Effect of lump ore ratio on the metallurgical properties of blast furnace charge

2024-01-11,

,

Research Institute,Baoshan Iron &Steel Co.,Ltd.,Shanghai 201999,China

Abstract:We conducted a series of experimental studies on the metallurgical properties of N-lump and F-lump ores used in Baosteel’s blast furnace,including thermal cracking,low-temperature reduction pulverization,reducibility,and droplet properties.The results show that the thermal burst properties of N-lump ore are better than those of F-lump ore.The low-temperature reduction degradation index (RDI) pulverization of the charge is the best when the ratios of N-lump ore and F-lump ore account for 35% each.The reduction performance of the charge is improved when F-lump and N-lump ores are mixed with sinter.In the softening-melting performance experiment,when the proportion of N-lump ore is 40%,the characteristic area value (S) as the charge permeability index is the smallest.When F-lump ore is mixed with sinter,its droplet performance improves compared with that of single F-lump ore.The proportion of F-lump ore should not exceed 15%.

Key words:lump ore ratio; metallurgical property experiment; softening-melting property; the RDI pulverization; reduction property

1 Introduction

In recent years,with the overcapacity in the steel industry and the continued decline in market demand,the cost of blast furnace iron-making has been increasing.Lump ore has the advantages of low price,saving the cost for equipment and land occupation of sinter and pellets production,and reducing environmental pollution.Major enterprises reduce the charge cost by continuously increasing the proportion of lump ore in the furnace and reducing or not using clinkers such as pellets[1].This also helps address the issues of cost reduction and emission reduction and improve efficiency and energy saving.

However,as lump ore belongs to green ore,its metal-lurgical performance is worse than that of sinter or pellet owing to the following reasons:(1) The sof-tening temperature of the lump ore is low,the soft melting zone is wide,the softening-melting perfor-mance is poor,and the droplet range is large,which leads to the poor permeability of the soft melting zone in the blast furnace and an increase in the differential pressure.(2) The thermal burst perfor-mance of the lump ore is poor.After the burst in the medium-temperature zone,a large amount of powd-er is produced via pulverization,which substantially affects the permeability and distribution of the gas flow.(3) The Al2O3/SiO2content in lump ore is high,which considerably affects blast furnace slagging.In particular,the primary slag affects the change in airflow in the furnace,resulting in a gradual increase in edge airflow.At the same time,the Al2O3content in the slag increases,which reduces the fluidity of the slag and the ability to remove sulfur,which affects the quality of cast iron.(4) Some lump ore varieties exhibit poor reducibility,increasing the blast furnace fuel ratio.

Therefore,substantially increasing the proportion of lump ore will cause poor charge reduction,increase of low-temperature reduction pulverization rate and poor droplet properties,which will hinder the smooth operation of the blast furnace and worsen the smelting index.Therefore,the metal-lurgical properties of single ore and the charge structure synthesis must be analyzed and studied.After long-term and extensive laboratory research on improving the lump ore ratio of the blast fur-nace,many iron and steel enterprises at home and abroad have taken a series of effective measures to improve the lump ore ratio of a blast furnace in production practice to ensure the stable and smooth operation of furnace conditions and achieve cost reduction and increased efficiency with respect to blast furnace production[2].

2 Experimental materials and method

2.1 Experimental materials

Two types of lump ores (N and F) and one type of sinter were used as the test raw materials and procured from Baosteel iron-making plant;the chemical compositions of these lumps and sinter are shown in Table 1.

It can be seen from Table 1 thatw(TFe) of N-lump ore is the highest,which is 63.13%.More-over,there is a marginal difference in thew(TFe) of F-lump ore and sinter,56.09% and 57.36%,respectively.The burning loss of F-lump ore is nearly twice that of N-lump ore.

2.2 Determination of the thermal burst index

Two types of lump ores with a particle size of 20-25 mm were selected for a parallel test,with 500 g in each of 10 groups.A muffle furnace was selected as the test equipment with a test temperature of 700 ℃ and maintained constant for 30 min.After the test,the ores were cooled to room temperature.The per-centage of particles smaller than 6.3 mm of each group was measured using the vibrating screen,and the average value of these 10 groups of results is defined as the thermal burst index of the ore.

The thermal burst indexes of F-lump ore and N-lump ore were found to be 16.9% and 8.5%,respectively.The thermal burst index of F-lump ore is considerably higher than that of N-lump ore because it contains higher amounts of crystalline water and carbonate.At 700 ℃,the crystalline water evaporates,and a small amount of carbonate decom-poses,resulting in a higher burst index.However,even F-lump ore with a high thermal burst index produces far less powder than low-temperature reduc-tion pulverization of sinter (proportion of less than 3 mm),which has a relatively marginal impact on the forward running of the blast furnace.Therefore,the thermal burst index of the lump ore should not be considered as an important index for evaluating the lump ore[3].

3 Test scheme for determining the metal-lurgical properties of furnace charge

The hot metallurgical properties of iron-bearing furnace charge mainly include low-temperature reduction pulverization,medium-temperature reduc-tion,and melting dripping.N-lump ore and F-lump ore were mixed with sinter in a certain proportion for the low-temperature pulverization test (550 ℃) and reduction test (900 ℃).The specific propor-tion scheme is shown in Table 2.

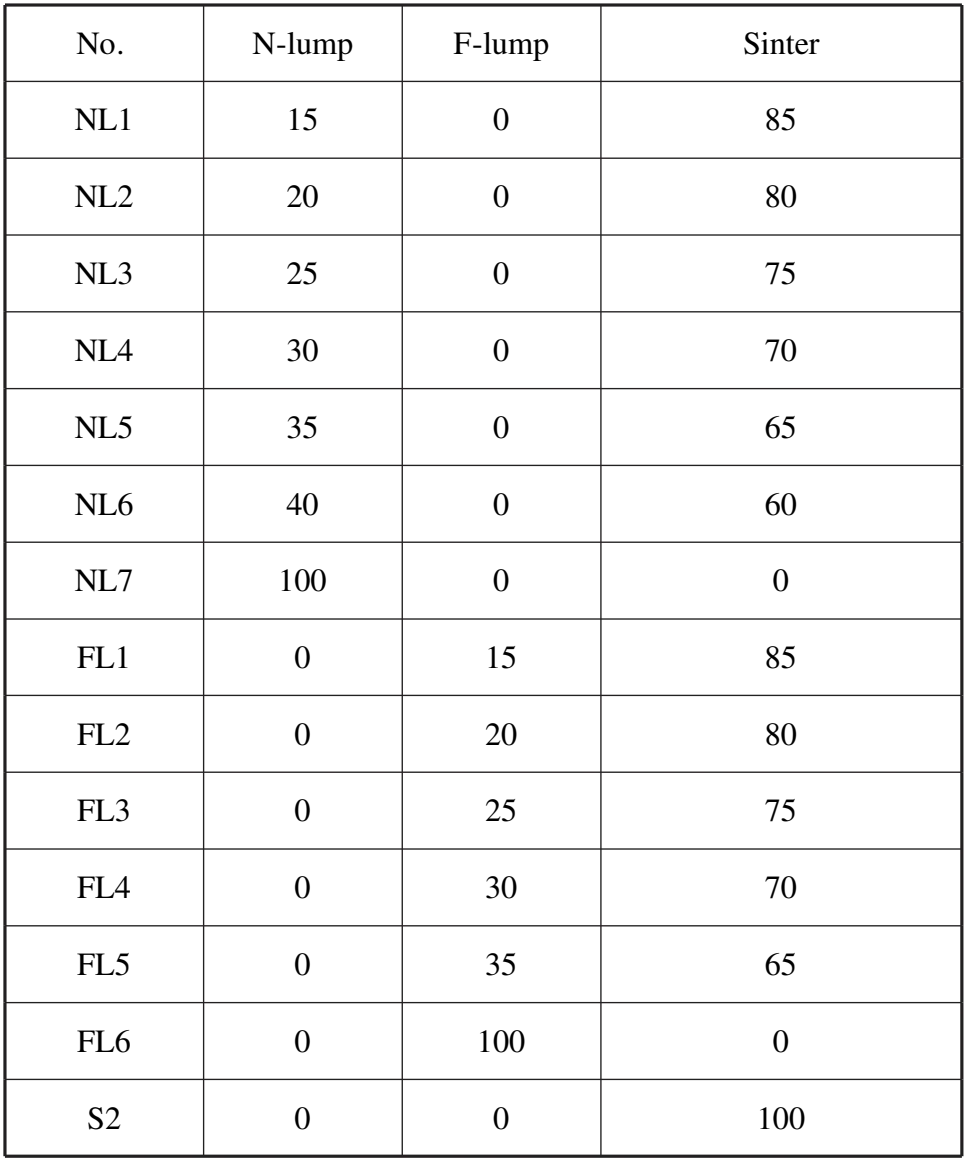

Table 2 Experimental scheme for determining the metal-lurgical properties of lump ores with different proportions Unit:%

3.1 Low-temperature reduction pulverization test results

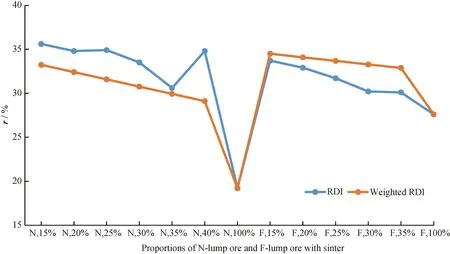

The low-temperature reduction pulverization test was conducted by simulating the upper conditions of the blast furnace,and the result is an important index to evaluate the metallurgical properties of the charge.The equipment used in this pulverization test was a nonstandard test furnace customized by the Jiangyin Nanzha thermal instrument factory,and the test followed the JIS standard.The low-temperature reduction of N-lump ore and F-lump ore under different proportions are compared and the relationship between the low-temperature reduction degradation index (RDI) and weighted RDI is shown in Fig.1.

Fig.1 shows that certain interactive reactions occur even in the low-temperature reduction pul-verization test.After the sinter is mixed with the lump ore,its low-temperature reduction pulveriza-tion rate decreases slightly.Different mixed ores are obtained by mixing two types of lump ores in the same ratio with the sinter.The low-temperature reduction pulverization rate of the mixed ore with F-lump is lower than that of the mixed ore with N-lump,indicating that the low-temperature reduction pulverization resistance of F-lump ore and sinter increases after mixing and will not substantially affect the air permeability of the upper part of the blast furnace under good screening.

Fig.1 RDI and weighted RDI of two kinds of lump ores in different proportions

3.2 Ore reduction test results

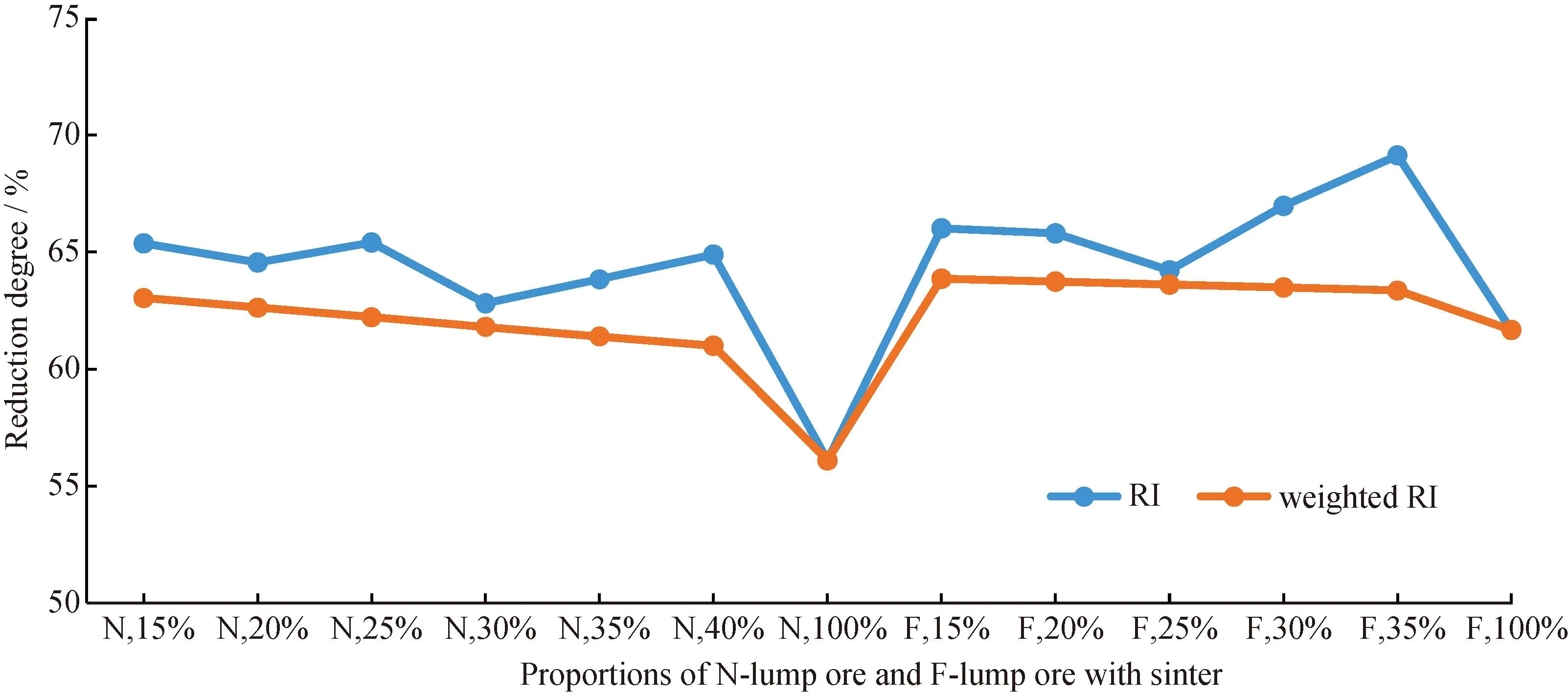

The equipment used in the ore reduction test was consistent with that used in the low-temperature reduction pulverization test;moreover,the ore reduction test followed the JIS standard.Fig.2 shows the reduction rate curves of different charges.As can be seen from Fig.2,F-lump ore has the fastest reduction rate (RI) and the sinter has the slowest RI.

Fig.2 Reduction rate curves of different charges

The reduction degree of the two lump ores mixed with the sinter under different ratios can be calculated based on the data obtained from the test and the reduction rate formula (Fig.3).

The test calculation shows that the reduction rates of the single lump ore was 61.68% for F-lump and 56.10% for N-lump.

Fig.3 shows that the reduction performance of F-lump ore is better than that of N-lump ore.The reason is that the internal porosity of N-lump ore is more developed than that of F-lump ore;moreover,the material with a dense structure has a relatively large resistance to gas diffusion from the outside to the inside,and the difficulty of reduction in the ore center increases,resulting in a decreased reduction rate[4].

Fig.3 Reduction degrees of two kinds of lump ores in different proportions

After N-lump ore is mixed with the sinter,the reduction rate of the mixed ore decreases slightly with an increase in the lump ore proportion.The overall change is small,but it is higher than that of single N-lump ore.After F-lump ore is mixed with the sinter,the reduction rate of the mixed ore first decreases and then increases with an increase in the lump ore proportion,which is higher than that of single F-lump ore.The reduction rate of the mixed ore combined with F-lump ore is higher than that of the mixed ore combined with N-lump ore.This can be attributed to the density and porosity of the ore.Additionally,there may be an interactive reaction between lump ore and sinter after mixing.

3.3 High-temperature performance test results and analysis

The drop test still followed the JIS standard.The parameters determined in the test,such as differential pressure rise temperaturets( i.e.,melting start temperature),drop temperature,and melting interval,are important parameters to evaluate the softening-melting performance of a charge structure.Under the same lump ore ratio,the influence of different types of lump ore ratios on smelting varies considerably.Optimizing the charge ratio is the key to maintaining a high-proportion lump ore smelting[5].

The scientificity and practicability of the identifica-tion index system of this test are as follows:(1)t10is defined as the softening start temperature,while the softening ending temperaturet40is defined as the temperature corresponding to the beginning of air tightness of the sample.At this time,the porosity of the sample is zero,which avoids the randomness of defining the steep rise temperature of differential pressure.(2) The evaluation index system estab-lishes a certain relationship between the test results and the soft melting zone in the blast furnace.If the temperature distribution in the blast furnace is known,the radial width of the soft melting zone of the blast furnace can be simulated based ont40andtd(the start temperature of dripping,i.e.,the end of the test).(3) The permeability of the ore bed in the blast furnace reduces gradually.We use (t40-t10) and (td-ts) to illustrate this situation.Al-though the ore bed softens in the (t40-t10) range,it can still let the air flow through.Moreover,although airflow cannot occur in the (td-ts) range,the latter has a greater impact on blast furnace smelting than the former[6].

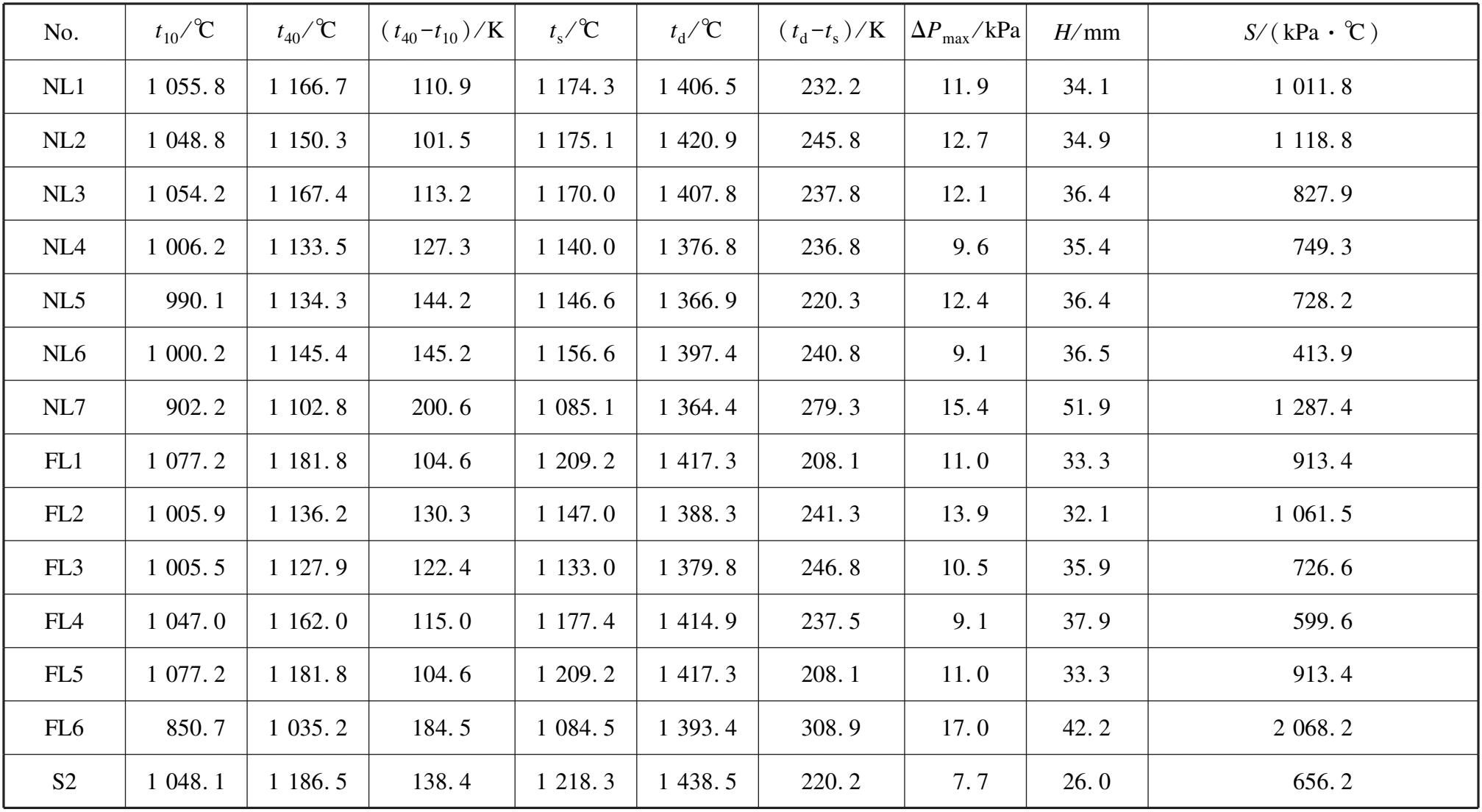

The test results are shown in Table 3,and the soft melting curve of every single ore is shown in Fig.4.

Table 3 Experimental results of single and mixed ores

In most cases,the softening-melting performance of the lump ore is worse than that of the sinter.In terms of droplet properties of three separate ores,the sinter is the best,followed by N-lump,and F-lump is the worst.This is due to the uneven mineral composition in the lump ore,including many low-melting-point and high-melting-point minerals.

After N-lump ore is mixed with the sinter,as the lump ore ratio increases (from 15% to 40%),itst10gradually decreases,(t40-t10) gradually increases,tsgradually decreases,and (td-ts) changes slightly and remains constant at approximately 240 K;when the proportion of N-lump ore is less than 25%,the maxi-mum pressure difference (ΔPmax) changes slightly,approximately 12 kPa;when the proportion of N-lump ore exceeds 25%,the change law is not obvious,which may be because the change in pore sizes of the lump ore particles is small;therefore,the pressure difference is small and stable.Moreover,the thickness of the soft melting layer increases slowly with an increase in the ore ratio,and the characteristic area value (S) decreases.

Fig.4 Melting curves of single ore

Compared with a single type of F-lump ore,the melting drop performance of the mixture of F-lump ore and sinter is obviously improved.When the proportion of F-lump ore is 20%,its melting drop performance is the worst.With an increase in the proportion of the lump ore (from 15% to 25%),the mixed oret10gradually decreases,while (t40-t10) gradually increases,tsgradually decreases,and (td-ts) gradually increases.When mixed with the sinter,the proportion of F-lump should not exceed 15%.When different lump ores with the same pro-portion are mixed with the sinter,the droplet melt-ing properties of the two types of mixed ores are similar.Thet10of the mixed ore of N-lump is higher than that of F-lump.The maximum differential pre-ssure,the thickness of the soft melting layer,and the values of the areaSof the mixed ore of F-lump,are slightly lower than those of N-lump.This may be because of the interaction between F-lump ore and sinter.

4 Conclusions

(1) The total iron content of N-lump ore is higher than that of F-lump ore,and the burning loss and the burst index of N-lump ore are both lower than those of F-lump ore.F-lump ore with a high thermal burst index will increase the amount of furnace dust and deteriorate the operation index of the blast furnace during smelting,which should be monitored during blast furnace proportioning.

(2) The RDI of N-lump ore is lower than that of F-lump ore.The two types of lump ores are mixed with the sinter.The RDI of the mixed ore combined with F-lump ore was lower than that of the mixed ore combined with N-lump ore.The reduction rates were in the order of sinter>F-lump ore>N-lump ore.After the same proportion of F-lump ore and N-lump ore were mixed with the sinter,the reduction rate of the mixed ore combined with F-lump was still higher than that of the mixed ore combined with N-lump.

(3) The droplet melting properties of a single ore are sinter>N-lump ore>F-lump ore.After the same proportion of F-lump and N-lump ores is mixed with the sinter,the droplet melting properties of the two types of mixed ores are similar,and the interaction between F-lump ore and sinter is more obvious after the mixing reaction.t10of the mixed ore of N-lump ore is higher than that of F-lump ore.The maximum differential pressure,soft melt layer thickness,and the characteristic area value of the mixed ore of F-lump and sinter,are slightly lower than those of N-lump.

(4) Based on the ratio test results of lump ore and sinter,when the mixed content of N-lump ore and sinter reaches 25%,the changes in droplet performance are not obvious and the pulverization and reduction performance index change slightly compared with other ratios.However,when the ratio of N-lump ore accounts for 40%,the characteristic area value as the charge permeability index is the smallest.Relatively speaking,the proportioning content of F-lump ore and the sinter should not exceed 15%.

杂志排行

Baosteel Technical Research的其它文章

- List of winners of excellent papers of Baosteel TechnicalResearch in 2023

- Accuracy analysis of iron content of galvanized coating using an X-rayfluorescence spectrometer with an L-spectrum

- Study on gas metal arc welding of two types of TMCP steels

- Effect of quenching and tempering processes on properties and microstructure ofG115 steel

- Research progress on protective coatings against molten nitrate salts for thermal energy storage in concentrating solar power plants

- Failure analysis of the needle valve body of R18CrNi8 steel