Effects of Deformation Rate and Degree of Compression on Texture Profile Analysis of Hard-boiled Egg

2011-10-13YUXiufangMAMeihuYANGFangLIULiliDUXinwu

YU Xiu-fang,MA Mei-hu,*,YANG Fang,LIU Li-li,2,DU Xin-wu

(1. College of Food Science and Technology, Huazhong Agricultural University, Wuhan 430070, China;2. School of Food and Bioengineering, Henan University of Science and Technology, Luoyang 471003, China;3. Vehicle and Power Engineering Institute, Henan University of Science and Technology, Luoyang 471003, China)

Effects of Deformation Rate and Degree of Compression on Texture Profile Analysis of Hard-boiled Egg

YU Xiu-fang1,MA Mei-hu1,*,YANG Fang1,LIU Li-li1,2,DU Xin-wu3

(1. College of Food Science and Technology, Huazhong Agricultural University, Wuhan 430070, China;2. School of Food and Bioengineering, Henan University of Science and Technology, Luoyang 471003, China;3. Vehicle and Power Engineering Institute, Henan University of Science and Technology, Luoyang 471003, China)

Three deformation rates (0.5, 1.0 mm/s and 2.0 mm/s) and seven degree of compression (10%, 20% through 70%)were selected for the texture profile analysis (TPA) of hard-boiled egg in order to explore the effects of the two parameters on the measurement of texture characteristics of hard-boiled egg. It was found that degree of compression was a more significant affecting parameter than deformation rate. Fitting of linear, quadratic polynomial and logarithmic models predicting texture characteristics in one experimental condition range was conducted, the results showed that the quadratic polynomial model best fitted the hardness, cohesiveness and resilience of egg white and yolk, and had statistical significance. In conclusion, it is suggested that the optimal parameters for the TPA analysis of cooked egg products were as follows: degree of compression, 60%for egg white and 30% for egg yolk; and deformation rate, 1.0 mm/s.

TPA;hard-boiled egg;degree of compression;deformation rate;regression

Hard-boiled egg is characteristic of compact elastic egg white and soft granulated egg yolk, and these sensory qualities could be measured by characteristic parameter of TPA.TPA has been widely applied to assess the mechanical behaviour of egg production such as gels of dehydrated egg white[1], stirred egg yolk[1-3]and salted egg yolks[4].Nevertheless, TPA is often used without knowledge of selection of suitable experimental conditions. Since TPA parameters vary with sample size and shape, ratio of compressing probe size versus sample, degree of compression, deformation rate, replicates and number of bites[5]. Therefore, some researchers have investigated the effects of test conditions such as deformation rate, degree of compression, sample size on textural parameters of potato and apple tissues[6],chicken sausage[7], apple slices[8], and noodles[9]. In prior papers about protein gels, the selection of TPA conditionswas not specified, and no study on selection of texture test conditions based on cooked shell egg has been reported.The find of regular change in textural parameters and the effect of test conditions on the TPA results could be helpful for test conditions selection of the treated samples.

TPA also called two bite test, was built in 1967. Texture analyser and the definitions of parameters were explained clearly in Bourne s bookFood Texture and Viscosity[10]. The characteristic parameters including hardness, springiness,cohesiveness, gumminess, adhesiveness, frangibility,chewiness and resilience were measured through the TPA curve on computer. In the present paper, the effects of compression percentage and deformation rate on TPA results of hard-boiled egg were discussed mainly in order to provide a practical reference for TPA applying to cooked whole egg products.

1 Materials and Methods

1.1 Samples preparation

Fresh eggs were purchased from a local supermarket(Wuhan, China). Eggs were cleared and then boiled at 100 ℃for 15 min, moved them quickly to cooling water in order to strip off eggshells easily. The hard-boiled egg white was cut into rectangular shape with dimensions 1.0 cm × 1.0 cm×0.5 cm and yolk was cut into two parts and the spherical surface was used for TPA analysis.

1.2 Methods of TPA test

For two-cycle compression, a Texture Analyzer TAXT2i(Stable Micro Systems, Surrey, England) was used to establish the force-time curve. All experiments were performed at room temperature about 20 ℃. The texturometer was programmed so that the downward movement began at a point 10 mm above the surface of the sample. Force-distance deformation curves were recorded at cross head speed of 5.0 mm/s and post test speed 5.0 mm/s. Four replicates were compressed twice to compression from 10% to 70% of their original height at test speeds of 0.5, 1.0 mm/s and 2.0 mm/s with a compression flat cylindrical aluminium probe (36 mm in diameter, P/36). Hardness, springiness, cohesiveness,adhesiveness, chewiness and resilience of boiled egg white and yolk were evaluated at the degree of compression ranged from 10% to 70%, at test speed 0.5, 1.0 mm/s, 2.0 respectively.Trigger type of auto-5.0 g, data acquisition rate of 200 pps and a rest period of 5 s between cycles.

1.3 Statistical analysis

Completely randomized design was used throughout the study. The experiments were run in four replicates. Data were presented as mean values ± standard deviation, and the mean values were examined for significance by analysis of variance (ANOVA) and mean comparisons were run by Duncan s multiple range tests. Statistical analyses were performed with the DPS software.

2 Results and Discussion

2.1 Curves analysis of TPA at different compressions and different test speeds

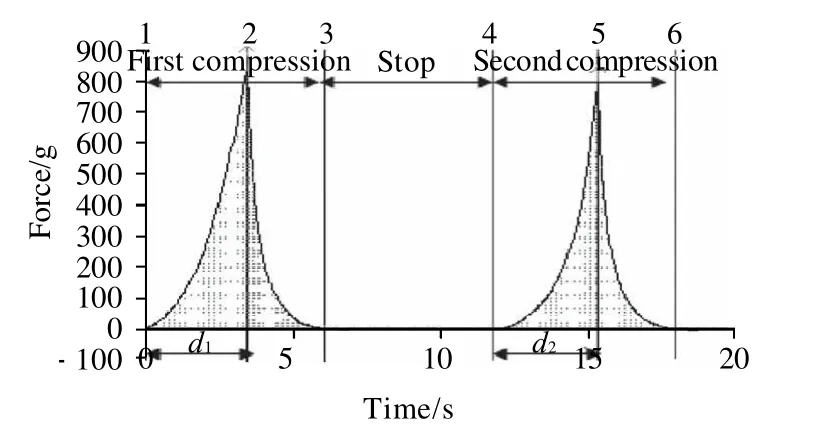

Typical curves of TPA on hard-boiled eggs were shown in Fig.1. As TPA probe compressed, the force strengthened.The samples broke down when it passed the point named bio-yield point. Parameters definition and calculation were performed as described by Bourne[11].

Fig.1 Typical texture curve of TPA test

TPA curves of hard-boiled egg white and yolk at compression 10%-70% and test speed 1.0 mm/s were shown in Fig.2 and Fig.3. Changes in TPA curve at different speeds and at compression 30% were shown in Fig. 4. As shown in Fig. 2, the peak appeared in the first compression was the hardness, and frangibility of samples disappeared.It was fount that the force increased as the compression levels growing at the first compression cycle. Fig. 2 and Fig.3 also show that at 10%-50% deformation, the curve for the upstroke of the plunger was almost symmetrical with respect to the downstroke portion. As the applied degree of deformation increased, curves did not show this symmetry,implying that the deformation was not followed by a rapid recovery. This is due to the fact that at higher compression levels, the potential damage to the structure is greater and recovery is less likely before the failure, indicating that deformation causes structural weakening. Characteristic curves of boiled egg yolk at different degree of compression were similar to egg white. The difference between F1(first peak) and F2(second peak) increased from 3-10 g to 61-573 g,which suggested a texture break of samples with increase incompression from 10% to 70%. For an imitation of the highly destructive process of mastication in the mouth, deformation values that will fracture the specimen are required,however, after a deep break, some parameters such as springiness or cohesiveness can become physically meaningless.Since the recovery capability has lost. At degree of compression 70%, it was found a deep break in structure of egg white caused by the strong force.

Fig.2 TPA curves of egg white at different degrees of compression

Fig.3 TPA curves of yolk at different degrees of compression

Fig.4 TPA curves at different deformation rates at compression 30%

Curves of TPA at compression 30% and deformation rate 0.5, 1.0 mm/s and 2.0 mm/s were shown in Fig.4. It was suggested that no obvious difference in force among deformation rates. However, the areas that made up of curve andXaxis reduced gradually because that increase in test speed resulted in decrease in run time. The results revealed that degree of compression affected significantly on TPA curves height (force), whereas, deformation rate didn t. Peleg[12]revealed that the more solid or elastic it is, the less is the rate effect in compressive and tensile tests.

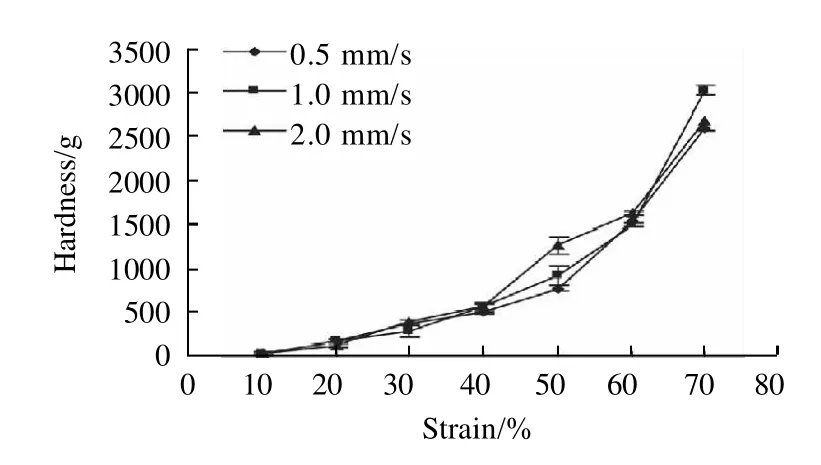

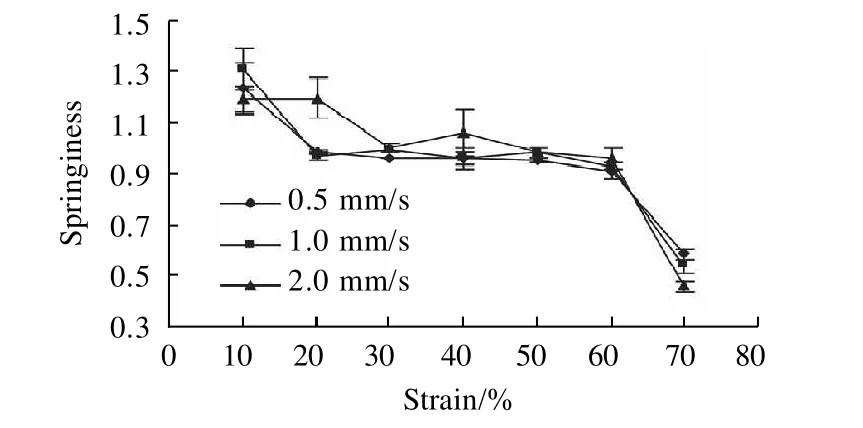

2.2 Effect of strain and test speed on characteristic parameters on hard-boiled egg white

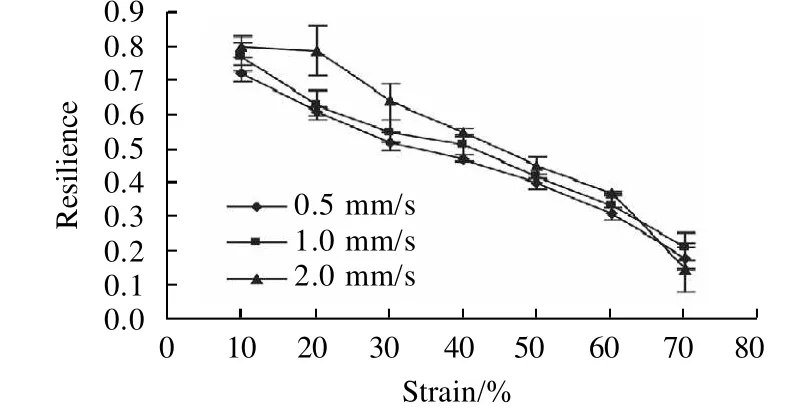

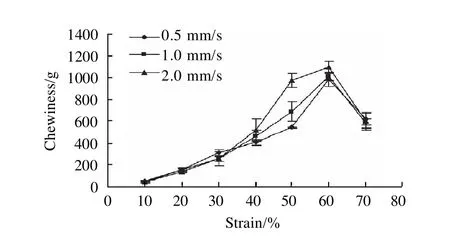

Results of TPA parameters for hard-boiled egg white were shown in Fig.5-9. It was obvious that as the compression increased, hardness of hard-boiled egg white increased gradually. Whereas, the springiness, cohesiveness and resilience decreased gradually when degree up to 60%, and then decreased sharply. The chewiness increased with the degree of compression up to 60% and decreased when the deformation at the sample-breaking degree of compression(70%). There was significant difference in terms of hardness and chewiness among different compression levels at the same deformation rate. Test speed affected hardness obviously at strain 50% (P< 0.05). The reduction of cohesiveness and resilience revealed that it was difficult for samples to return to original texture after the first compression as result of increase in the degree of compression and deformation.

Fig.5 Effects of deformation rate and degree of compression on hardness

Fig.6 Effects of deformation rate and degree of compression on springiness

Fig.7 Effects of deformation rate and degree of compression on cohesiveness

Fig.8 Effects of deformation rate and degree of compressionon resilience

Fig.9 Effects of deformation rate and degree of compression on chewiness

Many researchers abroad suggested the degree of compression ranged from 25% to 80%. Mohammad et al.[13]measured texture property of the date meat using degree of compression 75%. Herrero et al.[14]evaluated the textural parameter values of raw meat and cooked meat sausage using degree of compression 75%. Different heating methods and additives affected the egg s texture characteristic. The heat-formed gel of stirred egg yolk was tested using the degree of compression 80%[1]. Kaewmance et al.[4]tested salted egg yolk at degree of compression 50%. In the present study, the boiled whole egg white limited the sample size with dimensions 1.0 cm × 1.0 cm × 0.5 cm. The results revealed that the parameter values were stable up to the degree of compression 60%, meanwhile, it could reflect more texture properties though the imitation of the destructive process of mastication in the mouth at the compression 60%.Therefore, for the boiled whole egg white, the degree of compression 60%, deformation rate 1.0 mm/s were suitable for texture analysis of boiled egg white.

2.3 Effect of strain on characteristic parameters on hardboiled egg yolk

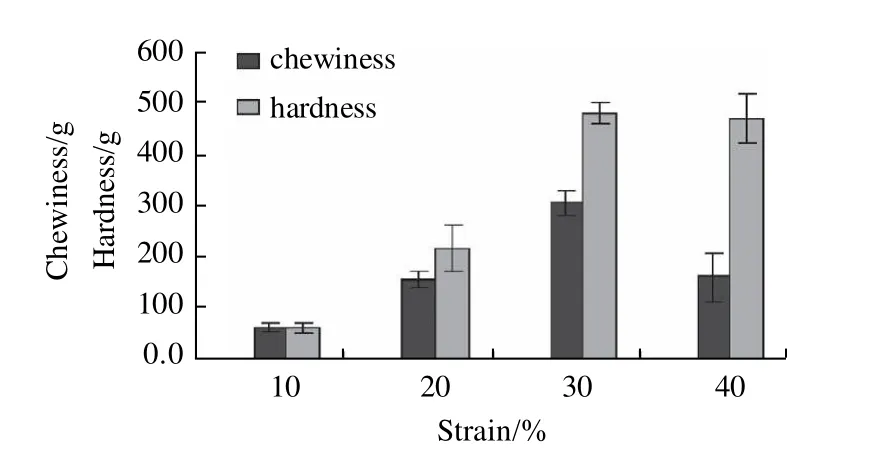

Changes in parameter values of egg yolk at different degrees of compression were measured by setting test speed at 1.0 mm/s (Fig.10, Fig.11). It was similar to egg white.Resilience, springiness and cohesiveness reduced with the compression increase. It was observed that chewiness increased with the degree of compression up to 30%, and decreased when the sample was broken hard (40%). Decrease in springiness, resilience and cohesiveness suggested egg yolk broke down inside.

Fig.10 Springiness, resilience and cohesiveness of yolk at different degrees of compression

Fig.11 Hardness and chewiness of yolk at different degrees of compression

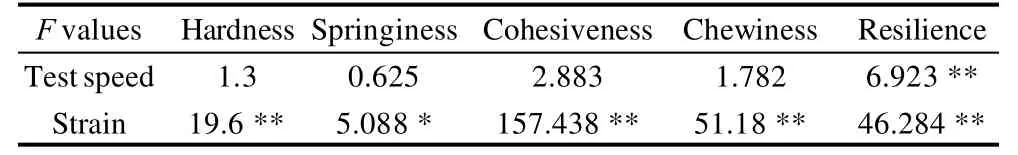

Table 1 ANOVA of TPA characteristic parameters

Table 2 R2of characteristic parameters in different models

Overall, there was significant difference (P<0.05) in terms of hardness, springiness, cohesiveness, chewiness and resilience among different compression levels, especially in hardness, cohesiveness, chewiness and resilience (P<0.01), while test speed had no significant influence in TPA parameters excluding resilience (P>0.05) (Table 1). Linear model, Quadratic model and Logarithmic model were fittedinto every parameters and theR2values of characteristic papermakers were shown in Table 2. Quadratic model was well fitted for most parameters with degree of compression and theR2values of hardness, cohesiveness, resilience and chewiness of egg white were above 0.9821. Therefore, it could be used to predict values of parameter at the same test conditions to some extent.

3 Conclusions

Effects of degree of compression and deformation rate on TPA curves and parameters of hard-boiled eggs were analyzed briefly. Results revealed that symmetry of TPA curve reduced with the degree of compression increasing to the critical point that showed structural damage. The critical points appeared at strain 70% and 40% for hard-boiled egg white and egg yolk respectively. The hardness and chewiness of boiled egg white increased, whereas the springiness, cohesiveness and resilience decreased when up to the degree of compression 60%. Degree of compression affected TPA parameters significantly involved (P<0.05),whereas test speed had no significant effect on TPA parameters (P>0.05) excluding resilience. The changes in texture properties of egg white and yolk were similar. The experiment suggested that suitable test conditions were degree of compression 60%, test speed 1.0 mm/s for hard-boiled egg white and 30%, 1.0 mm/s for egg yolk. The quadratic models were well fitted for TPA parameter which had statistical significance. The study based on the hard-boiled eggs provided a basic reference for choosing test conditions and estimating parameter values for boiled egg products such as brine egg, salted egg and so on.

[1] KALKANI A, PARASKEVOPOULOU A, KIOSSEOGLOU V.Protein interactions and filler effects in heat-set gels based on egg[J].Food Hydrocolloids, 2007, 21(2): 191-197.

[2] WOODWARD S A, COTTERILL O J. Texture and microstructure of cooked whole egg yolk and head-formed gels of stirred egg yolk[J].Journal of Food Science, 1987, 52(1): 63-67.

[3] KOIDIS A, PARASKEVOPOULOU A, KIOSSEOGLOU V. Fracture and textural properties of low fat egg yolk gels containing emulsion droplets[J]. Food Hydrocolloids, 2002,16: 673-678.

[4] KAEWMANCE T, BENJAKUL S, VISESSANGUAN W. Changes in chemical composition, physical properties and microstructure of duck egg as influenced by salting[J]. Food Chemistry, 2009, 112: 560-569.

[5] PONS M, FISZMAN S M. Instrumental texture profile analysis with particular reference to gelled systems[J]. J Texture Studies, 1996, 27:597-624.

[6] ALVAREZ M, CANET W, LOPEZ M. Influence of deformation rate and degree of compression on textural parameters of potato and apple tissues in texture profile analysis[J]. Eur Food Res Technol, 2002, 215(1): 13-20.

[7] JIANG Song, WANG Haiou. TPA and effect of experimental conditions on tpa test of apple slices[J]. Chinese Food Sci, 2004, 25(12): 68-71.

[8] JIANG ong, BIAN Xingwei, ZHAO Jiewen. Effect of experimental conditions on texture profile analysis (TPA) of chicken sausage[J]. Chinese Food Science, 2009, 30(1): 54-58.

[9] WANG Xiaobin, GUO Xingfeng, LOU Weina. Effect of test conditions on the texture properties of noodles[J]. Journal of Henan University of Technology: Natural Science Edition, 2009, 30(1): 14-17.

[10] BOURNE M C. Food texture and viscosity: concept and measurement[M]. New York: Academic Press INC, 1982: 114-117.

[11] BOURNE M C. Texture profile analysis[J]. Food Technology, 1978,32(7): 62-72.

[12] PELEG M. The basics of solid foods rheology[M]//H R MOSKOWITZ.Food texture, instrumental and sensory measurement. New York: Marcel Dekker, 1982: 1-33.

[13] RAHMANM S, AL-FARSI S A. Instrumental texture profile analysis(TPA) of date flesh as a function of moisture content[J]. Journal of Food Engineering, 2005, 66: 505-511.

[14] HERRERO A M, de la HOZ L, ORDONEZ J A, et al. Tensile properties of cooked meat sausages and their correlation with texture profile analysis (TPA) parameters and physico-chemical characteristics[J]. Meat Science, 2008, 80: 690-696.

形变速率和压缩程度对水煮蛋质构分析的影响

余秀芳1,马美湖1,*,杨 芳1,刘丽莉1,2,杜新武3

(1. 华中农业大学食品科学技术学院,湖北 武汉 430070;2. 河南科技大学食品与生物工程学院,河南 洛阳 471003;3. 河南科技大学车辆与动力工程学院,河南 洛阳 471003)

采用TPA方法研究压缩速率和压缩程度对水煮蛋质构分析的影响。分别在压缩速率0.5、1.0mm/s和2.0mm/s下,测定压缩程度10%~70%七个水平下的质构参数。结果表明,压缩程度比压缩速率对测定参数的影响更为显著。为了预测同一实验条件范围内的参数值,对参数进行线性、二次多项式和对数模型拟合,发现二次多项式模型对蛋白和蛋黄的硬度、内聚性和回复性拟合度较好,具有统计学意义。实验建议熟蛋制品TPA测试条件为:压缩程度:蛋白60%、蛋黄30%,测试速率1.0mm/s。

TPA;水煮蛋; 压缩程度;压缩速率; 回归方程

S858.31

A

1002-6630(2010)21-0147-05

2010-03-28

余秀芳(1983—),女,硕士研究生,主要从事畜产食品加工研究。E-mail:yxf840211@163.com

*通信作者:马美湖(1957—),男,教授,博士,主要从事动物性食品与蛋品科学研究。E-mail:mameihuhn@yahoo.com.cn