Effects of Heat Treatment on Processing Characteristics of Pork

2023-12-12TingBAILiTANGLeiWANGYingZHANGBowenZANWeiWANGLiliJIJiaminZHANG

Ting BAI Li TANG Lei WANG Ying ZHANG Bowen ZAN Wei WANG Lili JI Jiamin ZHANG

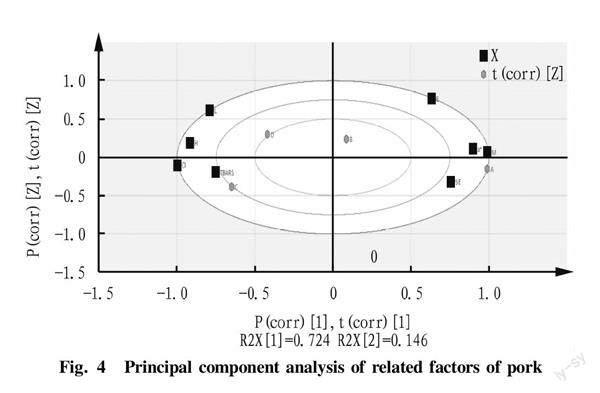

Abstract[Objectives] This study was conducted to explore the effects of heat treatment on processing characteristics of pork. [Methods] The effects of low-temperature long-term cooking (LTLT), high-temperature vacuum cooking, high-temperature cooking and high-temperature steaming on some indexes of pork products were studied, and principal component analysis was carried out. [Results] LTLT had significant effects on the total sensory score, moisture content, cooking loss rate, a* value, shear force, and TBARS of pork, and the corresponding optimal product indicators were 71.40 points, 72.36%, 14.20%, 4.79, 7 089.87 g, and 0.05 mg/kg, respectively. The microstructure changes in the LTLT group were relatively small, as the muscle fiber structure was relatively dense and uniform, and the gaps between muscle fibers were small. A total of 30 volatile flavor compounds were detected in the four groups, mainly alcohols, alkenes, alkanes, lipids, ketones, and aldehydes, and the LTLT group had more types and high contents. PCA analysis showed that the sensory evaluation, moisture content, elasticity, a* value and LTLT were positively correlated with principal component 1. [Conclusions] Various indexes comprehensively showed that the LTLT group had better meat color, flavor, texture characteristics and lower oxidation degree than traditional cooking and steaming methods, which provides a theoretical reference for its large-scale application in the processing of prepared meat products.

Key wordsHeat treatment; Pork; Processing characteristics; Principal component analysis

DOI:10.19759/j.cnki.2164-4993.2023.05.016

Prepared meat products are non-ready-to-eat meat products that are mainly made from poultry and livestock meat through cutting and grinding with seasonings, vegetables and other auxiliary materials and subsequent processing such as tenderizing and heating, and then transported, stored and sold through refrigeration and freezing. Most of them require secondary heating before consumption[1]. The heat treatment processes such as cooking and steaming have a significant impact on the color, flavor, and texture of the products[2]. Traditional cooking will increase cooking loss and water loss, affecting the quality of products such as color and tenderness[3]. Different from traditional methods, low-temperature cooking under vacuum conditions generates overpressure through saturated steam, and meat products will not directly contact with the heating medium, which helps to preserve cell structure, minimize protein-protein interaction and gelation and increase water-holding capacity[4]. Low-temperature vacuum long-time cooking (LTLT) has been used in high-end restaurants, central kitchens, and convenience food industries[5]. Its application in meat products is concentrated below 70 ℃[6], which can prevent the loss of water, nutrients, and volatile substances, and vacuum can suppress oxidation caused by cooking[7]. In recent years, it has been widely used in meat processing to improve the tenderness of meat by affecting protein denaturation and microstructure[9], while simultaneously affecting the cooking loss rate, water holding capacity and color of meat significantly[10].

There are various types of prepared meat products based on pork, and in recent years, the demand has surged. Through modern industrialization of prepared pork products, maintaining their safety and authenticity is an urgent problem to be solved while providing product diversification[11]. LTLT process optimization has been conducted to study the mechanisms of changes in pork color, texture and protein structure[12-13]. However, although LTLT has been applied to product processing as a preparing process, there is relatively little comparative research on the processing characteristics of pork with traditional high-temperature cooking and steaming. Therefore, the LTLT process optimized by response surface methodology was compared with high-temperature vacuum cooking, high-temperature cooking, and high-temperature steaming through analysis on the sensory evaluation, pH, moisture content, cooking loss rate, TBARS, chromatic value, microstructure, texture, shear force and volatile flavor substances of the products, and principal component analysis was conducted to explore the effects of LTLT on the processing characteristics of pork, providing a theoretical reference for the application of LTLT in the heat treatment of pork.

Materials and Methods

Materials and Reagents

Pork ham: provided by Suining Gaojin Food Co., Ltd.; dry chili, dried Sichuan pepper, cooking wine, green onions and ginger: all purchased in Shiling Haolegou Group Supermarket in Chengdu.

Trichloroacetic acid (analytically pure): Chengdu Jinshan Chemical Reagent Co., Ltd; ethylenediaminetetraacetic acid disodium salt (analytically pure): Fuchen (Tianjin) Chemical Reagent Co., Ltd.; 2-thiobarbituric acid (analytically pure): Shanghai Yuanye Bio-Technology Co Ltd.; ethanol, (analytically pure): Chengdu Kelong Chemical Co., Ltd.; 2,4,6-trimethylpyridine (analytically pure): Sigma-Aldrich, USA.

Instruments and equipment

5977A-7890B gas chromatography-mass spectrometer, Agilent Corporation, USA; TA-XT plus texture analyzer, Stable Micro Systems, UK; CR-400 color difference meter, Konica Minolta (China) Investment Co., Ltd; HHS-11-4 electric constant-temperature water bath, Medical Equipment Factory of Shanghai Boxun Industrial Co., Ltd.; SHA-B constant temperature oscillator, Jintan Jinnan Instrument Manufacturing Co., Ltd., Jiangsu Province; T6 new century UV spectrophotometer, Beijing PERSEE General Instrument Co., Ltd.; GY-ZB-6202 vacuum packaging machine, Jiangxi Ganyun Food Machinery Co., Ltd.

Experimental steps

Treatment of raw materials

Fresh pork ham was selected as the raw material, which was cut into pieces of 6 cm×6 cm, approximately 300 g. For each piece, cooking wine 2.67%, dry chili 0.17%, dried Sichuan pepper 1.67%, ginger 3.33% and scallions 3.33% were added to marinate for 30 min for later use.

Heat treatment

Group A was the low-temperature vacuum long-term cooking (LTLT) group. The processed meat cubes were put into high-temperature steaming bags, and the vacuum degree of the vacuum packaging machine used was adjusted to 0.09 MPa for vacuum packaging. Next, the temperature of the constant-temperature water bath was adjusted to 67 ℃, and the packaged meat pieces were added when the water temperature reached 67 ℃. The water level was 1 cm higher than the meat, and timing was started to heat for 4 h.

Group B was the high-temperature vacuum cooking group. The processed meat pieces were added into high-temperature steaming bags, and a vacuum packaging machine was used for vacuum packaging. Next, the bags were added into a cooling pot, and the water level was 1 cm higher than the meat. Timing was started when the water was boiled, and heating was lasted for 30 min.

Group C was the high-temperature cooking group. The processed meat pieces were added into a boiling pot with a water level 1 cm above the meat pieces. After the water was boiled, timing was started to heat for 30 min.

Group D was the high-temperature steaming group. The processed meat pieces were evenly placed on a steamer, and after the lower layer of water was boiled, timing was started to heat for 30 min.

Indicator determination

Sensory evaluation

The sensory evaluation standards of heat treatment on pork are shown in Table 1.

Determination of pH

A plug-in pH meter was used to directly measure the pH value in the middle of the sample meat. Each sample was measured in parallel for 3 times.

Determination of moisture content

The moisture content was determined according to the national food safety standard GB 5009.3-2016. The samples in each group were measured in parallel for 3 times.

Determination of cooking loss rate

The cooking loss rate was determined referring to Hu et al.[14] with some modifications. The surface moisture of the meat was dried before cooking, and each meat sample was accurately weighed. After cooking, the meat was naturally cooled, and the surface moisture of each meat sample was dried to accurately weigh it. The yield of each meat sample was calculated according to formula (1):

Cooking loss rate (%)=(M1-M2)/M1×100(1)

Wherein M1 is the mass (g) of the meat sample before cooking, and M2 is the mass (g) of the meat sample after cooking.

Determination of TBARS

According to the national food safety standard GB 5009.181-2016, the samples in each group were determined in parallel for 3 times.

Determination of chroma

The brightness value L*, red value a* and chartreuse value b* of lean meat in meat samples were determined by a color difference meter. Each meat sample was measured in parallel for 3 times, and the results were averaged.

Observation of microstructure

After tissue sampling, the tissue was washed twice with ultrapure water for 5 min each time, and dehydrated with a series of gradient ethanol at 30%, 50%, 70%, 80%, 90%, 95%, and 100% for 10 min per gradient. The sample was gently stuck onto conductive adhesive, and jet-plated by ion sputtering. Finally, it was observed under a microscope at a suitable position with an appropriate magnification.

Determination of texture

Referring to the method of Yang et al.[15] with slight modifications, a texture analyzer was used for determination. A processed lean meat portion was made into meat samples of 1 cm×1 cm×1 cm, which were placed vertically along the muscle texture, so that the direction of the muscle fibers was parallel to the downward pressing direction of the probe. The measurement conditions were as follows: a flat-bottomed cylindrical probe (probe model P/36R) with a speed of 2.00 mm/s before testing, a speed of 2.00 mm/s during testing and a speed of 5.00 mm/s after testing, deformation of 70%, a triggering force of 5 g, a return rate of 500 pps, and a testing environment of room temperature. Each group of samples was tested 3 times in parallel.

Determination of shear force

The determination referred to the method of sun et al.[16] with some modifications. The processed lean meat portion of each meat sample was made into samples of 1 cm×1 cm×3 cm, which were then measured using a texture analyzer. The measurement conditions were as follows: a probe (probe model HDP/PS) with a speed of 2.00 mm/s before testing, a speed of 2.00 mm/s during testing and a speed of 10.00 mm/s after testing, a displacement of 10.00 mm, a triggering force of 5 g, a return rate of 500 pps, and a testing environment of room temperature. Each group of samples was tested 3 times in parallel.

Determination of volatile flavor compounds

The determination referred to the method of Meng et al.[17] with slight modifications.

Data processing

SPSS 22.0 software was used for data processing and significance analysis, with P<0.05 standing for a significant difference. Tables and images were created using Origin 2021.

Results and Analysis

Effects of heat treatment on sensory evaluation and chroma

As shown in Fig. 1, Table 2 and Table 3, the color, smell, tissue status, overall acceptability and total sensory score of group A were significantly highest under the four groups of conditions (P<0.05), with values of 18.27,17.63, 17.70, 17.80, and 71.40, respectively. The L* value of group A was significantly lower than those of groups B and D (P<0.05), and the a* value was significantly higher than other groups (P<0.05), while the b* value had no significant differences between the four groups (P>0.05). The nutrients present in meat can affect its aromatic properties, and without sensory analysis, it is difficult to evaluate the impact of detected volatile compounds on meat palatability. A study involving limited flavor descriptors (meat flavor, bloody flavor, metallic flavor, and acidic flavor) showed that even though LTLT treatment (53 and 58 ℃, 6-30 h) enhanced the meat flavor sensation of pork and beef, the impact on tenderness and juiciness was more important for the overall acceptability of such meats[5].

Studies have shown that LTLT can improve tenderness and juiciness and thus meat palatability, and juiciness and moisture content reflect consumers perception of meat tenderness, and juicy and moist samples are often rated as more tender[18]. Color directly affects consumers appetite and is also an important indicator for evaluating meat grade[19]. Low temperature causes browning or low degree of caramelization on the surface of meat, resulting in a relatively pink color kept in meat, which lead to the highest a* value. However, consumers have a lower acceptability of pink meat, mainly because pink meat usually indicates blood or undercooked meat. In traditional cooking, the occurrence of the Maillard reaction results in a deeper yellow color of meat, but if the yellow color is too deep, the tenderness of meat will decrease. Therefore, there is a paradoxical relationship between the pink color of meat cooked under low temperature and vacuum for a long time and its tenderness[20].

Ting BAI et al. Effects of Heat Treatment on Processing Characteristics of Pork

Effects of heat treatment on pH value, moisture content, cooking loss rate and TBARS

As shown in Table 4, LTLT showed significant differences in moisture content, cooking loss rate, and TBARS of pork compared with other three groups (P<0.05), while the pH value only showed a significant difference compared with the steaming group (P<0.05). The water content in the LTLT group was significantly highest at 72.36%, and the cooking loss rate and TBARS value were significantly lowest (P<0.05), at 14.20% and 0.05 mg/kg, respectively. The pH value is related to the solubility of muscle protein, and appropriate pH is conducive to the formation of elastic gel and high water holding capacity[21]. The water content in meat products is an important quality indicator that affects the nutritional hygiene of meat during processing and storage[22]. Low-temperature conditions adopted by LTLT can inhibit water loss[23], making the products have a high moisture content.

The cooking loss rate is related to the juiciness and yield of final products. Reducing cooking loss is beneficial for large-scale processing, and it is an advantage of LTLT compared with other cooking methods that use higher temperatures. Research has shown that LTLT can lead to high cooking loss and low water content in the longissimus dorsi and masseter muscles of pigs[13], which contradicts the conclusion of high moisture content and low cooking loss in this study. High temperatures cause an increase in juice loss, including the reduction of water, and the dissolution of nutrients such as fat and small molecule proteins. After being heated, the protein denatures to form gel, which improves the water holding capacity, while a too-high temperature leads to a decrease in the water holding capacity[24]. These factors lead to a decrease in the quality of meat and affect the cooking loss rate. The low endpoint temperature of LTLT, the uniform heating and the slow average heat penetration rate provided by a constant temperature water bath, as well as vacuum packaging, can all reduce the cooking loss rate[6]. TBARS reflects the degree of lipid oxidation[25], which is positively correlated with the temperature[26]. However, LTLT adopted a low temperature for heating, and the degree of oxidation is also the lowest, which is beneficial for maintaining product quality.

Effects of heat treatment on texture and microstructure

From Table 5, it can be seen that the elasticity and shear force of the LTLT group were significantly highest and lowest (P<0.05), with values of 0.62 and 7 089.87 g, respectively, while there were no significant differences (P>0.05) in chewiness and resilience between the four groups. The structure of muscle tissue is an important internal factor that affects meat quality, and connective tissue, muscle fiber diameter, density, area ratio and sarcomere length all affect muscle quality[27]. Usually, the finer the muscle fibers, the tender the meat quality. In Fig. 4, the four groups of pork showed stretched and expanded muscle fibers, larger gaps, broken endomysium, and liquefied connective tissue and soluble collagen, and the muscle fibers contracted and were separated from the endomysium and perimysium. The pork of group A had the thinnest muscle fibers, a denser and more uniform structure, and the largest gap between muscle fibers. Groups B, C and D showed varying degrees of muscle fiber swelling, and group C among them exhibited a muscle fiber structure most severely damaged, with the most dissolved substances, which was consistent with the highest cooking loss rate in group C (Table 3). The heating temperatures of the four groups of pork were all above 60 ℃, and in the later stage, the main longitudinal contraction of muscle structure occurred[28]. The higher the temperature, the more intense the contraction, and the higher the cooking loss rate.

When meat is cooked at low temperatures (i.e. 55-75 ℃), its texture is influenced by the balance between "toughening" caused by myofibrillar protein denaturation (shorter heating time) and "tenderness" caused by connective tissue protein and collagen gelatinization (longer heating time). Elasticity is related to the changes in water holding capacity and solubility of proteins in muscles caused by thermal denaturation[29]. Shear force is a direct reflection of meat tenderness and a major evaluation indicator of meat texture. When heated, muscle fibers contract, while sarcoplasmic proteins expand and gather to form gel. These denatured gel and other particulate substances fill the gaps, resulting in muscle tightness[30] and increased shear force. Meanwhile, LTLT can increase the activity of proteolytic enzymes in meat, release free amino acids, improve tenderness, and lower shear force values[31]. Therefore, the shear force in group A was significantly lower than that in groups B, C and D, indicating good elasticity. The pork in group C was directly in contact with water, and showed a high heat transfer rate, the lowest elasticity, and high shear force, so the texture was the worst among the four groups. The elasticity, chewiness, recovery and shear force were not significantly different between groups B and D, indicating that the two heat treatment processes had the same impact on the texture of pork. Therefore, under the condition of low-temperature vacuum long-term cooking in group A, pork had good texture characteristics such as elasticity and tenderness.

Effect of heat treatment on volatile flavor substances

Table 6 shows the volatile flavor components and their absolute contents in the four groups of pork. A total of 44 volatile flavor compounds were detected, mainly aldehydes, alcohols, lipids, olefins, alkanes, ketones, and others. Different heat treatment processes had a significant impact on the volatile flavor compounds of pork. As the heating temperature increases, the presence of most volatile compounds (especially linear aldehydes) from lipid oxidation decreases (such as hexanal), and the level of volatile compounds from amino acid and/or thiamine degradation increases (such as nonanal)[32], which is also the main reason why the number and content of aldehydes in group A were higher than those in other three groups. Extending heating time is also crucial for flavor formation, but the products fail to produce the taste of cooked meat at high temperatures due to the absence of Maillard reaction at lower temperatures. Most volatile aromatic compounds that contribute to the palatability of cooked meat are formed at temperatures above 70 ℃. Therefore, in low-temperature cooking, there will be no pleasant cooking flavor[33].

The changes in flavor components of different types are shown in Fig. 3. Aldehydes mainly come from the oxidation hydrolysis of fats and the Maillard reaction of sugars, with a lower threshold and a greater contribution to the final flavor of products. Aldehydes also have a strong flavor effect that overlaps with other substances[34]. Hexanal has a grassy aroma, while nonanal has a light aroma. The LTLT group had a higher content of hexanal, which played an important role in the formation of its pork flavor[35]. The proportion of alcohols was the highest, and the alcohols in the four groups ranked as D>A>B>C. Alcohols mainly come from the automatic oxidation of fat, with a high threshold and a small contribution to the overall flavor, but play an important role in the formation of meat flavor[36]. 1-Octene-3-ol is an important characteristic flavor of cooked pork. It is an oxidation product of linolenic acid or other polyunsaturated fatty acids and has a mushroom aroma[37]. There was no significant difference between groups A and C, as well as between groups B and D, but the former two were significantly higher than the latter two. Esters are mainly products of the reaction between ethanol in spices and cooking wine and free fatty acids in meat[38], which have certain contribution to the formation of flavor. Ketones are also products formed by fat oxidation, with fewer types and lower content than aldehydes, but they have an enhancing effect on the flavor of meat. There were three types of ketone substances detected, and the LTLT group showed a higher content. It is reported that ketone substances often have a faint scent[39], which plays a regulatory role in the formation of pork flavor. Although the content of volatile flavor compounds such as alkanes is high, their threshold is high and their contribution to the flavor of meat aroma is small[40].

Principal component analysis

To further analyze the relationship between LTLT and product characteristic indicators, principal component analysis (PCA) was conducted on various indicators, including sensory evaluation (SE), cooking loss rate (CL), moisture content (M), TBARS, elasticity (E), shear force (H), and color (L*). As shown in Fig.43, a total of 2 principal components were extracted, including principal component 1 (72.40%) and principal component 2 (14.60%), with a cumulative contribution rate of 87.00%. In specific, sensory evaluation, moisture content, elasticity, a* value and group A were positively correlated with principal component 1, while shear force, cooking loss rate and L* value were positively correlated with principal component 2. The LTLT group was located in the first quadrant and had a high value, indicating that LTLT had a significant impact on the quality of pork and could significantly improve pork quality.

Conclusions

With pork as the object of study, the effects of heat treatment on the processing characteristics of pork were studied. The results showed that the sensory evaluation, cooking loss rate, moisture content, and TBARS value of pork in the LTLT group were significantly better than those in other three groups, with values of 71.40 points, 14.20%, 72.36%, and 0.05 mg/kg, respectively. There were no significant differences in pH value between the four groups. For the LTLT group, the a* value was significantly higher than other three groups, and its microstructure changes were relatively small, as the muscle fiber structure was relatively dense and uniform, and the gaps between muscle fibers were small. The volatile flavor compounds detected in the four groups were mainly alcohols, olefins, alkanes, lipids, ketones, and aldehydes, among which aldehydes, alcohols and lipids that play an important role in flavor showed higher contents and types in the LTLT group. PCA analysis showed that the sensory evaluation, moisture content, elasticity, a* value and group LTLT were positively correlated with principal component 1, while shear force, cooking loss rate and L* value were positively correlated with principal component 2. Therefore, pork cooked under low temperature and vacuum for a long time is tender in meat quality and low in the degree of oxidation, and thus has better safety and edible value. The research results can provide a reference basis for the selection of cooking methods and deep processing of prepared pork products.

Compared with traditional high-temperature steaming and high-temperature cooking processes, low-temperature long-term vacuum cooking has multiple advantages. Its ability to achieve heat balance with heating media can ensure uniform edible quality, reduce the risk of overcooking, and better control the maturity of products. Most importantly, when used in an appropriate combination of time and temperature, it is possible to obtain tender meat regardless of the characteristics of the raw meat (species, muscle type, or animal age). There is evidence suggesting that the tenderization observed under LTLT cooking is the result of a complex interaction between heat-induced protein denaturation and connective tissue protein hydrolysis (possibly muscle fiber structure), and the changes in protein structure caused by heat induction are related to the adsorption mechanism of flavor substances. Therefore, the mechanism by which LTLT cooking has better meat color, texture and flavor is not fully understood, and further in-depth research is needed.

References

[1] Institute of Food Science and Technology CAAS, Henan Doyoo Industrial Co., Ltd., Luohe Entry-Exit Inspection and Quarantine Bureau of the Peoples Republic of China[Z]. Industry Standards-Agriculture. 2011: 6P.; A4. (in Chinese).

[2] ELISA DOMINGUEZ-HERNANDEZ, ALVIJA SALASEVICIENE, PER ERTBJERG. Low-temperature long-time cooking of meat: Eating quality and underlying mechanisms[J]. Meat science, 2018(43): 104-113.

[3] WANG JF, HUANG F, SHEN QS, et al. The influence of low-temperature and long-time cooking on the quality of pork products[J]. Scientia Agricultura Sinica, 2021, 54(3): 643-652. (in Chinese).

[4] KWANG WOO JOUNG1, TAEWAN KIM1, JUNG-WOOK PARK. Decoupled frequency and voltage control for stand-alone microgrid with high renewable penetration[J]. IEEE Transactions on Industry Applications, 2019, 55(1): 122-133.

[5] ELISA DOMINGUEZ-HERNANDEZA, ALVIJA SALASEVICIENEB, PER ERTBJERG. Low-temperature long-time cooking of meat: Eating quality and underlying mechanisms[J]. Meat Science, 2018(143): 104-113.

[6] SANDRA ZAVADLAV, MARIJANA BLAnIC, FRANCO VAN DE VELDE, et al. Sous-Vide as a technique for preparing healthy and high-quality vegetable and seafood products[J]. Foods, 2020(9): 1537.

[7] DEEPIKA KATHURIA, ANJU K DHIMAN, SUREKHA ATTRI. Sous vide, a culinary technique for improving quality of food products: A review[J] Trends in Food Science & Technology, 2022(119): 57-68.

[8] FENG MC, KAUR L, ASTRUC T, et al. Shockwave processing of beef brisket in conjunction with sous vide cooking: Effects on protein structural characteristics and muscle microstructure[J]. Food Chemistry, 2020(343): 128500.

[9] ISMAIL I, HWANG Y H, BAKHSH A, et al. The alternative approach of low temperature-long time cooking on bovine semitendinosus meat quality[J]. Asian-Australasian Journal of Animal Sciences, 2019, 32(2): 282-289.

[10] WANG K, LIN X, ZHAO W, et al. Low-temperature steaming improves eating quality of whitefish [J]. Journal of Texture Studies, 2020, 51(5): 830-840.

[11] CHEN LH. Characteristics of changes in Chinas pork industry in the past decade[J]. Swine Industry Outlook, 2021(1): 15-17. (in Chinese).

[12] CHRISTENSEN LA, GUNVIG AB, ThRNGREN MAB, et al. Sensory characteristics of meat cooked for prolonged times at low temperature[J]. Meat Science, 20190(2): 485-489.

[13] BECKER A, BOULAABA A, PINGEN S, et al. Low temperature cooking of pork meat-Physicochemical and sensory aspects[J]. Meat Science, 2016(118): 82-88.

[14] HU XY, LI HJ, LI SB, et al. A comparative study of the optimization of processing technology of conditioning pine board meat by response surface methodology and BP neural network-particle swarm optimization[J]. Food and Fermentation Industries, 2019, 45(24): 9. (in Chinese).

[15] YANG Y, WANG W, WU Z, et al. O/W Pickering emulsions stabilized by Flammulina velutipes polysaccharide nanoparticles as a fat substitute: The effects of phase separation on emulsified sausages techno-functional and sensory quality[J]. Journal of the Science of Food and Agriculture, 2020, 100(1): 268-276.

[16] SUN HX, HUANG F, DING ZJ, et al. Changes in tenderness and water-holding capacity and underlying mechanism during beef stewing[J]. Food Science, 2018, 39(1): 7. (in Chinese).

[17] MENG WY, GU J, XU QQ, et al. Analysis of volatile flavor compounds in pork meat from different carcass locations and breeds by gas chromatography-ion mobility spectrometry[J]. Food Science, 2021, 42(24): 7. (in Chinese).

[18] KUMI SAITO, MANAMI YOSHINARI & SHIN-ICHI ISHIKAWA. Effects of low-temperature long-time sous-vide cooking on the physicochemical and sensory characteristics of beef and pork shank[J]. Journal of Culinary Science & Technology, 20220(2): 165-179.

[19] HUGHES JM, OISETH SK, PURSLOW PP, et al. A structural approach to understanding the interactions between color, water-holding capacity and tenderness[J]. Meat Science, 2014, 98(3): 520-32.

[20] KIEFFER KJ, CLAUS JR. Inhibition of pink color development in cooked, uncured ground turkey by the addition of citric acid[J]. Journal of Muscle Foods, 2000, 11(3): 235-243.

[21] ZHANG J, HE H, XIONG ZB. Effect of cooking methods on the quality and nutritive contents of pork[J]. Food and Machinery, 2018, 34(6): 21-25, 9. (in Chinese).

[22] LI H. Research on optimization of processing technology for conditioned pork products[D]. Luoyang: Henan University of Science and Technology, 2020. (in Chinese).

[23] ZIELBAUER B I, FRANZ J, VIEZENS B, et al. Physical aspects of meat cooking: Time dependent thermal protein denaturation and water loss[J]. Food Biophysics, 2016, 11(1): 34-42.

[24] ISMAIL I, HWANG YH, JOO ST. Effect of different temperature and time combinations on quality characteristics of sous-vide cooked goat gluteus medius and biceps femoris[J]. Food and Bioprocess Technology, 2019.

[25] XU XP. Study on the effect of different processing methods on lipids in pork[D]. Nanchang: Nanchang University. (in Chinese).

[26] KONG JH, WEN LM, ZHU YZ, et al. Effects of different processing methods on the quality of cooked Procambarus clarkii during refrigerated storage[J]. Science and Technology of Food Industry, 20243(17): 371-80. (in Chinese).

[27] QIN Z, KANG XT, LI GX. Relationship between histology characteristics of muscle fiber and meat quality[J]. Journal of Anhui Agricultural Sciences, 2006(22): 5872-5873, 5878. (in Chinese).

[28] LEPETIT J. A theoretical approach of the relationships between collagen content, collagen cross-links and meat tenderness[J]. Meat Science, 2007, 76(1): 147-159

[29] KO S, YOO SH, LEE S, et al. Effect of long low temperature-short high temperature cooking cycle on physicochemical properties of beef[J]. Food Science and Technology Research, 2011, 17(1): 11-6.

[30] ROLDBN M, ANTEQUERA T, MARTPN A, et.al. Effect of different temperature–time combinations on physicochemical, microbiological, textural and structural features of sous-vide cooked lamb loins [J]. Meat Science, 2013, 93(3): 572-578.

[31] CLAUSEN M P, CHRISTENSEN M, DJURHUUS T H, et al. The quest for umami: Can sous vide contribute?[J]. International Journal of Gastronomy & Food Science, 2018: S1878450X17300641.

[32] DEL PULGAR JS, ROLDAN M, RUIZ-CARRASCAL J. Volatile compounds profile of sous-vide cooked pork cheeks as affected by cooking conditions (vacuum packaging, temperature and time)[J]. Molecules, 2013, 18(10): 12538-12547.

[34] MARGIT D AASLYNG, LENE MEINERT. Meat flavour in pork and beef-from animal to meal[J]. Meat Science, 2017(132): 112-117.

[35] LIU JL, SUN XY, ZHANG XR, et al. Analysis of flavor components of fermented mutton jerky by GC-MS combined with electronic nose/electronic tongue[J]. Journal of Chinese Institute of Food Science and Technology, 2021. (in Chinese).

[36] ZHOU YJ, LI B, MA QS, et al. Effect of cooking methods on the eating quality and flavor compounds of spiced pork trotter[J]. 20243(13): 15-22. (in Chinese).

[37] LIN YS, CEN YY. Investigation into pork meat flavor[J]. Science and Technology of Food Industry, 2006(9): 194-197. (in Chinese).

[38] PEREA-SANZ L, MONTERO R, BELLOCH C, et al. Microbial changes and aroma profile of nitrate reduced dry sausages during vacuum storage[J]. Meat science, 2019, 147(1): 100-107.

[39] JIN G, ZHANG J, XIANG Y, et al. Lipolysis and lipid oxidation in bacon during curing and drying-ripening [J]. Food Chemistry, 2010, 123(2): 465-471.

[40] YANG Y, ZHANG X, WANG Y, et al. Study on the volatile compounds generated from lipid oxidation of Chinese bacon (unsmoked) during processing: Aroma generated from lipid oxidation in bacon (unsmoked)[J]. European Journal of Lipid Science and Technology, 2017, 119(10): 1600512(1-10).

[41] JOSEPHSON DB, LINDSAY RC, STUIBER DA. Enzymic hydroperoxide initiated effects in fresh fish[J]. Journal of Food Science, 2010, 52(3): 596-600.

Editor: Yingzhi GUANGProofreader: Xinxiu ZHU

Received: June 2023Accepted: August 5, 2023

Supported by Natural Science Foundation of Sichuan Province (2022NSFSC1644); Science and Technology Achievement Transfer and Transformation Demonstration Project of Sichuan Province (2022ZHCG0063); Sichuan Pig Innovation Team of the National Modern Agricultural Industry Technology System (scsztd-2023-08-07).

Ting BAI (1989-), female, P. R. China, assistant researcher, devoted to research about meat processing and quality control.

*Corresponding author.

杂志排行

农业生物技术(英文版)的其它文章

- Simultaneous Determination of 14 β-Receptor Agonists Residues in Mutton by High Performance Liquid Chromatography-Tandem Mass Spectrometry (HPLC-MS/MS)

- Application of Mass Spectrometry (MS)-coupled Techniques in Pesticide Residue Detection

- Optimization of Extraction Process of Polyphenols from Chrysanthemum morifolium and the Development of Chrysanthemum Rice Wine

- Discussion on Construction and Mechanism of Practice Bases for Professional Degree Postgraduates Based on the Integration of Production and Education in Local Universities

- Research on Identification Method of Apple Diseases in Southern Xinjiang Based on Deep Learning and Its System Implementation

- Research Progress on Mechanism of Ovulation Disorder in Polycystic Ovary Syndrome