ENERGY-SAVING MATCHING STRATEGY AND EXPERIMENTAL STUDY OF PUMPING SYSTEM FOR TRUCK-MOUNTED CONCRETE PUMP

2013-12-02LiAimin李艾民ChenFei陈飞

LiAimin(李艾民),Chen Fei(陈飞)

(School of Mechanical and Electrical Engineering,China University of Mining and Technology,Xuzhou,221008,P.R.China)

INTRODUCTION

In recent years,truck-mounted concrete pumps have undergone considerable developments and been widely used in constructions.The pumping system outputs the concrete through several actions,and delivers it to a certain place by adjusting the conveying boom[1],as shown in Fig.1.

Fig.1 Construction of truck-mounted concrete pump

The power source of this kind of truck is a diesel engine.And the execution parts are pumping system,boom system and legs.As the main part of the truck,pumping system occupies most resources of the engine to output concrete from a hopper along apipeline.The pumping speed is determined by the displacement of the main pump and the engine speed,meanwhile the carrying capacity is determined by the displacement of the main pump and the engine torque[2-3].

When the workload is fixed,the energy-saving of truck-mounted concrete pump means to reduce the fuel consumption as much as possible,that is to say:The power consumption is the lowest while the engine meets the load demand under different working conditions[4].

Aiming at the high fuel consumption of engine and use-cost in working,the matching relationship of the engine and the main pump of the pumping system is analyzed.A testing method is established to investigate fuel consumption and system performance when input value changes,and the experimental data are also analyzed to gain the energy-saving matching strategy.Therefore,a conclusion is drawn.The research results can be used as an important reference for the en-ergy-saving matching strategy research of truckmounted concrete pump.

1 ENERGY-SAVING MATCHING STRATEGY BETWEEN ENGINE AND MAIN HYDRAULIC PUMP

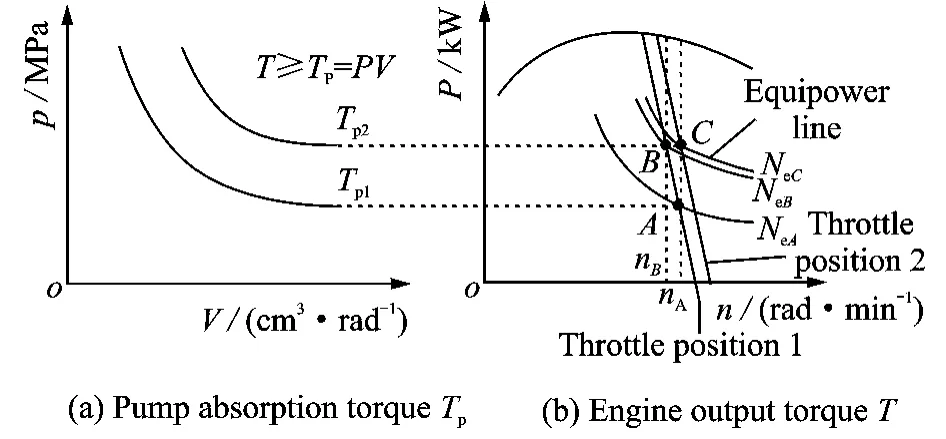

Fig.2shows the matching scheme diagram of engine and pump.In Fig.2,pis pumping pressure,Vpump displacement,Pabsorption power and nengine speed.In initial state,when the load is fixed,the engine works at point Aof throttle position 1.At this moment,nAis the engine speed,NeAthe output power,Tp1the pump absorption torque and the absorption power NpA=2πnATp1.When the load increases,the pumping pressure needs to be increased correspondingly,otherwise,the supervisor will adjust the fuel delivery per cycle to make the engine work at point B of throttle position 1to increase the output torque[5-6],at this moment,nB(nB<nA)is the engine speed,NeB(NeB>NeA)the output power,Tp2(Tp2>Tp1)the pump absorption torque,the absorption power NpB=2πnBTp2,and the speed differenceΔn=nA-nBwhen the load increases,which means the engine speed is not stable.

Fig.2 Matching scheme diagram of engine and pump

To meet the increasing demands of pumping load and stabilize the engine speed,two methods is taken as follows:

(1)Adjust the throttle position of engine

Adjust the throttle from position 1to position 2,then the working point of engine will be changed from Ato C correspondingly,and the output torque is increased.Here nAis the engine speed,NeC(NeC>NeB>NeA)the output torque,Tp2the pump absorption torque and c the absorption power.During this process,the engine speed stays stable while the load increase is met by increasing injection quantity of fuel to increase the output power[7].

(2)Decrease the displacement of pump

Keep the throttle at position 1,to make the engine speed stable and increase the pumping pressure,the displacement of the pump needs to be decreased to increase the carrying capacity(pressure).During this process,the absorption torque of pump remains unchanged,the engine works at A,and the speed is still nAwhile the output power is still NeA.

According to the analysis of the working performance of engine,it is clear that when the throttle position is arbitrary,a certain load corresponds to a maximum torque point and a most energy-saving point.When the engine and the pump matches,the working point is often near the two points,which allows the system to meet higher overload performance and gain better economical efficiency[8-9].

When the pumping system works,the pressure of hydraulic system is determined by the load.Therefore,when the load changes,the system pressure and the engine output torque will also change which is shown in the working characteristic curve in Fig.2.During this process,if the torque allowance is not enough,the working point will vary in a greater range which may cause the speed drop of engine.So when considering the match of engine and pump,the torque matching should be firstly involved,and then the power match[10-11].

2 EXPERIMENTAL SYSTEM

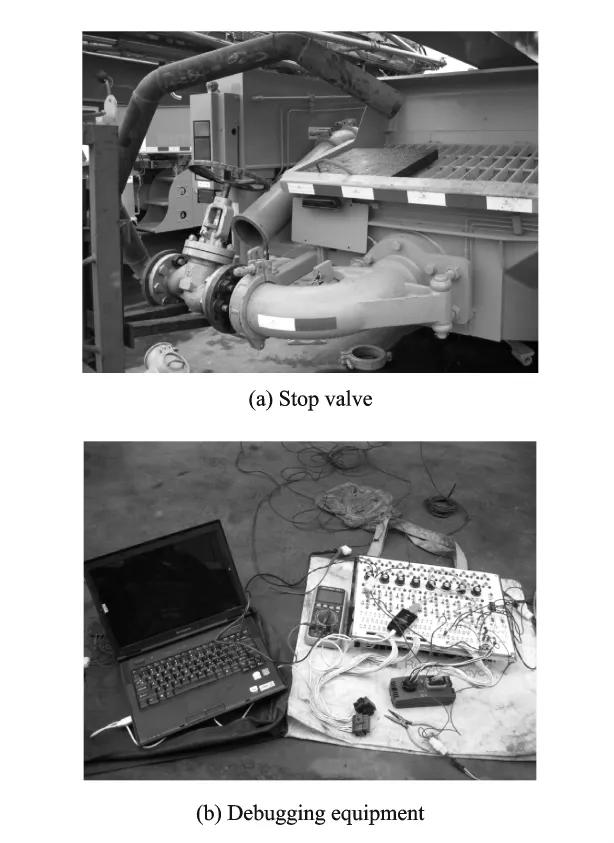

In this experiment,water is used for pumping instead of concrete.A stop valve(Fig.3(a))is installed at the outlet of pumping system to distribute valve,with which different load is simulated by adjusting the open size;By adjusting the control voltage of throttle,we can control the engine speed which can be gained from cotroller area network(CAN)bus directly;The displacement of the main hydraulic pump can be adjusted by controlling its input current.

Fig.3 Experimental equipments

According to certain experiments,fuel consumption of different working conditions within 2 minutes will be gained.Then adjust two input values by debugging equipment(Fig.3(b)):Control the voltage of the engine throttle and control current of the main hydraulic pump to detect the speed drop,the fuel consumption of the engine and the pressure of the hydraulic system,then analyze it.

3 EXPERIMENTAL RESULT AND DISCUSSION

3.1 Curve of engine fuel consumption

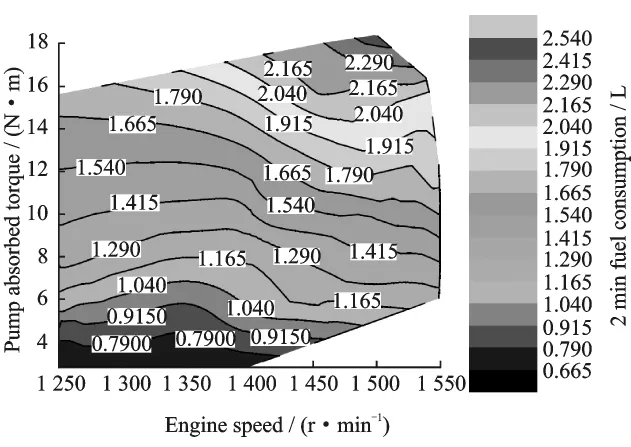

According to the experimental results,fuel consumption of different working conditions within 2min is gained,since the engine speed ranges within 1 250—1 550r/min,and the curve of engine fuel consumption is plotted,as shown in Fig.2(b).The abscissa is the engine speed(r/min);The ordinate is the product of equal value of pump absorption torque(the average pressure of system,MPa)and percentage of pump displacement(%).

When the pump works,if the engine speed is within the allowed limits,the following laws can be gotten by analyzing Fig.4:

(1)The general law is that when the engine speed is fixed,the lower the load is,the less the fuel will be consumed;when the load is fixed,fuel consumption of low engine speed will be smaller than that of high speed.

(2)Under all working conditions,the lowest fuel consumption point occurs when the engine speed is around 1 350r/min,but the pumping speed is slow relatively.

(3)For the same condition,the lowest fuel consumption point occurs when the engine speed is around 1 450r/min,and the pumping speed is fast relatively.

Fig.4 Curve of fuel consumption

3.2 Input value adjustment

Premise:The open size of the stop valve is fixed.

(1)Adjus the control current of the main hydraulic pump displacement

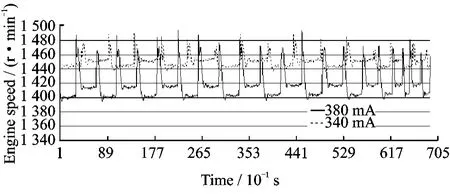

Initial input:Target engine speed is 1 500 r/min(aposition of throttle corresponding to a target speed),the control current of pump is 380mA (the corresponding displacement is 86%).The control voltage of throttle position is in proportion to the target engine speed while the control current is in proportion to the pump displacement.Keep the voltage of throttle and ad-just the control current of pump to 340mA(the corresponding displacement is 57%),the changes of the engine speed,the main system pressure and the fuel consumption are shown in Figs.5-7.

When the control current of pump is 380 mA,the engine speed drop is within 100r/min and the highest system pressure is about 25MPa;when the control current is 340mA,the speed drop is below 50r/min and the highest system pressure is 17MPa.That is to say:By decreasing the displacement of the main pump,the range of speed drop is smaller,the system pressure and the fuel consumption are lower.

Fig.5 Change of engine speed I

Define the amount of work for a liter of fuel as the result of the product of engine average speed and pump displacement percentage divided by the fuel consumption.By calculating the original data from Figs.5-7,it is clear that the amount of work after adjusting for a liter of fuel is 1.103times larger than before,which means the adjustment does well in energy saving.

(2)Adjust the control voltage of throttle

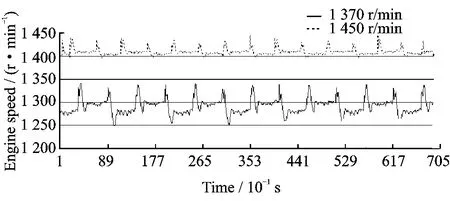

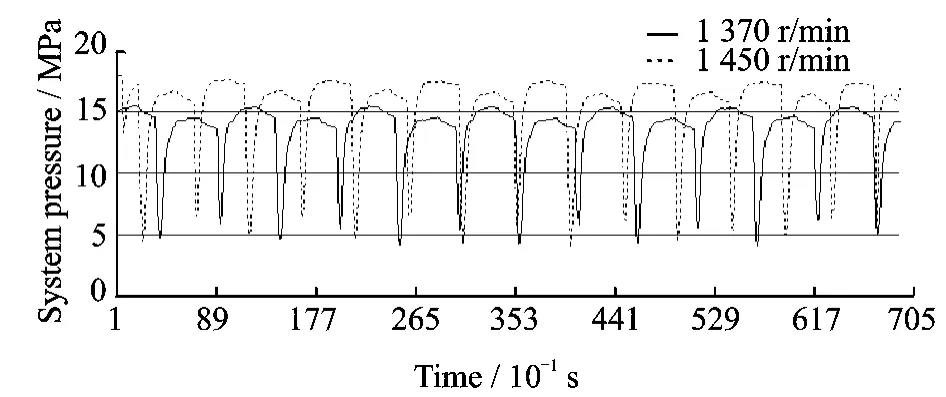

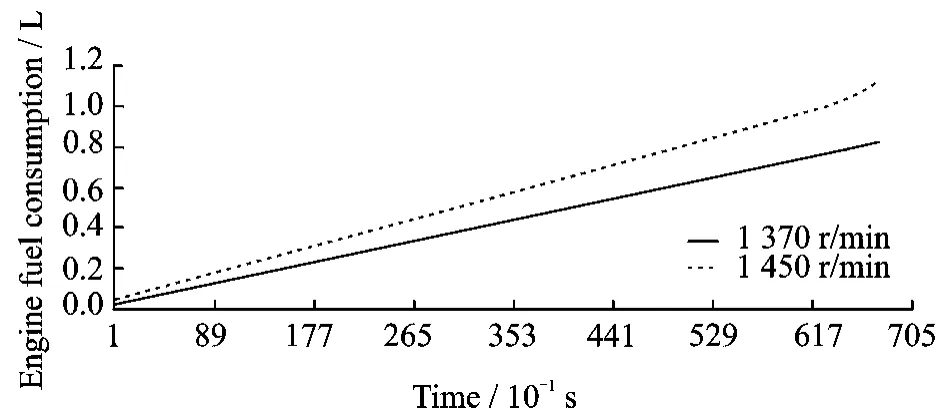

Initial input:The control current of the main pump is 350mA(the corresponding displacement is 64%),the target engine speed is 1 370r/min.Keep the current and adjust the control voltage of throttle to maintain the engine speed at 1 450r/min,the changes of the engine speed,the main system pressure and the fuel consumption are shown in Figs.8-10.

When the target engine speed is 1 370r/min,the drop is below 100r/min and the highest system pressure is about 15.5MPa;when the target engine speed is 1 450r/min,the drop is below 50r/min and the highest system pressure is 18 MPa.That is to say:By increasing the control voltage of throttle,the range of speed drop is smaller,but the system pressure,the fuel consumption and the pumping speed are higher.

By calculating the original data from Figs.8-10,it is clear that the amount of work before the adjusting for a liter of fuel is 1.261times larger than after,which means the adjustment takes more energy because of the increase of pumping speed which causes the increase of system pressure and fuel consumption.

Fig.8 Change of engine speed II

Fig.9 Change of engine speed II

Fig.10 Fuel consumption II

4 CONCLUSIONS

The energy-saving matching strategy of engine and main hydraulic pump is proposed as the engine speed can be stabilized by adjusting the control voltage of throttle and the control current of main pump to meet the load variation.

An experiment is designed and implemented to measure the fuel consumption of truck-mounted concrete pump under different working conditions,and also to analyze the system performance and energy-saving effect by changing input values.

According to the experimental results,the following conclusions can be drawn:

(1)In the same throttle position,as increasing the load,the speed drop and the fuel consumption increase; Under the same pumping load,as decreasing the control voltage of throttle(i.e.,decreasing the target engine speed),the speed drop and the fuel consumption decrease.

(2)The level of the engine speed drops can be taken into account whether the pumping system matches the load or not and as the reference for fuel consumption.More rotations which the engine speed drops indicate that the pumping system cannot match the load,thus the fuel consumption increases.

(3)If the engine rational speed drop is relatively high,taking energy saving into consideration and decreasing the displacement of the pump can increase the carrying capacity,stabilize the engine speed and reduce the fuel consumption with the same workload.Although the engine speed can be stabilized by increasing the control voltage of throttle,it can increase the fuel con-sumption which goes against energy saving.

[1] Ghielmetti C,Giberti H,Resta F,et al.A test rig and numerical model for investigating truck mounted concrete pumps[J].Automation in Construction,2011,20(8):1133-1142.

[2] Li Zhongxing,Wang Shenxu,Jiang Hong,et al.Research on power-matching of energy-saving for power system of the concrete pump truck[J].Machinery Design & Manufacture,2011(06):76-78.(in Chinese)

[3] Jie Linfeng,Li Yue,Liu Hongqing,et al.An energy saving control strategy for pumping operation of concrete pump trucks[J].Construction Machinery and Equipment,2010,41(12):20-23.(in Chinese)

[4] Yang Yunzi.Modeling of fuel consumption and optimization of operating conditions of concrete pump truck[D].Changsha:Changsha University of Science& Technology,2009.(in Chinese)

[5] Liu Bo,He Qinghua,Yang Zhongjiong.Load limit sensing control of power matching for engine-variable pump system[J].China Mechanical Engineering,2007,18(4):500-503.(in Chinese)

[6] He Weixing,Chen Xiaoping,Lu Senlin,et al.Realization of energy-saving control system for hydraulic excavator[J].China Mechanical Engineering,2008,19(21):2585-2588.(in Chinese)

[7] Xu Hongping.Energy-saving technology based on the graded power control on hydraulic excavator[J].Journal of Zhejiang University of Technology,2002,30(4):328-31.(in Chinese)

[8] Hao Pen.Research on power match and energy saving control of hydraulic excavator driving system[D].Changsha:Central South University,2008.(in Chinese)

[9] Tang Zhenzhou.Reasonable matching between engines and hydraulic pumps for hydraulic excavators[J].Journal of Changchun Instiute of Technology:Social Science Edition,2008,9(4):35-38.(in Chinese)

[10]Li Rongxiang.The matching calculation of pump and prime mover in closed hydraulic system[J].Mining Research and Development,2005,25(03):51-52.(in Chinese)

[11]Wang Yuexing.Study on the energy-saving control system in stationary concrete pump[D].Jilin,China:Jilin University,2005.(in Chinese)

猜你喜欢

杂志排行

Transactions of Nanjing University of Aeronautics and Astronautics的其它文章

- AIRCRAFT CONCEPT EVALUATION AND EFFECTIVENESS-BASED DECISION-MAKING

- SPH-BASED NUMERICAL ANALYSIS FOR GRANULAR MATERIAL MODEL OF SAND AND REGOLITH

- EXPERIMENTAL INVESTIGATION ON R134AAIRBORNE VAPOR-COMPRESSION REFRIGERATION SYSTEM

- PREDICTION OF SURFACE ROUGHNESS FOR END MILLING TITANIUM ALLOY USING MODIFIED PARTICLE SWARM OPTIMIZATION LS-SVM

- SOFT IMAGE SEGMENTATION BASED ON CENTER-FREE FUZZY CLUSTERING

- SPATIAL REGULARIZATION OF CANONICAL CORRELATION ANALYSIS FOR LOW-RESOLUTION FACE RECOGNITION