基于SU-8和AU-S的光纤传感制备及测试*

2012-06-12袁艳玲薛晨阳熊继军

袁艳玲,薛晨阳,张 强,熊继军

(中北大学电子测试国家重点实验室,太原030051)

The detection of chemical and biological agent is a key problem in environment protecting,food monitoring,defending against terrorist or biological weapons in modem battlefield orsociety.Traditionallaboratory methodscan accurately detectthe chemicaland biological agents,but need expensive device,special operators,and are also time consuming,which limit their widely applications.Thus,it is all urgent demand to develop rapid,economic,portable,accurate and Operated biological agent detection devices[1].

Fiber optical sensor is a kind of microanalysis technique.It offers a number of important benefits,such as low dissipation of transmit,anti-interference of electromagnet and small shaped[2-3].It has huge potential in many fields such as in the test of liquid refractiveindex,the concentration and different components of materials and so on[4].Noble metal nanoparticles such as gold and silver nanoparticles have unusual properties when their size on the same scale as biological macromolecules,proteins and nucleic acids,and possess unusual optical,magnetic,electronic,catalytic and mechanical properties.They have been the hot point in the research field of biological and chemical science[5-6].It will produce localized surface plasma resonance(LSPR)and hasa strong lightabsorption and scattering properties when the light shone on the nano-gold or nano-silver particles[7].

As we all known,there is an evanescent field when the light takes internal total reflection on the interface of the rare medium and the denser medium.Evanescent wave spectroscopy has become a very useful technique for examining the properties of materials.In this thesis,we choose the SU-8 as the oxygen groups cross-linking with the Silane coupling agent to modified Star-shaped Metal nanoparticles on the tapered optical fiber surface as the sensitive part of this sensor and used the evanescent field as exciting field,thus the surface plasma resonance between the evanescent wave and the surface plasma produced on the metal nanoparticles can induced the enhanced field under the function of the evanescent wave.The enhancement signal will be amplified when liquid molecules adsorbed on this sensitive surface.Based on this principle,we prepared the optical fiber sensor which based on Nano-modified and the alcohol and Crystal Violet were measured.

1 Principle

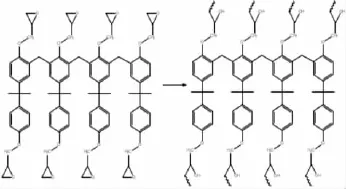

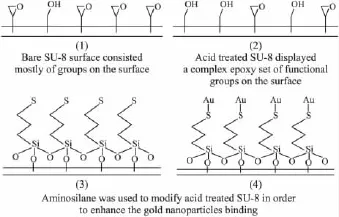

1.1 SU-8

SU-8 photo resist is an epoxy type,negative near-UV lithography Glue which is based on SU-8 epoxy resin.For each molecule containing an average of eight epoxy its name includes 8.SU-8 lithography mechanism summarized as follows:the photoinitiator in the resist takes chemical reaction when absorbs photons and generate a strong acid;its role is to promote cross-linking reactions in the drying process as an acid catalyst.Only the photoresist which the region is exposure to the light only contains a strong acid and the other region is not existence of such a strong acid.In the subsequent drying process,the exposure region takes cross-linking reaction under the effect of the strong acid.The cross-linking reaction grows as the chain mode and each epoxy could takes reaction with other epoxy of the same or other molecules[10].As mentioned earlier,the average per epoxy connected with another seven epoxy,and then expand to form a dense cross-linked network.SU-8 structure diagram was shown in Fig.1[11].

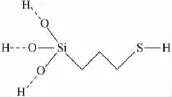

1.2 MPTMS(3-Sulfur Trimethoxysilane)

The MPTMS in Our experiments is a silane coupling agent.Its structure is shown in Fig.2.

Fig.1 Structure of SU-8 as a monomer and cross-linked in the polymer

Fig.2 The structure of MPTMS

The methoxy in MPTMS hydrolyzed into Silicon hydroxyl easily,they formed hydrogen bonds with the surface Silicon hydroxyl and absorbed on the surface.After heat treatment it will formed a SI-O-SI bond and thus formed a self-assembled film which the end was a surface layer with sulfur.So we choose SU-8 as the oxygen groups cross-linking with the MPTMS and make a preparation for the adhesion of MPTMS and gold particles.

1.3 AU-S

Since gold is inert metal the oxidation does not occur below the temperature of the melting point and most chemicals do not react at the same time.Au also has good chemical and biological compatibility,such as the cells could adsorbed or modified on the Au film.Therefore,we chose gold nanoparticles as the body modification to our optical sensor[12].The principle is based on the strong chemical binding between the thiol(-SH)and gold nanoparticles(Au)(to form Au-S bond,about170kJ/mo1)[13].The formation process of monolayer is the result of the forces between Au-SH bonding and the chain reaction.

2 Experiment Details

MPTMS and Na3-citrate obtained from Sinopharm Chemical Reagent Co.,Ltd(Shanghai,China),HAuCl4·4H2O from Beijing Reagent,and H2O2from Chemical Reagent.Sulfuric acid,Hexadecyl trimethyl ammonium bromide,Sodium borohydride,Silver nitrate,Ascorbic acid,and Glacial acetic acid were purchased from Sinopharm Chemical Reagent Co.,Ltd(Shanghai,China).Ultrapure water of about 18MΩ·cm was prepared by using a water purification unit in our lab.

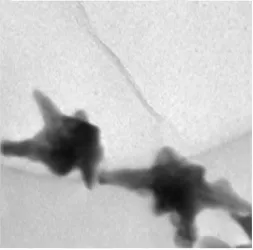

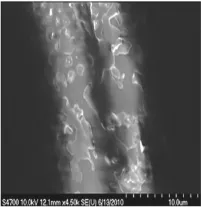

Star-shaped gold nanoparticles which sizes from 80 to 120nm were prepared following the seed-mediated growth method[14]. The SEM of star-shaped nanoparticles is in Fig.3.The single mode optical fibers were tapered through an oscillating flame torch and the tapered length is 25 nm.

Fig.3 SEM of Star-shaped nanoparticle

Firstly,the optical fibers were put into the Piranha solution(30%H2O2add to 98%H2SO4volume ratio being 1∶4 slowly)for 10 minute under 80 ℃.After that the fibers were washed with alcohol and ultrapure water for three times and natural dry for the reserve.Then,SU-8 2005 was dropped on the surface of the optical fibers in 45-degree angle position by pipette.During this process,the 45-degree angle position ensured that SU-8 could slide from the top to the bottom of the optical fiber.Next,these coated SU-8 optical fibers were put under the UV lamp which wavelength is 365 nm for 3~5 second and then put them into the acetic acid solution of MPTMS(1%by volume)for ten minutes,that’s for the acid treated and surface silanization.Then,Silanized optical fibers were put into the colloidal gold for twelve hours at the room temperature.This is the process of the formation of the AU-S.At last,they were washed by ultrapure water and alcohol for three times and put in the vacuum for half an hour.The optical fiber sensors assembled by gold nanoparticles were obtained.The Fig.4 and Fig.5 is the chart of the modification process and modified fiber surface.

Fig.4 The modification process of the optical fiber sensor

Fig.5 The chart of the modified fiber

3 Testing and Discussion

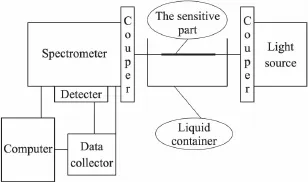

After Surface modification the optical fiber sensor was connected in our test system.Due to the volatility of the alcohol,we also choose different concentrations gentian violet to test.The testing system is shown in Fig.6.

Fig.6 The view of the test system

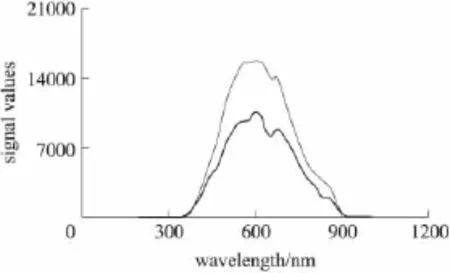

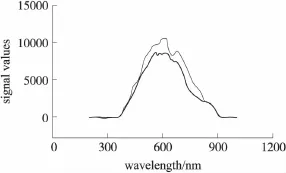

First,we choose alcohol which concentration is 98%as the analyze.The thin line in Fig.7 is the emission spectrum of the bromine tungsten light source and the black thick line is the spectrum of the optical fiber sensor which has modified star-shaped gold nanoparticles when the bromine tungsten light as the excitation light source.The Abscissa is wavelength and the Ordinate is signal values.From the comparison curve between the bromine these tungsten light source and the modified optical fiber sensor we can conclude that there is some of light leaking out as the optical fiber is tapered.

Fig.7 The spectrum between the bromine tungsten source and the modified optical fiber sensor

Next,we immersed this optical fiber sensor into alcohol which concentration is 98%.The thin line in Fig.8 is the transmission spectrum of the alcohol.Compared with the emission spectrum the alcohol will appear an apparent absorption peaks which peak wavelength position about from 590 nm to 700 nm after the surface modification and the absorption amount is visible and is approximately 300.

Fig.8 The spectrum of the sensor which modified gold nanoparticles tested in 98%alcohol

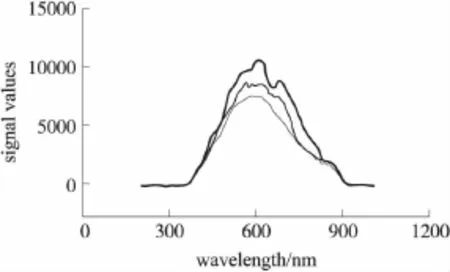

Due to the volatility of the alcohol,we also choose different concentration gentian violets to test.The dark thick curve in Fig.9 is the transmission spectrum of the gentian violet which concentration is 0.1%.Compared with the alcohol the most obvious peak is from 550 to 750nm.The absorb gap is wider and the absorption amount is greater.But we could not give a conclusion for the reason of the alcohol and the gentian violets were in different concentration.we will do that comparison in next experiment.From those testing we can conclude that the testing molecular could absorb on the nanoparticles and the absorb amount and absorb peak position are different in different mediums.

Fig.9 The spectrum of the optical Sensor coupled by mercapto tested gentian violet

The thin curve in Fig.10 is the spectrum of the gentian violet which concentration is 0.05%.There is a little difference between differentconcentration gentian violet curves.The absorb amount is about 200 less than the gentian violet which concentration is 0.1%.The higher the concentration,the greater the absorption.After careful analysis,the absorb amount is different in same volume with the different concentration liquid for the reason of the molecular amount is different.Based on this we can make a new sensor for the testing of different concentration liquid.

Fig.10 The spectrum of the sensor coupled by mercapto tested the different concentrations gentian violet

4 Conclusions

Different concentration alcohol and gentian violets were tested through the optical fiber sensor which has modified star-shaped metal nanoparticles.From the transmission spectrum analysis ofthe alcoholwe can concluded that because each molecule in SU-8 containing an average of eight epoxy and as the oxygen groups crosslinking to promote to the molecular between Silane coupling agent and the star-shaped gold nanoparticles.So this kind optical fiber sensor is very sensitive to different mediums and different concentration solutions and this nanostructure optical fiber sensor is promising to be used for high-sensitive detection.

[1] Zhang Sen,Liu Menghua,Wang Zhen,et al.Reflective Optical Fiber Micro-Displacement Sensor[J].Study on Optical Communications,2007(141).

[2] Kazemi A.Fiber Optic Hydrogen Detection System.SPIE,1999,3860:507-515.

[3] Zaatar Y.Fabrication and Characterization of an Evanescent Wave Fiber Optic Sensor for Air Pollution Control,Materials Science and engineering:BVolume:74,Issue:1-3,May l,2000,296-298.

[4] Joyce M Simpson,Daniel V Lim.Rapid PCR Confirmation of E.coli 0157:H7 after Evanescent Wave Fiber Optic Biosensor Detection[J].Biosensors and Bioelectronics,2005(21):881-887.

[5] Daniel V Lim.Detection of Microorganisms and Toxins with Evanescent Wave Fiber-Optic Biosensors[C]//Proceedings of the IEEE,2003,91(6):902-907.

[6] Carniglia C K,Mandel L,Drexage K H.Absorption and Emission of Evanescent Photons[J].Opt.Soc.Am.,1972,62(4):479-486.

[7] Gerald Steiner.Surface Plasmon Resonance Imaging[J].Anal Bioanal Chem.,2004,379:328-331.

[8] Chris Rowe Taitt,George P Anderson,Frances S Ligler.Evanescent Wave Fluorescence Biosensors[J].Biosensors and Bioelectronics,2005,20(8):2470-2487.

[9] Hriver-Lake L C,Anderson G P,Golden J P,et al.The Effect of Tapering the Optical Fiber on Evanescent Wave Measurements[J].Analytical Letters,1992(25):1183-1199.

[10] Gupta B D,Dodeja H,Tomar A K.Fibre-Optic Evanescent Field Absorption Sensor Based on a U-Shaped Probe[J].Optical and Quantum Electronics,1996,(28):1629-1639.

[11] Vlastimil Matejec,Miroslav Chomat,Marie Pospisilova,et al.Optical Fiber with Novel Geometry for Evanescent-Wave Sensing[J].Sensors and Actuators B,1995,(29):416-422.

[12] Wang A,Gunther’M F,Murphy K A,et al.Fiber-Optic Liquid-Level Sensor[J].Sensors and Actuators A,1992,35:161-164.

[13] Spenner K,Singh M D,Schult H,et al.Experimental Investigation of Fiber Optic Liquid Level Sensors and Refractometers[J].Optical Fiber Sensors,London,UK,1983:96-99.

[14] Granan K,Sun T.Fiber Optic Sensor Technology:An Overview[J].Sensor and Actuators,2004,82:40-61.