Advances in Large-eddy Simulation of Two-phase Combustion (I)LES of Spray Combustion*

2012-10-31ZHOULixing周力行LIKe李科andWANGFang王方DepartmentofEngineeringMechanicsTsinghuaUniversityBeijing00084ChinaDepartmentofThermalEngineeringBeihangUniversityBeijing009China

ZHOU Lixing (周力行)**, LI Ke (李科) and WANG Fang (王方) Department of Engineering Mechanics, Tsinghua University, Beijing 00084, China Department of Thermal Engineering, Beihang University, Beijing 009 China

Advances in Large-eddy Simulation of Two-phase Combustion (I)LES of Spray Combustion*

ZHOU Lixing (周力行)1,**, LI Ke (李科)1and WANG Fang (王方)21Department of Engineering Mechanics, Tsinghua University, Beijing 100084, China2Department of Thermal Engineering, Beihang University, Beijing 100191, China

Spray combustion is widely used in power, transportation, chemical and metallurgical, iron and steel making, aeronautical and astronautical engineering. In recent years, large-eddy simulation (LES) becomes more and more attractive, because it can give the instantaneous flow and flame structures, and may give more accurate statistical results than the Reynolds averaged Navier-Stokes (RANS) modeling. In this paper, the present status of the studies on LES of spray combustion is reviewed, and the future research needs are discussed.

spray combustion, large-eddy simulation, sub-grid scale model

1 INTRODUCTION

The CFD (computational fluid dynamics) simulation of spray combustion is widely used in power,transportation, chemical and metallurgical, iron and steel making, aeronautical and astronautical engineering.The traditional CFD method is the Reynolds averaged Navier-Stokes (RANS) modeling. In recent years,large-eddy simulation (LES) becomes more and more attractive, because it can give the instantaneous flow and flame structures, and may give more accurate statistical results than RANS modeling. In LES the governing equations are filtered and the filtered variables of large scales are directly solved. For variables of small scales (unresolved scales) it is necessary to use the sub-grid scale (SGS) models. Up to now, there is rapid development on the LES of spray combustion,which is used in gas-turbine combustors, rocket-engine combustors and internal combustion engines. Recently,Moin and Apte [1], Patel et al. [2, 3] and James et al. [4]published series of papers, reporting their LES results.The key problems are the SGS stress models, combustion models, and their detailed experimental validation.In the following text, a review is given to show these models and their simulation results, and some comments to these results are made.

2 LARGE-EDDY SIMULATION

2.1 Filtered governing equations for LES of two-phase combustion

The filtered gas governing equations for Eulerian-Lagrangian LES of two-phase combustion can be obtained as

In the Eulerian-Lagrangian LES, the particle-phase equations are the same as those in RANS modeling [5].

The accuracy and reasonability of LES are determined by: (1) sufficiently fine grids required for LES, (2) more accurate numerical scheme than that required by RANS modeling, (3) reasonable SGS stress and combustion models.

2.2 SGS stress models for single-phase gas flows

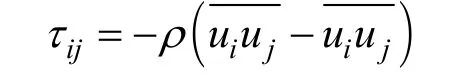

For single-phase gas flows the frequently used SGS stress models are the Smagorinsky eddy viscosity model, Germano’s dynamic eddy viscosity model and Kim’s SGS energy equation model. The SGS stress in the momentum equation is defined by

The Smagorinsky eddy viscosity model [6] is given by

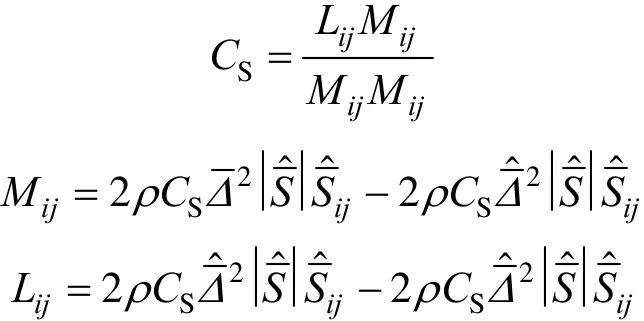

where CS= 0 .16 is the Smagorinsky constant, and Δ is the filtered scale. The shortcoming of the Smagorinsky model is its too large dissipation rate of the kinetic energy. Germano et al. [7] proposed a dynamic Smagorinsky eddy viscosity model, in which the coefficient CSis not a constant, but is determined by the following filtration process

Many investigators have indicated that in many cases the dynamic viscosity model gives better results than that given by the standard Smagorinsky model. Kim et al. [8] proposed a SGS kinetic energy model

The merit of the SGS kinetic energy model is that it avoids the negative value of eddy viscosity, so it is better than the eddy viscosity models. In applications it has been reported that the results of SGS kinetic energy model are close to those obtained using the dynamic eddy viscosity model.

2.3 SGS stress models for dispersed two-phase flows

Most of investigators use Eulerian-Lagrangian LES of dispersed two-phase flows, and the SGS stress model for single-phase flows is applied to the gas phase of two-phase flows without accounting for the effect of particles. Some investigators use Eulerian-Eulerian LES by adopting the SGS model similar to the Smagorinsky model for both gas and particle phases [9]. Recently, Simonin et al. [10] proposed a particle SGS stress model for Eulerian-Eulerian LES,but theoretically it is rather complex. Alternatively,Liu et al. [11] simply extended the idea of USM(unified secondorder moments) and k-ε-kptwo-phase turbulence models into two-phase SGS stress models and proposed the USM SGS and two-phase SGS kinetic energy equation models.

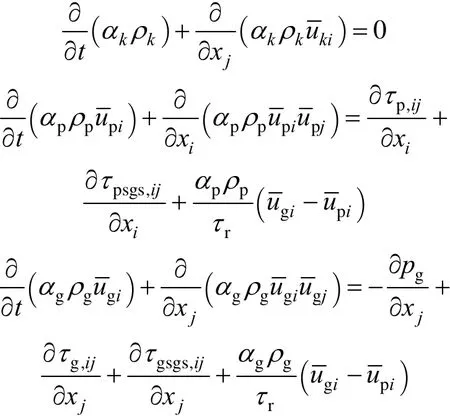

The filtered two-phase continuity and momentum equations in Eulerian-Eulerian LES can be given as

In the USM SGS model, the two-phase SGS stresses are defined by

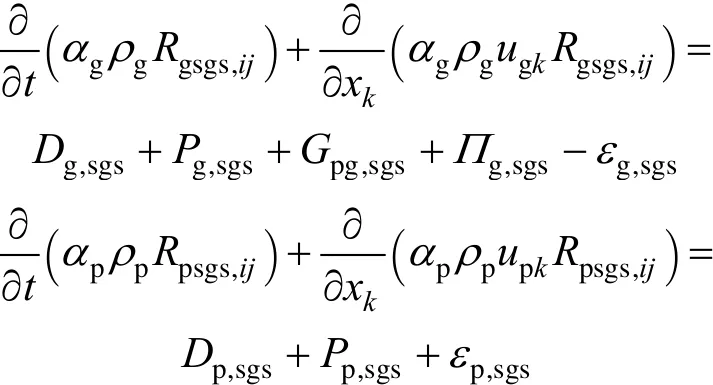

and these stresses are determined by the transport equations as

This model has been used to simulate swirling gas-particle flows with good results.

2.4 The gas combustion model for LES

For the gas combustion models in LES, different combustion models are used in RANS modeling, such as the eddy-break-up (EBU)-Arrhenius model, various presumed probability density distribution function(PDF) models, the laminar flamelet model (LFM), the conditional moment closure (CMC) model and the PDF equation model (the filtered PDF equation, or FDF)model. Most investigators frequently use the LFM for LES of non-premixed flames, the linear-eddy model and G-equation model for premixed flames, EBU and FDF models for both types of flames. The present authors and their co-workers make attempts to test different combustion models [12], and propose a second-order SGS combustion model (SOM SGS) for LES [13]

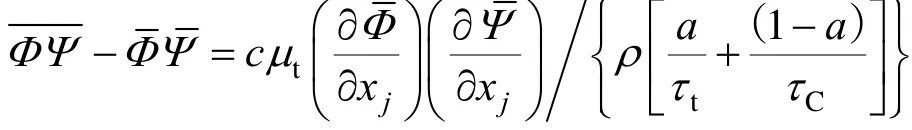

The sub-grid scale correlation terms are given by the algebraic expressions

where Φ and Ψ denote Yoxor Yfuor K,Cτ is the chemical reaction time,tτ is the turbulent diffusion time, a and c are model constants. The reaction time and fluctuation time are given by

where β is the stoichiometric coefficient. This SOM SGS model has been successfully used in LES of nonpremixed gas jet combustion, gas swirling combustion and gas premixed combustion behind a bluff body.

3 APPLICATIONS OF LES

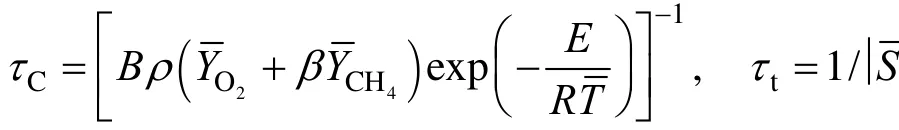

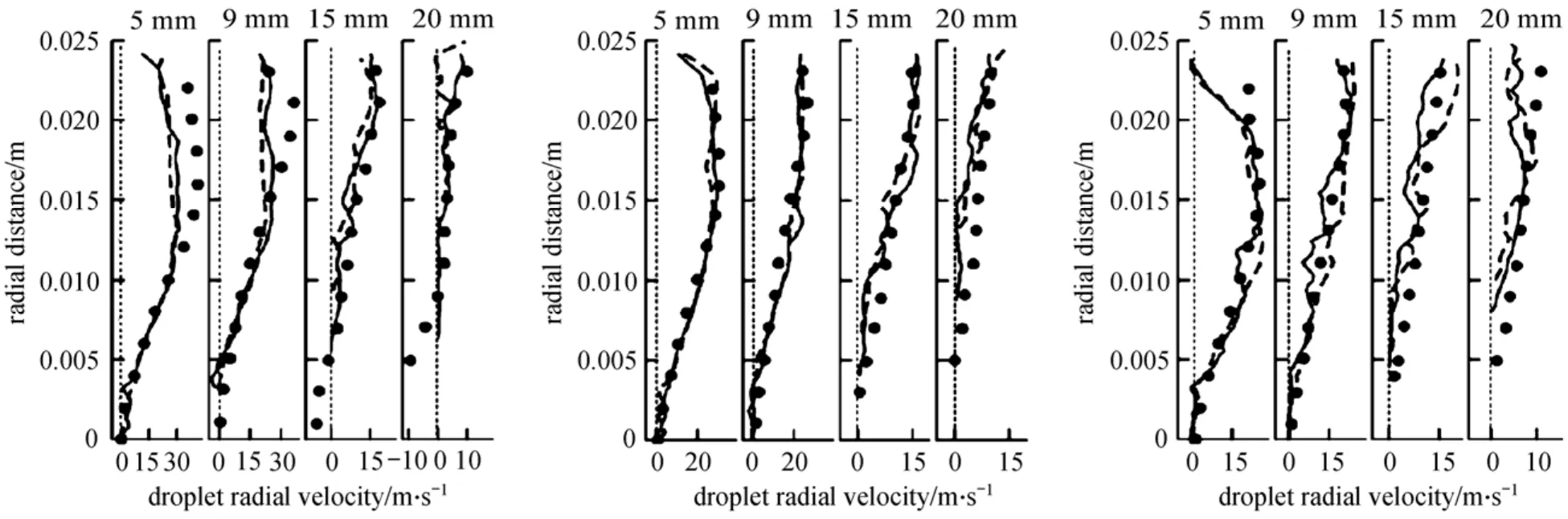

3.1 Spray combustion in gas-turbine combustors Moin and Apte [1] reported the LES of spray combustion in a gas-turbine combustor using a dynamic eddy-viscosity SGS stress model and a laminarflamelet combustion model with a presumed PDF. The statistical results for isothermal gas-particle flows are validated by experiments. For example, the predicted droplet velocity and its comparison with experiments are shown in Fig. 1. The instantaneous gas velocity map is given in Fig. 2, and the instantaneous temperature map in a gas-turbine combustor is shown in Fig. 3. The LES statistical results for the combustion case were validated for the temperature distribution only at a cross section. No other experimental validation for combustion processes was reported.

Figure 1 Droplet velocity distribution [1]

Figure 2 Instantaneous gas velocity map [1]

Figure 3 Instantaneous temperature map in a gas-turbine combustor [1]

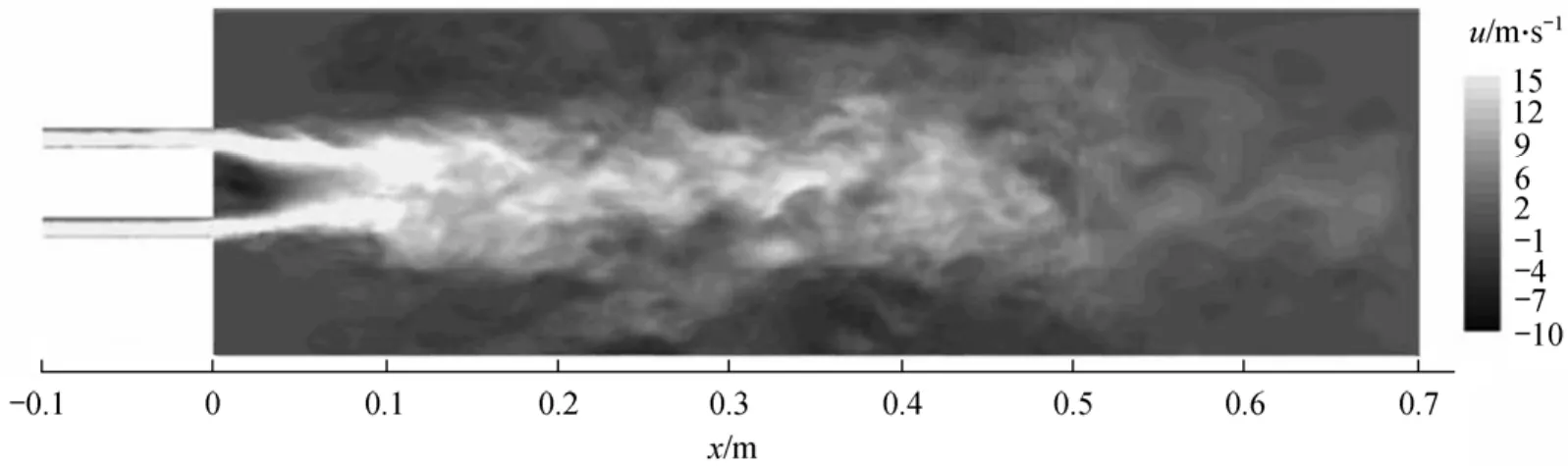

Figure 4 Isothermal gas velocity [2, 3]

Patel et al. [2, 3] did LES of spray combustion in a modelled and a full-scale gas-turbine combustor,using a SGS energy equation stress model and a lineareddy combustion model. The statistical results for gas time-averaged velocity, RMS (root mean square)fluctuation velocity and droplet velocity are well validated by experiments. For example, the predicted isothermal gas velocity profiles are in good agreement with the experiments, as shown in Fig. 4. The instantaneous temperature maps are given in Fig. 5. No experimental validation of the statistical results for temperature and concentration was reported.

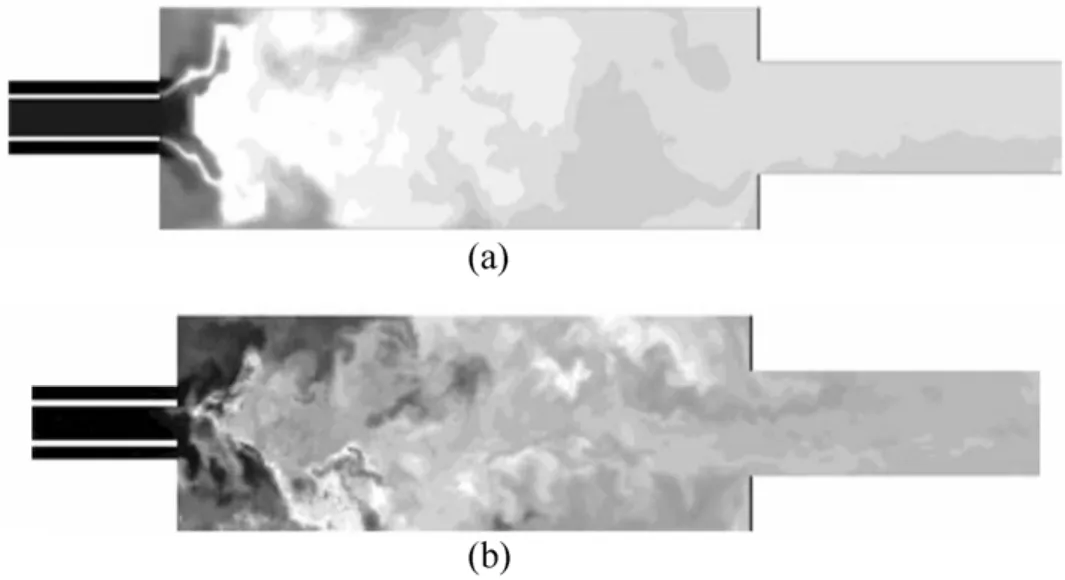

James et al. [4] conducted the LES of spray combustion in a gas-turbine combustor using standard and dynamic Smagorinsky, SGS energy equation stress models, simplified PDF and filtered PDF (FDF)equation combustion models. Validation of statistical results for isothermal flows by experiments shows that the dynamic Smagorinsky and SGS energy equation models are better than the standard Smagorinsky model. For the combustion case, the instantaneous velocity and temperature maps were obtained. For example, the instantaneous temperature maps are shown in Figs. 6 and 7. No validation of the statistical results for the spray combustion was reported.

Figure 5 Instantaneous temperature map [2, 3]

Figure 6 Instantaneous temperature map [4]

Figure 7 Instantaneous temperature map [4]

Boileau et al. [9] adopted a two-fluid-LES (Eulerian-Eulerian LES) to simulate an annular gas-turbine combustor. The Wale eddy-viscosity SGS stress model,similar to Smagorinsky model, was used for both gas and dispersed phases. A dynamic thickened-flame combustion model was used. The statistical results for isothermal swirling gas-particle flows are well validated by the measurement results. The instantaneous fuel concentration, droplet size and temperature maps,and the time series for ignition and flame propagation were obtained. No experimental validation of the statistical results for the combustion case was reported.

Zhao et al. [14] did LES of a gas-turbine combustor by using a SGS energy equation stress model and an eddy-break-up (EBU) combustion model. The obtained instantaneous velocity vectors are in qualitative agreement with the PIV measurement results. The statistical results for temperature and oxygen concentration at the exit are close to the measurement results.

3.2 LES of spray combustion using the SOM combustion model

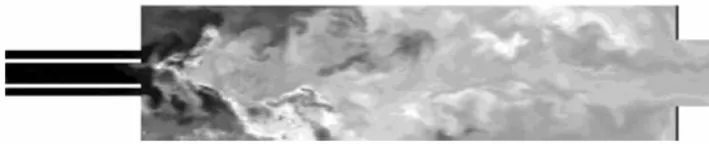

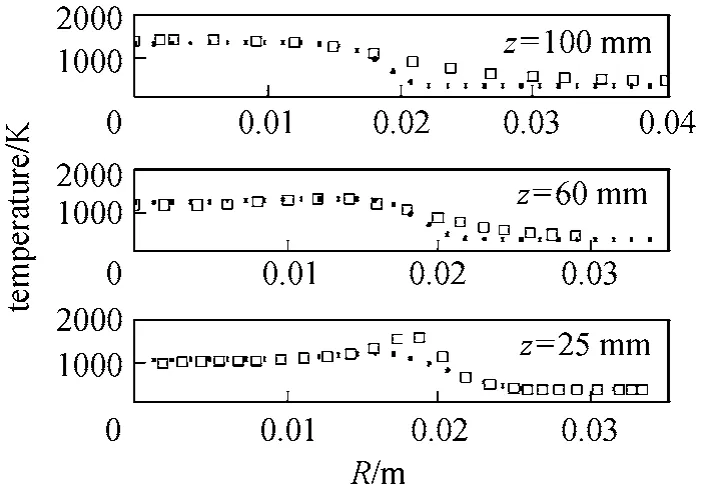

Recently Li and Zhou [15] used the SOM SGS combustion model in LES of ethanol spray combustion in a combustor measured in [16]. The SGS stress model is a SGS kinetic energy model. Fig. 8 gives the predicted time-averaged gas temperature using both SOM model and a finite-rate Arrhenius (FA) model without accounting for the effect of SGS reaction rate.The comparison is made among the LES results, experiments and RANS modeling results using the most complex PDF equation model reported in [16]. It is seen that the LES-SOM results are better than the LES-FA results, indicating that the small-scale temperature and concentration fluctuations do have obvious effect on combustion, in particular at 0.02 m where the LES-SOM results give the temperature peak at r 0.016 m observed in experiments, which cannot be given by the LES-FA results. Furthermore, the LES results are in much better agreement with the experiments than those obtained by RANS modeling using the most complex PDF equation model. Therefore, in general, LES can give more accurate statistical results than RANS modeling, even when using very simple one-step global kinetics.

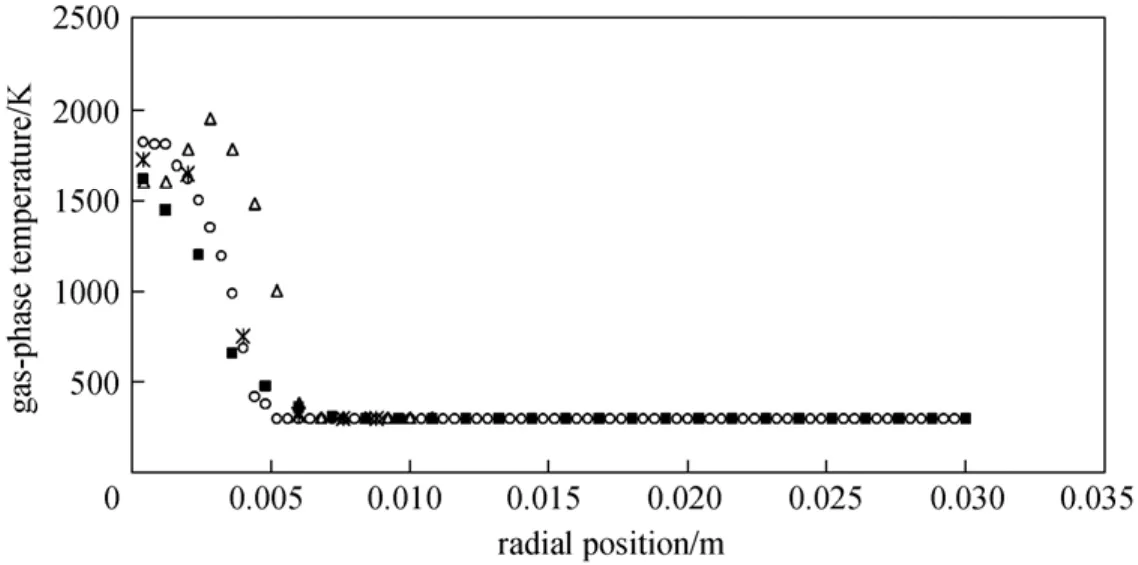

Figure 9 gives the predicted instantaneous vorticity map. The coherent structures are initially produced in the near-inlet shear region of fuel jet flows, then intensified to become large vortices, and finally weakened in the downstream region.

Figure 8 Statistically averaged gas temperature for ethanol spray combustion [15]

Figure 9 Instantaneous vorticity map [15]

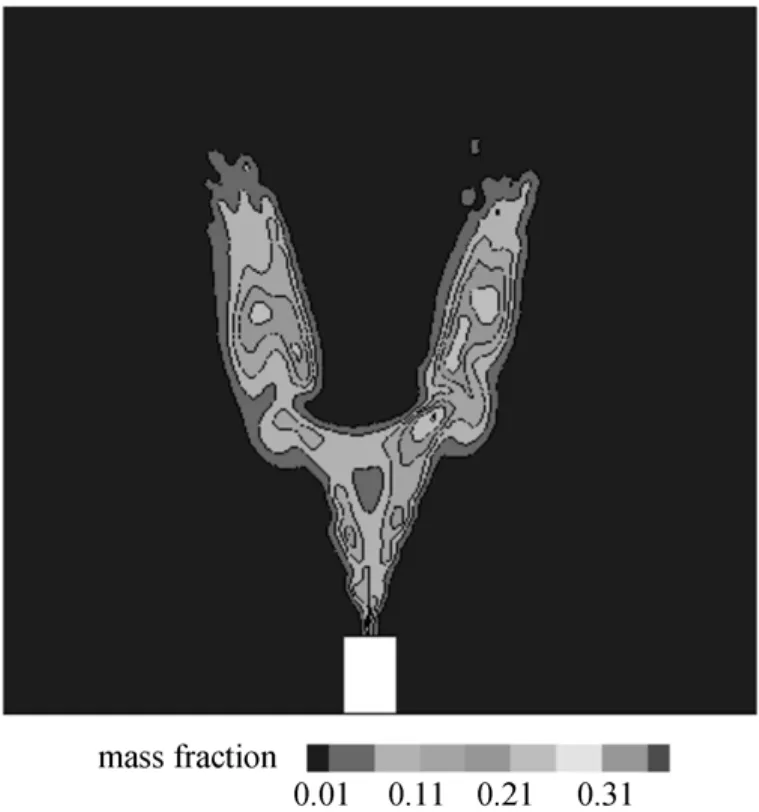

Figure10 Instantaneous fuel vapor concentration [15]

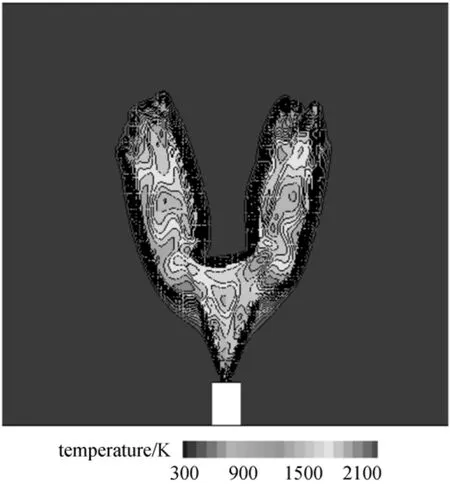

The instantaneous ethanol vapor concentration is given in Fig. 10. Clearly, intensive evaporation takes place in the shear region, and the highest fuel concentration is located at the periphery of the large-vortex region. Fig. 11 gives the instantaneous gas temperature map in the z-r plane. In the case of two-phase jet combustion, high temperature develops around the coherent structures in the region of high vapor concentration, but not inside the large vortices. Besides,there are many small flame islands, which do not exist in single-phase jet flame, showing the combustion of separate droplet groups.

Wang et al. [17] used SOM combustion model to simulate a methanol spray combustor by LES. The LES predicted statistically averaged temperature given in Fig. 12 also shows good agreement with the measurement results.

4 FUTURE RESEARCH NEEDS AND CONCLUSIONS

(1) LES of spray combustion has been used in practical combustors, in particular gas-turbine combustors.Different SGS stress models and combustion models are used, among which the laminar-flamelet model and EBU (EDC) model are frequently used.

Figure 11 Instantaneous gas temperature for ethanol spray combustion [15]

Figure 12 Temperature distribution for methanol spray combustion [17]□ Exp.; ● LES-SOM

(2) In many LES studies there is no detailed experimental validation for the statistically averaged results. Further studies on SGS combustion models are still an important task for CFD modellers.

(3) The SOM combustion model proposed by the present authors is well validated by experiments and is proved to be one of the reasonable and economical models. Further application of this model to various combustors and extended validation should be made.

(4) All of available combustion models for two-phase combustion are taken from the gas combustion models. There is a need to develop a two-phase SGS combustion model based on DNS (direct numerical simulation), since the two-phase flame structures are different from the single-phase flame structures.

ACKNOWLEDGEMENTS

This paper was written and accomplished during the first author’s visit to VTT Technical Research Center of Finland, financially supported by this center.Thanks to Dr. Kallio from VTT Technical Research Center for her help and encouragement.

NOMENCLATURE

B pre-exponential factor

D dissipation term

E activation energy, J·mol−1

h ehalpy

k sub-grid scale kinetic energy, m2·s−2

M relative molecular mass

P production term

Pr Prandtl number

p pressure, Pa

r radius, m

u velocity component, m·s−1

S source term

Sc Schmidt number

T temperature, K

t time, s

wsreaction rate, kg·s−1

wsgssub-grid reaction rate, kg·s−1

x, y, z space coordinate

Y mass fraction

β stoichiometric ratio

µ dynamic viscosity, kg·m−1·s−1

μtsubgrid-scale turbulent viscosity, kg·m−1·s−1

ρ density, kg·m−3

τ subgrid-scale stress

τCchemical reaction time, s

τTturbulent diffusion time, s

Superscript

− filtered value

Subscripts

C chemical reaction

fu fuel

g gas

i, j, k components of coordinates

ox oxygen

p particle

sgs sub-grid scale

t turbulents

1 Moin, P, Apte, S.V., “Large-eddy simulation of realistic gas turbine combustors”, AIAA J., 44 (4), 698-708 (2006).

2 Patel, N., Menon, S., “Simulation of spray-turbulence-flame interactions in a lean direct injection combustor”, Combust Flame, 153,228-257 (2008).

3 Patel, N., Kirtas, M., Sankaran, V., Menon, S., “Simulation of spray combustion in a lean direct injection combustor”, Proceedings of the Combustion Institute, 31, 2327-2334 (2007).

4 James, S., Zhu, J., Anand, M.S., “Large-eddy simulations as a design tool for gas turbine combustion systems”, AIAA J., 44 (4), 674-686 (2007).

5 Zhou, L.X., Theory and Numerical Modeling of Turbulent Gas-Particle Flows and Combustion, CRC Press, Florida (1993).

6 Smagorinsky, J., “General circulation experiments with the primitive equations (I) The basic experiment”, Monthly. Weather Rev., 91,99-164 (1963).

7 Germano, M., Piomelli, U., Moin, P., Cabot, W.H., “A dynamic sub-gridscale eddy viscosity model”, Physics of Fluids A, 3 (7), 1760-1765 (1991).

8 Kim, W.W., Menon, S., Mongia, H.C., “Large-eddy simulation of a gas turbine combustor flow”, Combustion Science and Technology,143, 25-62 (1999).

9 Boileau, M., Pascaud, S., Riber, E., Cuenot, B., Gicquel, L.Y.M.,Poinsot, T.J., Cazalens, M., “Investigation of two-fluid methods for large eddy simulation of spray combustion in gas turbines”, Flow Turbulence and Combustion, 80, 291-321 (2008).

10 Moreau, M., Simonin, O., Bédat, B., “Development of gas-particle Euler-Euler LES approach: A priori analysis of particle sub-grid models in homogeneous isotropic turbulence”, Flow, Turbulence and Combustion, 82, 295-324 (2010).

11 Liu, Y., Zhou, L.X., Xu, C.X., “Large-eddy simulation of swirling gas-particle flows using a USM two-phase SGS stress model”,Powder Technology, 198, 183-188 ( 2010).

12 Zhou, L.X., Hu, L.Y., Wang, F., “Large-eddy simulation of turbulent combustion using different combustion models”, Fuel, 87, 3123-3131(2008).

13 Zhou, L.X., “Development of SOM combustion model for Reynolds-averaged and large-eddy simulation of turbulent combustion and its validation by DNS”, Science in China E, 51 (8), 1073-1086(2008).

14 Yan, Y.W., Zhao, J.X., Zhang, J.Z., Liu, Y., “Large-eddy simulation of two-phase spray combustion for gas turbine combustors”, Applied Thermal Engineering, 28, 1365-1374 (2008).

15 Li, K., Zhou, L.X., “Large-eddy simulation of ethanol spray combustion using a finite-rate combustion model”, In: Seventh International Symposium on Coal Combustion, Harbin Institute of Technology Harbin, China (2011).

16 Ge, H.W., Düwel, I., Kronemayer, H., Dibble, R.W., Gutheil, E.,Schulz, C., Wolfrum, J., “Laser-based experimental and Monte Carlo PDF numerical investigation of an ethanol/air spray flame”, Combustion Science and Technology, 180 (8), 1529-1547 (2008).

17 Wang, F., Leboeuf, F., Huang, Y., Zhou, L.X., Sayma, A.I., “An algebraic sub-grid scale turbulent combustion model”, In: Proceedings of the ASME Turbo Expo, ASME, USA, Vol.2, Parts A and B, 1-8(2010).

2011-10-24, accepted 2011-10-28.

* Supported by the National Natural Science Foundation of China (50606026, 50736006) and the Foundation of State Key Laboratory of Engines, Tianjin University (K-2010-07).

** To whom correspondence should be addressed. E-mail: zhoulx@mail.tsinghua.edu.cn

猜你喜欢

杂志排行

Chinese Journal of Chemical Engineering的其它文章

- Analysis of Absorption and Reaction Kinetics in the Oxidation of Organics in Effluents Using a Porous Electrode Ozonator*

- Flame Imaging in Meso-scale Porous Media Burner Using Electrical Capacitance Tomography*

- Modelling and Fixed Bed Column Adsorption of Cr(VI) onto Orthophosphoric Acid-activated Lignin

- Top-cited Articles in Chemical Engineering in Science Citation Index Expanded: A Bibliometric Analysis

- Adsorptive Removal of Para-chlorophenol Using Stratified Tapered Activated Carbon Column

- Mass Transfer of Copper(II) in Hollow Fiber Renewal Liquid Membrane with Different Carriers*