Preparation and Characterization of Ni0.5Zn0.5Fe2O4 Nanomaterials via Sol-GelTechnique

2013-08-16ZHUXiangrongXUZhongpingZHUZhigangCHENCheng

ZHU Xiang-rong,XU Zhong-ping,ZHU Zhi-gang,CHEN Cheng

Preparation and Characterization of Ni0.5Zn0.5Fe2O4 Nanomaterials via Sol-GelTechnique

ZHU Xiang-rong,XU Zhong-ping,ZHU Zhi-gang,CHEN Cheng

(Schoolof Urban Developmentand EnvironmentalEngineering,ShanghaiSecond Polytechnic University, Shanghai201209,P.R.China)

Ni0.5Zn0.5Fe2O4powderis synthesized by sol-geltechnique and sintered at600°C—950°C.Structural,infrared and magnetic properties of materials,as wellas microwave absorbing testwere investigated.Both X-ray diffraction(XRD) spectra and atomic force microscopy(AFM)topography image demonstrate thatthe powdersize is on nanometer scale level. Infrared absorbing band over 500 cm-1—600 cm-1are clearly observed forthe powder.High sintering temperature leads to larger grain size,as wellas lower coercivity field and saturating filed appearing in the sample for the magnetic properties. The microwave reflection attenuation could reach to 1.8 dBm over the frequency range from 6 GHz to 10 GHz forthe samples with an average thickness of0.33 mm.

Ni0.5Zn0.5Fe2O4;nanomaterials;characteristics;sol-geltechnique

0 Introduction

The spinel Ni-Zn ferrites,NixZn1-xFe2O4,have been widely studied forseveraldecades due to theirextensive application prospects on microwave and electronics devices,or environmentalengineering field[1-9]. Recently,many scientists are devoting to exploring the potentiality on stealth or anti-microwave radiation of Ni0.5Zn0.5Fe2O4,due to its large molecular magnetic momentand large magnetic losses[7].The properties of Ni0.5Zn0.5Fe2O4,including structure and magnetism, should be wellcontrolled to obtain excellentmicrowave absorbing properties,such as widerband gap and higher working frequencies nearcentimeterwave.Meanwhile, nano-Ni0.5Zn0.5Fe2O4powder is increasingly become a hot topic because its nanosized effect would help to adjustorimprove the magnetic loss and microwave absorbing properties[2,7,10-11].

Nanosized Ni0.5Zn0.5Fe2O4powder could be synthesized by many techniques such as combustion synthesis,hydrothermal method,sol-gel technique and oxalate precipitation method[2,4-5,8-9].Among above methods,sintering is a key step,and the sintering temperature is normally chosen above 1 000°C.In this paper,we adopt lower sintering temperature beneath 1 000°C to synthesize nanosized Ni0.5Zn0.5Fe2O4materials by means of sol-geltechnique.The characteristics ofthe materials including structural,infrared,magnetic and microwave absorbing properties were investigated.

1 Experimental

To synthesize Ni0.5Zn0.5Fe2O4samples by sol-gel technique,analytical grade nickel nitrate hexahydrate ((Ni(NO3)2·6H2O,w(mass fraction)>98.5%),ferric nitrate nonahydrate((Fe(NO3)3·9H2O,w>98.5 %),zinc nitrate hexahydrate((Zn(NO3)2·6H2O,w>99%)were chosen as the sources of Ni,Zn and Fe. They were accurately weighed in such way that their molar ratio could meet the nominal composition of Ni0.5Zn0.5Fe2O4.These materia chemicals were dissolved in deionized water in one beaker to form uniform solution by ultrasonic vibration and then magnetic force stirring for 1 hour.The beaker with the nitrate solution was placed in 80°C waterbath surroundings.During the water bath,some reagents including acylamide,N,N′-methylenebisacrylamide and ammonium persulfate were added into the solution.Then the finalprecursorsolution was obtained,which was placed in one vacuum drying box for 12 hours’baking at 90°C.After baking,the solution became drying gel.The gelwas sintered at600°C,800°C and 950°C for 90 minutes,respectively.The samples were slowly cooled down to room temperature(RT)aftersintering.Finally, the samples were milled into powders for characterization.

Powder X-ray diffraction(XRD)technology was used to investigate the crystallization of the samples.The surface morphology of the samples was observed by Shimadzu SPM-9600 atomic force microscope(AFM).The infrared properties were measured by Burkers IFS 66v/S Fourier transform infrared (FTIR)spectrometer.One vibrating sample magnetometer(VSM)was used to measure the magnetic properties of the samples at room temperature.Finally,reflecting method was adopted to measure the microwave absorbing properties ofthe samples.

2 Results and discussion

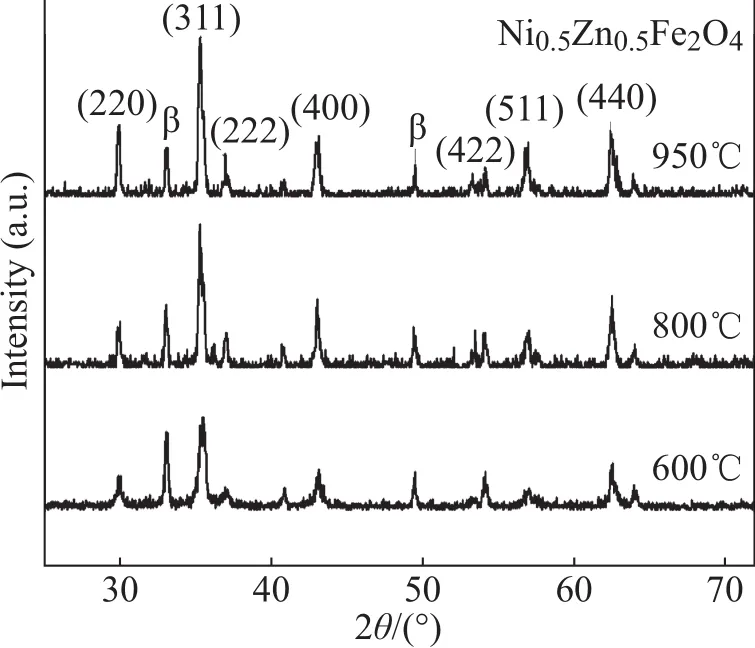

Figure 1 shows the XRD spectra of Ni0.5Zn0.5Fe2O4samples underdifferentsintering temperatures.According to Figure 1,the samples present typical polycrystalline spinel structural characterization.The high intensity of(311)peak reveals the crystallinity of Ni0.5Zn0.5Fe2O4.The additionalβpeaks imply there are few secondary phases in these samples, which mightbe Fe2O3.On the one hand,the strength of (311)peak increases with sintering temperature.On the other hand,the strength ratio between strongest(311) peak andβpeak is lowest for the sample which sintered at 600°C,and highest for the sample sintered at 950°C.Thus,itcould be concluded thatthe sample sintered at950°C presents bestcrystallinity.The crystallite or grain size of the samples for the most intense, (311)plane was determined from the X-ray data using Debye–Scherrerformula[5]:

whereλis the wavelength of X-ray;βthe full width athalfmaximum(FWHM);θis the Bragg’s diffraction angle of(311)peak.

Fig.1 The XRD spectra ofthe Ni0.5Zn0.5Fe2O4samples

Accordingly,the grain size of all the samples could be estimated beneath 100 nm.Thus allthe samples are nanosized.However,the full width at halfmaximum is largestfor sample sintered at950°C,implying thatthe grain size ofthe samples would increasing with sintering temperature.This result is similar to that reported by Coasta et al.[11],where the sintering temperate vary from 1 100°C to 1 400°C.Furthermore,the 2θposition ofthe samples is very similar,revealing thatthe samples presentclose lattice constants although they were sintered atdifferenttemperatures.

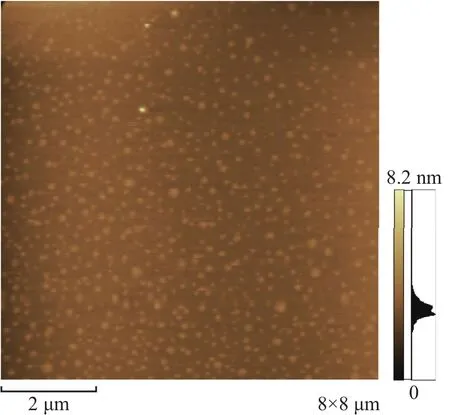

AFM is a relative simple instrument to observe the morphologies ofmaterials.Comparing to the scanning electron microscopy(SEM)or transmission electron microscopy(TEM),while observing ferromagnetic samples,AFMis more suitable since the samples might contaminate the lens of SEM or TEM.To prepare the sample forAFM,few Ni0.5Zn0.5Fe2O4powdersamples were uniformly dispersed into ethanolby ultrasonic vibration to form suspension liquid.Then the liquid was dropped onto one mica slice.When mostof the ethanol on the mica slice was vaporized,the morphology ofthe powders could be observed.Figure 2 shows the AFM topography image of the sample sintered at 950°C. Nanoparticles with less than 100 nm are clearly visualized on AFMimage.Forthe samples sintered atother temperatures,similar morphologies were also observed by AFM.

Fig.2 The AFMtopography image of the sample sintered at950°C

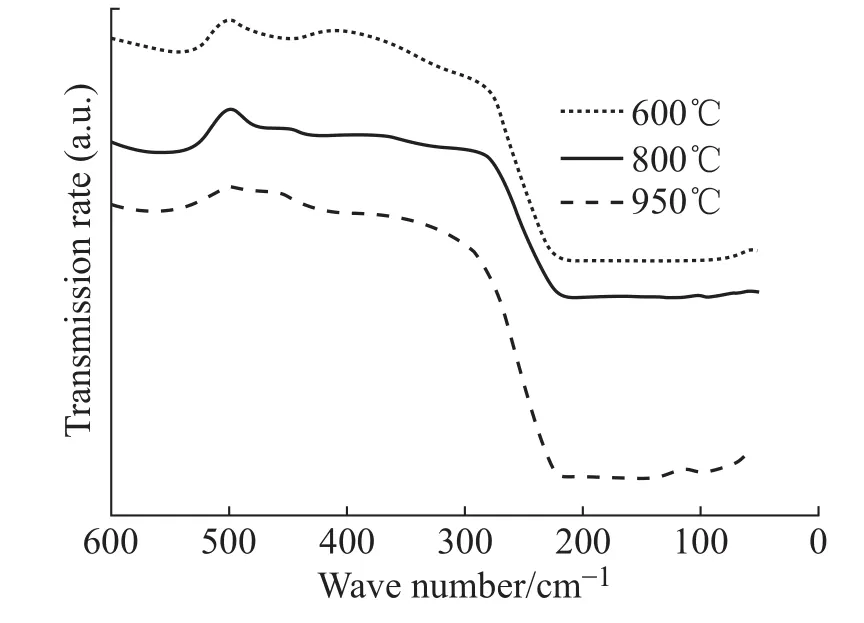

The infrared spectra of the samples are displayed in Figure 3.The measuring range ofinfrared wave was below 600 cm-1.KBr crystals were chosen as the window materials for FTIR measurements.In the FTIR spectra of spinelmetallic oxides,there are usually two main IR absorbing bands.One is defined asν1band, in the range 500 cm-1—600 cm-1,corresponding to intrinsic stretching vibrationsofthe metalatthe tetrahedralsite(Td),Mtetra↔O.The otherisν2band,usually observed in the range 450 cm-1—385 cm-1,assigned to octahedral-metalstretching(Oh),Mocta↔O[12].As shown in Figure 3,theν1band is obvious in the samples.Whereas theν2band is obscure.These results mean thatstretching vibrations ofthe metalatthe tetrahedralsite is more active than atoctahedralsite.Moreover,theν1is different among the samples sintered at different temperature.The sample sintered at 950°C presents highestν1,566 cm-1.Whereas the sample sintered at600°C presents lowestν1,547 cm-1.The shiftreveals the differences ofproperties ofmetal-oxide bond among the samples.In addition,below 230 cm-1, the transmission rates decline steeply,which is related to the IR absorbing properties of the window materials KBr.

Fig.3 The FTIR spectra ofthe Ni0.5Zn0.5Fe2O4samples

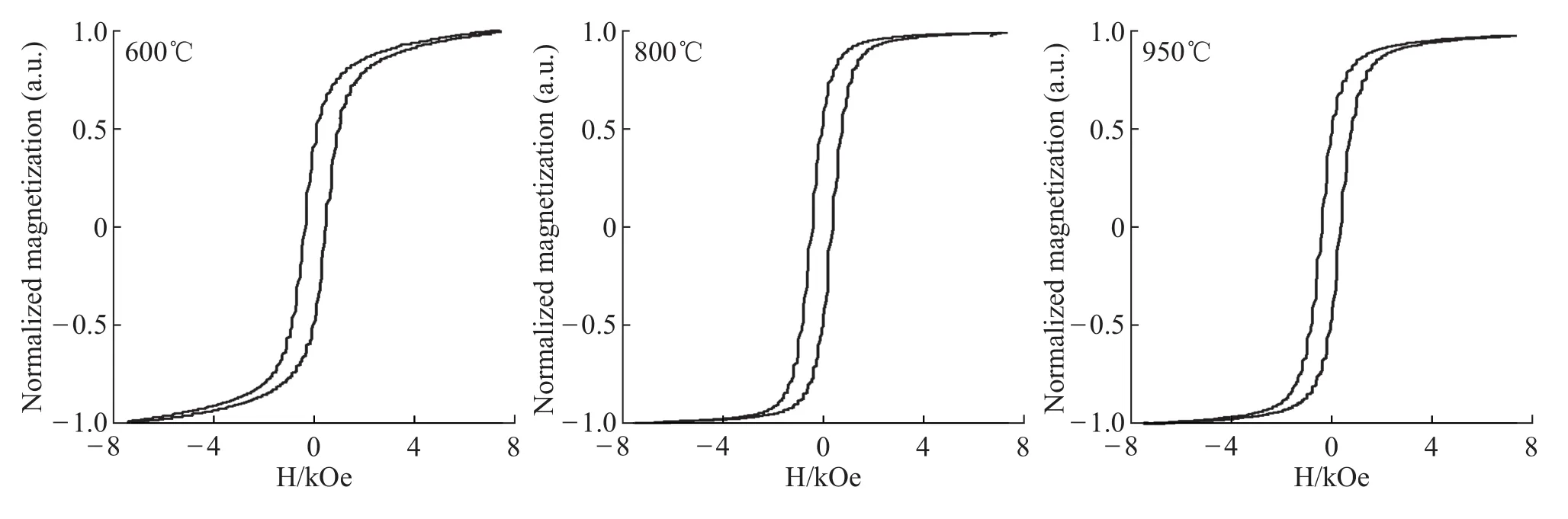

Figure 4 exhibits the static magnetization hysteresis loops of the samples.Typical soft magnetism is shown in Figure 4.It is well known that the magnetic properties of Ni-Zn ferrites are first determinedby the distribution of Ni,Zn and Fe in the spinel cell, which is correlated with the superexchange(A–O–B) interaction[12-13].The structuralcharacteristics such as the crystallite size also play importantroles in the magnetic behavior of Ni-Zn ferrites.On the one hand,the sample sintered at600°C is relatively difficultly magnetized.The field forsaturating magnetization amounts to above 8 kOe.However,for the samples sintered at 800°C and 900°C,the saturating field is much lower, just below 4 kOe.On the other hand,for the samples sintered at600°C,800°C and 950°C,the corresponding coercivity field is 415 Oe,393 Oe and 346 Oe,respectively.Namely,the coercivity field increases with sintering temperature decreased.Usually,the coercivity field is related to the grain size of materials.Larger grainstend to constructa large numberofdomain walls. The magnetization caused by domain wall movement requires less energy than that by domain rotation.As the number of domain walls increases with increasing grain size,the contribution ofwallmovementto magnetization is greater than thatof domain rotation.Therefore,samples with larger grains are expected to have a low coercivity,H[11]c.As indicated in XRD spectra(Figure 1),the grain size increases with the sintering temperature.Thus the sample sintered at 600°C presents highestcoercivity field and saturating field.

Fig.4 Static magnetization loops of the samples Ni0.5Zn0.5Fe2O4atroom temperature

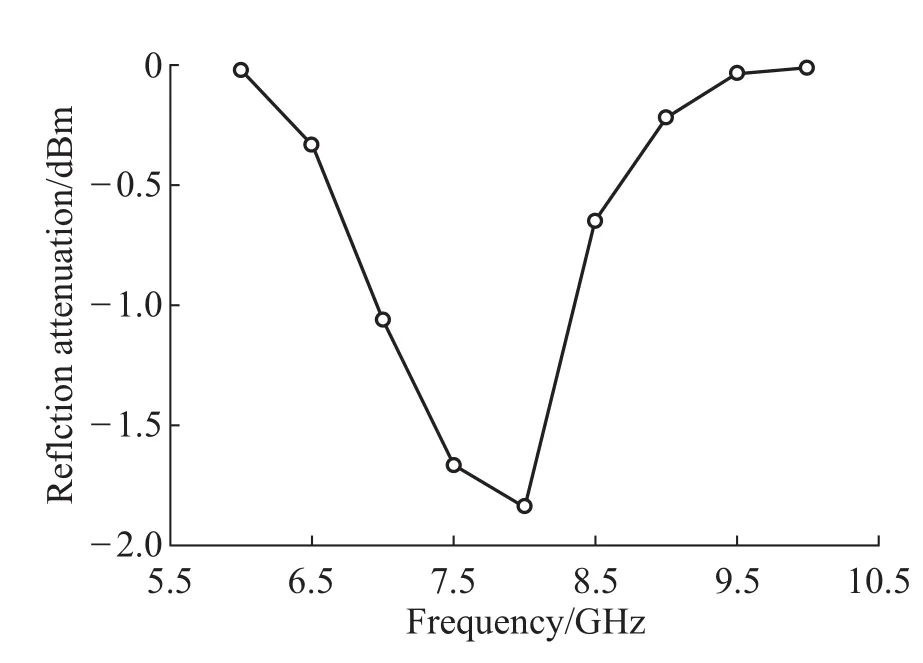

The samples sintered at 950°C were chosen to investigate the microwave absorbing properties.For measuring the microwave absorption,the samples were paved on the surface ofone 10 cm×10 cm square aluminum plate.One Agilentsignalgeneratorwas used to emitout high frequency signal.Via a couple of conic antennas,one beam of microwave signal with given high frequency and initial 1 mW(0 dBm)power was transmitted to the surface of the samples,reflected and absorbed by the samples on the aluminum plate.The reflected signal was received by one Agilent spectrum analyzer.The microwave absorbing ability was evaluated by calculating the power attenuation between the incidence signaland reflection signal.Figure 5 showsthe microwave reflection attenuation spectra ofthe samples.The microwave frequency,ranging from 6.0 GHz to 10 GHz,is related to the bandwidth of the antennas. According to Figure 5,the maximum powerattenuation reaches to 1.8 dBm,occurring near 8.0 GHz.

Fig.5 The microwave reflection attenuation spectra ofthe samples sintered at950°C

The microwave absorbing abilities among the Ni-Zn ferrites are quite different,according to the reports in differentliteratures.Usually the microwave properties are dependent on both the structural properties of the materials such ascrystallite size and the measuring condition,including the thickness and distributing area of the samples.Evidently the microwave absorption would be enhanced by raising the thickness of the samples. However,absolutely raising the thickness would result in high application cost.For further investigating the capability ofmicrowave absorbing foroursamples,the average thickness of the paved samples was calculated according to their weight and distributing area on the aluminum plate.We assume the density of the samples was theoreticalvalue of Ni-Zn ferrites,8.35 g/cm3.The average calculated thickness is 0.33 mm,which means the layer of the sample is much thinner.These results imply thatthe samples have reasonable microwave absorbing properties forcertain application.

3 Conclusions

The nanosized Ni0.5Zn0.5Fe2O4powder was synthesized by sol-gel technique,which presents typical spinel structural and soft magnetism at room temperature.Obvious infrared absorbing band over 500 cm-1—600 cm-1is observed forallthe samples. Highersintering temperature led to largergrain size and lower saturating field and coercivity field.For the samples with an averaged thickness of 0.33 mm paved on a 10 cm×10 cm square aluminum plate,the maximum microwave reflection attenuation reaches to 1.8 dBm overthe frequency range from 6 GHz to 10 GHz.

[1]RAHIMI M,KAMELI P,RANJBAR M,et al.The effect ofzinc doping on the structuraland magnetic properties of Ni1-xZnxFe2O4[J].J.Mater.Sci.,2013,48:2969-2976.

[2]WANG HW,KUNG S C.Crystallization ofnanosized Ni-Zn ferrite powders prepared by hydrothermal method[J]. J.Mag.Mag.Mater.,2004,270:230-236.

[3]AKHTAR M N,YAHYA N,KOZIOL K,et al.Synthesis and characterizations ofNi0.8Zn0.2Fe2O4-MWCNTscomposites for their application in sea bed logging[J].Ceram. Int.,2011,37:3237–3245.

[4]ZAHIS,HASHIMA M,DAUD A R.Synthesis,magnetic properties and microstructure of Ni-Zn ferrite by sol-gel technique[J].J.Mag.Mag.Mater.,2007,308:177-182.

[5]SHINDE T J,GADKARIA B,VASAMBEKAR P N.DC resistivity of Ni-Zn ferrites prepared by oxalate precipitation method[J].Mater.Chem.Phys.,2008,111:87-91.

[6]KULKARNI D C,PATIL S P,PURI V.Properties of NixZn(1-x)Fe2O4thick films atmicrowave frequencies[J]. Microelectronics Journal,2008,39:248-252.

[7]ZHAO D L,LV Q,SHEN Z M.Fabrication and microwave absorbing properties of Ni-Zn spinel ferrites[J].J.Alloys Compd.,2009,480:634-638.

[8]SREEJA V,VIJAVANAND S,DEKA S,et al.Magnetic and M¨ossbauer spectroscopic studies of Ni-Zn ferrite nanoparticles synthesized by a combustion method[J].Hyperfine Interact,2008,183:99-107.

[9]TANGCHAROEN T,RUANGPHANIT A,KLYSUBUN W,etal.Characterization and enhanced photocatalytic performance ofnanocrystalline Ni-substituted Zn ferrites synthesized by DEA-assisted sol-gelauto-combustion method [J].J.Sol-GelSci.Technol.,2013,66:387-398.

[10]TING T H,YU R P,JAU Y N.Synthesis and microwave absorption characteristics of polyaniline/NiZn ferrite composites in 2—40 GHz[J].Mater.Chem.Phys.,2011,126: 364-368.

[11]COASTA A C F M,TORTELLA E,MORELLIMR,etal. Synthesis,microstructure and magnetic properties of Ni-Zn ferrites[J].J.Magn.Magn.Mater.,2003,256:174-182.

[12]SERTKOL M,K¨OSEOˇGLU Y,BAYKAL A,et al.Microwave synthesis and characterization of Zn-doped nickel ferrite nanoparticles[J].J.Alloys Compd.,2009, 486:325-329.

[13]CHOI Y,CHO N I,KIM H C,et al.Magnetic properties of Ni-Zn ferrite powders formed by self-propagating high temperature synthesis reaction[J].J.Mater.Sci:Materials in Electronics,2000,11:25-30.

溶胶-凝胶法制备Ni0.5Zn0.5Fe2O4纳米材料特性的研究

祝向荣,许中平,朱志刚,陈诚

(上海第二工业大学城市建设与环境工程学院,上海201209)

利用溶胶-凝聚法制备了Ni0.5Zn0.5Fe2O4;粉末材料,烧结温度范围600°C~950°C。对材料的结构、红外、磁学和微波吸收特性进行了研究。材料的XRD图谱和原子力显微镜形貌观察表明,材料在纳米尺度范围之内。在500 cm-1~600 cm-1波数范围内,材料具有明显的红外吸收特性。材料的晶粒尺寸随着烧结温度的提高而增加,且较高温度烧结的材料具有相对低的矫顽力和饱和磁场。利用反射衰减实验研究材料在6 GHz~10 GHz波段范围的吸波特性,结果表明,0.33 mm厚度的样品在常温下的反射衰减达到1.8 dBm。

Ni0.5Zn0.5Fe2O4;纳米材料;特性;溶胶-凝聚法

TB39

A

1001-4543(2013)04-290-06

2013-05-07;

2013-10-30

祝向荣(1971–),男,江西人,副研究员,博士,主要研究方向为信息及环境友好功能材料,电子邮箱xrzhu@sspu.edu.cn。

上海“东方学者”计划项目、上海第二工业大学校基金项目(No.A30XK121101,No.A20XK11X020)资助