Optimization of Withering and Fermentation Parameters during the Manufacture of Congou Black Tea of Sichuan

2013-09-18HongQianRuanGangChenXiZhangXiaoYuanQuHongLinLiuHuaRongTong

Hong-Qian Ruan,Gang Chen,Xi Zhang,Xiao-Yuan Qu,Hong-Lin Liu,Hua-Rong Tong

1.College of Food Science,Southwest University,Chongqing,400716,China.2.Yibin Chuanhong Tea Group Co.,Ltd,Sichuan,644000,China.

Supported by the Pillar Program of the Ministry of Science and Technology of China 2012BAF07B05.

The tea leaves were processed using the conventional method of Congou black tea of Sichuan.The tip leaves were indoor withered through passing ambient air at about 25℃ for a pre-determined time.The humidity of the air during the withering was 60% ~80%,and it was controlled over 90%during the fermentation process.After traditional rolling,the leaves were spread out in dustpans and placed in different fermentation room for a predetermined time with oxygen availability,while the fermentation temperature was set at different levels according to Table 1.The fermentation leaves were dried at 120℃ for 10 minutes,and then cooled off,finally dried at 100℃until moisture content was reduced to less than 4%.After cooling off,the leaves were put into plastic packs and stored for further analysis[2].

The Congou black tea of Sichuan was developed after 1949,and later became well-known international brands,while it was frustrated in the 1990s.Recent years,it is more and more popular in China[1].The processing procedure of Sichuan congou black tea is as:fresh leaves,withering,rolling,fermentation and drying.Now the main tea fresh leaf to process the congou black tea is plucked from clones such as Fuding Dabai'and Zao Baijian'[2].

Although each stage of process is much important to the quality of black tea,the fermentation is the most critical stage as a series of biochemical reactions occurring for obtaining great black tea.The endogenous flavanols in the tea leaves undergo various oxidative enzymatic reactions.Catechins,as the main component of polyphenol fractions,are the substrates for the enzyme polyphenol oxidase(PPO),which play a key role in the formation of theaflavins(TFs)and thearubigins(TRs)[3].The condition of withering,and rolling,and the temperature,humidity,time,oxygen availability during fermentation all are the significant factors of these enzyme reaction,which is a contribution to high levels of black tea[4].TFs are related to brightness of black tea liquor,besides;TRs are concentrated strength and body of black tea liquor on.The ratio of TF:TR which is 1∶10 or 1∶12 is considering being high quality CTC black tea by Owuor[5].So far,the use of TF,TR values as parameters for the evaluation of black tea quality has been reported in some literature[3,5,6].

The Response Surface Methodology(RSM)is a multivariate statistical method.With the multivariate quadratic regression equation between the response and factors by reasonable experimental design,we could get the optimal process parameters and predict the responses at the optimum condition.RSM is widely used in food engineering,biological engineering,chemical engineering,agriculture,machinery,industry and other fields now.Box-Behnken Design(BBD),Uniform Shell Design(USD)and Central Composite Design(CCD)are three commonly experimental designs of RSM[7-9].In the present study,withering time,fermentation temperature and fermentation time were chosen as controlling factors and designed according CCD with three levels.This papers aim is to apply CCD and RSM statistical method by choosing TF and TR as detection target to optimization withering and fermentation processing,and to gain great quality Congou black tea of Sichuan[6].

1.Material and methods

1.1.Materials,reagents and equipment

The fresh:Tea leaves(Camellia sinensis cv.Fuding Dabai,the apical bud)were manually plucked during September 21-22,2013 in Gao County,Yibin City in Sichuan province.

Ethyl acetate,butyl alcohol,alcohol(95%),sodium bicarbonate and oxalic acid are all analytical reagent,that bought from ChengDu Kelong Chemical Reagent Company,(Chengdu,China)coupled with TU-1900 Double beam UV-Vis spectrophotometer were used for chemical analysis.

1.2.Black tea manufacture

The tea leaves were processed using the conventional method of Congou black tea of Sichuan.The tip leaves were indoor withered through passing ambient air at about 25℃ for a pre-determined time.The humidity of the air during the withering was 60% ~80%,and it was controlled over 90%during the fermentation process.After traditional rolling,the leaves were spread out in dustpans and placed in different fermentation room for a predetermined time with oxygen availability,while the fermentation temperature was set at different levels according to Table 1.The fermentation leaves were dried at 120℃ for 10 minutes,and then cooled off,finally dried at 100℃until moisture content was reduced to less than 4%.After cooling off,the leaves were put into plastic packs and stored for further analysis[2].

Table 1.Factors and levels of the central composition design.

1.3.Chemical analysis

TF and TR of black tea were analyzed by the method of Roberts[10].

1.4.Experimental design

A CCD-RSM with three variables and three levels was applied.The three factors were withering time(x1),fermentation time(x2)and fermentation temperature(x3),besides,-1,0,+1 represent the levels of variables(Table 1).

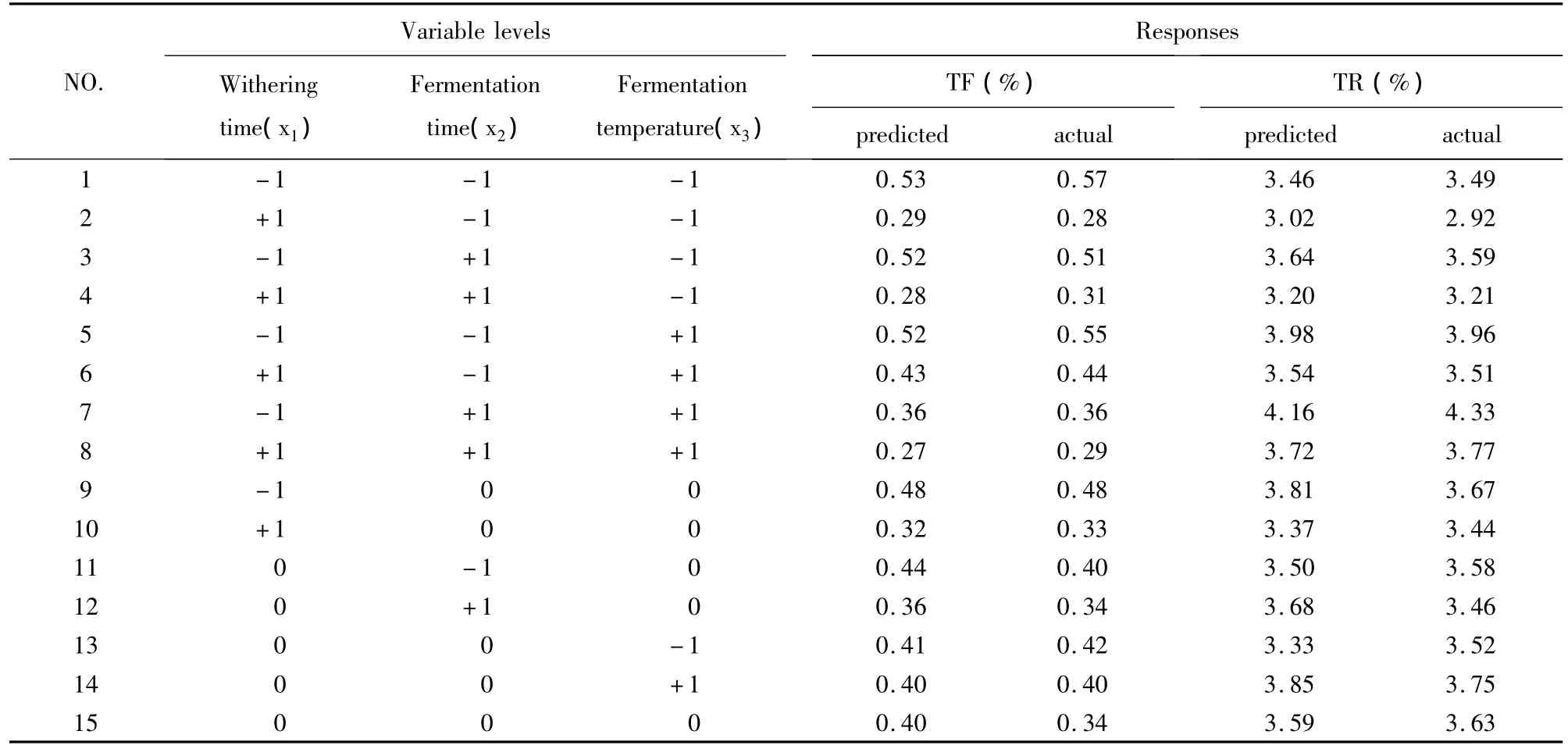

In the CCD-RSM design,NO.1 to NO.8 configuration combinations are factorial experiment and the experimental points are factorial points.The experimental points of NO.9 to NO.14 are axial point,and the final point is center point[11].In this study,15 different experiments were required to perform as Table 2.Data was analyzed by the tool of Design Expert 8.0.

2.Rusults and discussion

2.1.Results of responses and fitted regression equation

A CCD establishes a mathematical equation and the predict response y is estimate the response of the dependent variable according to following equation:

Table 2.CCD-RSM design and the results of three responses.

Where x1x2x3are the independent variables,b0the intercept,b1b2b3the linear,b11b12b13the interaction and b11b22b33are quadratic.

The results were statistically analyzed by the analysis of variance(ANOVA),the insignificant terms were removed(not counting those required to support hierarchy)for improving the model and then run ANOVA again,a new result of ANOVA was shown in Table 3.After the second ANOVA,obtained the following improved models which were used to quantitative research withering time,fermentation time and fermentation temperature with the correlation of TF and TR formation:

*Use of coded factors to get the final equation

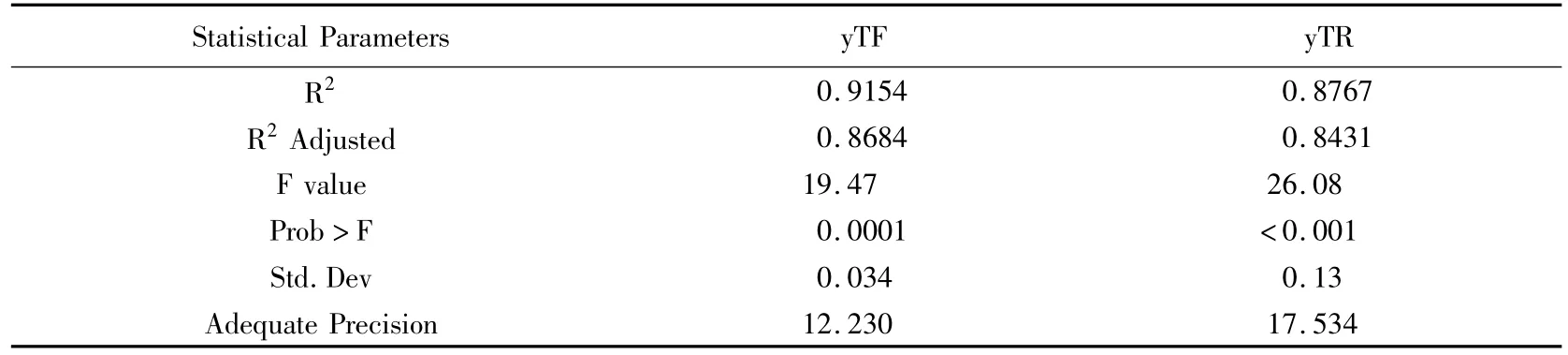

The final models for TF and TR formation were significant at 0.05 level.From the Table 3,the R2were 0.9154 and 0.8767 for the models of TF and TR,which described that the responses change come from the selected variables with 91.54%and 87.67%,respectively.Adj R-Squared represents calibration coefficient of model,therefore,more than 84%changes of response which obtained in this experiment can be explained by the improved equations.The signal of Adeq Precision measurement to noise ratio and a ratio more than 4 is available.The models for TF and TR formation can be used to navigate the design space according to Table 3.

Table 3.The evaluation parameter of ANOVA for fitted model.

2.2.Response surface analysis

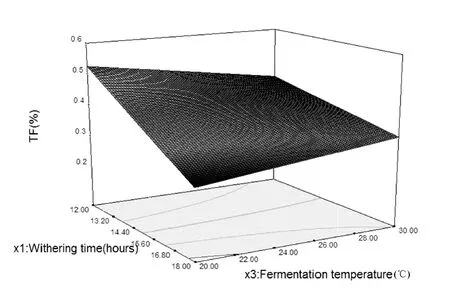

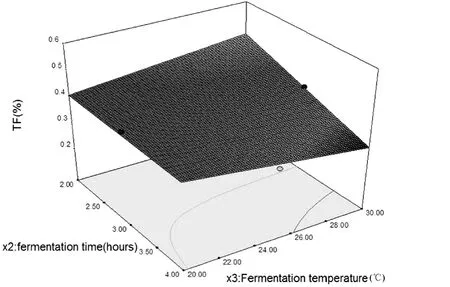

In order to provide a better illustrate the impact of various factors on the TF,the three-dimensional surface plots are shown in figure 1 and figure 2 by Design Expert 8.0.Contour plot and 3-D plot can be chosen to describe interaction between the two factors or more factors;graphical 3-D plot is highly recommended[6].In the present study,only the significant interaction terms in the fitted models are selected for graphic depiction of response functions,this is why graphic depiction of response functions for the interaction term of variables affect the TR formation is not shown here.

The graphic depiction of response functions are shown in figure 1 and figure 2.Figure 1 showed the dependence of the theaflavins formation on withering time and fermentation temperature for that the fermentation time is set at its central level(3 hours).When fermentation time was 15 hours,the highest of TF formed was with the withering time being at about 12 hours and the fermentation temperature being at 20℃.The tendency of TF formed was from highest to lowest,and then slowly increase with withering time and fermentation temperature being increases when the fermentation time was constant.This indicated that at the same fermentation time,low fermentation temperature was conducive to the formation of TF during appropriate withering time.This has been reported in related literature[12].On the other hand,reduced withering time(i.e.increased water content of leaf)was also beneficial to accumulation of TF at the same fermentation temperature and time from Figure 1,Ullah obtained the relevant conclusions about CTC black tea[13].

Figure 2 present the dependence of the theaflavins formation on fermentation time and fermentation temperature for the withering time is set at its central level(15 hours).When withering time was 15 hours,the highest of TF formed was with the fermentation being at about 2 hours and the fermentation temperature being at 30℃,and the lowest of TF formation was with the fermentation time at about 4 hours and the fermentation temperature at 30℃.The figure 2 indicated that the influence of the increase of fermentation time on TF formed was small with low fermentation temperature(20 ~ 21℃)and constant withering time.The higher level of the fermentation temperature and time were,the less of TF were.The short fermentation time was beneficial to accumulation of TF at the same fermentation temperature and withering time.

Fig.1.Second-order response surface plot of withering time(x1)vs.fermentation temperature(x3)on TF formation(fermentation time was kept constant at 3 hours).

Fig.2.Second-order response surface plot of fermentation time(x2)vs.fermentation temperature(x3)on TF formation(withering time was kept constant at 15 hours).

2.3.Optimization of experiment

Optimal process parameters for the maximum of TF and TR formation were obtained at withering time of 12 hours,fermentation 2 hours,and fermentation temperature 30℃ by Design Expert 8.0.The prediction of TF and TR formation were 0.52%and 3.98%.

3.Conclusions

In this study,using CCD-RSM establish mathematical models for the response of TF and TR formation.The factors were withering time,fermentation time,and fermentation temperature.The models of regression equations were significant by ANOVA.The second-order response surface figures presented that interaction term is correlation with TF.Optimal process parameters for maximizing the TF and TR formation were obtained by the RSM.The results obtained in this study showed that the Response Surface Methodology could be an effective tool to optimize the process parameters of the manufacture of Congou black tea.

The authors sincerely thank the valuable assistance of worker in Factory of Linhu.

1.Chen G,Zheng J G.Congou black tea of Sichuan'is the pride of Yibin.Technology of Yibin,2011,131(2):46-47(in Chinese).

2.Du CY,et al.Black tea of Sichuan.Chengdu science and technology publisher:Chengdu,China,1989,pp367-383(in Chinese).

3.Hafezi M,Nasernejad B,Vahabzadeh F.Optimization of fermentation time for Iranian black tea production.Iranian Journal of Chemistry and Chemical Engineering,2006,25(1):29-33.

4.Muthumani T,Kumar R S.Influence of fermentation time on the development of compounds responsible for quality in black tea.Food Chemistry,2007,101(1):98-102.

5.Owuor P O,Reeves S G.Optimising fermentation time in black tea manufacture.Food Chemistry,1986,21(3):195-203.

6.Emdadi L,Nasernajad B,Shokrgozar S T,et al.Optimization of withering time and fermentation conditions during black tea manufacture using response surface methodology.Scientia Iranica,Trans.C,2009,16(1):61-68.

7.Yang WX,Gao YX.Response surface methodology & its application in food in dutry.China Food Additives,2005,2:68-71.(in Chinese).

8.Myers R H,Anderson-Cook C M.Response surface methodology:process and product optimization using designed experiments.Wiley.com,2009.

9.Bezerra M A,Santelli R E,Oliveira E P,et al.Response surface methodology(RSM)as a tool for optimization in analytical chemistry.Talanta,2008,76(5):965-977.

10.Roberts E A H,Smith R F.Spectrophotometric measurements of theaflavins and thearubigins in black tea liquors in assessments of quality in teas.Analyst,1961,86(1019):94-98.

11.Ws l V,Fell A F.Central composite design as a powerful optimisation technique for enantioresolution of the rac-11-dihydrooracin-the principal metabolite of the potential cytostatic drug oracin.Journal of Biochemical and Biophysical Methods,2002,54(1):377-390.

12.Cloughley J B.The effect of fermentation temperature on the quality parameters and price evaluation of Central African black teas.Journal of the Science of Food and Agriculture,1980,31(9):911-919.

13.Ullah M R,Gogoi N,Baruah D.The effect of withering on fermentation of tea leaf and development of liquor characters of black teas.Journal of the Science of Food and Agriculture,1984,35(10):1142-1147.

杂志排行

茶叶的其它文章

- A Study on Effects of Turn-over Technology on the Quality of Jinmudan Oolong Tea

- Fluoride in Tea and Its Risk Assessment

- A Review on Decaffeination of Tea Products

- A Study of Historical References of Korean Royal Court Tea Culture through the Periods of Three Kingdoms,Goryeo Kingdom and Joseon Dynasty

- The Beauty of Elegance‘Pungnyu’in the Tea Culture of Korea