Study on Solid Fermentation and Antioxidant Function of Natto

2024-02-26JunxiaSONGHongbingQIYanhongMAO

Junxia SONG, Hongbing QI, Yanhong MAO

1. School of Geographical Sciences, Lingnan Normal University, Zhanjiang 524048, China; 2. Life Science and Technology School, Lingnan Normal University, Zhanjiang 524048, China

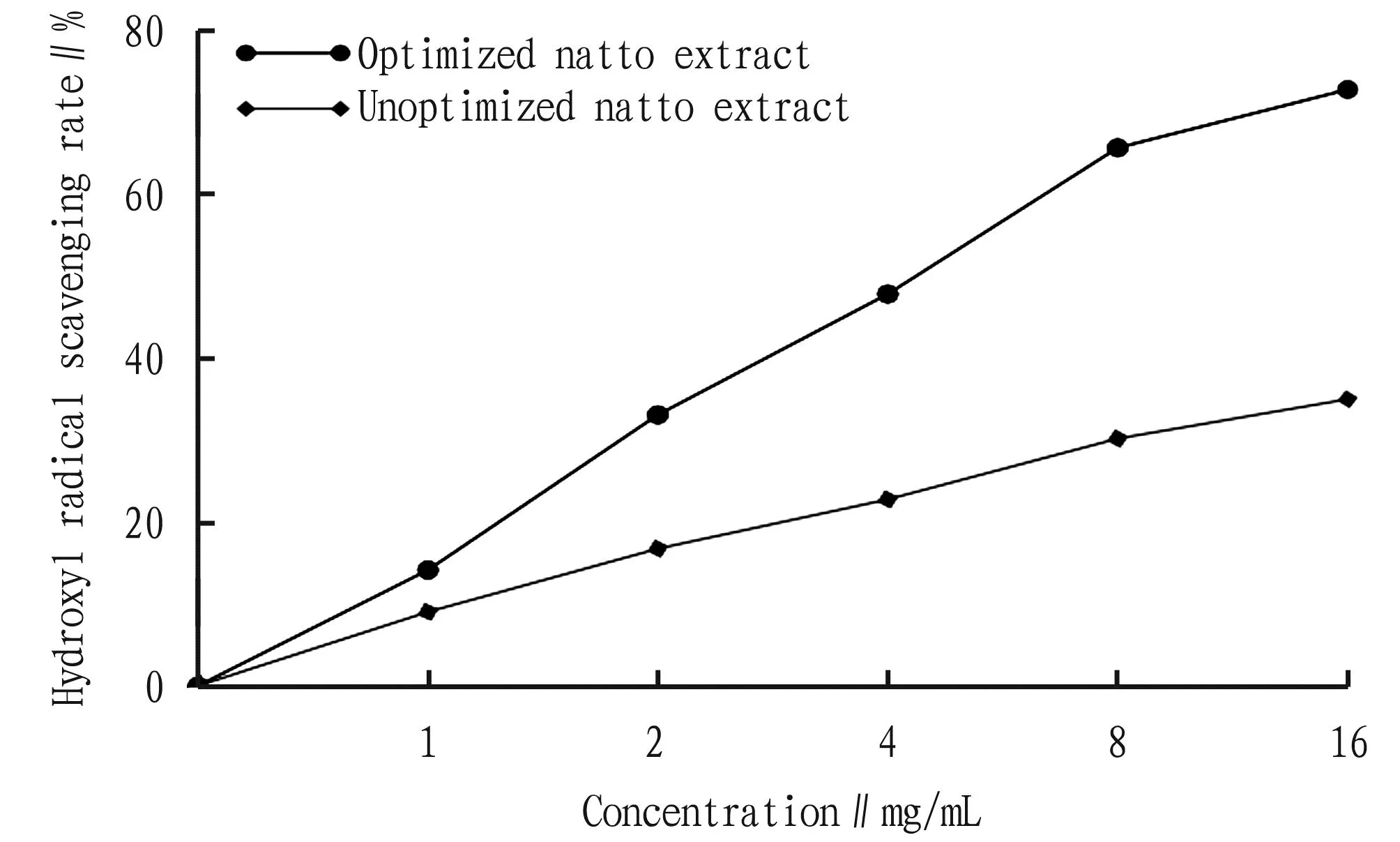

Abstract [Objectives] To study the optimum conditions of solid fermentation of natto with antioxidant function as an index. [Methods] Single factor experiment and orthogonal experiment were designed to study the effects of temperature, time, initial pH and inoculum amount on the antioxidant activity of natto solid fermentation. The optimum conditions of natto solid fermentation were determined and the antioxidant activity of natto extract was compared. [Results] The optimal fermentation conditions were as follows: temperature 32 ℃, initial pH 7.0, inoculation amount 8%, fermentation time 32 h. The hydroxyl radical scavenging rate of natto solid fermentation crude extract was the highest, which was 82.7%. The optimized natto fermentation extract showed stronger scavenging ability for ·OH and and showed obvious dose-effect relationship. IC50 was 3.63 and 4.24 mg/mL, respectively, and the scavenging efficiency was 1.3 and 1.9 times higher than that of the unoptimized fermentation extract, respectively. [Conclusions] Natto is rich in nattokinase and other functional factors, and its antioxidant activity can be improved by optimizing fermentation technology, so that natto products can be widely used, including cosmetic raw materials, natto skin care soap, health food and medicine, etc., and have a broader development prospect.

Key words Natto, Solid fermentation, Hydroxyl radical scavenging rate, Antioxidant activity

1 Introduction

Natto is a traditional nutritious food in Japan. During the Tang Dynasty, Monk Jianzhen brought fermented soya bean from Yunnan, China to Japan, and then it evolved into natto. Similar to fermented soya bean in China, it is a micro-ecological health food fermented byBacillusnatto, and it is alkaline and contains hundreds of physiological active substances needed by human body[1]. Natto is rich in nutrients, containing 61.8% water, 9.26% crude protein, 8.17% crude fat, 6.09% carbohydrate, 2.2% crude cellulose and 1.86% ash. During natto fermentation, soybean protein is degraded, protein digestibility is increased and all essential amino acids are contained[2]. At the same time, natto also contains nattokinase[3], unsaturated fatty acids, superoxide dismutase, isoflavones[4], dietary fiber[5], vitamin B, vitamin K[6]and essential elements for human body (such as calcium and iron)[7]. Japanese people call soybeans "meat produced in the fields", "tuna in the mountains" and "comprehensive nutrients of gold". Compared with soybean, natto has better nutritional value, including thrombolytic effect[8-9], antibacterial and antiseptic effect[10-12], osteoporosis prevention effect[13], degradation effect of anti-nutritional factors[14], anti-cancer effect[15], antioxidant function[16], hangover protection and liver protection effect[17], slow weight loss without rebound[18],etc.

In order to study the effects of fermentation temperature, inoculum amount, fermentation time and initial pH on the antioxidant function of natto in solid fermentation, the hydroxyl radical scavenging rate of natto crude extract was used as an indicator to optimize the fermentation conditionsinvitro, which provided a reference for the production of natto with high antioxidant function.

2 Materials and methods

2.1 Materials

2.1.1Strains and media.Bacillusnatto: isolated and preserved from Life Science and Technology School, Lingnan Normal University.

Soybeans: purchased from Xinhe Supermarket of Lingnan Normal University.

Basic medium: peptone 1%, beef extract 0.5%, sodium chloride 0.5%, pH 7.0-7.2.

2.1.2Main reagents and preparation. Saffron O, analytically pure, Shanghai Miaoyan Biotechnology Co., Ltd.; potassium dihydrogen phosphate, disodium hydrogen phosphate, 30% hydrogen peroxide, analytically pure, Guangzhou Jinhua Chemical Reagent Co., Ltd.; disodium ethylenediamine tetraacetate, analytically pure, Guangdong Xilong Chemical Plant; ferrous sulfate, analytically pure, Tianjin Damao Chemical Reagent Factory.

2.1.3Test instruments and equipment. SW-CJ ultra-clean workbench (Jintan Fuhua Instrument Co., Ltd.); ZHWY-100C Desktop Refrigeration Constant Temperature Oscillator (Shanghai Ruixin Automation Equipment Co., Ltd.); GL221R desktop high-speed refrigeration centrifuge (Haizhizheng Centrifuge Co., Ltd.); Model HHB-11500 biochemical incubator (Shanghai No. 1 Yuejin Medical Instrument Factory); 722N visible spectrophotometer (Shanghai Precision Scientific Instrument Co., Ltd.); Allegra X-22 desktop high-speed refrigeration centrifuge (BACKMAN, Germany).

2.2 Test methods

2.2.1Activation and culture ofB.natto. 20 mL of basic culture medium was prepared in a conical flask and sterilized by high pressure steam. The strains preserved in the laboratory were inoculated into it, sealed with 8 layers of gauze, and cultured in a shaking table at a rotational speed of 160 r/min and a temperature of 37 ℃ for 12 h.

2.2.2Natto production process. Soybean-cleaning-soaking-draining-sterilizing-cooling to room temperature-inoculation-fermentation-post-ripening-sampling analysis: taking 50 g of soybean, washing and soaking it for 14 h; placing it in a culture dish, autoclaving at 115 ℃ for 30 min, naturally cooling, inoculating with 6% culture seed solution, stirring evenly with sterile glass sticks; cultivating in incubator at 37 ℃ for 32 h, with initial pH 7.0 and humidity 85%-90%; after ripening in refrigerator at 4 ℃ for 24 h.

2.2.3Single factor test. Fermentation temperature, inoculation amount, fermentation time and initial pH were adjusted. The fermentation temperatures were 27 ℃, 32 ℃, 37 ℃ and 42 ℃, respectively; the inoculation amount was 2%, 4%, 6% and 8%, respectively; the fermentation time was 16, 24, 32 and 40 h respectively; the initial pH values were separately adjusted to 6.0, 7.0, 8.0 and 9.0 for fermentation. The scavenging rate of hydroxyl radical (·OH) in the crude extract of fermented products was used as a measurement indicator, and the average value was taken for three times to investigate the best fermentation conditions of natto solid fermentation.

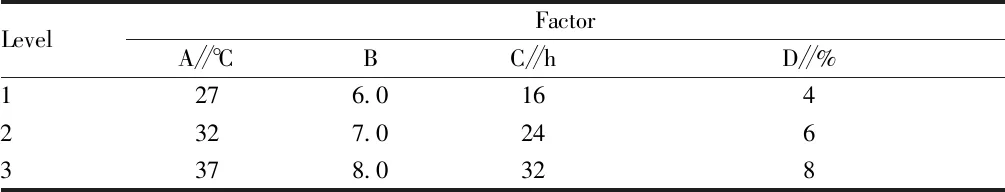

2.2.4Orthogonal test. According to the results of single factor test, four factors, namely fermentation temperature (A), initial pH (B), fermentation time (C) and inoculum (D) and their levels were selected, and L9(34) orthogonal test with four factors and three levels was carried out according to Table 1.

Table 1 Factor level of orthogonal experiment

2.2.5Preparation of crude natto extract. The natto was stirred and mixed with sterilized glass rod, then 1 g of sample was put into a 10 mL centrifuge tube, mixed with 6 mL phosphoric acid buffer with pH 7.0, centrifuged for 10 min at a rotating speed of 4 000 r/min, and the supernatant was freeze-dried for later use.

2.2.6Determination of antioxidant function. (i) Scavenging of hydroxyl radical (·OH). ·OH is produced by EDTANa2-Fe (II)-H2O2system. Because ·OH can fade the color of saffron specifically, the content of ·OH can be measured by colorimetry according to the fading degree.

Reaction system[19]: In a 10 mL test tube with stopper, pH 7.4 phosphate buffer solution, saffron solution (520 μg/mL), 3.8 mmol/L EDTANa2-Fe (II) solution were added in turn, and then sample solutions with different concentrations were added. Finally, 0.075% H2O2solution was used to start the reaction, and double distilled water was added to 10 mL. After mixing evenly, the absorbance (A) was measured in a water bath at 40 ℃ for 30 min. In the blank group, equal volume of reevaporated water was used instead of the sample solution; in the control group, the sample solution and EDTANa2-Fe (II) solution were replaced by the same volume of reevaporated water.

The test results are expressed as scavenging rateIC:IC= (Asample-Ablank) × 100%/(Acontrol-Ablank), andIC50represents the sample concentration with scavenging rate of 50%. Each group of data is the average of 3 replicates.

Calculate the inhibition rate of oxygen free radicals by the following formula:

Scavenging rate (%)=(Vcontrol-Vsample)/Vcontrol×100

whereVcontrolis the autoxidation rate of pyrogallol in control group, △OD/min;Vsampleis the autoxidation rate of pyrogallol in sample group, △OD/min.

2.3 Data processingExcel 2007 was used to process the average data of three parallel samples in each part of the test, andt-test was used to analyze the significance of the difference, and the test level was 0.05.

3 Results and analysis

3.1 Single factor test results and analysis

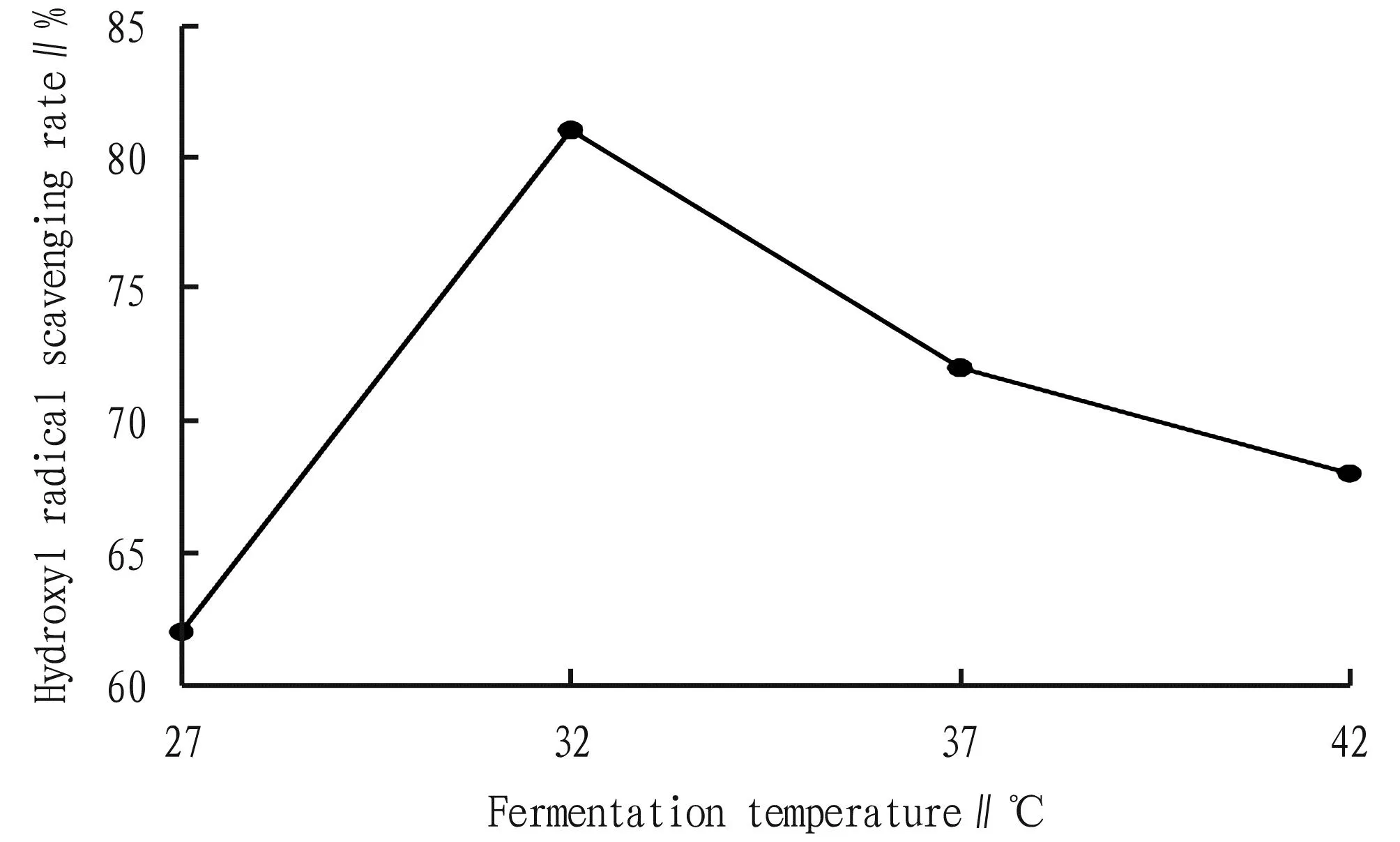

3.1.1Effect of fermentation temperature on antioxidant activity of natto. The effect of fermentation temperature on hydroxyl radical scavenging rate is shown in Fig.1. As can be seen from Fig.1, changing the fermentation temperature will obviously affect the scavenging rate of hydroxyl radicals by natto solid fermentation crude extract. When the fermentation temperature was 32 ℃, the hydroxyl radical scavenging rate of natto solid fermentation crude extract was the highest, reaching 81.0%. Natto fermented at this temperature had the best antioxidant function.

Fig.1 Effect of fermentation temperature on hydroxyl radical scavenging rate

Temperature had a great influence on the growth and metabolic activity ofB.natto. When the fermentation temperature was lower than 32 ℃, the metabolic activity ofB.nattowas weak; when the fermentation temperature was higher than 32 ℃, the antioxidant activity ofB.nattodecreased.

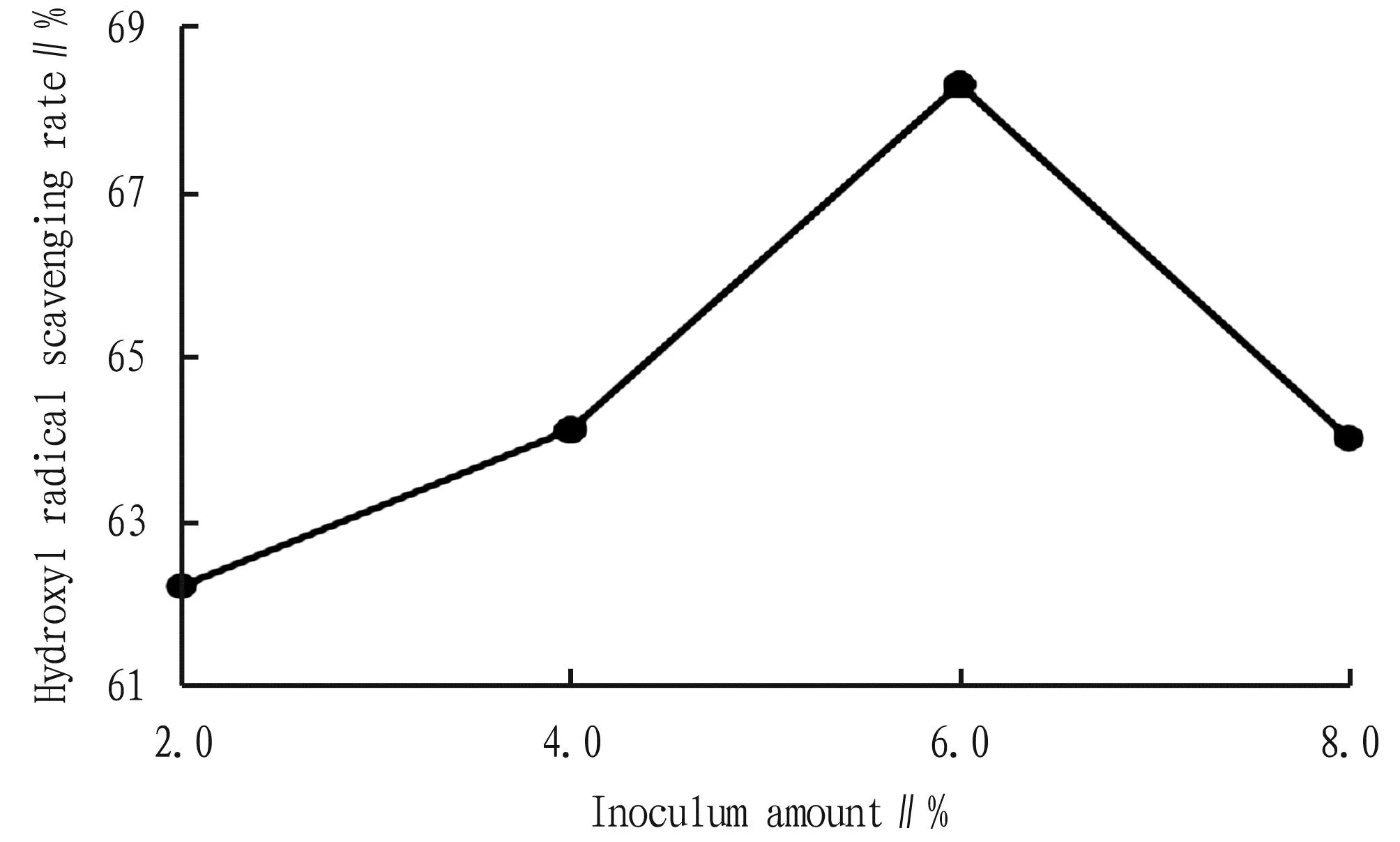

3.1.2Effect of inoculation amount on antioxidant activity of natto. The effect of inoculation amount on hydroxyl radical scavenging rate is shown in Fig.2. As can be seen from Fig.2, when the inoculation amount was 6.0%, the scavenging rate of hydroxyl radicals by the crude extract of fermented natto solid fermentation was the highest, reaching 68.3%. Natto fermented with this inoculation amount had better antioxidant activity. Strain concentration plays an important role in substrate metabolism, and it is particularly important to control the inoculation amount in order to ensure that strains can better play their functions. However, compared with temperature, inoculation amount has little effect on hydroxyl radical scavenging rate.

Fig.2 Effect of inoculation amount on hydroxyl radical scavenging rate

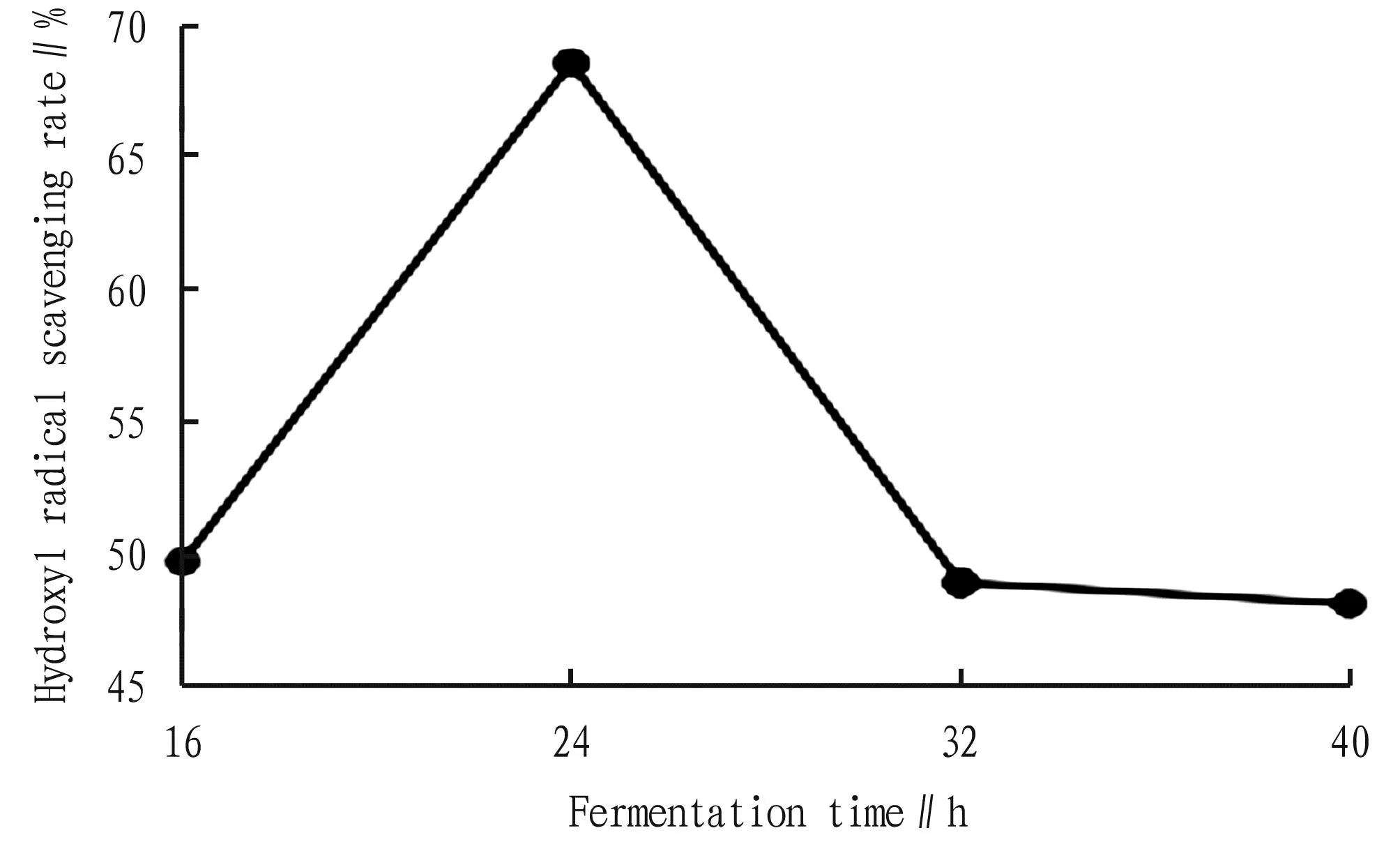

3.1.3Effect of fermentation time on antioxidant activity of natto. The effect of fermentation time on the antioxidant activity of natto is shown in Fig.3. From Fig.3, it can be concluded that when the fermentation time was 24 h, the scavenging rate of natto solid fermentation crude extract on hydroxyl radicals was the highest, reaching 68.5%. After the fermentation time exceeded 24 h, the scavenging rate of hydroxyl radicals began to decrease; this may be related to the excessive growth ofB.natto, destroying the antioxidant active factors produced by fermented natto. The growth rate of microorganisms gradually increased in a certain period of time, and when the number of microorganisms reached a certain number, the growth rate gradually decreased until it tended to zero. Fermentation time determined the amount ofB.nattoin the reaction system, and then affected the decomposition of substrate soybean.

Fig.3 Effect of fermentation time on hydroxyl radical scavenging rate

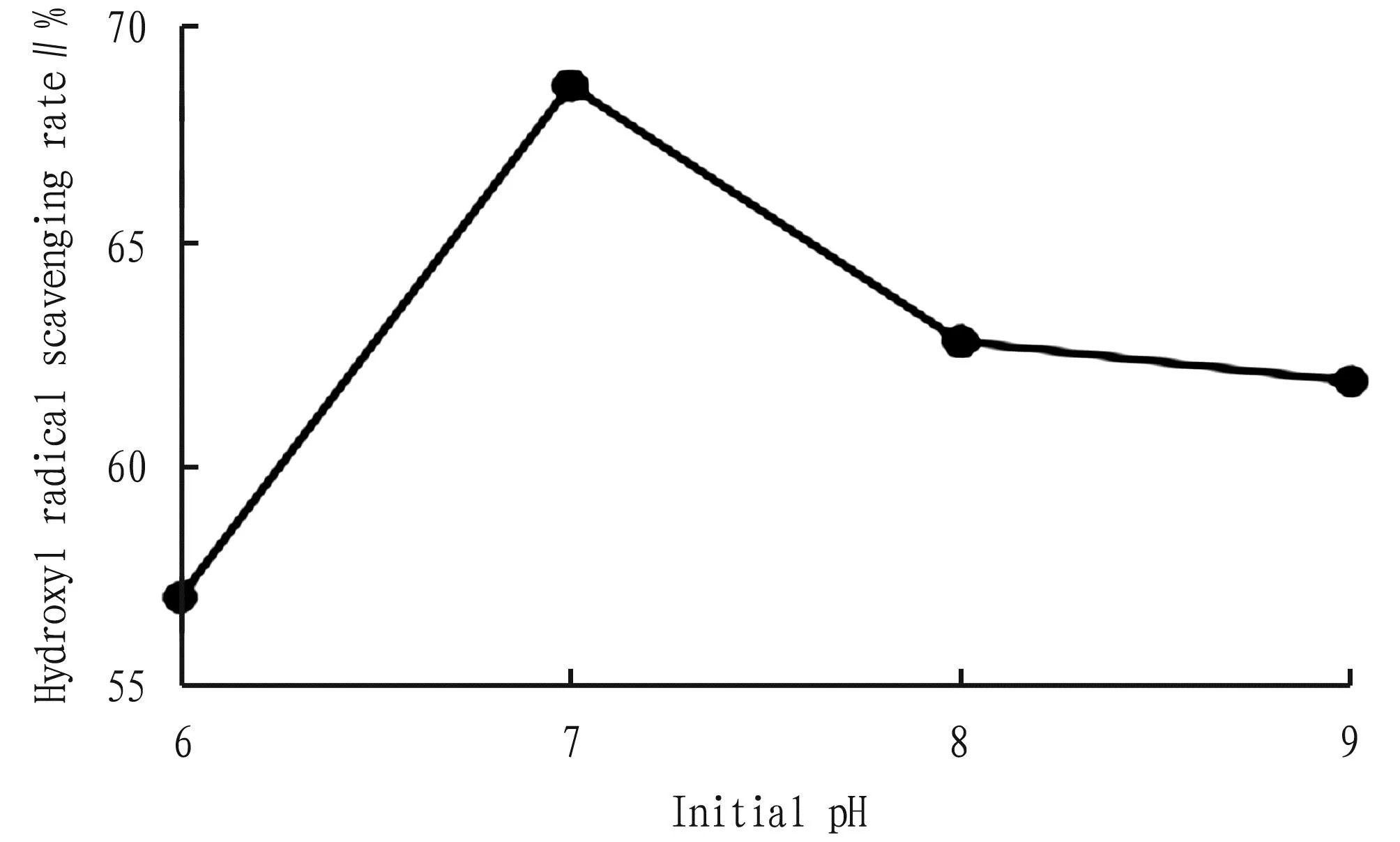

3.1.4Effect of initial pH of fermentation on antioxidant activity of natto. The pH mainly affects cell membrane charge, membrane permeability and ionization degree of substances, thus affecting cell enzyme activity and nutrient absorption. The effect of initial pH of fermentation on antioxidant activity of natto is shown in Fig.4. From Fig.4, it can be concluded that at the initial pH of 7.0, the scavenging rate of hydroxyl radicals reached the maximum value, which was 68.6%. The crude extract of natto solid fermentation had stronger antioxidant function. It also showed that the antioxidant function of fermented natto was most beneficial whenB.nattogrew vigorously.

Fig.4 Effect of initial pH of fermentation on hydroxyl radical scavenging rate

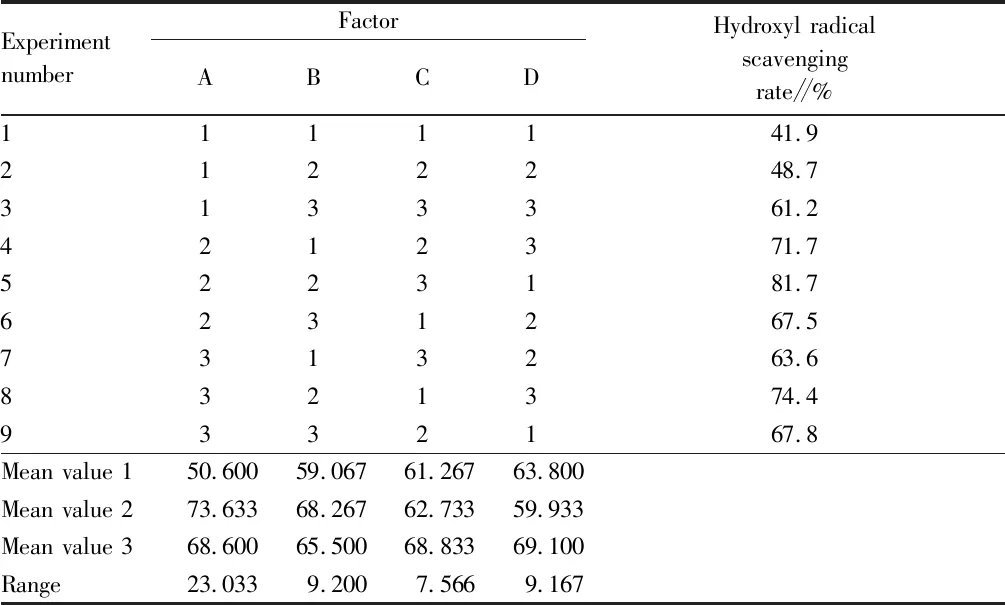

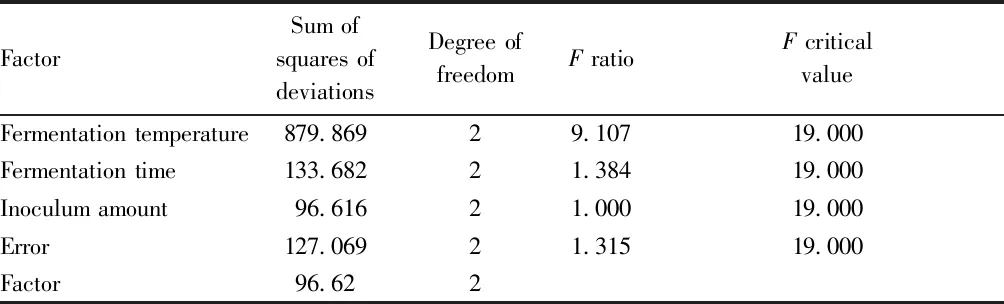

3.2 Orthogonal test results and analysisIt can be concluded from Table 2 that the average temperature 2 was the largest, so it was best to take level 2, that is, 32 ℃; the other three factors were as follows: pH (pH 7.0) at level 2 was the best, fermentation time at level 3 (32 h) was the best, inoculation amount at level 3 (8%) was the best, and the best ratio of A2B2C3D3was obtained by combining the four factors. Under these conditions, the activity of scavenging hydroxyl radicals of soybean dregs fermentation supernatant was the highest. Range analysis (Table 3) showed that A>B>D>C, and the influencing factors were in the order of temperature, pH, inoculation amount and fermentation time in descending order.

The optimum conditions were as follows: fermentation temperature 32 ℃, initial pH 7.0, fermentation time 32 h, inoculation amount 8%. The results of verification experiment showed that the scavenging rate of hydroxyl radicals was 82.7%.

Table 2 Results of L9 (34) orthogonal test

Table 3 Analysis of variance of L9 (34) orthogonal test

3.3 Antioxidant activity

3.3.1Ability to scavenge ·OH. Hydroxyl radical (OH·), a kind of free radical with strong oxidation ability, can undergo electron transfer, participate in hydrogen capture reaction and hydroxylation reaction, and oxidize sugars, amino acids, proteins, nucleic acids and lipids, causing them to suffer damage and destruction. Hydroxyl radicals are related to aging, tumor, radiation damage and cell phagocytosis, so it is urgent to strengthen the research on the role of hydroxyl radicals.

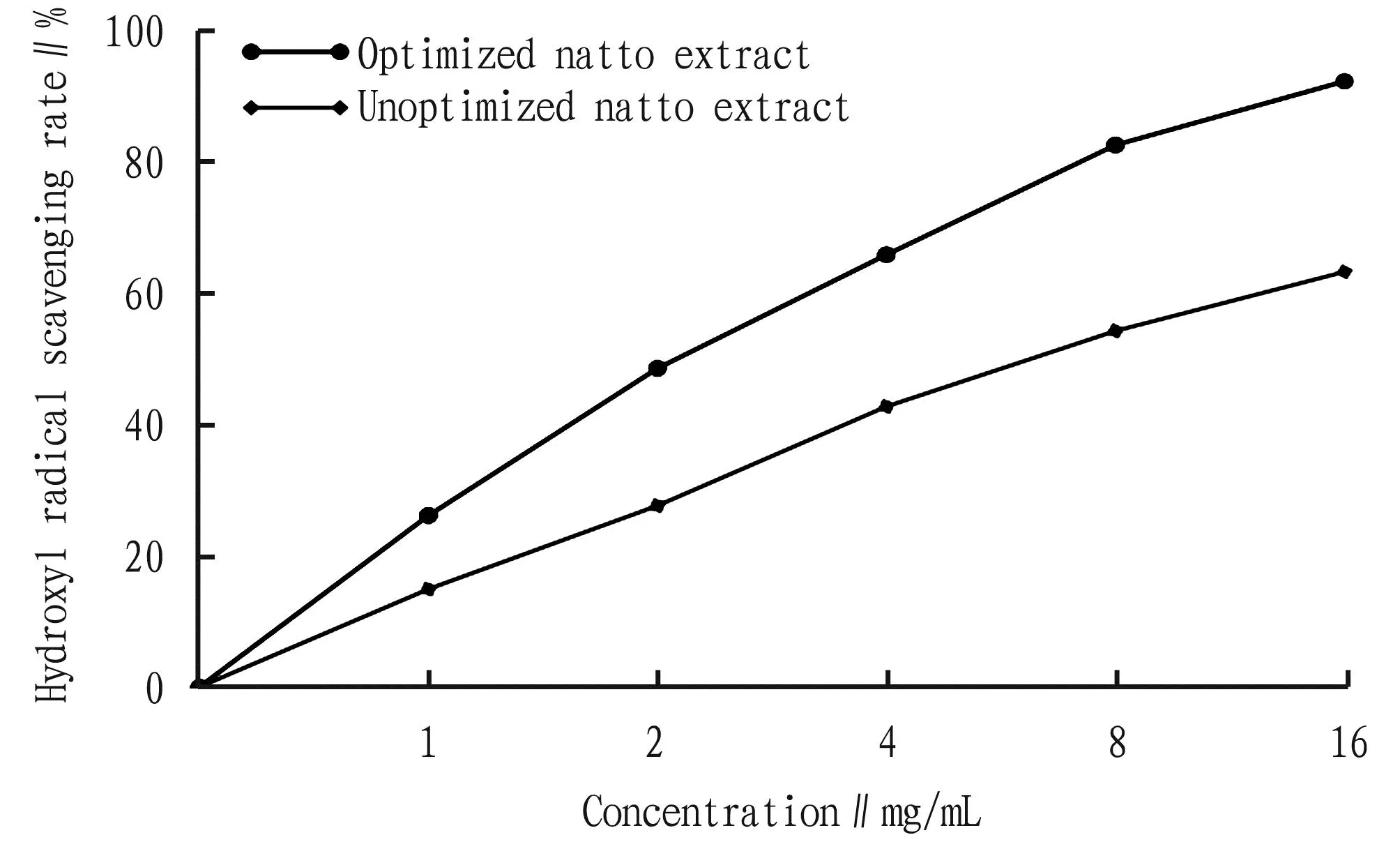

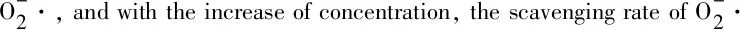

The test results of ·OH scavenging ability (Fig.5) showed that the optimized natto fermentation broth displayed stronger scavenging ability to ·OH, and displayed obvious dose-effect relationship.IC50was 3.63 mg/mL, and the scavenging efficiency was 1.3 times higher than that without optimization.

Fig.5 Ability of natto extract to scavenge hydroxyl radicals

Fig.6 Ability of natto extract to scavenge oxygen free radicals

4 Conclusions

The results of this experiment showed that with the scavenging hydroxyl radical as the index, the optimum fermentation conditions were obtained by single factor test and orthogonal test: fermentation temperature 32 ℃, initial pH 7.0, inoculation amount 8%, fermentation time 32 h. The antioxidant activity of natto was the highest, and the scavenging rate of hydroxyl radical was 82.7%.

Natto is rich in nattokinase and other functional factors, and its antioxidant activity can be improved by optimizing fermentation process, so natto products have a wider application range, such as being used as cosmetic raw materials, natto skin care soap, health food and medicine, and have a broader development prospect.

杂志排行

Asian Agricultural Research的其它文章

- Practice and Thinking of Agricultural Science and Technology Experts Serving the Grassroots to Promote Rural Revitalization

- Technique of Earthworms Restoring Soil in Greenhouse Cultivation

- Research Progress on Nutritional Requirements of Carp

- Discussion on Land Use Mode Reform in Coal Opencast Mining

- Guarantee Strategy for the Safety of Agricultural Industry in Hunan Province

- Validation of Molecular Detection Methods for Gluten Allergens in Infant Formula