999:89 - 105.

[84] Kikuchi T,Kajiwara S.Shape memory effect and related transformation behavior in an Unausaged Fe-Ni-Co-Ti alloy[J].Mater.Trans.JIM,1993,34(10):907 -918.

[85] Ogawa K,Kajiwara S.HRTEM study of stress-induced transformation structures In an Fe-Mn-Si-Cr-Ni shape memory alloy[J].ibid,1993,34(12):1169 -1176.

[86] Maki T,Furutani.S,Tamura I.Shape memory effect related to thin plate marten-site with large thermal hysteresis in ausaged Fe-Ni-Co-Ti alloy[J].ISIJ International,1989,29(5):438 -445.

[87]徐祖耀.铁基形状记忆合金[J].上海金属,1993,15(2):1-10;15(3):1-8.

[88]杨大智,吴明雄.NiTi形状记忆合金在生物医学领域的应用[M].北京:冶金工业出社,2003.

[89]杨杰,吴月华.形状记忆合金及其应用[M].合肥:中国科技大学出版社,1993.

[90]张春才,苏佳灿.形状记忆材料[M].上海:第二军医大学出版社,2003.

[91]徐祖耀,江伯鸿,杨大智,等,形状记忆材料[M].上海:上海交通大学出版社,2000.

[92] 宫崎修一.Shape memory alloys for biomedical applications[M].Woodhead Publishing Ltd,2009.

[93] 宫崎修一.Shape memory and Superelastic alloys[M].Woodhead Publishing Ltd,2011.

[94] Miyazaki S,Fu YQ,Huang WM.Thin film shape memory alloys[M].Cambridge University Press,2009.

[95] Manasa L.Ferromagnetic shape memory alloys[M].Trans Tech Publication Ltd,2007.

[96] Chen HR.Shape memory alloys:manufacture,properties and application[M].Nova Science publishers Inc.2010.

[97] Shimizu K.Effect of stress and magnetic fields on martensitic transformations[J].Transactions of Japan Institute of metals,1986,27(12):907 -922.

[98] Hara T,Ohba,T,Okumishi E,et al.Structural study of R-phase in Ti-50.23at%Ni And Ti-47.75%Ni-1.50%Fe alloys[J].Materials Transactions,JIM,1997,38(1):11 -17.

[99] Miyazaki S,Otsuka K,Wayman CM.Morphological changes associated with the R-phaseand martensitic transformations in Ti-Ni single crystals[J].ISIJ International,1989,29(5):423-429.

[100]Mazutani U.Hume-Rothery rules for structurally complex alloy phases[M].CRC Press,2011.

[101]ASTM International F2063-05,Standard specification for wrought Nickel-Titan ium shape memory alloys for medical devices and surgical implants[S].2012.

[102]Mabe JH,Calkins FT,Butler GW.Boeing's variable geometry chevron,morphing Aerostructure for jet noise reduction[R].AIAA Adaptive Structures Conference Newport R1 MAY 1st thru May 4th 2006,AAIA 2006 -2142.

[103]Adharapurapu RR,Jiang F,Vecchio KS.Aging effects on hardness and dynamic Compressive behavior of Ti-55Ni(at%)alloy[J].Materials Science and Engineering,2010,A527:665 -1676.

[104]吉见幸春,北春一浩.高Ni(55%Ni)のTi-Ni形状记忆合金[J].金属,2012,82(4):312 -316.

[105]Krauss G,Marder AR.The morphology of martensite in iron alloys[J].Metall.Trans,1971,2:2343 -2357.

[106]Thomas G.Electron microscopy investigations of ferrous martensite[J].ibid,1971,2373 -2385.

[107]Benerjee S,Vijayaker SJ,Krishnan R,Strength of zirconium-titanium marten-Sites and deformation behavior[J].Acta metall.,1978,26:1815 -1831.

[108]任颂赞,陈德华,叶俭.金相分析原理及技术[M].上海:上海科学技术文献出版社,2008.

[109]Ericksen RH,Taggart R,Polonis DH.The martensite transformation in Ti-Cr binary alloys[J].Acta metallurgica,1979,17:553 -564.

[110]Davis R,Flower HM,West DRF.martensitic transformation in Ti-Mo alloys[J].Journal of materials Science,1979,14:712 -722.

[111]Williams,Taggart R,Polonis DH.The morphology and substructure of Ti-Cu martensite[J].Metallurgical Transactions,1970,1:2265 -2270.

[112]Zangvil A,Yamamoto S,Murakami Y.Electron microscopic determination of orientation relationship and habit plane for Ti-Cu martensite[J].Metallurgical Transactions,1973,4:467-475.

[113]Mills K,Davis JH,Destefani JD,et al.Metals Handbook,V.9,9th ed.ASM,Metals Park,Ohio,1985.

[114]Davis JR,Allen P,Lampman SR,et al.Metals Handbook,V.2,10th ed.ASM Internation - al,661 -669,1990.

[115]王奇卓,潘婉仪.重水堆核电站译文集[M].北京:原子能出版社,1983.

[116]Benerjee S,Krishnan R.Martensitic transformation in zirconium-niobium alloys[J].Acta metallurgica,1971,19:1317-1326.

[117]Srivastava D,Mukhopadhyay P,Benerjee S,et al,Morphology and substructure of lath martensites in dilute Zr-Nb alloys[J].Materials Science and Engineering,2000,A288:101-110.

[118]Tewari R,Srivastava D,Dey GK,et al.Microstructural evolution in zirconium Based alloys[J].Journal of Nuclear Materials,2008,383:153 -171.

[119]Neogy S,Srivastava D,Chakravartty JK,et al.Microstructural evolution in Zr-1Nb and Zr-1Nb-1Sn-0.1Fe alloys[J].Metallurgical and Materials Transactions,2007,38A:485-498.

[120]Srivastava D,Madangopal K,Benerjee S,et al.Self accommodation morphology of martensite variants in Zr-2.5wt%Nb alloy[J].Acta Metall.Mater.,1993,41(12):3445 -3454.

[121]Srivastava D,Dey GK,Benerjee S.Selection of lattice invariant shear in dilute Zr-Nb alloy for bcc-hcp martensitic transformation[M].Phase Transformation and Diffusion,Ed.Kale GB,Sundararaman M,Dey CK,et al.Trans.Tech.Publica-tions,Ltd.,2008:139 -146.

[122]Cohen M.The strengthening of steel[J].Transactions of the metallurgical socie-Ty of AIME,1962,224:638 -656,1962.

[123]大村孝仁,津崎兼彰.局所力学特性评価によるマルテンサィトの强化機構解析の新展開[J].铁と鋼,2006,32(5):295-309.

[124]森户茂一,一ノ谷健太,大庭卓也,et al.中炭素鋼ラスマルテンサィトの三次元構造[J].热处理,2013,53(3):97-98.

[125]Krauss G.Martensite in steel:strength and structure[J].Materials Science and Engineering,1999,A273/275:40 -57.

[127]Leslie WC.The physical metallurgy of steels[M].McGraw-Hill Book Company,1981.

[128]Pickering.The optimisation of microstructure in steel and their relationship to mechanical properties,In Hardenability concepts with applications to steel,Eds Doane DV,Kirkaldy JS,179,1978.

[129]椿野晴繁.铁鋼材料の强化因子と劣化因子[J].热处理,1999,39(5):227 -232.

[130]Maropoulos S,Paul JDH,Ridley N.Microstructure-properties relationships in tempered low alloy Cr-Mo-3.5Ni-V steel[J].Materials Science and technology,1993,9:1014-1019.

[131]徐祖耀,李鹏兴.材料科学导论[M].上海:上海科学技术出版社,1986.

[132]Weng Yuqing.Ultra-fine grained steels[M].Metallurgical Industry Press Beijing and Springer-Verlag GemB,Berlin Heidelberg,2009.

[133]Baker TN.Yield,flow,and Fracture of polycrystals[M].Applied Science Publishers Ltd,1983.

[134]Norstrom LA.On the yield strength of quenched low-carbon lath martensite[J].Scandinavian Journal of Metallurgy,1976,5:159 -165.

[135]Young CH,Bhadeshia HKDH.Strength of mixture of bainite and martensite[J].Materials Science and technology,1994,10:209.

[136]Kelly A,Nicholson RB.Strengthening methods in crystals[M].Elsevier Publish-Ing Company Ltd.,1971.

[137]McMahon JA,Thmos G.Development of economic,tough,ultra-high-strength Fe-Cr-C Steels[M].Microstructure and design of steels,1973.

[138]Chilton JM,Kelly PM.The strength of ferrous martensite[J].Acta Metallurgica,1968,16:637 -656.

[139]Kelly PM,Pollard G.The movement of slip dislocation in internally twinned Martensite[J].Acta Metallurgica,1969,17:1005 -1008.

[140]Huang D H,Thmos G.Structure and mechanical properties of tempered martensite and lower bainite in Fe-Ni-Mn-C steels[J].Metallurgical Transactions,1971,2:1587 -1598.

[141]Sleeswyk AW,Verbraak GA.Incorporation of dislocation in mechanical twins-1[J].Acta metallurgica,1961,9:917 -927.

[142]Klem GJ,Miner RE,Hultgren FA,et al.Internal friction in ferrous martensites[J].Metallurgical Transactions A,1976,7A:839 -849,1976.

[143]Sleeswyk AW.Twinning and the origin of cleavage nuclei in α-iron[J].Metallurgical Transactions,1962,10:803 -812.

[144]Zackay VF.High-strength Materials[M].John Wiley &Sons,Inc.,1965.