Failure mechanisms of reinforced concrete slabs in fire

2011-12-22YUXinmengZHAXiaoxiongHUANGZhaohui

YU Xin-meng,ZHA Xiao-xiong,HUANG Zhao-hui

(1.Department of Civil&Environmental Engineering,Harbin Institute of Technology,Shenzhen,518055,China;2.Department of Civil and Structural Engineering,University of Sheffield,UK)

余新盟1,查晓雄1,HUAN G Zhao-hui2

(1.哈尔滨工业大学深圳研究生院土木与环境工程学科部,深圳,518055;2.英国谢菲尔德大学土木与结构工程系)

Failure mechanisms of reinforced concrete slabs in fire

YU Xin-meng1,ZHA Xiao-xiong1,HUANG Zhao-hui2

(1.Department of Civil&Environmental Engineering,Harbin Institute of Technology,Shenzhen,518055,China;2.Department of Civil and Structural Engineering,University of Sheffield,UK)

When a slab is subjected to fire attack,the material property degradation and thermal expansion make the failure mechanism quite different from that at ambient temperature in stress distribution,deformation,integrity failure and ultimate load resistance.In this research,the failure mechanism of RC slabs at ambient and in fire is studied analytically and numerically.The study on cracking mechanisms and spalling influence on the fire resistance of RC slabs in fire leads to a general understanding of failure mechanisms of RC slabs in fire and some recommendations on post-fire structural health monitoring and spalling prevention are given.

Slab failure mechanism;Numerical modelling;Integrity failure;Concrete cracking;Spalling of concrete;Structural fire engineering

1 Introduction

Traditionally,the design of reinforced concrete(RC,and hereafter)slabs is based on classical small deflection elastic bending theory of thin plates,to calculate the response including the deflection and elastic stress distribution.However,for slabs subjected to large deflections,ultimate limit state analysis is necessary.The most usual design method for reinforced concrete slabs is the Yield Line Theory[1],which can be used to investigate the ultimate limit state failure mechanism.Yield line theory assumes a collapse mechanism defined by a pattern of yield lines,across which the reinforcing bars have yielded and about which plastic rotation occurs.The flat concrete plate facets between the yield lines are assumed to remain rigid and perfectly planar.The pattern of yield lines is governed by the type of loading,the geometry of the slab,and the boundary conditions.Yield line theory only considersthe moments and shear forces at the yield lines without considering the development of in-plane forces as displacement increases.With the development of computational technology and the advance of numerical modelling,performance based design is increasingly accepted and implemented in engineering practice by many industry pioneers such as Arup,Buro-Happold,and so on.

Fire disasters have shown that structures design safe at ambient temperature is not necessarily safe in fire.Experimental studies[2-5]show that the structural behaviour of RC structures in fire is quite different from that at ambient temperature.Spalling might happen at high temperatures because of thermally induced stresses and high pore pressurein concrete. Degradation of material strength and non-uniform thermal expansion inten-sify structural deformation which may form through thickness cracking and spread the flame into adjacent compartments.Therefore it is necessary to understand the failure mechanism in fire so that adequate measures can be made to design safer buildings.

However,fire experiments are very expansive and not scalable.A general methodology is to develop numerical models based on the knowledge gain from a number of small scale fire tests.Then the models are used to model the fire performance of full scale structures.Numerical study also provides a powerful alternative to the techniques of experimentation and observation,when phenomena are not observable or measurements are impractical or too expensive.This is especially valuable in predicting potential damages in structural health monitoring.

This paper aims at investigating numerically the failure mechanism of RC slabs in fire,including progressive cracking of concrete and the spalling influence on the fire resistance.Recommendations for structural health monitoring are also provided.

2 The failure mechanism of RC slabs at ambient temperature

图1 常温下板截面应力分布机制Fig.1 Stressing mechanisms in the cross section of slabs at ambient temperature

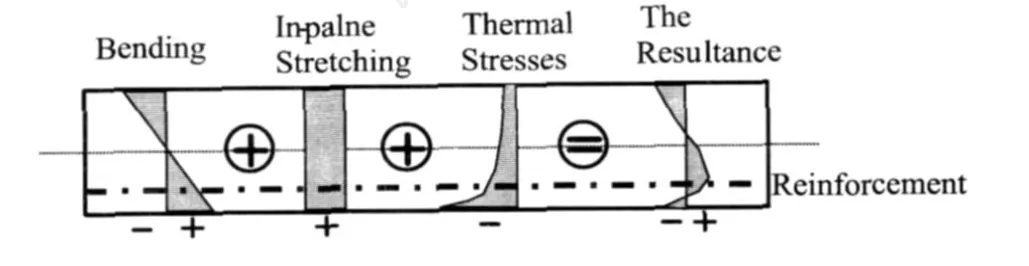

Mechanical theories are usually based on material properties at ambient temperature.When a structural member is subjected to bending,the member bends along its neutral axis and the maximum stresses are on the top and bottom surfaces;if there exist in-plane stresses,then the resultant stresses governs the most critical positions(see Fig.1).rules,the applied load can only cause small displacement and the stresses are small.With the increase of displacement,geometric nonlinearity can no longer be ignored.If the slab is four-edge effectively supported,the membrane action due to double curvature will greatly enhance the ultimate load bearing capacity.A general characteristic is the formation of a tensile zone in the centre surrounded by a compressive ring as shown in Fig.2.

图2 板在双曲变形下的膜效应Fig.2 Membrane action in a doubly curved slab

Concrete is strong in compression but weak in tension,therefore,anti-cracking rebars are applied to resist tension in reinforced concrete slabs.Even though,cracking will occur once concrete is excessively stressed.A slab usually subjected to sagging moment in the centre and hogging moment at the supports,therefore the cracking initiates from the bottom surface in the centre and top surface at supports.

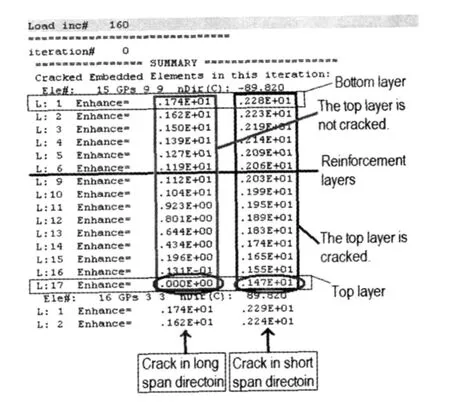

A layered slab element[6]enhanced with embedded weak discontinuities is developed by the authors to model the progressive cracking of RC slabs at large displacements.Fig.3 shows the numerical result of openings of the crack from bottom to top near the centre of the Slab M1[2].It can be seen from the figure that the through thickness crack is formed along the short span,but the top layer is not cracked along the long span.This agrees well with the test observation.

3 The failure mechanism of RC slabs in fire

图3 常温下RC板的裂缝自下而上拓展Fig.3 Cracking propagates from bottom to top in an RC slab at ambient temperature

In addition to the stressing mechanisms at ambient temperature,thermally induced stresses arealso involved in fire(Fig.4).Both material degradation and thermal stresses increase the deflection of slabs so that enforce the membrane action.

图4 火灾下板截面应力分布机制Fig.4 Stressing mechanisms in the cross section of slabs in fire

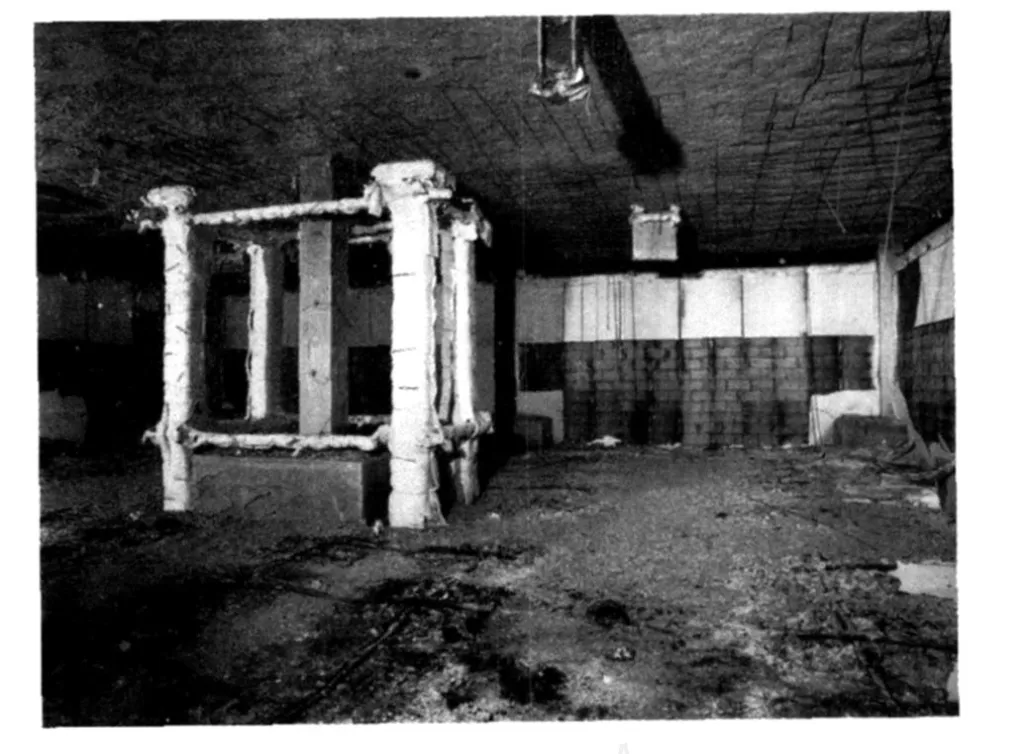

The thermally induced stressesstem from thermal expansion mismatch due to the gradient temperature distribution in the slab or from boundary restraining.Different from the tension on the bottom surface at ambient temperature,the high temperature gradient in fire makes the bottom concrete expansion overweight bending induce tension,by which spalling may occur to expose the reinforcement inside(Fig.5,refer to Section 3.2 for more illustration),or lead to internal cracking without spalling.If the deflection is large enough,the tensile strain exceeds the sum of thermal strain and concrete tensile strain limit,then the bottom surface cracks,which issignificantin cooling stage.Cracking,spalling and slippage of reinforcement are main failure modes of RC slabs in fire,but only cracking and the influence of spalling are discussed in this paper.

图5 Cardington火灾试验中混凝土剥落暴露出了钢筋[7]Fig.5 Spalling exposed the reinforcement in Cardington fire test[7]

3.1 Cracking failure of RC slabs in fire

In an experimental study[2]on a 1.8m by 1.2m simply supported Slab MF1,a 75mm large crack was formed along the short span.The slab is modelled again using the embedded slab model.It is known from numerical modelling(Fig.6)thatthe crack propagates to the top surfacewhen the reinforcement exceeds 150℃.This is accompanied by a suddenly increase of stress in the reinforcement.However,this stress concentration is soon tuned down by stress redistribution in the slab.The crack on the top surface increases to 0.5mm when the reinforcement temperature reaches 580℃,the moment only about half of the strength left.The reinforcement stress reaches its strength when temperature is elevated to 700℃.Then the slab fails quickly. The slab losses its stability when the opening width reaches 45mm with the reinforcement temperature reaches 800℃.

图6 板MF1靠段跨裂缝处的钢筋应力变化Fig.6 The reinforcement stress near the large crack along the short span in Slab MF1

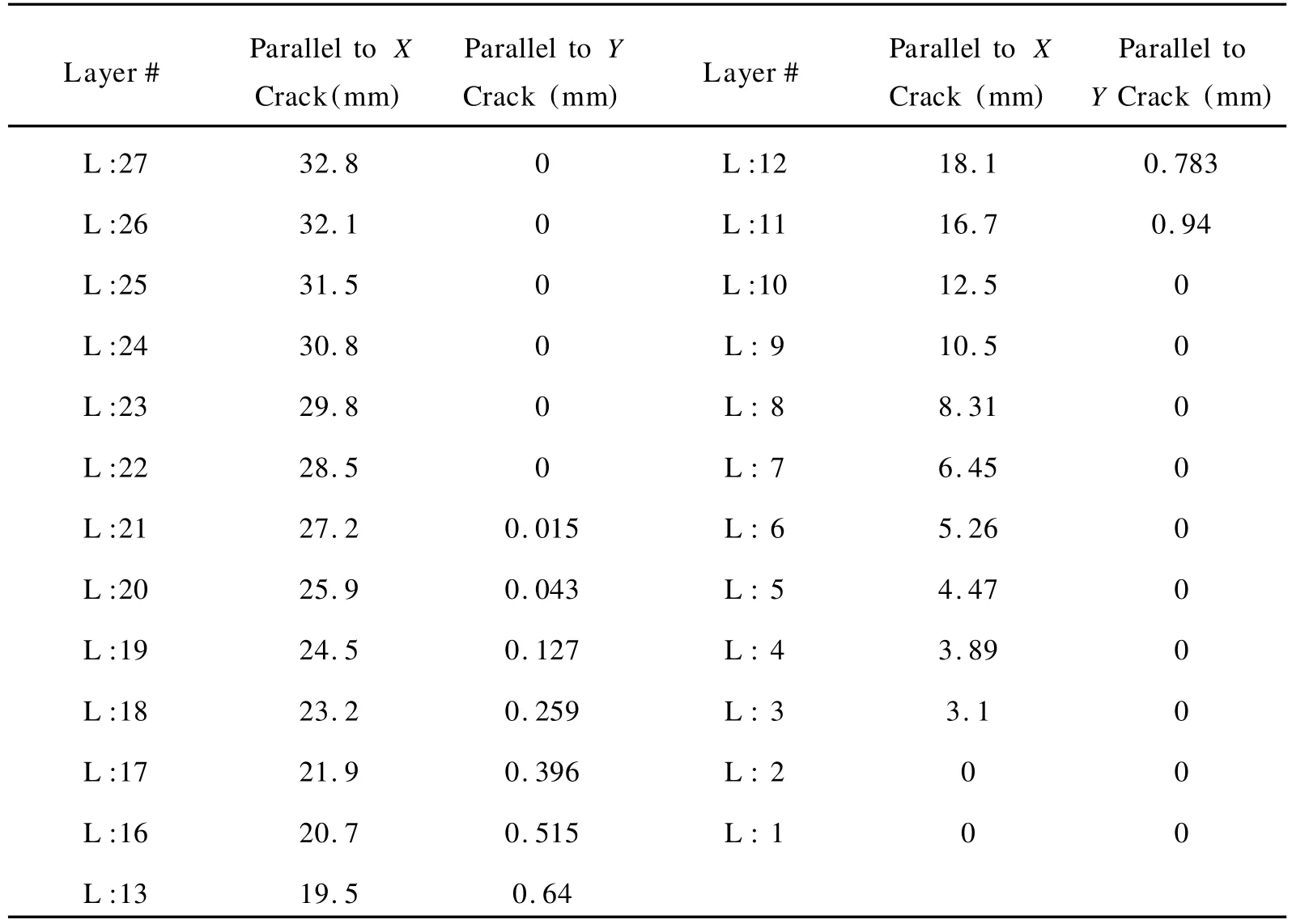

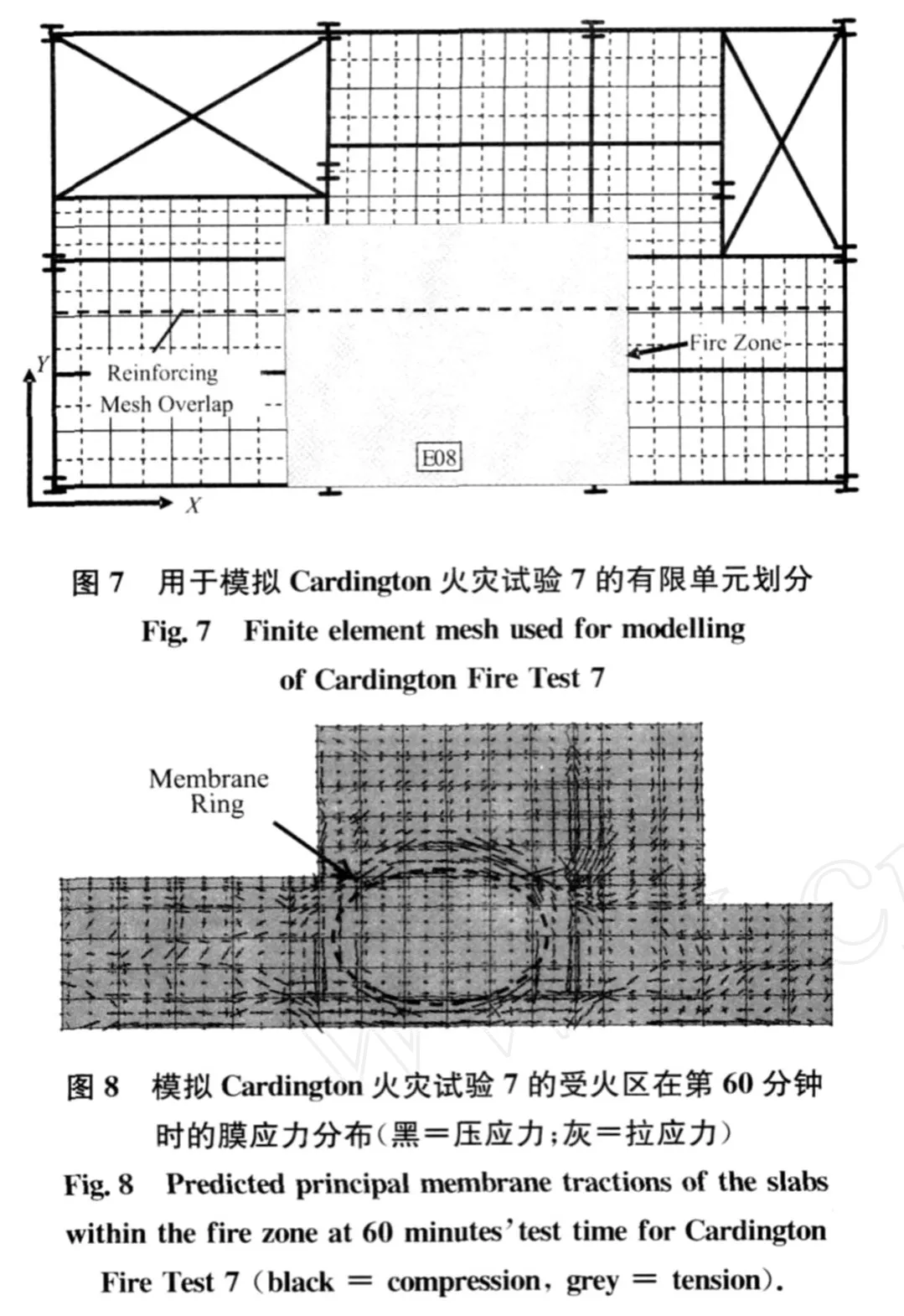

In order to understand the failure mechanism of RC slabs in a frame structure,the full scale Cardington Fire Test 7 is modelled.The observation of the test is given in[8].The profiled slab is transformed into a flat one with an equivalent thickness defined in Eurocode 4[9].The slab is further subdivided into 27 layers with the steel reinforcement occupying layers 14 and 15.In order to take into account the imperfect bond between the overlapped reinforcing meshes,only half of the reinforcement strength is used within that area of the slab in the modelling.The FE discretization is shown in Fig.7.According to the current analysis,a very clear membrane ring(Fig.8)is formed in the slab in the fire zone.This is because of the effective vertical support by the beams[10]and the large deflection of the slab in fire.The cracking details of the element E08 alongX-axis andY-axis(see Fig.7)are listed in Table 1.The opening width decreases from top to bottom along the X-axis due to hogging moment from the underneath beam restraining.It is worth to note that only some of the internal layers are cracked along the Y-axis.This internal cracking phenomenon is quite different from that at ambient temperature.The cracking mechanism is governed by the coupled action of bending,in-plane stretching and thermal expansion.This should not be neglected in the assessment of the damage of buildings after fire attack.

表1 模拟Cardington火灾试验7中单元E8在第60分钟时的各层开裂情形(X,Y轴定义参看图7)Table 1 The predicted crack opening width in each layer of slab elements E8 at 60 minutes test time in Cardington Fire Test 7(X,Y-axes are labeled in Fig.7).

3.2 The influence of spalling on the fire resistance of RC slabs in fire

Concrete is a porous material which consists mainly of mineral aggregate bound by a matrix of hardened cement paste.The paste is highly porous and,unless artificially dried,normally contains a large amount of free(evaporable)water.Normal concretes are made using Portland cement,and are not particularly intended to serve at very high temperatures,although they may be exposed to them accidentally.The component in concrete undergoes physical and chemical reactions at elevated temperatures,such as dehydration and expansion,as well as the decrease of binding strength(when the temperature exceeds 180℃).Experiments have shown that spalling might happen and consequently reduces the load capacity of RC structures.

Heating rate is always regarded as one of the most important factors influence the spalling of concrete.Higher moisture content is more susceptible to spalling than low moisture content in that evaporation of free water increases about 1700 times in volume which is condensed in small pore spaces waiting for releasing.The permeability of concrete is a very important factor in affecting the rate at which water vapour can escape from within the concrete.The spalling of concrete is also affected by many other factors,such as type of aggregate,amount of reinforcement,load and restraint to free thermal expansion,tensile strength,water/cement ratio,size and shape,and so on.However,these factors interact and competing with each other make the prediction of spalling very difficult,e.g.,mixture type influences spalling of concrete via affecting the permeability/porosity,thermal conductivity,tensile strength,and so on.

As concrete ages its moisture content generally reduces,and this suggests that the tendency for spalling should lessen.However,there do seem to be some contradictory conclusions about the influence of age of concrete and how this relates to moisture content.For example Zaman and Sullivan[11]suggested that spalling would not occur for older concretes due to the low moisture contents,while Malhotra[12]concluded that older concretes,which are denser and with reduced permeability,were more vulnerable.Purkiss et a1[13].reported unpublished work by others which also showed that the age of the concrete appeared to be a critical factor,with lower moisture contents resulting in an increased probability of spalling;however,this may again be due to reduced permeability over time.These apparently contradictory conclusions may be associated with the relationship between water/cement ratio and other properties-for example a lower water/cement ratio is associated with higher strength and lower porosity.This may also explain why Shorter and Harmathy[14]also found that only concrete of a certain humidity suffered from spalling,since a very high water/cement ratio will increase permeability and porosity which in turn reduces the tendency for spalling.

It is generally believed that the mechanisms of spalling of concrete in fire associated with the thermally induced stresses and the accumulation of pore pressure in the concrete[15].Spalling of concrete in fire can be categorized into progressive spalling and explosive spalling.Progressive spalling stems mainly from the differential thermal stresses generated by the incompatibility of ther-mal expansions caused by thermal gradient in concrete,while explosive spalling is mainly due to rapid accumulation of pore pressure by evaporating of concentrated moisture faster than escaping rate.However,spalling prediction models available are still at the stage of academic value.It is difficult to predict the time and extent of spalling in real RC structures.

No doubt,spalling affects the fire resistance of RC slabs.A quantitative understanding of this influence can be done by evaluating the ultimate limit state by assuming a certain degree of spalling happened at a certain time.Literature review[15]on the spalling of concrete in fire shows that spalling usually happens at 15-25 minutes of fire with a temperature in the range of 200℃~400℃.The later spalling occurs,the deeper into the concrete.In assessing the severity of spalling,three classes have been defined[16]:

®Minor:The concrete surface spalls without reaching the reinforcement.

®Major:The spalled zone reaches the steel reinforcement and leaves it exposed.

® Severe:Concrete spalling reaches large depths,inside the steel reinforcing cage,and occurs with very high explosive energy.

Only minor and major spallings are studied in this research.It is assumed ideally that minor spalling sloughs a half thickness of the concrete cover at 15 minutes of fire while major spalling removes the whole cover at 25 minutes of fire.

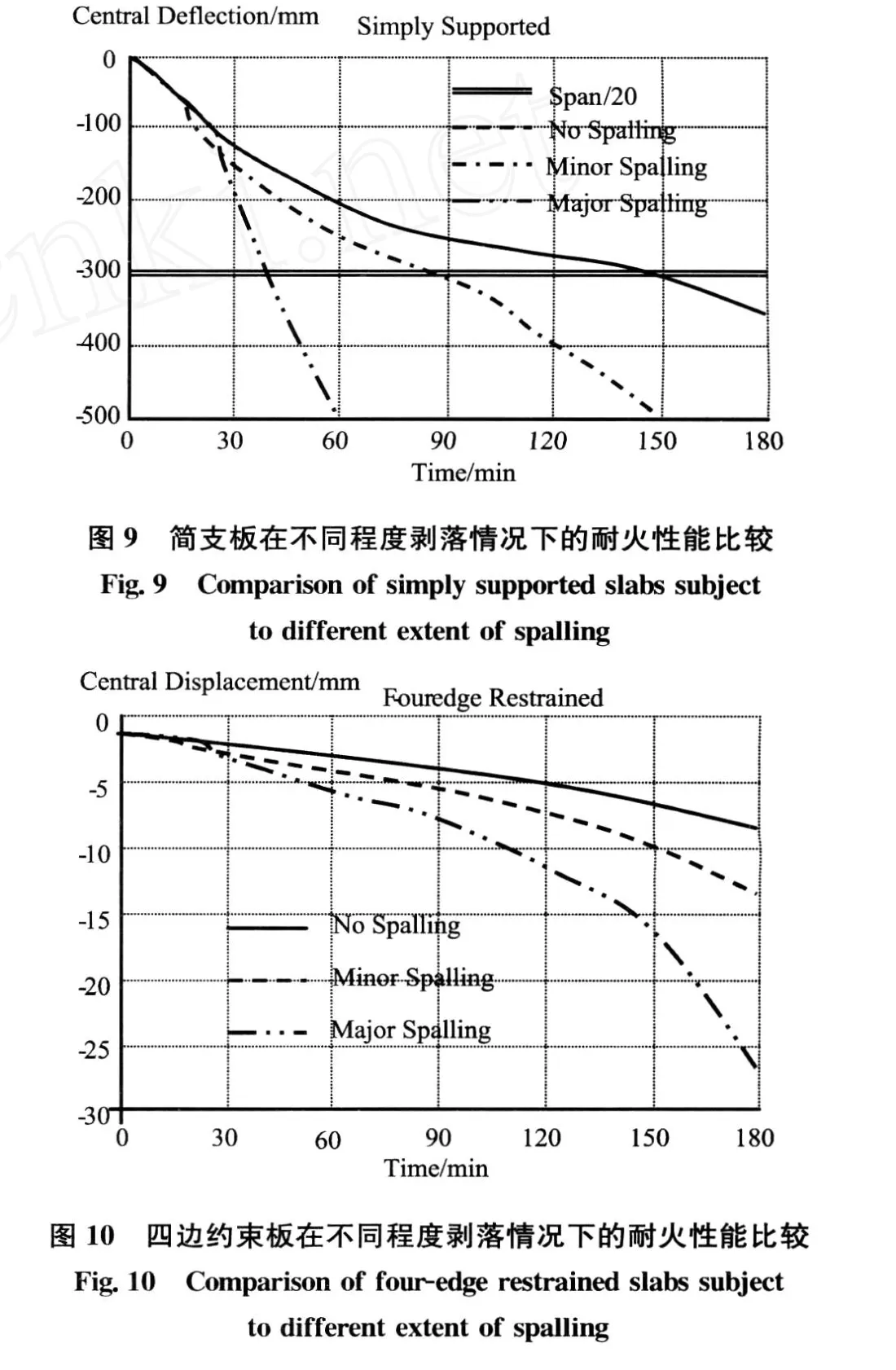

The structural fire engineering software package Vulcan developed at the University of Sheffield is used to perform thermal and structural analyses.The block of spalled concrete is modeled as“void”,which is defined as no thermal and mechanical properties.The temperature data predicted is then used in structural analysis. The predictions of slabs with four-edge restrained and simply supported boundary conditions are shown in Figs 9 and 10.An edge is"restrained"means restraining horizontal movement across the edge,as well as preventing rotation about it.It can be seen that spalling has little influence on the fire resistance of restrained(or continuous)slabs.This explains why no collapsing happened although major spalling did occur,e.g.Fig.5,in many fire tests.However,minor or major spalling reduces the fire resistance time by 40%or 75%.Therefore,for slabs at the corner or edge of buildings,where the boundary is similar to simply supported,it is necessary to apply adequate measures to limit the spalling to satisfy design requirements.

4 Conclusions

In this paper,the failure mechanisms of reinforced concrete slabs in fire are analyzed analytically and numerically.Different from the cracking failure at ambient temperature,which is initiated and propagated from one surface to the other,the thermal gradient in slabs in fire enforces large deflections and forms membrane action.

In this research,a layered slab element enhanced with embedded weak discontinuities is used to study the progressive cracking failure of RC slabs in fire.The study shows that:(a)Slabs tend to undergo large displacements and form tensile membrane action;(b)Cracking occur at large deflections causes stress redistribution in the slab;(c)Slabs loss the load bearing capacity quickly when the stress in the reinforcement reaches its degraded yield strength;(d)Thermal expansion may leads to invisible internal cracking which should not be neglected in structural damage assessment after fire.

Another failure mechanism is the spalling of concrete which sloughs outer concrete and exposes the reinforcement to the fire.Spalling accelerates the reinforcement temperature growth and deteriorates bearing capacity of slabs.In order to have a quantitative understanding of the spalling influence on the fire resistance of RC slabs,the structural fire engineering software Vulcan developed at the University of Sheffield is used to study the limit state of RC slabs subject to predefined extents of spalling at predefined times.The spalled concrete blocks are assigned as“void”,which has no thermal and mechanical properties.Numerical study shows that spalling has little influence on the fire resistance of four-edge restrained slabs.However,minor or major spalling in a simply supported slab may reduce the fire resistance time by 40%or 75%,and therefore measures must be done to prevent avoid this spalling to satisfy the design requirements.

[1]Johansen K W.Yield-line formulae for slabs[M].Cement and Concrete Association, Taylor &Francis,1962.

[2]Bailey C,Toh W S.Small-scale concrete slab tests at ambient and elevated temperatures[J].Engineering Structures,2007,29(10):2775-2791.

[3]Foster S J.Tensile membrane action of reinforced concrete slabs at ambient and elevated temperatures[D].PhD Thesis.University of Sheffield,2006.

[4]Foster SJ,Bailey C G,Burgess I W,Plank R J.Experimental behaviour of concrete floor slabs at large displacements[J].Engineering Structures,2004,26(9):1231-1247.

[5]Lim L C S,Wade C.Experimental fire tests of two-way concrete slabs[R],Fire engineering research report 02/12,University of Canterbury,2002.

[6]Yu X M,Huang Z.An embedded FE model for modelling reinforced concrete slabs in fire[J].Engineering Structures,2008,30(11):3228-3238.

[7]DTI.Report on spalling of concrete structures[R].DTI Construction Industry Directorate Project Report,No.209-977 cc 2376,2003.

[8]Yu X M,Huang Z,Burgess I W,Plank R J.Nonlinear analysis of orthotropic composite slabs in fire[J].Engineering Structures,2008,30(1):67-80.

[9]BS EN 1994-1-2:2005,Eurocode 4:Design of composite steel and concrete structures-Part 1.2:General rules-Structural fire design[S].

[10]Abu A K,Burgess I W,Plank RJ.Effects of slab panel vertical support on tensile membrane action[A].3rd International Conference on Steel and Composite Structures(ICSCS07)[C],Manchester,U K,2007.

[11]Zaman A A A,Sullivan P J.Explosive spalling of concrete exposed to high temperatures[R].Concrete Structures and Technology Research Report,Imperial College,London,1970.

[12]Malhotra H L.Fire resistance of structural concrete beams[R].Fire Research Note No.741,Joint Fire Research Organization,Borehamwood,1969.

[13]Purkiss J A,Moris W A,Connolly R J.Fire resistance of reinforced concrete columns-Correlation of analytical methods with observed experimental behaviour[A].Proceedings of the 7th International Fire Science and Engineering Conference[C],eds.Franks,C.and Grayson,S.,26-28 March,St John’s College,Cambridge,Interscience Communications,531-541.

[14]Shorter G W,Harmathy T Z.Moisture clog spalling[A].Proceedings of Institution of Civil Engineers[C],1965,20:75-90.

[15]Yu X M,Huang Z,Burgess I W,Plank R J.Concrete Spalling in Fire:A Review of the Current State of Knowledge[R].Report to KICT,Korea.Also Research Report DCSE/06/F/01,University of Sheffield,2006.

[16]Ali F,Ali N,Silcock G,Abu-Tair A.Outcomes of a major research on fire resistance of concrete columns[J].Fire Safety Journal,2004,39(6):433-445.

1004-5309(2011)-0001-08

2010-11-23;修改日期:2010-12-21

中国博士后科学基金(20100471075)

余新盟(1970-),男,汉,2008年10月获英国谢菲尔德大学结构工程博士学位,现在哈尔滨工业大学深圳研究生院从事博士后研究工作。主要研究方向为结构抗火,计算力学,局部破坏等。

钢筋混凝土在火灾中的破坏机制分析

钢筋混凝土楼板由于材料退化和热膨胀的作用,在火灾条中的破坏机制与常温下有很大的区别,体现在应力分布、变形程度、局部破坏、极限承载力等方面。从数值分析的角度分析了钢筋混凝土楼板在火灾中的破坏机制,对爆裂防护位置提出了建议,并指出了过火结构健康检测时应注意的问题。

楼板破坏机制;数值模拟;局部破坏;混凝土开裂;混凝土爆裂;结构抗火

TU375.2

A

余新盟1,查晓雄1,HUAN G Zhao-hui2

(1.哈尔滨工业大学深圳研究生院土木与环境工程学科部,深圳,518055;2.英国谢菲尔德大学土木与结构工程系)