防泥沙型船开发迫在眉睫

2010-05-26大连远洋运输有限公司李玉平

大连远洋运输有限公司 李玉平

防泥沙型船开发迫在眉睫

大连远洋运输有限公司 李玉平

我国港口水域有一个显著特点,那就是多泥沙,这给船舶安全带来了巨大隐患。以油运主角VLCC为例,它们在卸下原油的同时,大量含泥沙的海水也被注入了船舱。这些泥沙天长日久就会将船舶纵骨掩埋。由此,船舶风险将不可控制。那么,如何破解这一困扰中国船东的难题呢?

结构强度遭遇泥沙“劫”

长江、珠江都是多泥沙河,船舶在泊靠上海、宁波-舟山等长江沿岸港口及珠江水域港口时,我们常常会发现这样一种现象:船舶在卸下货物的同时,成千上万吨混浊的压载水也被灌注到船舶底层压载舱内。由于含沙量大,这些压载水在船舶每个航次都要积淀下几十甚至上百吨的淤泥。这些淤泥有的伴随到船舶拆解才得以见到光亮。据史料记载,曾有一艘早期的8.7万载重吨散装船,拆解时从双层底舱中挖出4700吨淤泥。而导致该船拆解的最直接原因,是船中拱起异常,船底中部纵骨60%断裂,特别是已断裂的纵骨基本被淤泥掩埋。因为船舶强度构件已被淤泥掩埋,令船级社无法做出评估。船底堆满淤泥,配载数据显示的剪力和弯矩就会失真。所以,众多的船舶损毁事故,有依据证明是由泥沙所致。

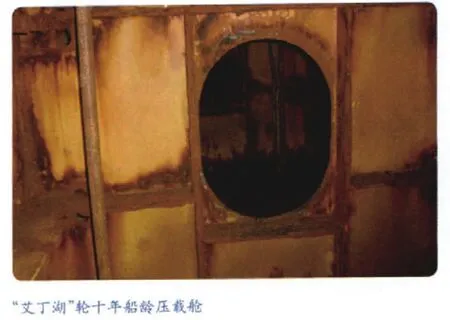

泥沙之祸,让船东苦不堪言。特别是作为石油进口大国,油运主角VLCC的命运特别值得关注。不久的将来,我国原油进口将达4亿吨,而其中2亿吨要用100艘VLCC送到宁波—舟山港口,卸下后经由输油管道送往上海、南京、武汉等地炼制。这些VLCC在卸下原油的同时,每船至少要把当地含有约1.5%泥沙的7到10万吨海水注入船舱。如果不及时将泥沙处理掉,一条新船在经历大约30个月的运营后,泥沙就会全面封住船底纵骨和横肋板的流水孔,日久必然将纵骨掩埋。之后,在双层底舱内形成宽60米、长约250米、高0.8米的厚厚堆积层。约12000吨的淤泥被大舱拖来拖去,无法检查到船舶的腐蚀、皱折、屈曲、断裂等情况。由此引发的油耗、航速、载货、吃水、操船等风险都会不可控制。造成上述问题的最根本原因,就是现有船型不适合我国港口和水域情况。

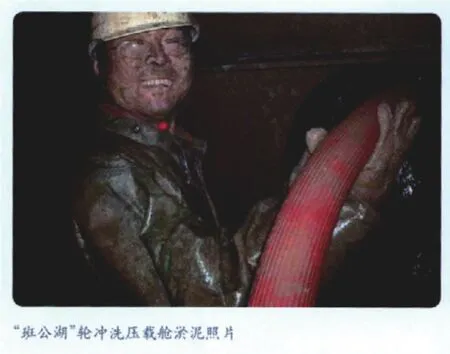

对此,船东也想出了一些应对之策,如尽可能寻找时机将中国港口的压载水在合适海域海况早些置换掉;在船舶满载而且有涌浪时,用压、排少量海水进舱晃荡;修船时尽量掏挖。最常用的办法是在满载时可以进人下到压载舱并用高压海水冲洗,但这项额外维修保养工程做起来艰苦异常,而且都非长久之计。

如 果 说30年前买欧洲和日本的二手船,中国船东无法改变既定船型,20年前我们也无造船和设计能力,那么近10年来,中国造船业已飞速发展,在船型设计上我们理应有所作为,针对中国港口和水域泥沙多的实际情况,设计出适合中国港口和水域的“防泥沙型船”。

压载水处理再添难题

中国船东面临的问题不止是防泥沙,还有一个大的难题是压载水处理。

我国现有的VLCC,设计上基本是沿袭日本VLCC船型:平底、边底双层连通,底部隔栅分舱结构。这些船的经典航线是中国至中东,中东至欧洲,中东、西非至美湾。由于每航次这些船舶都要在装货时向港内倾倒十万吨左右外来压载水,因而欧洲、美湾乃至中东各港口国纷纷要求这些船舶在距海岸200海里、水深200米以上的水域把舱内压载水置换掉;更进一步的要求是,船上必须装备经IMO认可的压载水处理装置并确认排放在当港的压载水已经处理达标。还有一个不容忽视的问题:国际压载水公约即将生效。

如此,每年超过亿吨的舟山海水被携带到中东港口,中东港口国又要求这些压载水必须处理掉,庞大的VLCC船队如何解决这一问题?

目前的办法是早换水,离开舟山就尽快换水,主要目的是防止泥沙沉淀;接近阿拉伯海时还要换水,为满足中东各港口国的要求。但航行中频繁把压载舱内的水排空、压进,船舶受力就无法控制。所以,换水只是权宜之计,最终还是要处理压载水。

于是,花大价钱购置压载水处理装备就不可避免。即使如此,在正常装货期间处理完8至10万吨压载水,以目前的压载水处理设备研发成果,则要再建一个类似现有机舱的设备间。无疑,代价太高昂了。

出路在哪里?即使是现有船型以牺牲船期为代价来换取压载水处理达标,那么将来呢?办法只能是减少在港口必须处理的压载水量。那么,需要换一种思维方式:减少在港口必须处理的压载水量,也就是进行设计开发新船型,并以当港压载水处理量4至5万吨为目标。

“国情船型”开发刻不容缓

大船管理的关键是结构强度。强度取决于结构构件完好,构件状态取决于涂层完好率。为此,相关国际组织出台了CSR(共同规范)和PSPC(涂层技术标准)。但是,CSR和PSPC生效前,航运市场的火爆导致船东抢订了大批散货船和油轮订单。这些国内各大船厂的在建船舶均属于不满足上述规范的船舶。可以预见,这些船5年内水舱内表面会布满锈钉,10年内锈层基本连片,构件开始腐蚀。15年后,腐蚀裕量消耗殆尽。到那个时候,船东为了维护强度,修船时就会割换1000吨甚至3000吨钢板。即使换上3000吨板也未必能完全保证结构强度,腐蚀还会加速。到20岁或25岁船龄时,船员和公司管船人员要不停地监视每一块强度构件,谨防某一局部皱折或断裂。如果碰到恶劣海况等,将酿成难以预料的灾难。

几十厘米的淤泥布满舱底,令船舶管理人员无法断定船底纵骨和舷侧纵骨是否有失稳及腐蚀程度。由此,不难看出,设计适合我们自己水域和港口的防泥沙型船舶已迫在眉睫。

The Yangtze and Zhujiang River are Sediment-laden rivers. Vessels reaching the ports along the rivers such as shanghai,Ningbo-Zhoushan, Ballast water with sediment is pumped into the ballast tank at the vessel bottom while unloading cargo, which leads to dozens or even hundreds of tons sediment left on board. The shear force and bending moment of load data would distortion. Lots of ship wrecks are proved to be caused by sediment.

China’s crude oil imports will reach 400 million tons, of which 2 billions will be send to Zhou Shan-Ningbo by 100 VLCCs. About 70, 000 to 100,000 tons local water with about 1.5% sediment will be pumped onboard the ship every time. If the Sediment can not be clean up timely, the drain hole of bottom longitudinal and transverse ribs of a new ship will be fully sealed up by sediment after operating about 30 months. Then the bottom longitudinal will be covered totally after years. As a result, a thick accumulation of sediment will be formed at the double-bottomed tank, which are 60 meters in width, 250 meters in length and 0.8 meters in height. About 12 thousand tons sediment will be carried back and forth about in the large cabin.The corrosion, corrugation, bending and fracturing of the vessel can not be detected timely. Risks related to fuel consumption, ships speed, haul loading, draft and operation will be out of control. The main reason for this problem is that the type of the existing vessels is not conformed with China’s waters and ports. The“sediment-proof vessel type” for China’s port and water needs developing.

The existing VLCC basically follows Japanese VLCC designs: flat bottom, double-bottomed and edge connectivity, grille-subdivision structure. Those vessels will dump to ports hundreds of thousands tons ballast water while are loading delivery every voyage. They are required to replace the ballast water in the waters deep more than 200 meters and 200 miles off the coast by European countries, U.S. and middle east port states. Those vessels are requested to equipped with the ballast water treatment plant recognized by IMO and confirm that the ballast water is conformed with the standards before discharging. Additionally,“IMO BWM Convention” be come into force in the near future.

After replacement of ballast water in advance, the vessels are required to do it again before reaching Arabian Sea by the Middle East port state authorities.Frequent replacement of ballast waters will make vessel stressed beyond control. It will cost a fortune to purchase ballast water treatment plant to treat the ballast water. But how about in the future? The only way is to design and develop new vessel forms, and aim at treating 40 to 50 thousands ballast water at ports.

Before the CSR and PSPC coming into force, a lager number of bulk carrier and tank ordered all do meet with this criteria. All those vessel will covered with rusty nail in the eternal surface of water tank in five years;the rusty scale will link up into a single stretch, the component parts start to rust in 10 years, corrosion allowance will deplete in 15 years. When repairing ship,steel plant of 1000 tons to 3000 tons will be renewed.The structural strength could not completely guaranteed yet. Corrosion will continue accelerating. After 20 to 25 years, every part of structural strength has to be noticed to avoid one of them winkling or snap real. Therefore,we are in urgent need to design sediment-proof vessel types suitable for our own water and ports.

To Develop Anti-sediment Vessel Form is Critical

By Li Yuping