FLEXURAL CAPACITY OF RC BEAM STRENGTHENED WITH PRESTRESSED C/AFRP SHEETS

2013-12-02WangXiaomeng王小萌ZhouChuwei周储伟AiJun艾军ZhangJian张剑WangDong王东

WangXiaomeng(王小萌),Zhou Chuwei(周储伟),Ai Jun(艾军) Zhang Jian(张剑),Wang Dong(王东)

(1.College of Aerospace Engineering,Nanjing University of Aeronautics and Astronautics,Nanjing,210016,P.R.China;2.State Key Laboratory of Mechanics and Control of Mechanical Structures,Nanjing University of Aeronautics and Astronautics,Nanjing,210016,P.R.China;3.Lianyungang Highway Management Office,Lianyungang,222000,P.R.China)

INTRODUCTION

The strengthening method with fiber reinforced polymer(FRP)has been widely used in recent years because of its good durability and high strength.It is a new and effective strengthening method.Researches showed that the prestressed FRP strengthening technology could improve the performance of structure and inhibit the crack extension in a significantly effective way[1-3].

Carbon fiber reinforced polymer(CFRP)is the most widely-used fiber reinforced polymer material.The tensile strength and elastic module of carbon fiber are higher than those of any other fibers.Besides,it is more stable and durable.However,the elongation of CFRP is low and the price is high.To solve this problem,a method for hybrid fiber is proposed.

Both glass fiber and aramid fiber have low price and high elongation.The difference between them is obvious.Tensile strength and elastic module of glass fiber are relatively low,so glass fiber is not suitable for long-term usage.The elastic module and heat resistance of aramid fiber are high.Aramid fiber can maintain high strength even at high temperature.

In order to increase the plasticity of the strengthened structure and reduce cost,FRP sheets can be made from carbon fiber and aramid fiber,which is also called hybrid fiber sheets.Intraply hybrid C/AFRP sheet is better than single carbon sheet or simple interlaminar hybrid sheet.This is mainly because fracture of fiber is a gradually developing process.There must be some ubtle fracture,defects and other weak links in fiber materials.When the fibers are in tension,FRP begins to break from its weak links.As a result,other fibers will have more stress.It will continue like this until all fibers break up.As to intraply hybrid C/AFRP,the additional load that caused by breakage of carbon fiber with low elongation can be undertaken by aramid fiber which has higher elongation.Therefore the micro-crack caused by breakage of carbon fiber is inhibited.As a result,the average fracture strain of FRP is increased[4].

In order to meet the specific needs of different projects,the ratio of hybrid fiber should be adjusted.The existing tests indicated that the prestressed FRP strengthening technology was able to meet practical construction requirements.The method for using prestressed intraply hybrid C/AFRP in strengthening technology can greatly improve the structural properties and inhibit the extension of crack,but the working mechanism of the hybrid sheets also need to be studied through a lot experiments.Five beams have been tested to analyze the relationship between the flexural capacity and both the level of prestress and the ratio of the components of C/AFRP.

1 TEST CONTENT

1.1 Design of test concrete beam and materials

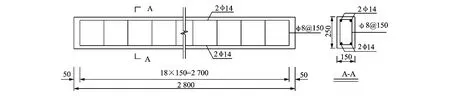

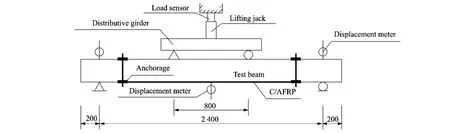

The size of test beam is designed as 150mm×250mm×2 800mm(Fig.1).According to the Standard of Reinforcement Design for Concrete Structure(GB50367—2006)[5],the strength grade of reinforced concrete structure should not be less than C15,and the strength grade of concrete in this test is C40.

According to the Standard of Test Method of Ordinary Concrete Mechanics Performance(JB/T 50081—2002)[6],the calculation result of compressive strength of cube concrete is fcu,k=45.94MPa,which is slightly larger than C45.The steel bar is HRB335.The diameter of longitudinal steel bar is 14mm.The stirrup is HPB235.

Fig.1 Test beam(unit:mm)

1.2 Test materials and strengthening scheme

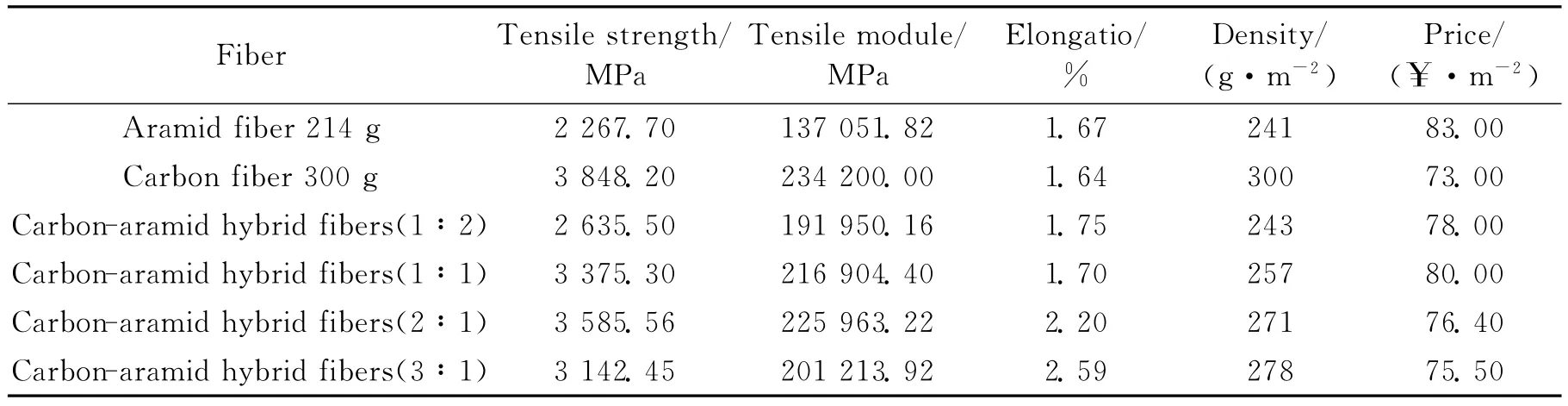

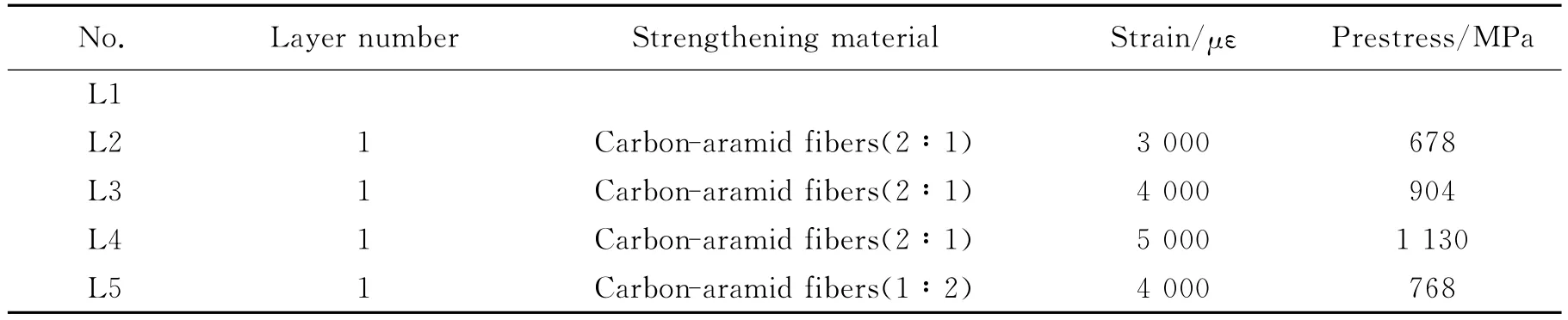

The C/AFRP used in this test is produced by Nanjing Haituo Co.Ltd. Considering the strength,elongation and price(according to Table 1),carbon-aramid fibers whose hybrid ratio is 2∶1and 1∶2are chosen as test material.The strengthening scheme is in Table 2.

Table 1 Performance comparison of carbon-aramid fibers

Table 2 Strengthening scheme

1.3 Test scheme

The whole tests include material performance test,pre-splitting test of RC beam,tension and anchor of C/AFRP sheets and static load test.

Because the main research object is old bridge that needs to be strengthened,all test beams are presplited under step load before they are strengthened.The pre-split load is 26—33kN(60%—70%of ultimate load).

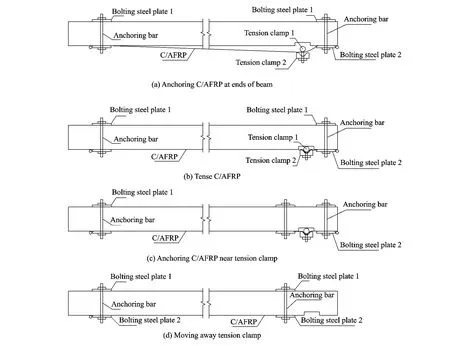

The method for strengthening is″anchoring first,post-tensioning″(Fig.2).Anchor C/AFRP at the ends of the beam with bolting steel plates(Fig.3),and spread epoxy glue on FRP.Then put the tension clamp near the end of FRP(Fig.4),rotate the screw cap with a wrench,and observe strain data of C/AFRP cloth during the whole tension process.When the strain of C/AFRP reaches the expected value,anchor C/AFRP near the tension clamp.The tension clamp can be moved away when the epoxy glue is hardened.

The schematic diagram of static loading test is shown in Fig.5.Strengthened beams are tested under a static monotonic load.

Fig.2 Anchoring process

Fig.3 Anchoring end

Fig.4 Tension clamp

Fig.5 Schematic diagram of static load test(unit:mm)

2 ANALYSIS OF TEST RESULTS

2.1 Analysis of invert arch

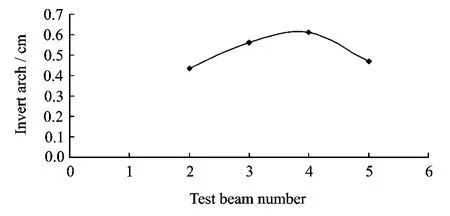

After C/AFRP is pasted,the crack begins to close(the maximum crack width is only 0.2mm).There is a certain amount of invert arch(Fig.6).The invert arch value tends to increase with the prestress and the ratio of carbon fiber in C/AFRP hybrid sheets.

Fig.6 Invert arch value

2.2 Strain analysis of steel and C/AFRP sheets

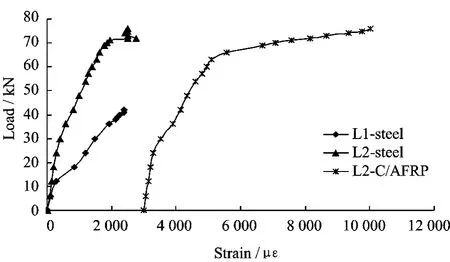

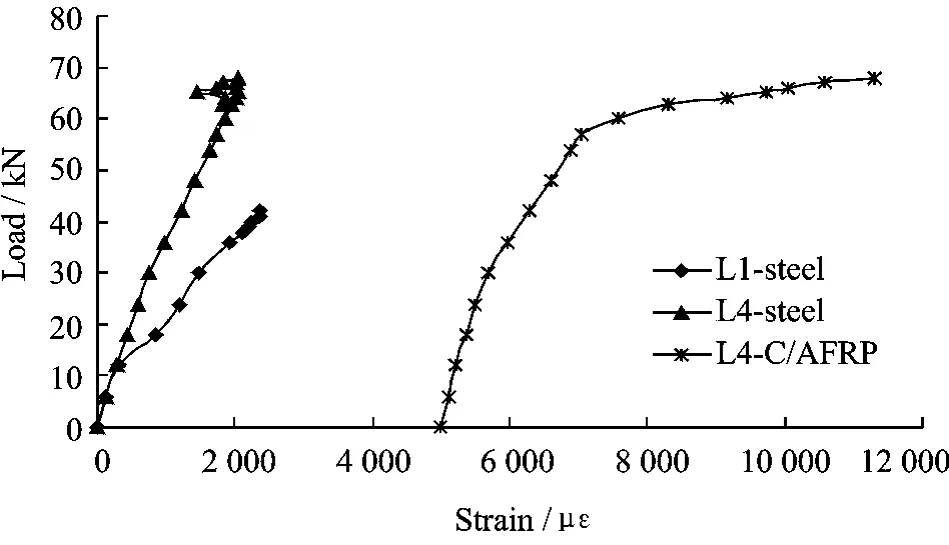

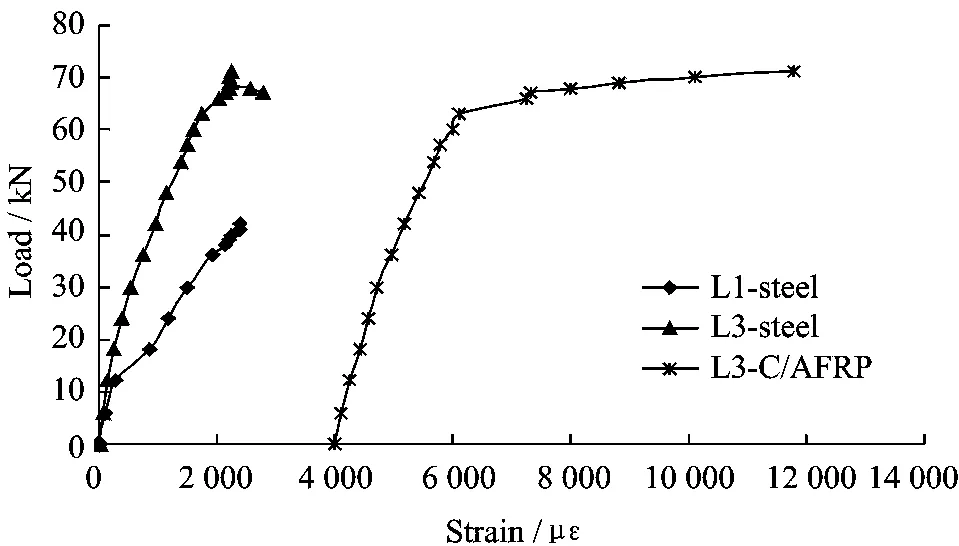

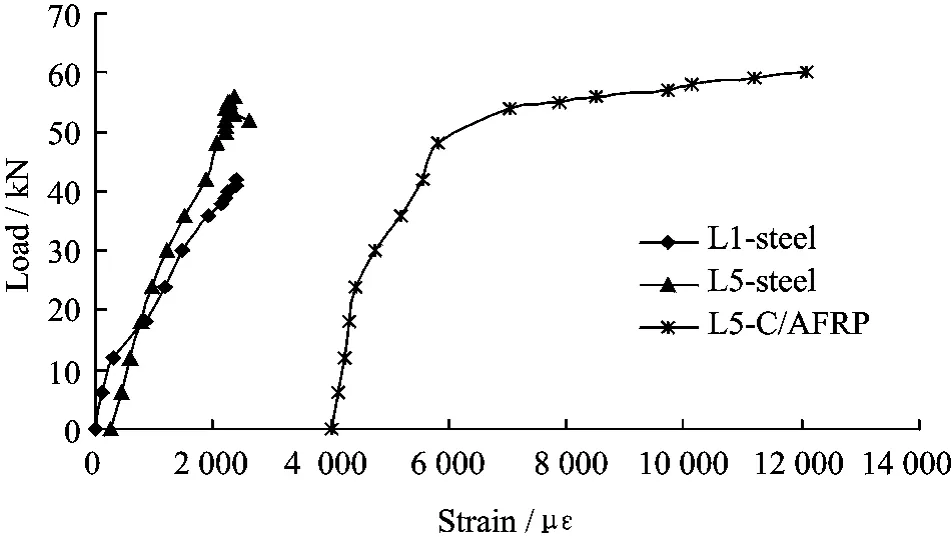

The experimental results of the strain of steel and C/AFRP sheets are shown in the following Figs.7-10.

Fig.7 Load-strain curve of steel and C/AFRP of L1 and L2

Fig.8 Load-strain curve of steel and C/AFRP of L1 and L4

Fig.9 Load-strain curve of steel and C/AFRP of L1 and L3

Fig.10 Load-strain curve of steel and C/AFRP of L1 and L5

Figs.7-10show that at the very beginning,the deformation of C/AFRP is small,and it does not have much effect on the strength of the beam.When steel yields,the deformation of steel and C/AFRP is growing very fast.The growing speed of the deformation of C/AFRP is much faster than steel.The stress difference between C/AFRP and steel becomes larger and larger.At this time,C/AFRP plays an important role in tensile resistance,and delaies the failure process of the strengthened beam.Prestressed intraply hybrid C/AFRP is superior to other strengthening materials.

The yield load tends to increase with the prestress of C/AFRP.The ultimate load is directly related to the ultimate tensile strain of C/AFRP.The ultimate load of L2is the highest,while its ultimate tensile strain of C/AFRP is the largest(10 579με).

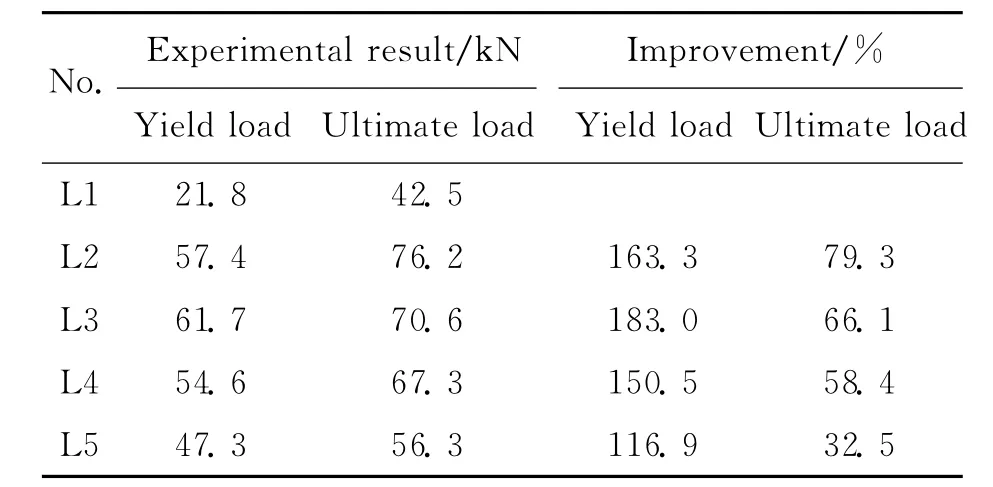

2.3 Bending capacity of strengthened beam

It can be seen from Table 3that both the yield load and ultimate load of strengthened beams are higher than those of non-strengthened beams.Yield load is greatly improved,which means the performance of the beam under the normal usage is much better.The depth of the concrete compression zone tends to increase with prestress of C/AFRP,which leads to the decrease of ultimate load of strengthened beam.Therefore the prestress of C/AFRP should not be too high.

Table 3 Improvement of flexural carrying capacity of strengthened beams

The higher the content of carbon in hybrid fiber sheets is,the greater the improvement of the bearing capacity of strengthened concrete beam is.The optimal hybrid ratio of carbon-aramid hybrid fiber is 2∶1.

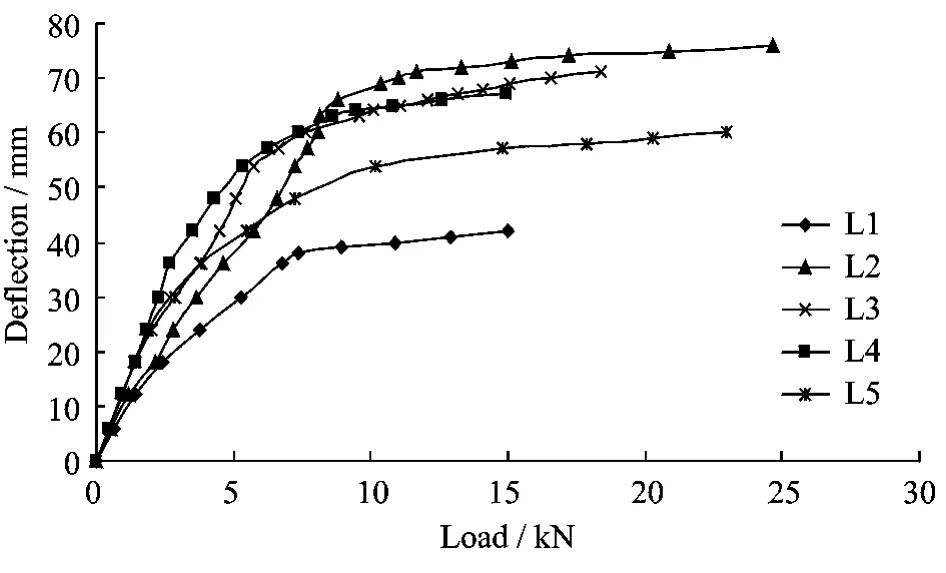

2.4 Deflection analysis of test beams

The load-deflection curves of test beams are shown in Fig.11.Compared with the nonstrengthened beam,the deflection of strengthened beam is smaller under the same load.It′s because the stiffness of strengthened beam is higher. Prestressed C/AFRP effectively inhibits cracks and reduces the speed of failure.The deflection of strengthened beam tends to decrease with the ratio of carbon fiber in C/AFRP sheets.

The shapes of load-deflection curve and loadstrain curve of steel and C/AFRP are similar.The whole process can be divided into three periods:Non-crack,crack and destruction.

At the first stage,the concrete in midspan of the beam is still at work.The load-deflection curve is a straight line.The concrete at the bottom of beam and C/AFRP bears the tensile stress together.

Fig.11 Load-deflection curves

At the second stage,the beam works with cracks.With the increase of loads,the tensile strain of some parts of the pure bending section of the beam reaches the ultimate tensile strain.With the development of cracks,some parts of the tensile stress are undertaken by steel and C/AFRP sheets now instead of concrete.The stiffness of test beam is significantly reduced.With the development of cracks,the deflection of test beam grows faster,and a turning point appears in the load-deflection curve.The deformation of test beam is approximately in proportion to the growth of load.

At the third stage,steel in tensile area yields,and a sharp turn appears in load-deflection curve.C/AFRP plays an important role in this stage.After the steel yields,the deflection and strain of the beam will increase rapidly.Cracks also increase rapidly and the maximum crack width is more than 2mm.Since C/AFRP has high strength and high module of elasticity,there is no obvious yield point.With the increase of deformation,there is still much room for stress growth of C/AFRP cloth after steel bars yields.

C/AFRP is able to undertake more stress,so the strengthened beam has a better ductility than non-strengthened beam, and the damage of strengthened beam is delayed.

2.5 Analysis of development of cracks

There are significant bending cracks in all beams in the loading test.Compared with nonstrengthened concrete beam,cracks of strengthened beams appear relatively late and develop more slowly[7].The number of cracks is bigger,and the crack width is smaller.It shows clearly that the development of cracks in strengthened concrete beam is inhibited,so the bending resistance of strengthened beam is much higher.

3 CONCLUSIONS

(1)The method for using prestressed hybrid fiber sheets is effective to improve the bearing capacity of RC beam.The yield load and ultimate load are greatly improved,while the increase of yield load is more obvious.The bearing capacity of strengthened beam tends to increase with the ratio of carbon fiber in C/AFRP sheets.The ultimate bearing capacity of strengthened beam is directly related to the ultimate tensile strain of C/AFRP sheets.

(2)A certain invert arch appears when the beam is strengthened by prestressed C/AFRP.The invert arch value and the flexural stiffness of strengthened beam tend to increase with prestress.The deflection of strengthened beam tends to decrease with prestress. The ductility of strengthened beam is improved in a certain way.

(3)The prestressed C/AFRP strengthening method is a kind of active strengthening method.C/AFRP sheets can resist both live load and dead load of the strengthened beam,readjust the original internal structural force state,unload tensile stress of the steel,and restore structural deformation.More important,the prestressed C/AFRP can be used to close the crack,reduce the crack width and delay the launching of small cracks,thus improving the durability and the performance of the strengthened beam.

(4)The prestressed intraply hybrid C/AFRP sheets have better performance-price ratio and strengthening efficiency than single-fiber sheets or interlaminar hybrid sheets.Besides,they have a better ductility.Therefore,they are ideal strengthening materials and have great economic and social benefits.A large number of data show that single-fiber sheets have been gradually re-placed by hybrid FRP sheets.

[1] Ceroni F.Experimental performances of RC beams strengthened with FRP materials[J].Construction and Building Materials,2010,24(9):1547-1559.

[2] Xie J H,Huang P Y,Guo Y C.Fatigue behavior of reinforced concrete beams strengthened with prestressed fiber reinforced polymer[J].Construction and Building Materials,2012,27(1):149-157.

[3] Hollaway L C.A review of the present and future utilisation of FRP composites in the civil infrastructure with reference to their important in-service properties[J].Construction and Building Materials,2010,24(12):2419-2445.

[4] Yu Lin.Bending performance of concrete beams strengthened by hybrid fiber cloth[D].Nanjing:Hohai University,2005.(in Chinese)

[5] Ministry of Construction of People′s Republic of China.Standard of reinforcement design for concrete structure(GB50367—2006)[S].Beijing:China Architecture &Building Press,2006.(in Chinese)

[6] Ministryof Construction of People′s Republic of China.Standard of test method of ordinary concrete mechanics performance(JB/T 50081—2002)[S].Beijing:China Architecture &Building Press,2003.(in Chinese)

[7] Wang Xiaomeng.Study on flexural performance of RC beams strengthened with prestressed C/AFRP sheets[D].Nanjing:Nanjing University of Aeronautics and Astronautics,2012:46-54.(in Chinese)

猜你喜欢

杂志排行

Transactions of Nanjing University of Aeronautics and Astronautics的其它文章

- CALCULATION FOR KERNEL OF INTERVAL GREY NUMBER BASED ON BARYCENTER APPROACH

- MULTI-OBJECTIVE PROGRAMMING FOR AIRPORT GATE REASSIGNMENT

- ACTIVE VIBRATION CONTROL OF TWO-BEAM STRUCTURES

- OUTPUT MAXIMIZATION CONTROL FOR VSCF WIND ENERGY CONVERSION SYSTEM USING EXTREMUM CONTROL STRATEGY

- MINIMUM ATTRIBUTE CO-REDUCTION ALGORITHM BASED ON MULTILEVEL EVOLUTIONARY TREE WITH SELF-ADAPTIVE SUBPOPULATIONS

- IMPROVED DOPPLER WARPING METHOD FOR AIRBORNE RADAR WITH NON-SIDELOOKING ARRAY