新型石墨烯涂层使金属耐腐蚀性提高百倍

2012-09-21

新型石墨烯涂层使金属耐腐蚀性提高百倍

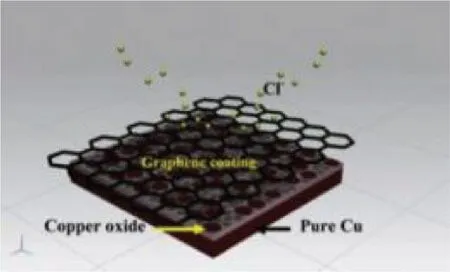

方面的潜能。研究小组通过一种叫做“化学气相沉积”的技术,在800~900摄氏度时使石墨烯紧密贴在铜上,并在盐水中对其进行测试。

“我们的成果也是迄今为止所报道的最佳改进之一。”论文合著者曼纳卡·玛加姆德说,“其耐腐蚀性比未经处理的铜提高了近100倍。其他研究可能只有五六倍或更多。这是一个相当大的飞跃。”

该研究的主要实验人员帕拉玛·班纳吉说,石墨烯具有优良的机械性能和很高的强度。

金属上常用的聚合物涂层很容易被刮伤,降低了保护性能。虽然石墨烯涂层从外观上既看不到也摸不着,却更加坚固抗损伤。“我把它叫做‘神奇的材料’。”

“在澳大利亚这样被海洋包围的国家,用原子涂层为环境提供特殊保护尤为重要。”班纳吉说,虽然初步实验仅限于铜,目前他们已在用其他金属开展实验。

研究人员指出,这项技术具有广泛的应用前景,从远洋轮船到电子产品,在任何用到金属并有腐蚀风险的地方,都能大大延长金属的使用寿命。这也意味着许多行业将因此节约巨大的成本。

目前,该技术的工艺过程尚处于实验测试阶段。玛加姆德说,他们不仅在各种金属上进行实验,还研究怎样在低温下制作涂层,这将简化生产并提高产品的市场潜力。

Graphene films—highly resistant to damage—could protect metals in harsh environments

A coating so thin it's invisible to the human eye has been shown to make copper nearly 100times more resistant to corrosion, creating tremendous potential for metal protection even in harsh environments.

In a paper published in the September issue of Carbon, researchers from Monash University and Rice University in the USA say their findings could mean paradigm changes in the development of anti-corrosion coatings using extremely thin graphene fi lms.

Graphene is a microscopically thin layer of carbon atoms.It is already in use in such things as smartphone screens, and is attracting research attention for its possibilities as a means of increasing metal's resistance to corrosion.

"We have obtained one of the best improvements that have been reported so far," said study coauthor Dr Mainak Majumder."At this point we are almost 100 times better than untreated copper.Other people are maybe five or six times betier, so it's a pretiy big jump."

Dr Parama Banerjee, who performed most of the experiments for this study, said graphene had excellent mechanical properties and great strength.

The polymer coatings that are often used on metals can be scratched, compromising their protective ability, but the invisible layer of graphene – although it changes neither the feel nor the appearance of the metal – is much harder to damage.

"I call it a magic material," Dr Banerjee said.

The researchers applied the graphene to copper at temperatures between 800 and 900 degrees, using a technique known as chemical vapour deposition, and tested it in saline water.

"In nations like Australia, where we are surrounded by ocean, it is particularly significant that such an atomically thin coating can provide protection in that environment," Dr Banerjee said.

Initial experiments were confi ned to copper, but Dr Banerjee said research was already under way on using the same technique with other metals.

This would open up uses for a huge range of applications, from ocean-going vessels to electronics: anywhere that metal is used and at risk of corrosion.

Such a dramatic extension of metal's useful life could mean tremendous cost savings for many industries.

The process is still in the laboratory-testing stage, but Dr Majumder said the group was not only looking at diff erent metals, but also investigating ways of applying the coating at lower temperatures, which would simplify production and enhance market potential.

最近,澳大利亚莫纳什大学和美国莱斯大学研究人员合作,用肉眼看不见的石墨烯薄膜作为涂层,使铜的耐腐蚀性增强近百倍,为恶劣环境下的金属防洪提供了巨大潜力。研究人员指出,用石墨烯薄膜作防腐蚀涂层也意味着在开发保护性涂层方面有了模式性转变。相关论文发表在9月出版的《碳》杂志上。

作为广受关注的新材料,目前,科学家们正在开发用石墨烯提高金属耐腐蚀性