A Study on Effects of Turn-over Technology on the Quality of Jinmudan Oolong Tea

2013-09-18JingZhuHuiJingXuYingWuFeiLongCuiLingYunZhang

Jing Zhu,Hui-Jing Xu,Ying Wu,Fei-Long Cui,Ling-Yun Zhang*

1.College of Horticulture,South China Agricultural University,Guangzhou 510642,China.2.Yinzhou district forestry technology management service station,Ningbo 315000,China.

*:Corresponding author:LY Zhang,E-mail:lingyunzh@163.com

1.Introduction

Different processes create different teas,such as black tea,oolong tea,green tea,and scented tea and so on.As we all known,tea is one of the most consumed beverages worldwide.In the past few decades,oolong tea has been the most favorite choice for Chinese because of its special taste and flavor.In the preparation of oolong tea,young green shoots are freshly plucked and allowed to undergoing a semi-fermentation processes(including sun withering,cooling,tossing,withering,fixation,rolling and drying)where the term fermentation'refers to natural browning reactions induced by oxidative enzymes in the cells of tea leaves.

At present,the leaves of Jinmudan have been as the materials for the oolong tea production.The Jinmudan was bred from the Tieguanyin(♀)and the Huandan(♂)by Hybridization[1],it has been through the national breed identification in 2010[2].The Jinmudan has many good characteristics,such as high survival rate of cutting,good adaptability and resistance,early germination,a strong ability to maintain fresh of leaves and the thick leaves[3].The lingering charm of the oolong tea made by Jinmudn is obvious.The olong tea made by Jinmudn has maintained the fine qualities of the Tieguanyin and the Huangdan.Even,the fragrance and the good qualities have made the oolong tea made by Jinmudan better than the oolong tea made by Tieguanyin and Huandan.Therefore,the Jinmudan Oolong tea got widely recognized from the general consumers.

Turn-over is the key process in the production of olong tea.The changes of biochemical components in the process of turn-over are closely related to the quality of oolong tea.Pengcheng Zheng and Fuping Huang both think that increase in the number of turn-over will increase the total amount of aroma compounds and essential oils in the oolong tea production.And Fuping Huang believed the Nerolidol,Linnalol,α-Farnesene,(Z)-Hexanoic Acid,3-Hexenyl Ester+Benze neacetaldehyde etc.aroma components significantly increased accordingly.The number of turn-over will affect the embedded substance of oolong tea.

The effect of the turn-over on the quality of Jinmudan has not been reported so far.In this paper,we use leaves of the Jinmudan as raw materials under the same conditions,to produce the Jinmudan Oolong tea.Setting different treatments by the different numbers of turn-over,we study the effect of the turn-over on the quality of Jinmudan Oolong tea.

2.Materials and methods

2.1.Samples and reagents

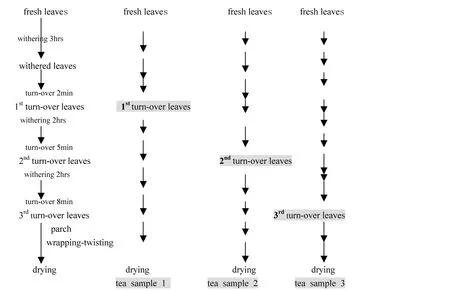

The fresh leaves were picked in Yinzhou district Zhangshui Yongjie tea garden with the standard in one bud and three or four leaves in October 2012.The sample was made by the way of oolong tea processing as follow:

The following chemicals were used:diethyl ether,sodium sulphate anhydrous and ethyl decanoate were purchased from CongYuan instrument Co.,Ltd(Guangzhou,China).

2.2.Sensory quality evaluation of tea

Three grammes of tea sample were infused with 150 mL freshly boiled water for 5 min.The tea quality was estimated and scored by professional tea tasters FL Cui and W Qing from the Department of Tea Science at South China Agricultural University.The grading was based on a total score of 100,of which 20%was awarded for the appearance of dry tea,30%for the tea aroma,5%for the infusion color,35%for the taste and 10%for the infused leaves.

2.3.Chemical analysis

2.3.1.Determination of extractable solids

The amount of extractable solids obtained after brewing was determined using the method described by zhong[15].Three grammes of tea sample were infused with 500 mL freshly boiled distilled water in a boiling water bath for 10 min.The infusion was filtered through filter paper and then weighed to the nearest 0.0001 g.Aliquots were placed in pre-weighed containers and the solution was dried to a constant weight using a drier set at 105℃.The weight of the dried matter was determined and the recovery of the dried extractable solids was calculated and expressed in mg per g of tea brewed using the method described by zhong[15].

2.3.2.Determination of polyphenols

Five grams of ground sample were extracted with 500 mL boiling distilled water in a boiling water bath for 10 min and then filtered through a filter paper.Polyphenol concentrations of the filtrates were determined by the spectrophotometric method described by Zhong[15].

2.3.3.Analysis of amino acids

Contents of amino acids in the earlier tea infusions were determined by a spectra-photometric method with Kjeldalhl's method[15],respectively.

2.4.Preparation of volatile concentrates

A Likens-Nickerson type simultaneous steam distillation and extraction(SDE)apparatus was used to extract volatile compounds[8-10].For SDE extraction,20.0 g of the sample were transferred to 1000 mL round bottom flask mixed with 450 mL of distilled water,to which 100 g of internal standard ethyl decanoate was added.The extraction was performed for 1 h at 100℃.As the extraction solvent,50 mL of diethyl ether was used.Obtained extracts were dried over sodium sulphate anhydrous and concentrated to approximately 1 mL.The concentrated extract was stored at 4℃ until further analysis was performed.

2.5.GC-MS analysis

Analyses were carried out by a TRACE GC-2000 GC-MS(Thermo Finnigan)using a DB-1(100%dimethyl polysiloxane)column(30 m ×0.32 mm).Helium was used as the carrier gas at a flow rate of 1.0 mL/min.Thermal desorption of the compounds from the column was carried out in the GC splitless injector at 230℃.The oven temperature was programmed to increase from 50℃ (2 min)to 110℃ (2 min)at a rate of 3℃ /min.The temperature was then raised to 170℃ (2 min)at a rate of 5℃ /miin,and then to 230℃ (1 min)at a rate of 10℃ /min.Aroma compounds were analyzed by MS with electronic impact(EI)70 eV quadripolar filters.The mass range for this acquisition is 35-335 amu.

2.6.Identification

All compounds were identified by comparison to NIST library(including Wiley,Mainlib and Replib)spectral data bank.Only compounds whose similarity is more than 800 were reported here.Quantitative analysis was based on the ratios between the peak area of a particular component in the powder of Jinmudan Oolong Tea and the total peak area of all components in the powder.

3.Results and Discussion

3.1.Sensory quality of the tea samples

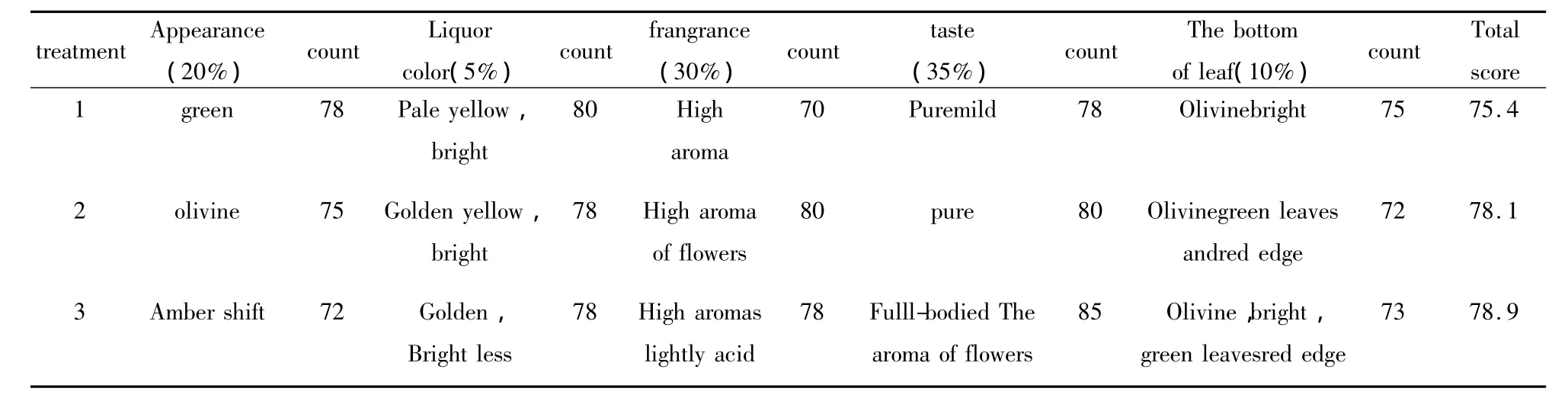

As shown in table 1,the highest score is tea samples no.3,the lowest score is the tea samples no.1.The score of tea aroma quality is tea sample 2>tea samples 3>tea samples 1.It means that aroma quality increased with the increase in the numbers of turn-over,instead that the aroma quality was positively correlated with the numbers of turn-over.Increasing the numbers of turn-over would make the color of Jinmudan Oolong tea yellow and the color of the tea solution deepen,and the taste become strong.

Table 1.Sensory evaluation of tea samples.

3.2.The changes of biochemical composition in the tea sample

Water soluble extracts of tea mainly contains tea polyphenols,amino acids,water-soluble pectin,caffeine,water-soluble carbohydrates,water-soluble pigment,its content is generally 30% to 47% .The level of water extracts is one of the indicators to assess the quality of tea.To some extent,it assessed the level of quality of tea[12].

As we can see from the Table 2,content of water extracts is also significantly increased.,with the increase in the numbers of turn-over.The content of water extracts in Tea samples three is 38.858% ,and it is higher than the contents of tea sample two(33.243%)and tea sample one(32.253%)by 5.615%and 6.605%.Water extracts of the three tea samples exist very significant changes(P <0.01)between each other.

This is due to the increase in the numbers of turn-over,making the mechanical damage of tea severe[13].And thus in leaching process,the soluble substances of tea are leached more easily.Some insoluble protein and polysaccharide translate into soluble amino acids and soluble sugar through hydrolysis,some tea polyphenols become soluble pigment material by the function of oxidation.The tea taste becomes more intense is consistent with the increase numbers of turn - over,which is matching with the sensory evaluation.There is a special phenomenon,which is the content of polyphenol was increased firstly and then decreased.

Amino acid has larger changes in the tea processing,some amino acid becomes aroma substance,some itself is one kind of flavor substances.We can know that the content of the three amino acids in the tea samples has a very significant difference from table 2.For the trend about the amino acids,we analyzed that:free amino acids may be mainly combined with other materials during the preliminary of turn-over,which decreased the content of amino acid.However,the metabolism of protein hydrolysis became a major role in the latter of turn-over,increasing the content of the total amino acids,which is matching with the sensory evaluation[14].

Table 2.Main component contents of tea samples(by dry weight,%).

3.3.volatile compounds of Jinmudan Oolong tea with different turn-over processing

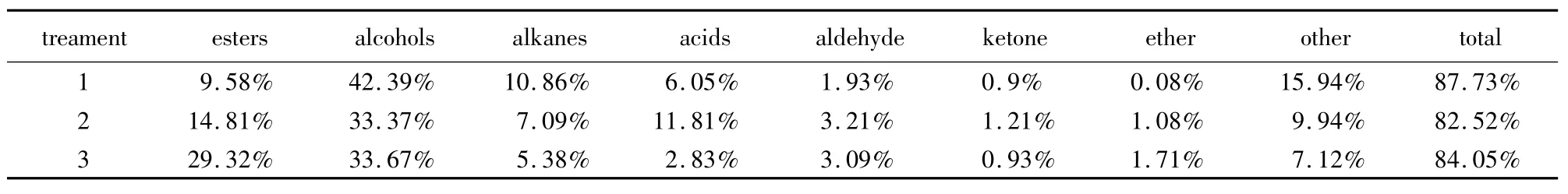

According to the table 3 and table 4,there are 57 kinds of volatile compounds in the tea samples one and the total content was 87.73%.57 kinds of volatiles compounds were found in the tea sample two and its content was 82.52%.In the tea sample three,the number of the kinds of volatile compounds is 51,and the number of the content is 84.05% .With increasing the number of turn-over,the kinds of the volatiles compounds became less,but they are all more than 50.

Table 3.Volatiles in Jinmudan Oolong tea with different turn-over treatments.

Table 4.Volatile compounds in three tested tea samples.

3.4.Changes in volatiles with turn-over processing

The volatile compounds are mainly esters,alcohols and alkanes of the three tea samples.the main volatile compounds one of tea sample 1 was alcohols,the total content was 42.39%.And alkanes accounted for 10.86%and esters accounted for 9.58%,the alcohols in tea sample 2 accounted for 33.37%of the total content,the content of the alcohols has reduced 9.02%and the content of the alkane has decreased by 3.77%compared with the tea samples 1,but the content of esters rose 5.32%.The content of esters in tea samples 3 is relatively more for 29.32%,but the alcohol is still the primary substance,accounting for 33.67%of the total content.

In simple terms,With the increase in the number of rolling green,the percentage content of alcohols and alkanes is reduced,but there is a larger increase in the content of esters.And there is a small increase in the content content of aldehydes and ethers.

As shown in Table 5,6 and 7,the major volatile compoundss of the three Jinmudan Oolong tea samples are nerolidolcistrans,α-farnesene,palmitic acid,indole and 9,12,15-octadecatrienoicacid,methyl ester.The content of these volatile compoundss is more than 40%.And the content of nerolidol was 25.75%,29.32%and 27%.Remove these shared aroma,the content of alcohol was relatively large in tea sample 1,the level of acid and esters were high in tea samples 2,and the content of docosanoic acid,methylester in tea samples 3 was 19.84%,which had a large effect on the tea sample 3.It means that the content of volatile esters would increase due to the degree of turn-over.The content of the nerolidol and α-farnesene was increased and then decreased,which is consistent with results of the review.

Table 6.Changes in volatile compounds with turn-over processing.

Name Percentage composition(%)1 2 3 15-tetramethyl 0.4 0 0 Eicosane 0.24 0 0.36 Nerolidolcistrans 25.75 29.31 27 Pentadecane,2-methyl 0.21 0 0 Tetradecanal 0.28 0.16 0.18 3-Oxo-2-(2-pentenyl)-,methyl ester,[1R-[1.alpha.,2.beta.(Z)]]-Cyclopentaneacetic acid 0.28 0.27 0.49 Hexanoic acid,2-Phenylethyl ester 0.39 0.47 0.31 2,7-Dimethyl-9-(2,2-dimethyl)-oxiranyl-3,7-dec-dien-1-ol 0.92 0.22 0.38 Pentadecane,2,6,10-trimethyl 0.24 0.14 0.3 Octadecyl 0.28 0.35 0 2,6,10-Trimethyl-tetradecane 0.15 0 0.5 Hexadecane,3,7,11,15-tetramethyl 0.72 0 0 2-Methyl nonadecane 0.21 0 0 Diisobutyl phthalate 0.34 0.18 0.27 2,3-Dimethyl-heptacosane 0.42 0 0 Docosanoic 1.28 0.49 0.1 Methyl hexadecanoate 0.47 0.68 0.41 Palmitic acid 6.05 5.11 2.25 Hexadecane,2,6,10,14-tetramethyl 0.39 1.44 1.4 9,12,15-Octadecatrienoicacid,methyl ester 3.01 2.98 3.99 3,7,11,15-Tetramethyl-2-hexadedcen-1-ol 0.74 0.07 4.64 Octadecanoic acid,methyl ester 0.26 1.06 0 2-Methyl-1,3-dioxolane 0 1.12 0 Acetaldehyde di-sec-butyl acetal 0 1.16 0.25 n-Propylbenzene 0 0.23 0 Pentane,2-butoxy- 0 0.59 0 Butane,2,2'-oxybis 0 1.08 0.62 Propane,2-ethoxy 0 1.24 0 Carbamic acid,N,N-dimethyl-,ethyl ester 0 0.3 0 1,3-Dioxolane,2-(1-methylethyl)- 0 1 0(-)-Alpha-Terpineol 0 0.05 0 1,3,5,8-Undecatetraene 0 0.11 0 Undecane 0 0.21 0 6-Octadien-1-ol,3,7-dimethyl-2 0 0.1 0 Ethyl succinyl chloride 0 1.04 0 Phenethyl isobutyrate 0 0.24 0 5-Decanolide 0 0.15 0.28 1,6,10-Dodecatriene,7,11-dimethyl-3-methylene 0 0.16 0.19 cis-3-Hexenyl benzoate 0 0.15 0.09 Pentadecane,4-methyl 0 0.21 0 Eicosanoic acid,methyl ester 0 4.97 0 Pentadecanoic acid 0 0.27 0 2-Methyl-octadecane 0 0.17 0 Eicosanoic acid 0 6.43 0 Hexyl hexanoate 0 0 0.96 3-Hydroxy-2-butanone 0 0 0.23 Pentane,2-butoxy 0 0 1.09 4-Methyl undecane 0 0 0.07 4,6-Dimethyl dodecyl 0 0 0.29 Eicosane 0 0 0.33 Geranylacetone 0 0 0.13 Pentadecane 0 0 0.72 Pentadecane 0 0 0.21 2,6,10,14-Tetramethyl pentadecane 0 0 0.14 Docosanoic acid,Methylester 0 0 19.84 Methyl oleate 0 0 0.34 Stearic acid 0 0 0.58 Heptadecane,2,6,10,Geranylacetone 000.13

4.Conclusion

Turn-over is an important manufacturing processing in oolong tea.The tea leaves are processed(turn-over)while they are intact and alive;they are wounded during processing under water-stress conditions.It has been reported the emission of volatiles and expression of the genes involved in volatile biosynthesis is induced by stresses such as insect attack and wounding in various plant species[16-18].In addition to increased production of volatiles,it is well known that abiotic stresses trigger a wide variety of plant responses,including alteration in gene expression,the accumulation of phytohormones such as abscisic acid(ABA),jasmonic acid,and ethylene,and enhanced synthesis of specific proteins(e.g.,heat shock proteins and enzymes that function in various metabolite biosynthesis,such as sugars and osmoprotective raffionse-family oligosaccharides.These plant responses lead to acclimation and tolerance to environmental stresses[19,20].In the same way fluctuation of various metabolites in tea leaves must occur in response to stresses such as UV-irradiation,drought and wounding during the manufacturing process[21].During oolong tea manufacture,tea leaves are exposed to various stresses,such as plucking(wounding),solar withering(drought heat,and UV/light radiation),indoor withering(drought),and turn over(wounding).it has been reported that volatiles of monoterpenes such as linalool and ocimene and of C6-compounds such as hexanal and hexenols are pfoduced by in sect attack and wounding[16,17,22].Continuous mechanical wounding has also been reported to make leaves of the lima plant emit a variety of volatiles[23].Hence it is most likely that various stresses during manufacture ales cause the production of volatiles moneterpene alcohols and C6-compounds.

Wang dongmei has reported that a large increase in the aroma compounds of group II,which is considered not to be directly concerned with the glycosides in their formation during the oolong tea manufacturing process.was apparent due to the substantial formation of jasmine lactone and indole during the manufacturing process[24].Jasmine lactone,which possesses a jasmine-like floral and fruity odor,is wellknown to be one of the most important compounds to oolong tea aroma[25],and its content increased from 0.56 to 31.55 mg in 100 g of oolong tea during the manufacturing process.The content of indole also increased from the trace content in dried fresh leaves to 12.52 mg/100 g of oolong tea.The combined amount of these two compounds constituted ~35%of the oolong tea aroma compounds.the above results for the formation of oolong tea aroma during the manufacturing process also suggested that compounds in group II might be more important than the alcohols of group I.Consequently,one or more biosynthetic pathways,such as the formation of jasmine lactone and indole,should be considered to take priority over the hydrolysis of glycosides.This is quite different from the formation of black tea aroma,in which the hydrolysis of glycosides plays the main role as we described in as their study[26].But the mechanism for the formation of the two compounds has not yet been clarified.

The present work encompassed the understanding the changing of the typical flavour compounds during oolong tea turn-over processing.Our present work show that then main volatile compoundss are cis-nerolidol,a-Farnesene,palmitic acid,indole and 9,12,15-Octadecatrienoicacid,methyl ester in the three Jinmudan Oolong tea samples.It not means that the more turn-over,the better quality of the Jinmudan Oolong tea,but it means that the certain turnover can create a good product.In our experiment,the quality of the tea sample 2 is the best.Appropriate changes in the number of turn-over can be conducive to the accumulation of amino acid,and improve the taste of tea and water extracts,increase the concentration of tea.The content of volatile esters would increase due to the degree of turn-over.

Acknowledgements

This work was supported in part by the rural science and technology innovation fund project of technology division from Ningbo city science and technology bureau(No.201001C8002011201002C1011003)for financial support.We thank the Ningbo city Yinzhou district Zhangshui Yongjie Tea Company for helping in the preparation of tea samples.

1.Guo JC,Yang RX,Zhang WJ,et al.Selection and application of Camellia Sinensis Hybrids:Jinmudan and Huangmeigui.The National Conference on Science and Technology of Tea,2007:31-37.

2.Wang RJ,Guo JC,Yang J,et al.Analysis of the characteristics and cultivation techniques of Camellia Sinensis Hybrids:Jinmudan.Tea in Fujian,2010:20-24.

3.Guo JC,Yang RX,Zhang WJ,et al.The economic characters of oolong tea varieties in different regions.Tea in Fujian,2002,4:4-6.

4.Zeng ZY,Wei XY,He DB.The report introduction of new varieties of tea to try to grow golden peony Preliminary.Agricultural Research and Application,2011,1:19-20.

5.Feng HY,Liu HY,Liang GZ,et al.The trial research about tea varieties Jinguanyin.China Tropical Agriculture,2013,3:49-50.

6.Anhui agricultural.Manufacture of tea.Beijing:Agriculture Press,1997.

7.Zheng PC,Ning JM,Zhao CR,et al.The effect on quality of oolong by different turn-over.Journal of Anhui Agricultural University,2009,36(1):110-115.

8.Huang FP,Chen RB,Chen W,et al.The effect of the strength of turn-over to the oolong tea quality and the influence of the aroma composition.Fujian Journal of Agricultural Sciences.2001,16(3):28-34.

9.Lee S,Ahn B.Comparison of volatile components in fermented soybean pastes using simultaneous distillation and extraction(SDE)with sensory characterization.Food Chemistry,2009,114(2):600-609.

10.Li N,Zhang FP,Chen HT,et al.Identification of volatile components in Chinese Sinkiang fermented camel milk using SAFE,SDE,and HS-SPMEGC/MS.Food Chemistry,2011,129(3):1242-1252.

11.Majcher M,Jeleń H H.Comparison of suitability of SPME,SAFE and SDE methods for isolation of flavor compounds from extruded potato snacks.Journal of Food Composition and Analysis,2009,22(6):606-612.

12.Huang FP,Cheng W,Cheng HD,et al.Effects of fine manipulation on biochemical constituent content in oolong tea.Journal of Fujian Agricultural University(Natural Science),2002,2:199-202.

13.Zhang M,Huang YH,Zhao WX,et al.Effects of green-making technology on the quality of Dancong oolong Tea.China Tea Processing,2012,2.

14.Su MJ,Mao ZF,Shi HG,et al.Study on the changes of water soluble matter,tea polyphenols and total amino acids during turning-over.China Tea Processing,2007,(3):17-20.

15.Zhong L.Methods of chemical and physical evaluation of tea quality(in Chinese).Shanghai:Shanghai Science and Technology Press,1989.

16.Arimura G,Kost C,Boland W.Herbivore-induced,indirect plant defences.Biochimica et Biophysica Acta(BBA)-Molecular and Cell Biology of Lipids,2005,1734,91-111.

17.Bartram S,Jux A,Gleixner G,Boland S.Dynamic pathway allocation in early terpenoid biosynthesis of stress-induced lima bean leaves.Phytochemistry,2006,67:1661-1672.

18.Howe GA,Schilmiller AL.Oxylipin metabolism in response to stress.Current Opinion in Plant Biology,2002,5:230-236.

19.Mahajan S,Tuteja N.Cold,salinity and drought stresses:an overview.Archives of Biochemistry and Biophysics,2005,444:139-158.

20.Mittler R.Abiotic stress,the field environment and stress combination.Trends Plant Science,2006,11:15-19.

21.Cho JY,Mizutani M,Shimizu B,Kinoshita T,Ogura M,Tokoro K,Lin ML,Sakata K.Chemical profiling and gene expression profiling during the manufacturing process of Taiwan oolong tea"Oriental Beauty".Bioscience,Biotechnology,and Biochemistry,2007,71(6):1476-1486.

22.Pichersky E,Gershenzon J.The formation and function of plant volatiles:perfumes for pollinator attraction and defense.Current Opinion in Plant Biology,2002,5:237-243.

23.Mithofer A,Wanner G,Boland W.Effects of feeding Spodoptera littoralis on lima bean leaves.II.Conditions of mechanical wounding resembling insect feeding are sufficient to elicit herbivory-related volatile emission.Plant Physiology,2005,137:1160-1168.

24.Dongmei Wang,Kikue Kubota,Akio Kobayashi,I-Ming Juan.Analysis of glycosidically bound aroma precursors in tea leaves.3.Change in the glycoside content of tea leaves during the oolong tea manufacturing process.Journal of Agricultural and Food Chemistry,2001,49:5391-5396.

25.Yamanishi T,Kosuge M,Tokitomo Y,Maeda R.Flavor constituents of Pouchong tea and a comparison of the aroma pattern with jasmine tea.Agricultural Biology and Chemistry,1980,44:2139-2142.

26.Wang D,Kurasawa E,Yamaguchi Y,Kubota K,Kobayashi A.Analysis of glycosidically bound aroma precursors in tea leaves.2.Changes in glycoside contents and glycosidase activities in tea leaves during the black tea manufacturing process.Journal of Agricultural and Food Chemistry,2001,49:1900-1903.

杂志排行

茶叶的其它文章

- Optimization of Withering and Fermentation Parameters during the Manufacture of Congou Black Tea of Sichuan

- Fluoride in Tea and Its Risk Assessment

- A Review on Decaffeination of Tea Products

- A Study of Historical References of Korean Royal Court Tea Culture through the Periods of Three Kingdoms,Goryeo Kingdom and Joseon Dynasty

- The Beauty of Elegance‘Pungnyu’in the Tea Culture of Korea