Study on Lysine and Methionine Content Promotion of Soybean Meal by Probiotic Fermentation Process

2012-07-02LuZhiyongGaoXuejunHuangJianguoLiuRongLiuYingQiaoBinandQiuYouwen

Lu Zhi-yong, Gao Xue-jun, Huang Jian-guo, Liu Rong, Liu Ying, Qiao Bin, and Qiu You-wen

Key Laboratory of Dairy Science of Ministry of Education, Northeast Agricultural University, Harbin 150030, China

Introduction

Soybean meal (SBM)is commonly used for livestock feeds. SBM is the major source of protein in livestock diets used in the United States and several other countries (FAO, 2004). The amino acid profile of SBM fits well with that of corn and some other cereal grains to balance livestock diets; however, its inclusion in diets for livestock is limited due to some antinutritional factors and antigenic soybean proteins causing hypersensitivity. The SBM proteins glycinin and β-conglycinin have been identified to cause hypersensitivity in young pigs (Song et al., 2010; Feng et al., 2007). Processing of soybean may inactivate some antinutritional factors through heat treatment or extrusion; however, those processes may also reduce availability of amino acids, especially when SBM is overcooked. Fermentation has been proven to improve the nutritional value of soybean by increasing the bioavailability of nutrients and reducing antinutritional factors (Yamamoto et al., 2010; Song et al., 2008).The objective of this study was to increase essential amino acids by fermentation process. In addition,the suitability of a commercially available fermented soybean meal (FSBM)was gained to replace the SBM in livestock diets.

Materials and Methods

Materials

Bacillus natto (CCTCC 92068 EU711067.1); Leuconostoc mesenteroides ATCC 8293 (ATCC 8293);and defatted soybean meal containing 41% protein.

Main reagents

30 mg · mL-1dinitrochlorobenzene (CDNB); DL-methionine (chromatographic pure, Tianjin Guang Fu Fine Chemicals Research Institute); DL-methionine-sulfone(Alfa Aesar, Stock#B25094); DL-lysine (chromatographic pure, Tianjin Guang Fu Fine Chemicals Research Institute); and Na2CO3-NaHCO3buffer (pH 9.0).

Main instruments

Ultrafilter (Cole-Parmer Instrument Company);Transferpettor (X96316, Finnpipette); HZQ-C Airbath Alternator (Harbin Dongming Medical Treatment Instruction Limited Company); LC-10AT VP high efficiency liquid chromatography (Shi Mad Zu);SPD-10A VP UV-VIS detector (Shi Mad Zu); and chromatographic column (Dikma Technologies).

Methods

Strains medium

M17 (10 g yeast extract, 10g peptone, 20 g glucose,10 g beef extract, 2 g K2HPO4, 2 g diammonium citrate, 5 g sodium acetate, MgSO4· 7H2O, 0.25 g MnSO4, pH 6.4)and MRS (5 g soybean peptone, 5 g poly peptone, 0.5 g ascorbic acid, 5 g yeast extract,11 g β-glycerol phosphate disodium, Tween80 1 mL,1 mol · L-1MgSO4· 7H2O 1 mL, 0.5% lactose, pH 7.1).Fermentation medium. 111.11 g mixture (soybean meal and corn gluten meal were mixed by 3:1 ), 1.5%glucose, 1.5% soybean peptone, 0.5% yeast extract,0.1 mol · L-1phosphate buffer, 4 mL salt solution (0.2 g CaCO3, 0.48 g Mg2SO4, 1.0 g K2HPO4, 2 g KH2PO4,10 g NaHCO3, 2 g NaCl, and 500 mL distilled water).

Experimental design

The raw materials were prepared by the method described in a previous report (Huang, 2009).

Enzymolysic hydrolization

After sterilization (121℃/15 min)the protein content of the raw materials had been determined, protease(0.5%)and trypsin (1.5%)were put into the raw materials. The enzymolysic hydrolization was carried out in an orbital shaker at 150 r · min-1, 39.8℃ for 4.5 h.This enzymolysic hydrolization was kept pH 6.5-7.0.

Microorganism and inoculum

The microorganisms used in this work were previously isolated from cereals. The isolation of microorganisms and cultivation was carried out in Petri dishes using MRS and M17 medium at 37℃. All stock cultures were stored at 10℃.

The urea (1%), Na2SO4(0.5%), K2SO4(0.2%)and phosphate buffer (0.1 mol · L-1, pH 7.0)at a proportion of 4 : 1 (v/w)were added to the fermentation medium(Vardanega et al., 2010). The essential amino acid production was finished by two microorganisms. After sterilization (121℃/15 min), it was inoculated with Leuconostoc mesenteroides and incubated in climatic chamber at 27℃, with humid air injection. After sterilization (121℃/15 min), it was inoculated with Bacillus natto and incubated in climatic chamber at 37.5℃. After 18 h of fermentation, the final liquid was dried at 40℃.

Detection

Determination of methionine

“A到VP”格式中“VP”在语义表达的虚实上有所不同。根据表义的倾向性,我们归纳为表描摹、表描摹兼程度、表程度三类,这三类并非各自封闭,而是构成一个由描摹到程度的连续统。“A到VP”中这样的表达方式并不是在以往的书面语体中没有出现过,而是在近来的网络语言中这些用法使用频率更高更广泛。从我们搜集的这三类语料看,VP对A性状的说明正呈现由真实趋于虚拟,由客观趋于主观的发展趋势。以下我们将作具体分析。

The feed was hydrolyzed and dealed according to the acid hydrolysis method of GB/T 18246-2000, and mixture of amino acids was obtained. The amino acid mixture was reacted with 2, 4-dinitrochlorobenzene to make methionine into dinitrochlorobenzene-methionine and methionine-sulfone into dinitrochlorobenzenemethionine-sulfone. The product was filtrated through a 0.45 μm filter membrane. The chromatographic system used was equipped with a 10 uL loop and UV detector (Agilent Corporation, USA). To detect methionine, separation was performed in a 150×4.6 mm reversed-phase C18 analytical column(Diamonsil, USA). The mobile phase was made of 30% methyl cyanides in the sodium acetate buffer(pH 5.2). The flow rate was 0.8 mL · min-1and the analytical wavelength was 350 nm.

Determination of lysine

Determination of lysine was the same to the methionine. The amino acid mixture was reacted with 2, 4-dinitrochlorobenzene to make lysine into dinitrochlorobenzene-lysine. The mobile phase was made of 25% methanol in the sodiumacetate buffer.

Animal experiments

15 days experiment was carried out with 15 Holstein cows milked (23.65±0.1)kg · day-1and 3 years old. All animal procedures were approved by the Institutional Animal Care of Northeast Agricultural University.A first group of five cows were fed normal diets.A second group were normal diets with 0.3% SBM and the third group were fed normal diets with 3%fermented soybean meal (FSBM), they were allowed to become familiar with their surroundings. Therefore,all measurements started to be recorded on day 3 after normal diets and their milk was collected 4:00 a.m.and 2:30 p.m. everyday.

Results

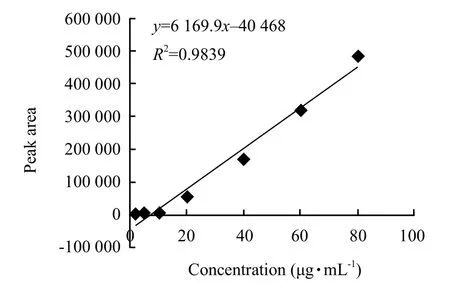

Standard curves of methionine

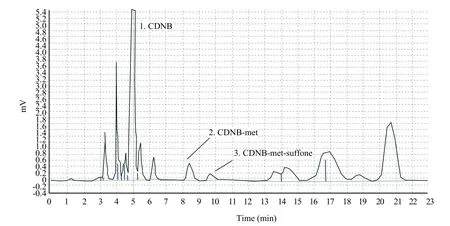

Fig. 1 showed a HPLC profile of metionine standard sample, the column hold-up time was 9.788 min. The standard curve of methionine was experimentally calculated from the peak capacity by the average (Fig. 2).

Fig. 1 HPLC result of methionine standard liquid of 60 μg·mL-1

Sample and standard curves of methionine sulfone

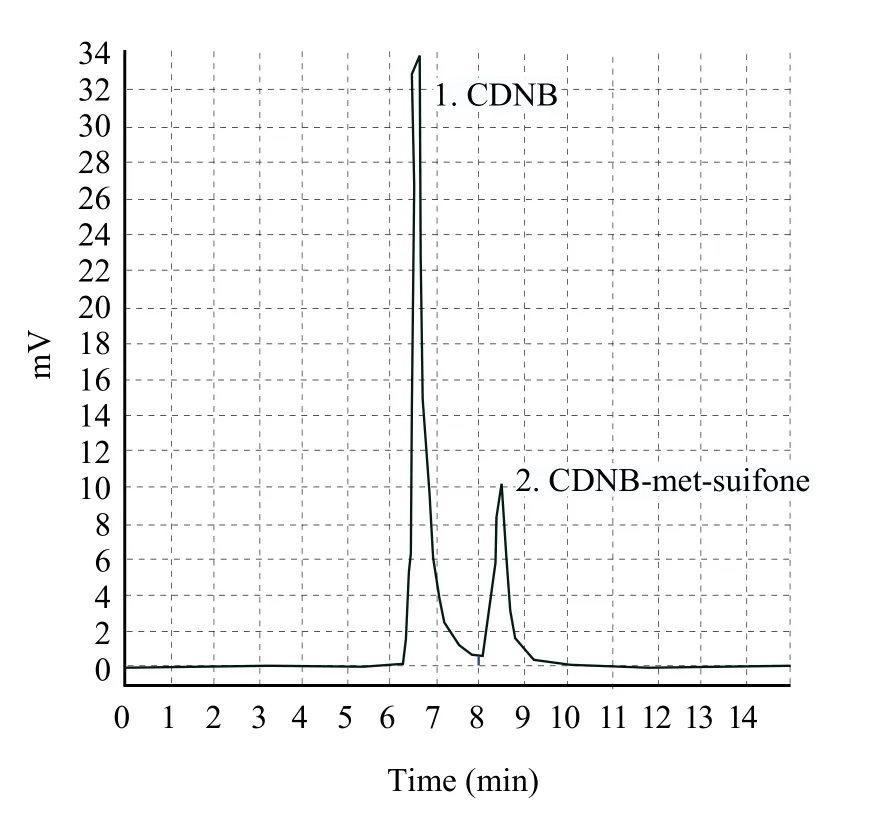

In Fig. 3, the methionine sulfone column hold-up time was 8.463 min, successful separation by acetonitrile largely depended upon a suitable solvent system (Fig. 4).The selection of solvent system for the target compound was one of the most important steps and not an easy task in acetonitrile, either.

Fig. 2 Standard curve of methionine

Fig. 3 HPLC result of methionine sulfone standard liquid of 80 μg·mL-1

Fig. 4 Standard curve of methionine sulfone

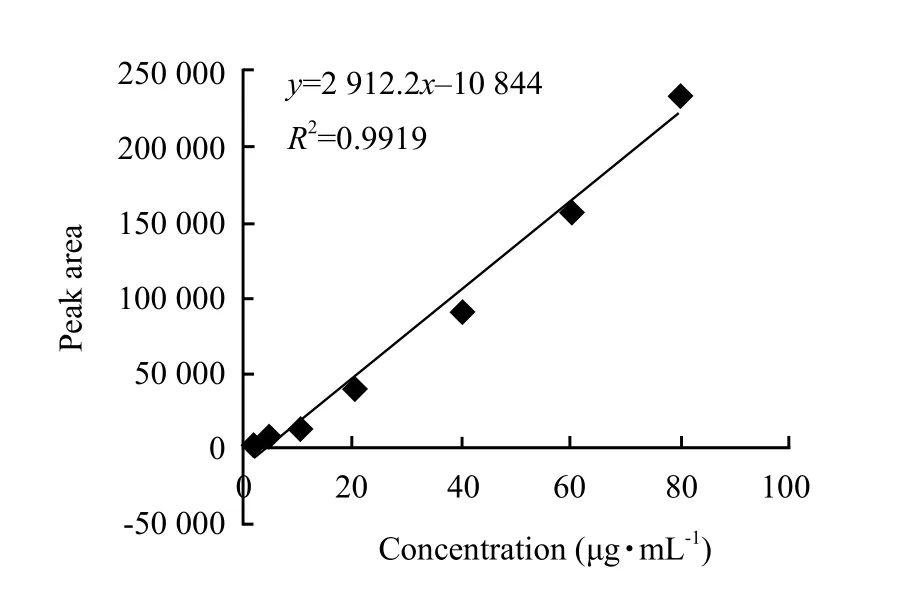

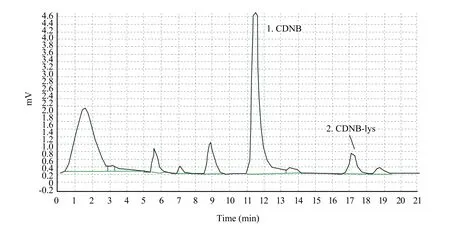

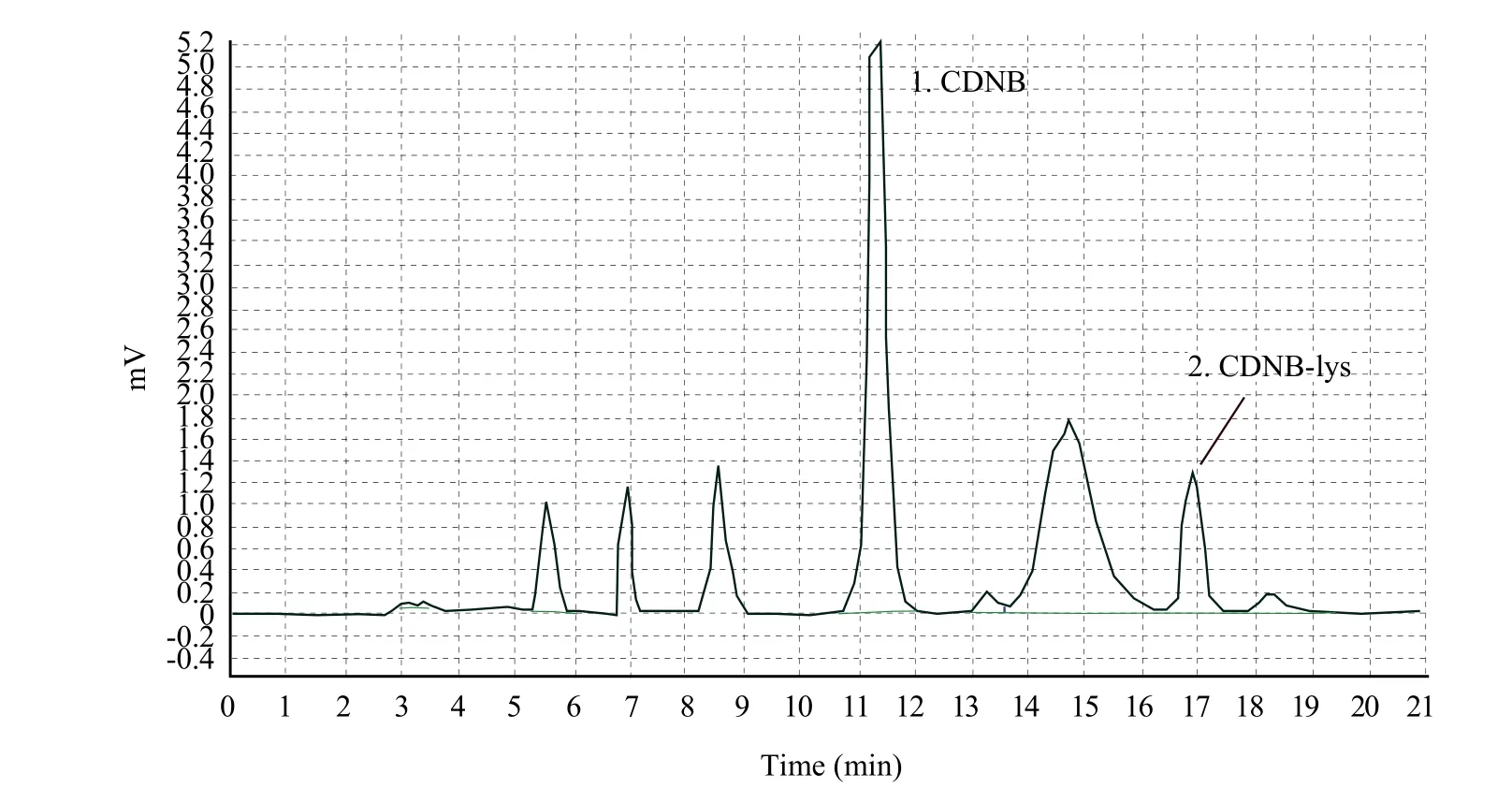

Standard curves of lysine

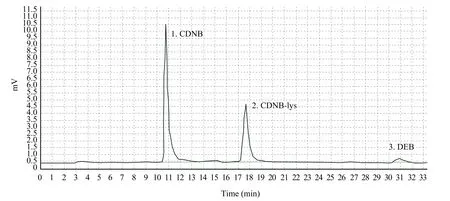

HPLC results of lysine standard liquid of 60 μg · mL-1was shown in Fig. 5, while Fig. 5 showed the retention time was 17.652 min. The solvent system was made of 25% methanol in the sodium acetate buffer (Fig. 6).

Fig. 5 HPLC result of lysine standard of 60 μg·mL-1

Fig. 6 Standard curve of lysine

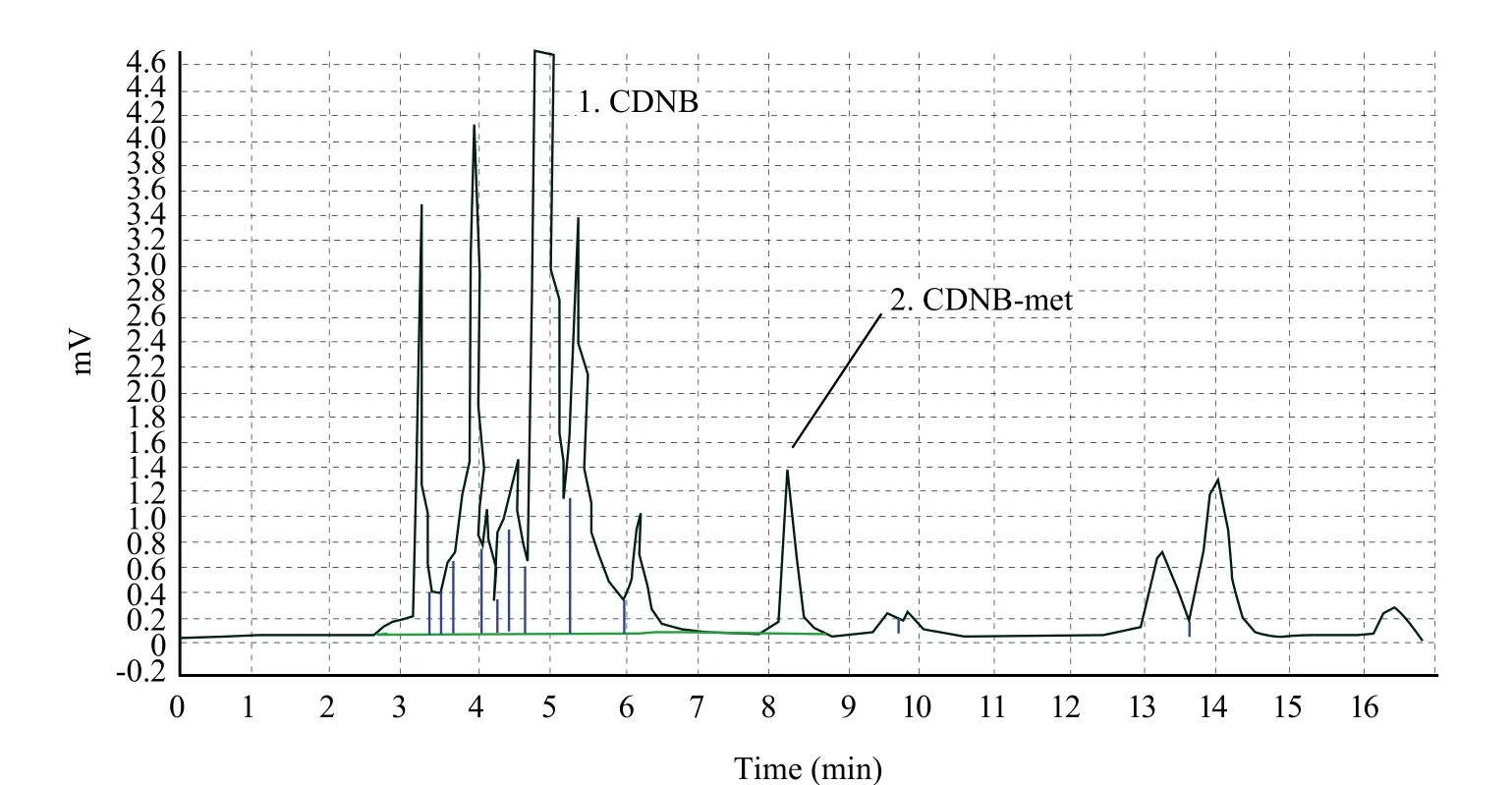

Analysis of derived liquid of sample

The chromatogram of the methionine of raw material and fermentation liquid of samples are shown in Figs.7 and 8, respectively. The peak area in Fig. 8 was about twice than the peak area in Fig. 7, showing that the methionine was more higher in FSBM.

The CDNB-lys spectra and retention times of raw materials and fermentationliquid are shown in Figs. 9 and 10. The lysine content was raised in FSBM.

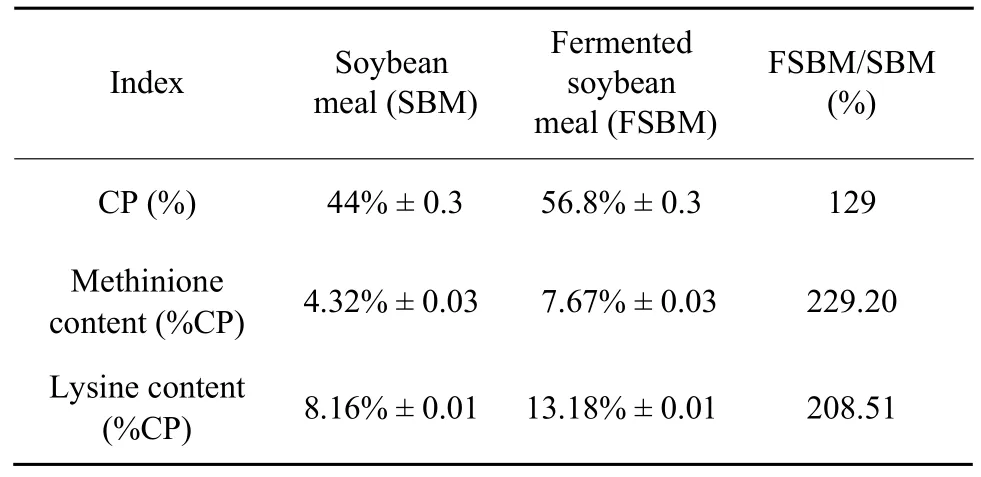

This process has high feasible, higher methionine and lysine yield, CP was 56.8%, methinion content rised 229.2% (compared with the rough material);lysine content rised 208.51% (compared with the rough material)(Table 1). HPLC method for detection of lys and met contents has been set up in this experiment.

Fig. 7 HPLC result of methionine of raw materials

Fig. 8 HPLC result of methionine of fermentation

Fig. 9 HPLC result of lysine of raw materials

Fig. 10 HPLC result of lysine of fermentation liquid

Table 1 Indexes of the FSBM (n=5)

As expected, cows fed the diets, which had no FSBM, grew milk yield and milk quality more and better than cows fed the diets. Some studies indicate that incorporation of lysine and methionine to the diet led to increase the milk yield. In addition, the presence of Kunitz and Bowman-Birk protease inhibitors in SBM-based diets reduce trypsin and chymotrypsin activities, leading to abnormal intestinal protein digestion (Hong et al., 2004). Fermentation of soybeans also degrades its proteins and carbohydrates to the extent of low molecular weight and watersoluble compounds that facilitates their digestibility(Kiers et al., 2000). In this study, we suggest the use of a fermentation process as a strategy to increase the soybean proteins and consequently avoid detrimental effects in cows.

Conclusions

This study researched and analyzed the production process of lysine and methionine that had been prepared by Bacillus natto and Leuconostoc mesenteroides fermentation, this process has a high feasible,CP was 56.8%, methionine content was 43.56 mg · g-1,and lysine content was 74.872 mg · g-1. In this study,there was relationship between cow's milk yield and FSBM. Milk yield of cows fed a diet with the FSBM raised 14.2%, the change in the milk protein, the lactose and the dry matter content had also obvious increase.

Feng J, Liu X, Z. Xu R, et al. 2007. Effect of fermented soybean meal on intestinal morphology and digestive enzyme activities in weaned piglets. Dig Dis Sci, 52: 1845-1850.

Food and Agricultural Organization of the United Nations, World Health Organization (FAO). 2004. Assessing quality and safety of animal feeds. FAO, Rome. pp. 55-57.

Hong K J, Lee C H, Kim S W. 2004. Aspergillus oryzae GB-107 fermentation improves nutritional quality of food soybeans and feed soybean meals. Med Food, 7: 430-434.

Huang J G. 2009. The preparation of small peptides from feed protein source and its impact on cows lactation. Northeast Agricultural University, Harbin.

Kiers J L, Nout R M J, Rombouts F M. 2000. In vitro digestibility of processed and fermented soya bean, cowpea and maize. Sci Food Agric, 80: 1325-1331.

Song Y S, Frias J, Martinez-Villaluenga C, et al. 2008. Immunoreactivity reduction of soybean meal by fermentation, effect on amino acid composition and antigenicity of commercial soy products. Food Chemistry, 108: 571-581.

Song Y S, Pérez V G, Pettigrew J E, et al. 2010. Fermentation of soybean meal and its inclusion in diets for newly weaned pigs reduced diarrhea and measures of immunoreactivity in the plasma.Animal Feed Science and Technology, 159: 41-49.

Vardanega R, Remonatto D, Arbter F, et al. 2010. A systematic study on extraction of lipase obtained by solid-state fermentation of soybean meal by a newly isolated strain of Penicillium sp. Food Bioprocess Technol, 3: 461-465.

Yamamoto T, Iwashita Y, Matsunari H, et al. 2010. Influence of fermentation conditions for soybean meal in a non-fish meal diet on the growth performance and physiological condition of rainbow trout Oncorhynchus mykiss. Aquaculture, 309: 173-180.

猜你喜欢

杂志排行

Journal of Northeast Agricultural University(English Edition)的其它文章

- Actuality and Inf l uencing Factors of Integrated Production Capacity of Foodstuff in Heilongjiang Province

- Developing Potential of Low-carbon Agriculture in Heilongjiang Province

- Crop Yield Forecasted Model Based on Time Series Techniques

- Screening for Enterobacteriaceae Bacteria in Infant Formula Powder

- Application of Radio Frequency Identif i cation (RFID)in Dairy Information Management