PARAMETRIC MODELING OF COMPONENT LIBRARY FOR LANDING GEAR BASED ON CATIA/CAA

2013-12-02RenJie任杰NieHong聂宏WeiXiaohui魏小辉FuYongfeng傅涌峰

Ren Jie(任杰),Nie Hong(聂宏),Wei Xiaohui(魏小辉),Fu Yongfeng(傅涌峰)

(College of Aerospace Engineering,Nanjing University of Aeronautics and Astronautics,Nanjing,210016,P.R.China)

INTRODUCTION

Landing gear is one of the most crucial components of aircraft to support weight and absorb stroke energy during the process of parking,taxiing,taking off and landing.It has been described as″the essential intermediary between the aeroplane and the catastrophe″[1].The functions of landing gear consist of many important aspects for the flying safety,including supporting the dynamic and static load,absorbing and dissipating the energy generated in the process of landing and taxing on runway,alleviating vibration,depressing landing load and maintaining the flight more comfortable[2].

Traditional design process of landing gear consists of the following steps:Conceptual design phase,preliminary design phase,detail design phase,pre-production prototype machine and pro-totype machine flight test.In the conceptual design phase,parameterization technology is used to create the three-dimensional shape model of landing gear.For example,Li Haibin,et al presented aparametric modeling method which adopted computer aided three-dimensional interface application(CATIA)as the development platform[3].Shi Yongsheng,et al described the modern intelligent landing gear design and analysis in expert system[4].As a result,definitions of the key parameters of landing gear components can be accessed through the interface implemented by Visusal Basic(VB),which is involved in the development of CATIA.And the expert system theory can also help the user to deal with the cases related to landing gear design.

Most of the developments of CATIA are based on VB application (VBA)because it is a relatively easy but powerful tool[5].Other meth-ods like Script language,Java,are not supported by VBA environment and may not ever be.Despite the difficulty of software development,C++is the most supported CAA/rapid application development enviroment(RADE)language with the advantages of object oriented power.Their different development levels are shown in Table 1.

Table 1 Object oriented option overview

Accordingly, based on the CAA/RADE method,which is more effective to develop CATIA to implement the functions of parametric modeling,a method to classify the parts and components of landing gear is presented based on structure and functions.Then the development technology for component library and related engineering knowledge and algorithm are described.In this redeveloped system,users can complete the parametric modeling by inputting the exact value of the parts which have been defined in the phase of construction of the database.Knowledge of the design and completion of this function have been raised in terms of CAA/RADE and is introduced.Presently,some resolutions have been presented.The system utilizes oracle database to manage the directories of every parts and components of landing gear,the geometry parameters and property parameters and the engineering knowledge and algorithms.

1 CLASSIFICATION OF LANDING GEAR PARTS AND PRODUCTS AND IMPLEMENTATION IN DATABASE

Research on the library of landing gear compo-nents and the integrated design system is an instructive work involving particular structures of landing gear system according to the entire requirements of digital engineering.It is also the curial contents of the researches on component library of aircraft manufacture digital engineering related to the integrated model-correlated system.The components are divided into four levels according to the aircraft design phase:Conceptual design phase,drafts design phase,assembling design phase and detail design phase.The components of first level are used in the conceptual design process,which is also the model of the entire parametric modeling.Components in the other levels,on the basis of different requirements in different phases,are used for manufacturing parametric products.The first level components,which consist of many aspects of properties and structure characteristics,are constructed according to the criteria of three-dimension parametric modeling which is regarded as the typical components of the special design field.The filtered properties and geometry parameters are preserved accompany with the model after definition or edit.The geometry parameters can accomplish the construction of model.Properties and the parameters edited to describe the function and performance attributions provide base data for the function construction and prototype construction in simulation analysis.The parametric prototype utilizes the analysis in the following fields:Motion mechanism,drop test,shimmy,fullscale model taxing,turning,steering system,and braking.Primary structures,estimating dimensions and kinematic pair of key components,can be determined.The components data conserved in the database are described in seven different tables,as shown partially in Tables 2-4.

Tables 2-3are connected by PRODUCT-ID and SUBPART-ID as foreign-key,which leads to a rapid query for SUBPART-ID through PRODUCT-ID.

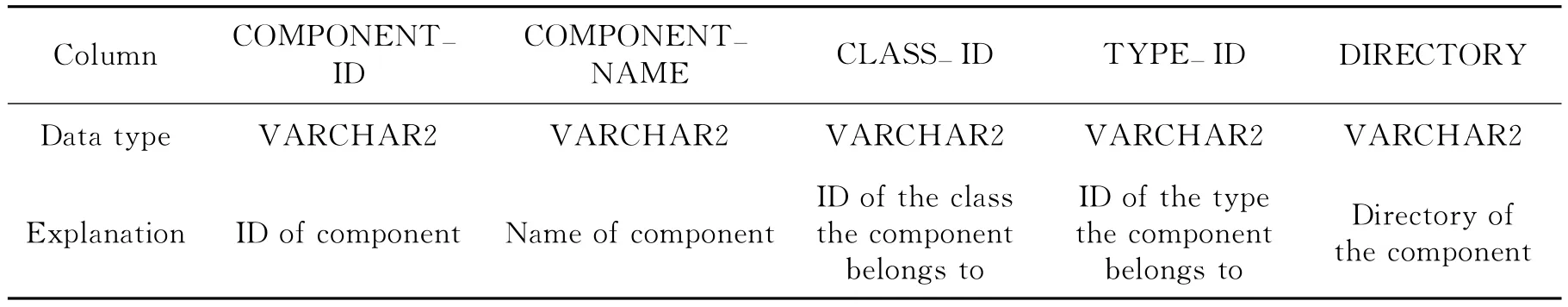

Table 4is used to save the information of the parts defined by user directly,and it is connected with the tables of properties and geometry parameters by column COMPONENT-ID. Considering the products′special parts on its own,Tables 3-4do not have the foreign-key constraints.

Table 2 Structure of landing gear product

Table 3 Structure of part belong to landing gear product

Table 4 Structure of landing gear part defined directly

2 COMPONENT LIBRARY FOR LANDING GEAR BASED ON CATIA/CAA

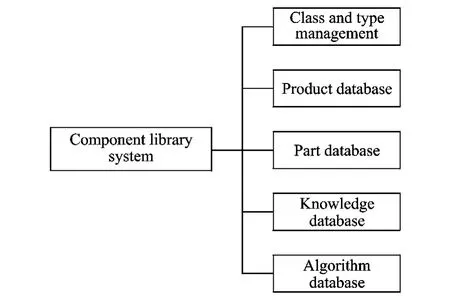

Based on the platform of CATIA/CAA,three databases are constructed for component library system by utilizing Oracle 10g:Component library,knowledge library and integrated system library.And two subsystems,component library system and integrated system,are also implemented.

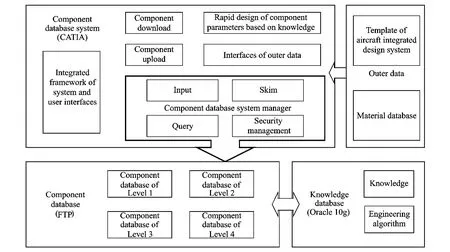

Fig.1shows that the structures and the functions of the component library system.It primarily includes three sections:Component library system,component library and knowledge library.The system should be operated by integrated framework of system and user interfaces.

Fig.1 Complete structure of system

CATIA V5,with unique and powerful functions on surface molding,reconstruction and comprehensive combination analysis,are widely used in the aircraft and the automobile industry[6].CATIA V5is developed based on object oriented options CAA/RADE,which provides access to more functions in most areas of CATIA.CAA is a significant method to reach the interactive,integrated and user-definition functions.Users can expand CATIA by developing CAA components.However,CAA/RADE′s data structure is different from that of Visual C++.It has three basic elements:Workspace,framework,module[7].A framework has no counterpart in C+ +,but is similar to a project.It is very convenient for users.

The component library system consists of two key libraries:Part library and product libraries,implemented by Oracle database.

There are two main methods to develop parametric modeling design within CATIA V5:Using the knowledge expert module and developing the part and the product libraries based on CAA.Considering the flexible parameters of landing gear and different requirements and optimization results,parameters,especially the geometry ones,need to be changed frequently.So it is not convenient to use catalog to manage parts and products.Utilizing CATIA/CAA can meet complex requirements for the geometry parameters as well as the properties of the parts and assembly products.Therefore,the component library system is constructed according to the characteristics of landing gear components.Fig.2shows the primary modules.The class and type management are partly shown in Fig.3.

The special steps are divided into four sections illustrated in the following paragraph.The first step is the components entering.Also,connecting to Oracle database is implemented by ActiveX data objects(ADO)[8]firstly.

Fig.2 Component library system

Fig.3 Classification of components of landing gear

Construction of components is the primary stage of the first section.Mechanical products are assembled by components and parts with hierarchical relationships.A component usually con-sists of some parts whose structure tree can reflect the relationships.The vertexes in the tree represent the ownership between components and parts.According to the structure tree,it can be seen that the components of the CATPart type are insert without constraints and share the same coordinate system[9].The position relationships are guaranteed by relative coordinate system configured by designer.However,due to the type of product,every part has independent coordinate system,and constraints can define the relative position between the parts.When the size of any part changes,the whole product will change to keep the assemble relationship unchanged.This makes product and part,as the type,become the factor to design the product library respectively.

Fig.4 Upload products of certain landing gear

Fig.4shows the dialog box of uploading a product,and the parts that constitute the product are uploaded to FTP at the same time.

The geometry parameters and properties,materials,for instance,are encapsulated within the part uploaded to the library.For parametric driving,by utilizing the relationship of parameters created by knowledge model and part′s geometry measurement,geometry features are changed with the change of parameters.The remarks and the properties are also displayed during the process of downloading the part.As shown in Tables 2-3,the database provides instance information of the parts or the parts which the product concludes.

During the process of downloading,the system finds out part ID number in the database that matches the part,and then reads the tables saved in Oracle database which includs the parameters and properties of the downloaded parts.After downloading the part,the geometry are edited and altered before instantiation.This step can improve the efficiency of designing the part apparently,especially for those parts with similar characteristics and structures. Fig.5shows the process of downloading apart.The geometry parameters and properties are displayed,which contributes to the rapid design of landing gear.The following discussion explains the main method of catching the geometry parameters to alter the part features.

Fig.5 Detail dialog of part in downloading process

Through the editor shown in Fig.6,the geometry can be modified by the clients whenever the part is used.By referring to the notes of the parts,clients can realize the special characteristics of different parts and make proper decision.

Fig.6 Geometry parameter renewing

In Fig.6,the geometry parameters represent the values of a round platform;the primary values are two lengths and two thicknesses.According to the verified model values,renewed model can be updated.The key program codes are implemented mainly by the following two methods:Method GetRootContainer()and method GetAll-Children()[10].GetRootContainer()obtains Part Container which belongs to a document.Then according to the pointer which specially indicates a container,the feature handle of parts can be obtained.Method GetAllChildren ()belongs to CATIParmPublisher.Model features can be obtained by this method.Then all the features are stored into pointer piProductParmSpecObject.

3 APPLICATION EXAMPLE

Fig.7shows the example of utilizing component library.Firstly,the client needs to define the relative parts to meet the optional requirements in the conceptual phase.On the basis of the design knowledge,properties and the modifiable parts,the client can download the required parts.Downloading parts means to download the parts and its information stored in the database,especially its geometry and non-geometric parameter information.After the parts downloaded,dialog box of geometric parameters will be kept flickering on desktop for a while.According to the required size,default size of the parts can be modified.Assembly downloading is a similar process but there is no parametric change.

Fig.7 Application instance of component library system

Part uploading is one of the most important steps in the process of parametric component library.It needs a series of user-defined data when it has been uploaded.Defined data are stored in an Oracle database with relative parts.Assembly uploading is different from part uploading,although there is no need for defining geometric parameters.The subparts of the assembly need to be captured by the system,and then the list of the subparts is concluded.Finally,the assembly can be stored in the database with part information.As Fig.7shows,in addition to filling in the assembly name,assembly ID and description,the software traverses the assembly sub-components,including sub-level assemblies and parts.In the dialog box shown below sub-parts index,all the assembly is shown as the parts of their own.It means that the file types are CATPart.Part Number and the local path are also shown.At last,the assembly is uploaded to FTP which has been installed and maintained by database administrator.

Under this circumstance,the product can be downloaded in the future.Relative parameters can be redefined if needed.The notes can be the instructive guides in the process of design.

4 CONCLUSION

An effective geometry aided component library based on CAA/ADO are implemented,and the reusability of the parts and the products in this system can significantly impact the parametric modeling involved in rapid design system.Constructing the parametric geometry feature is not an simple process since it usually involves finding the accurate parameters which needs to be altered before instantiation. Experiences and knowledge accumulated for years can be utilized and the primary clients can easily learn the method in conceptual phase of landing gear relying on the knowledge in database and form the foundation of a new rapid parametric design system.More importantly,it can be seamlessly integrated with computer aided engineering.An approach is presented to implement the function of dimension driving which is seldom applied in the past in redevelopment systems.The significance is that it makes more progress in the field of developing CATIA by using CATIA/CAA instead of VB/Automation which has been used normally before.The proposed method improves the level of user definition of parameters,especially when applying the two key methods,method GetRoot-Container ()and method GetAllChildren ().Compared to the preceding approaches,the presented method provides effective reference for the development of full parametrical modeling.

The main contribution of our work is to pres-ent a library system which guides the clients to construct or invoke the parts and the products of landing gear.It is believed that the improvement of automotive degree of software can bring about significant economic benefit and also can networking.It is hoped that the interfaces with other simulation software can be accomplished so as to achieve the integrated computation and simulation in a short period of time.

[1] Currey N S.Aircraft landing gear design:Principles and practices,AIAA education series[M].Washington:American Institute of Aeronautics and Astronautics Inc,1988.

[2] Cao Rongsheng.Establishing of aircraft landing gear system and simulation analysis of landing capacity[D].Harbin:Harbin Engineering University,2007.(in Chinese).

[3] Li Haibin,Yu Yinting,Sun Yufeng.Study of parametric modeling of landing gear parts[J].Science Technology and Engineering,2010,10(4):1049-1053.(in Chinese)

[4] Shi Yongsheng,Song Yunxue.Study of aircraft landing gear system[J].Aircraft Design,1999,12(4):6-9.(in Chinese)

[5] Wu Gang,Zhu Shihe,Guo Jinjin.Development technology of parametric design system ofmechanical part based on CATIA ActiveX automation[J].Journal of Tianjin Institute of Technology,2003,19(4):60-62.(in Chinese)

[6] Hu Tianyuan,Yu Xiongqin.A parametric modeling of flying-wing configuration using API in CATIA[J].Aircraft Design,2007,27(6):10-13.(in Chinese)

[7] He Chaoliang,Du Tingna,Zhang Chao.The secondary development of CAA-based CATIA[J].Computer Applications,2006,25(9):37-40.(in Chinese)

[8] Sa Shixuan,Wang Shan.Database system generality[M].Third Edition.Beijing: Higher Education Press,2001.

[9] Deng Donglai,Zhou Laishui,Chen Gong,et al.Design and implementation of CATIA-Based construction tool for component library[J].Journal of South China University of Technology,2007,35(1):138-141.

[10]Dassault Systemes.CAA V5encyclopaedia[M].Paris:Dassault Systemes,2000.

杂志排行

Transactions of Nanjing University of Aeronautics and Astronautics的其它文章

- CALCULATION FOR KERNEL OF INTERVAL GREY NUMBER BASED ON BARYCENTER APPROACH

- MULTI-OBJECTIVE PROGRAMMING FOR AIRPORT GATE REASSIGNMENT

- FLEXURAL CAPACITY OF RC BEAM STRENGTHENED WITH PRESTRESSED C/AFRP SHEETS

- ACTIVE VIBRATION CONTROL OF TWO-BEAM STRUCTURES

- OUTPUT MAXIMIZATION CONTROL FOR VSCF WIND ENERGY CONVERSION SYSTEM USING EXTREMUM CONTROL STRATEGY

- MINIMUM ATTRIBUTE CO-REDUCTION ALGORITHM BASED ON MULTILEVEL EVOLUTIONARY TREE WITH SELF-ADAPTIVE SUBPOPULATIONS