Ballistic penetration damages of hybrid plain-woven laminates with carbon,Kevlar and UHMWPE fibers in different stacking sequences

2023-09-02ZhiyongLiYousongXueBaozhongSunBohongGu

Zhi-yong Li,You-song Xue,Bao-zhong Sun,Bo-hong Gu

Shanghai Frontier Science Research Center for Modern Textiles,College of Textiles,Donghua University,Shanghai,201620,China

Keywords:Hybrid laminates Ballistic impact damages Energy absorption Finite element analysis (FEA)

ABSTRACT Hybrid composite materials combine different fibers in preform and take advantages of different mechanical behaviors for improving ballistic impact damage tolerances.Here we report ballistic impact damages of plain-woven laminates with different hybrids and stacking sequences.Three kinds of hybrid laminates,i.e.,carbon/Kevlar,carbon/ultra-high molecular weight polyethylene (UHMWPE),and UHMWPE/Kevlar,had been prepared and tested in ballistic penetration with fragment simulating projectiles(FSP).The residual velocities of the projectiles and impact damage morphologies of the laminates have been obtained to show impact energy absorptions for the different hybrid schemes.A microstructural model of the hybrid laminates had also been established to show impact damage mechanisms with finite element analysis (FEA).We found that the UHMWPE/Kevlar hybrid laminates with Kevlar layers as the front face have the highest energy absorption capacity,followed by the carbon/Kevlar hybrid laminates with carbon layers as the front face.The main damage modes are fiber breakages,matrix crack and interlayer delamination.The ballistic damage evolutions from the FEA results show that the major damage is shear failure for front layers,while tension failure for the back layers.We expect that the ballistic impact performance could be improved from the different hybrid schemes.

1.Introduction

Fiber hybridization has been regarded as improving ballistic performance without increasing weight of fiber reinforced composites [1,2],for example,interlayer hybrid laminates [3,4].The hybrid laminates consist of different fiber layers to obtain different impact energy absorptions during ballistic penetration.Carbon,Kevlar and ultra-high molecular weight polyethylene (UHMWPE)fibers are often used for preparing hybrid laminates to satisfy ballistic protection requirements [5,6].Carbon fibers have high modulus and could limit impact deformation.Kevlar fibers are traditional bullet-proof materials.UHMWPE fibers have high modulus/density ratio.The hybrid laminates with the three fibers would have high impact energy absorption and low impact deformation with an optimized layer combination.

Several investigations have already shown the hybrid effect on ballistic impact performance.Bandaru et al.[7]studied the ballistic performance of hybrid composite armors made of carbon,Kevlar and glass fibers and proposed an optimal hybrid principle for ballistic composites,while the UHMWPE fibers were not involved.Mousavi et al.[8]reported an artificial neural network-based algorithm to optimize the energy absorption capability of the hybrid laminates reinforced with carbon,Kevlar and glass fibers.They found that the ballistic performance is sensitive to the fiber combinations and laminate stacking sequence.The optimum hybrid can lead to a considerable improvement in ballistic penetration energy absorption.Pandya et al.[9]investigated hybrid laminates made of carbon and E-glass fabric with epoxy matrix,the E-glass layers in the exterior and carbon layers in the interior have a higher ballistic limit.Bao et al.[10]presented hybrid effects on ballistic properties of hybrid carbon/aramid woven laminates and found that the addition of carbon layer enhanced the resistance penetration force of the laminates under impact.Zulkifli et al.[11]conducted ballistic test for UHMWPE/carbon hybrid composites to present the ballistic penetration behaviors.The low amounts of carbon fiber/epoxy composite layers in the UHMWPE-based hard ballistic panels led to significant improvement in ballistic performance.Sapozhnikov et al.[12]have studied of hybrid laminates for improved ballistic performance using different combinations of Aramid and Dyneema fibers.They found that hybrid composites made of aramid fabrics with thermoplastic matrix placed on the strike face of UHMWPE recognized as good alternative to improve ballistic performance.Yang et al.[13]concluded that the material of the front sensitive region for UHMWPE hybrid composites had a significant influence on ballistic impact behavior including transverse deflection,failure modes and energy absorption.Cunniff et al.[14]found that when Kevlar fabric layers were placed on the striking face before UHMWPE laminates,ballistic limit(V50)exhibited an increase than the hybrid composites with reversed sequence.Kedzierski et al.[15]studied the perforation and trauma resistance of hybrid composites reinforced with UHMWPE and aramid and found that arrangement of UHMWPE on the striking face shows a negligible influence on ballistic performance.Yang et al.[16]found that the basalt fiber/UHMWPE fiber reinforced epoxy composites can provide an improved ballistic performance when basalt layer is placed at the front of the composites.Muhi et al.[17]studied the ballistic impact behavior of E-glass fiber reinforced composite hybridized with a layer of Kevlar fiber and concluded that hybridization improves the laminates performance under penetration.The abovementioned results present the influence of hybridization on ballistic performance of the hybrid composites;however,there is a lack of comparison among different hybrid schemes and ballistic penetration damage mechanisms.Furthermore,the ballistic penetration damages of hybrid laminates with carbon,Kevlar and UHMWPE fibers are still unavailable.

Here we report ballistic impact behaviors of the hybrid laminates with carbon,Kevlar and UHMWPE fibers.The ballistic impact damages and energy absorptions will be compared to show the hybrid advantages.The ballistic impact behaviors will be presented both from the tests and finite element analysis (FEA) results.The optimized hybrid scheme will also be proposed.

2.Materials and tests

2.1.Specimen preparation

The hybrid laminates had been prepared with carbon,Kevlar and UHMWPE fibers plain-woven fabrics and epoxy resin.Vacuumassisted resin transfer molding (VARTM) technique shown in Fig.1(a) was used for the hybrid laminate consolidation.Carbon fiber composites are seldom used for ballistic impact protection because of brittle behaviors of carbon fibers.While the addition of thin carbon composite layers at the front and back of the hybrid laminates would have different ballistic performances.Kevlar and UHMWPE fabrics are the most common flexible materials used for ballistic protection.Hybrid laminates with the Kevlar and UHMWPE fabrics could be a potential solution to improve the ballistic performance.In order to understand the part of the hybridization effect,six kinds of hybrid laminates,named as C7K20,K20C7,C7PE11,PE11C7,PE5K18and K18PE5,have been prepared as listed in Table 1 and shown in Fig.1(b).The subscript number is the layer number,for example,C7K20represents a hybrid laminate with 7 layers of carbon fabrics at the front surface and 20 layers of Kevlar fabrics at back surface.Table 2 lists the fabric specifications.The weight ratio of resin/hardener was 10:3,and the curing procedure was in an oven for 3 h at 50°C then naturally cooled down to room temperature.Test specimens were cut into 350×350 mm2square pieces.

Table 1Description of hybrid laminates preparation.

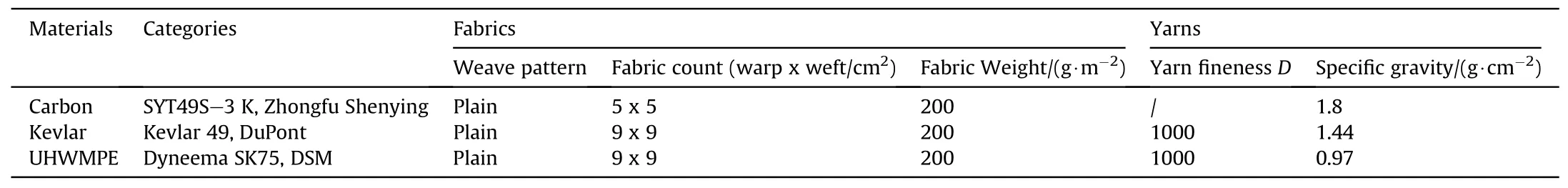

Table 2The specifications of fabrics and yarns.

Fig.1.Specimen preparations: (a) Sketch of the fabrication procedure;(b) Hybrid structures of C7K20,C7PE11 and PE5K18.

2.2.Ballistic tests

The ballistic impact tests were carried out using an automatic projectile system,as shown in Fig.2.A projectile of 1.1 g fragment simulating projectile (FSP) was used according to China Military Standard GJB 5115A-2012 in the test.The size and photograph of the FSP are shown in Fig.2(a).The laminates were fixed in a square frame with a size of 300 x 300 mm2as shown in Fig.2(b).The tests of the laminates were full perforation under striking velocities of the projectiles ranging from 410 m/s to 640 m/s.In the test,the laminate target was placed 5000 mm from the tip of gun nozzle.The time detectors were used to measure the strike velocities and residual velocities of the projectile as shown in Fig.2(c).

The estimated ballistic limit (EV50),which is the estimated striking velocities at which the projectile has 50% possibility to perforate the target,was calculated by Ref.[18].

whereVsandVrare the striking velocities and residual velocities are obtained from the ballistic test.The total energy absorption[19]was calculated by

whereEais the total energy absorption,mFis the FSP mass.The ballistic performance indicator (Ead) was calculated from Ref.[20].

whereADis the area density of the composite panel.

3.Numerical simulation

Commercially available finite element code LS-DYNA R11 is used to simulate ballistic penetration of fragment simulating projectile(FSP) into hybrid laminate target.

3.1.Geometrical model

Geometrical model of the hybrid laminate was established by design software CATIA.Considering the symmetry,one-quarter geometrical model with a size of 150 × 150 mm2was adopted,as shown in Fig.3(a).The geometrical model consists two parts:microstructural model and continuum model.The microstructural model was based on the actual structures of the hybrid composites,and the size was a square of 30×30 mm2.The weft and warp yarns and the epoxy matrix were modeled respectively,and the crosssection of yarns was lenticular (Fig.3(b)).The continuum model was modeled as a stack of individual layers,each layer was modeled as a homogenous orthotropic plate.The thickness of the individual layers model for the carbon,Kevlar and UHMWPE laminates was equal to 0.22 mm,0.22 mm and 0.4 mm respectively according to the actual thickness in the hybrid laminates.

Fig.3.Geometrical model: (a) Hybrid laminate;(b) Plain-woven.

3.2.FEA model

The FEA model was created from geometrical model and meshed with hexahedral solid elements in HyperMesh 2020 software.Fig.4(a)exhibits the detailed structure of the FEA model.For the continuum model,smaller elements were used near the interface between the microstructural model and continuum model,and the mesh size gradually increased to the outer edges for improving efficiency.The fixed constraints were applied on the free edges of the continuum model to imitate experimental conditions.The other two edges were applied the symmetric constraints.Fig.4(b) shows the cross-section comparison between microstructural model and actual structure of hybrid laminates.The microstructural model is consistent with the actual hybrid laminates.

3.3.Material model

The mechanical behavior of yarns is assumed transversely isotropic homogeneous material with an elastic linear behavior.The constitutive relationships in the elastic region are defined for the engineering constants:E11,E22,E33,ν12,ν13,ν23,G12,G13and G23whereE,ν,andGare the Young’s modulus,Poisson’s ratio,and shear modulus,respectively.Materials directions 11-direction is the longitudinal direction,while the 22-direction is the transverse direction,and 33-direction represents the out of plane direction of the yarns.The MAT 054 with Chang-Chang failure criterion in LSDYNA were utilized to simulate the yarns material model [21].Table 3 lists the material parameters and failure criteria of the carbon,Kevlar and UHMWPE yarns [8,22-26].Several modeling parameters,such as ALPH,FBRT,YCFAC and BETA,need to be calibrated by trial and error,which have no physical meaning or cannot be determined experimentally.The detailed parametric studies can be found in Ref.[21].The TFAIL =0 indicates no element deletion by time step size.The SOFT =0 indicates that the elements at the crush front retain their pristine strength and no softening occurs.According to Ref.[21],the simulation results require extensive tuning and calibration of those failure parameters to reach an agreement between experiment and simulation.

Table 3Material properties and the failure criteria for carbon,UHMWPE and Kevlar yarns.

In the elastic stages,the constitutive relationships are given by

where ε and σ are used for stress and strain in the longitudinal direction and transverse direction respectively,Eis the young’s modulus,ʋ12and ʋ21are the in-plane Poisson’s ratios,Gis the shear modulus and α is the shear weighing factor.

The Chang/Chang failure criterion inside LS-DYNA has the following formulation:

whereef,ec,emandedare called history variables and they are failure indices for fiber tension,fiber compression,matrix tension,matrix compression failure.XtandXcare the fiber tensile and compressive strength respectively,YtandYcare the matrix tensile and compressive strength respectively,Scis the shear strength.

The Johnson-Cook equation was adopted to simulate the strainrate effect of Kevlar yarns [8].

where σ is the dynamic tensile strength of Kevlar yarns at the strain rate ε,σ0is the quasi-static tensile strength at the strain rate ε0,Cis the strain rate hardening model parameter and the value was 0.04386 [27]in this study.The Cowper-Symonds equation was applied for the strain-rate effect of UHMWPE yarns

where σdis the yield stress at a high strain rate,σsis the static yield stress,ε is the strain rate,the values ofCandpfor UHMWPE yarns were 372 and 3.72,respectively[28,29].

The continuum model was modeled with the material type MAT 22 [30],which corresponds to an orthotropic material model.The material properties of carbon,UHMWPE and Kevlar laminates employed in the model [8,25,31-33]are presented in Table 4.

Table 4Material properties of carbon,UHMWPE and Kevlar laminates.

The MAT 003-PLASTIC_KINEMATIC was adopted for the resin to model elastic-plastic material [19,24].Table 5 lists the material parameters of the epoxy resin.Moreover,the FSP was regarded as the rigid body and its plastic deformation was neglected.

Table 5The specifications of epoxy resin.

3.4.Algorithm

The contact-impact algorithm for dealing with this kind of sliding and impact along interfaces are based on the penalty method.The method consists of placing normal interface springs between all penetrating nodes and the contact surface.Each slave node is checked for penetration through the master surface.If the slave node does not penetrate,nothing is done.If it does penetrate,an interface force is applied between the slave node and its contact point.The algorithm can be described as follows [34,35].

The initial conditions can be described through three aspects.First,geometrical condition is that the surfaces on two contact bodies should not penetrate each other,can be written as

where Ω is continuous bodies.S is surfaces of the bodies.In contact interface,the position vectors (x1and x2) of a contact point are equal,and the unit outward normal vectors(n1and n2)with regard to both body surfaces are along the opposite direction

Second,the initial kinematics condition defines the velocities(ʋ1andʋ2)of the points on the contact interface of the both bodies to satisfy

Third,for momentum to be balanced on contact interface,the initial kinetic equation is

where f is the Cauchy stress.We assume that no tensile tractions can occur on the contact interface is written as

Subsequently,the penalty functions are used in contact-impact problems can be involved three steps.The first step is a determination of master segment containing slave node.Then we identify the contact point.The third step is the nodal force update and gives an interface stiffness matrix.The algorithms can be described as follows.

First,we find for each slave node its nearest point on the master surface.Ifmsandnsdo not coincide,nscan usually be shown to lie in a master segmentsivia the following tests:

where vectors ciand ci+1are along edges of siand point outward fromms,msis master nodes,nsis slave nodes,and vector s is the projection of the vector beginning atms,ending atns,and denoted byg,on to the plane being examined

Here,the case ofnslocated at the intersection of two master segment,the maximum value for the quantity is calculated from

Second,we check the penetrations.The contact point defined as the point on master segment which is closest to slave nodes (ns).The parametric expression of the master surface segment(si)can be written as

ξj,ηj,take on their nodal values at (±1,±1),andis the nodal coordinate of thej-th node in the ith direction.ris a master segment with a unique normal and is at least once continuously differential,the normal is nonzero,

The contact point coordinates (ξc,ηc) onsihave to be found by determining the smallest distance between the master segment and slave node.Then,the following equations can be solved

wheretis a position vector drawn to slave nodens.

Finally,we ensure a reasonable value for the interface stiffness.Penetration is judged with respect tolas

Iflis negative

is normal to the master segment at the contact point.It indicated that slave nodenshas penetrated through master segmentsi.In this case,an interface force vectorfsis applied the normal to the master segment,

At the same time,an equal and opposite force in the master segment nodes is expressed as

The stiffness factorkifor master segmentsifor brick elements can be written as

where theKi,ViandAiare the bulk modulus,volume and face area of the element that includssi,fsiis a scale factor for the interface stiffness and is normally defaulted to 0.1.

3.5.Contact and delamination modeling

The keyword of AUTOMATIC_SURFACE_TO_SURFACE was adopted for contacts between the weft and warp yarns in the microstructural model.The ERODING_SURFACE_TO_SURFACE was used for the contact between the projectile and the target model.The static and dynamic friction coefficient in the contact type was equal to 0.23 and 0.18 respectively [25].The AUTOMATIC_SURFACE_TO_SURFACE_TIEBREAK was employed to describe the delamination between two adjacent laminates in the continuum model,and the keyword was also used for the contact between the yarn and matrix in the microstructural model.The failure criterion of delamination/debonding was determined from

where σnand σsare normal tensile stress and shear stress of the contact surface respectively.NFLS and SFLS are normal strengths and shear strengths of the interface,respectively.The NFLS =34.5 MPa and SFLS =9 MPa[25]were used to describe the Kevlar interlayer behavior,the NFLS and SFLS in carbon laminates were equal to 100 MPa and 70 MPa [31],and both values in UHMWPE laminates were equal to 15 MPa and 60 MPa [36].The values of the NFLS and SFLS were 30 MPa and 80 MPa respectively[8]for the delamination between the layers of C/Kevlar,C/UHMWPE and Kevlar/UHMWPE.In addition,microstructural and continuum model in the FEA model were tied together using the TIED_NODE_TO_SURFACE contact type in LS-DYNA.

Before the calculations,a mesh convergence study was run on the single-layer FEA model to determine the suitable element size for computational accuracy and expense.The continuity and reliability of the tied connection between microstructural and continuum model are taken into consideration.

4.Results and discussions

4.1.Residual velocity

Table 6 lists the ballistic test and FEA results,and Fig.5 shows the comparison of residual velocities in tests and FEA.From Fig.5(a),the lower residual velocities are.

Table 6Ballistic test results of hybrid laminates.

Fig.5.Comparison of residual velocity between tests and FEA: (a) K27,C7K20 and K20C7;(b) PE18,C7PE11 and PE11C7;(c) K27,PE5K18 and K18PE5.

Obtained on the C7K20in the C/K group.Fig.5(b)shows that the residual velocities of the C7PE11and PE11C7are higher than that of the neat one,there is a negative hybrid effect on the residual velocities.Fig.5(c) shows that the K18PE5with the placement of UHMWPE layers on the back face exhibits lower residual velocities in the PE/K group.Moreover,the residual velocities increase nonlinearly with the striking velocities can be observed in Fig.5.The non-linear increase relationship can be explained by the strain rate effect of Kevlar and UHMWPE fibers[26,37].The residual velocities in the FEA are consistent with the test results.The errors of between tests and FEA are in a range of 1%-14%,which have a mean absolute percentage error of 4.24%.It is proven that the FEA model is reliable for the penetration damage simulation.The discrepancy between the experiments and FEA may be attributed that excessively distorted elements are removed before the deletion at failure criterion preset values.And the fiber bundles were assumed to a 3D solid continuum body with anisotropic homogenous material properties.The actual yarn consists of hundreds of fibers.All fibers do not fail simultaneously under ballistic impact.Stress wave propagation and energy dissipation are nonuniform.There are the possible reasons for the discrepancy.

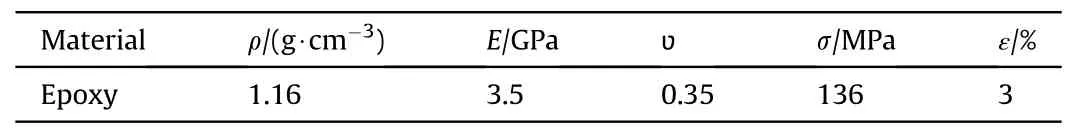

4.2.Ballistic limit and energy absorption

Fig.6 shows the ballistic impact performance in terms of estimated ballistic limit value (EV50) and energy absorption capacity(Ead).From Fig.6,it can be observed that Fig.6(a) shows that the C7K20and K20C7exhibit approximately 8.52% and 2.17% improvement in theEV50respectively when compared against the K27.And Fig.6(c)shows theEV50of the C7PE11and PE11C7is 9.42% and 11.94% lower than that of the PE18,respectively.Fig.6(e) shows the increases in theEV50of the PE5K18and K18PE5are 1.91% and 7.07%,respectively,compared to the K27.For the energy absorption capacity (Ead),theEadof the C7K20and K20C7is about 18.61% and 4.10% higher than that of the K27,respectively,as shown in Fig.6(b).Fig.6(d)shows theEadof the C7PE11and PE11C7drop by 19.62% and 25.08% in mean values,respectively.Fig.6(f) shows a 3.55% and 13.65% increase for the PE5K18and K18PE5in the Eadthan the K27.These results suggest that different hybrid configurations have a significant effect to affect the allistic limit and energy absorption capacity.The C7K20specimen shows the highestEV50value of 444.52 m/s,followed by specimens of the K18PE5(438.58 m/s).The K18PE5panel shows the maximum mean value ofEadis 13.25 J/kg·m2,and the K18PE5is 12.68 J/kg·m2.The FEA results of the hybrid laminates exhibit a relatively good correlation with experimental data.

Fig.6.Comparison of ballistic performance among different specimens in tests and FEA.

4.3.Damage morphology

Fig.7 shows the external damage morphologies of the hybrid composites after ballistic impact at the striking velocity of 500 ± 10 m/s.From Fig.7,it can be observed that even though combinations and stacking sequence in the hybrid laminates changed,the front damage morphology remained almost same for all the specimens.The damage morphologies on the front face show circular perforations,fiber breakage and matrix cracking.The perforation diameter ranges between 8 mm and 25 mm.The specimens with carbon layer at the front side show the minimum front damage diameter(Fig.7(a)and Fig.7(b)),and the specimens with UHMWPE layer at front side exhibit a relatively large damage diameter (Fig.7(b) and Fig.7(c)).In contrast,the damage morphologies on the back face show different patterns,the back Kevlar layers show the open petal-shaped appearance,fibrillation,fiber breakage,and matrix cracking (Fig.7(a) and Fig.7(c)).The back carbon layers at the back side show a fragile failure appearance and the splitting (Fig.7(a) and Fig.7(b)).The back UHMWPE layers at the back side show the open petal-shaped appearance,fibrillation,fiber breakage,tension failure,matrix cracking and large damaged area (Fig.7(b) and Fig.7(c)).These results indicate that when carbon layers are placed on the front face before the Kevlar layer,the front damage area is decreased,but carbon layers at the back face have a little influence(Fig.7(a)).When the carbon layers are placed on the back face behind the UHMWPE layer,the damage area is also decreased obviously,but the inferior ballistic performance in the PE11C7has been observed.In contrast,the K18PE5exhibits a large damage area on the back face,but it shows the maximumEadvalue.

Fig.7.Damage morphologies on the front and back surface at the striking velocity of 500 ± 10 m/s.

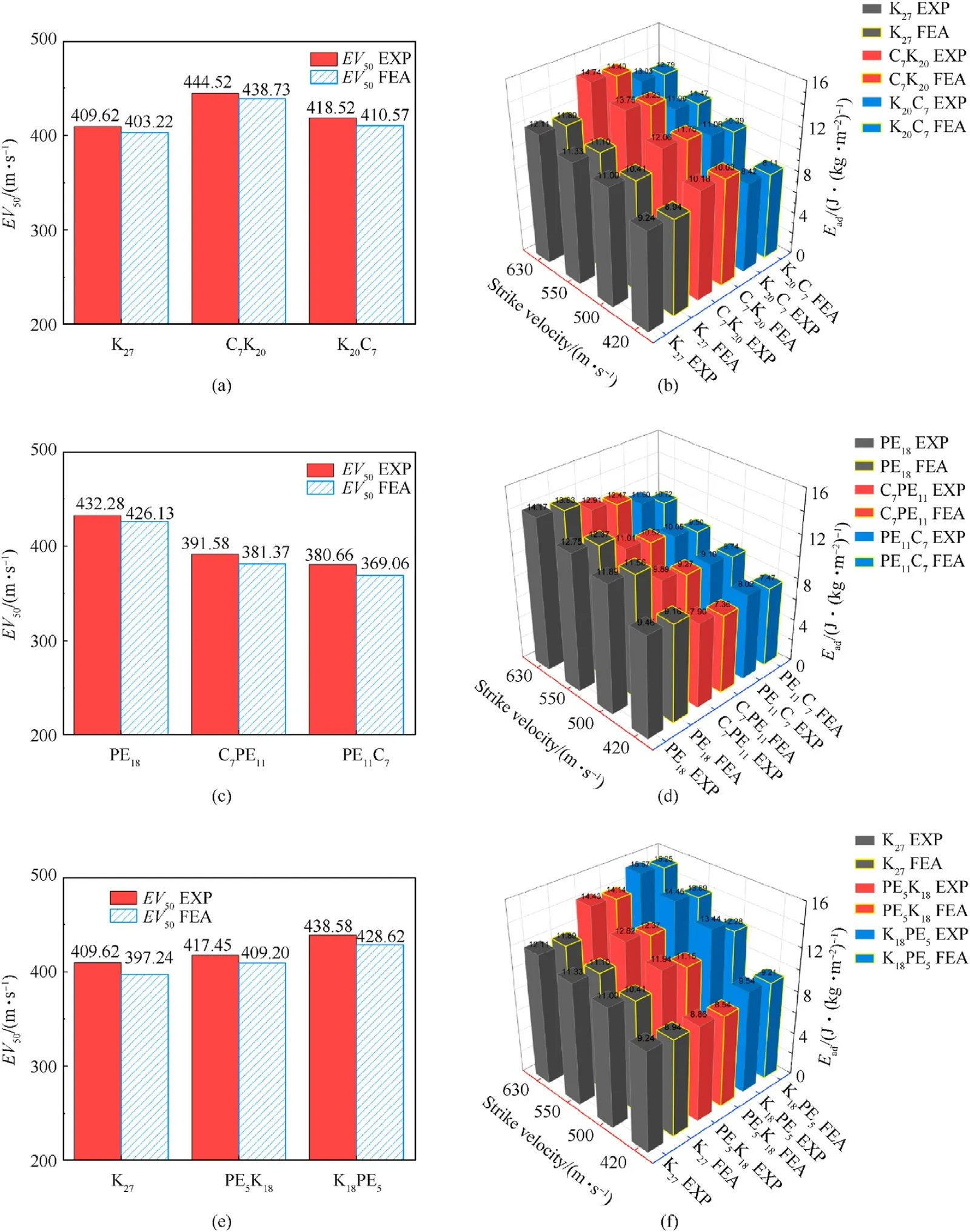

4.4.Cross-sectional view of impact position

Fig.8 shows cross-section images of post impacted hybrid composites under striking velocity 500 ± 10 m/s in experiments and FEA.From Fig.8,there are different damage modes along the penetration path in the hybrid laminates.The damage modes can be generally divided into two parts along thickness direction.Firstly,the damage modes involve a shear failure and matrix cracking at the front side.Secondly,tensile failure,large deformation,delamination and fiber stretching are observed as major damage modes at the back side.However,the K20C7and PE11C7have no deformation and delamination at the back along the penetration path(Fig.8(a)and Fig.8(b)).The high stiffness carbon laminates at the back side prevented the plastic deformation of Kevlar or UHMWPE layer in the in-plane direction.The damage modes of the carbon layers at back side exhibited local brittle failure,characteristics of shear failure are the most notable,which corresponded to an inferiorEadandEV50.It indicates that some of the key material properties,i.e.,delamination,tension failure and plastic deformation,may be absorbed much more impact energy[38].Moreover,the failure modes along the penetration path are well captured in the numerical simulations can be seen in Fig.8.This result confirms the accuracy and reliability of FEA.

Fig.8.Comparison of cross-section damage between tests and FEA at the striking velocity of 500 ± 10 m/s.

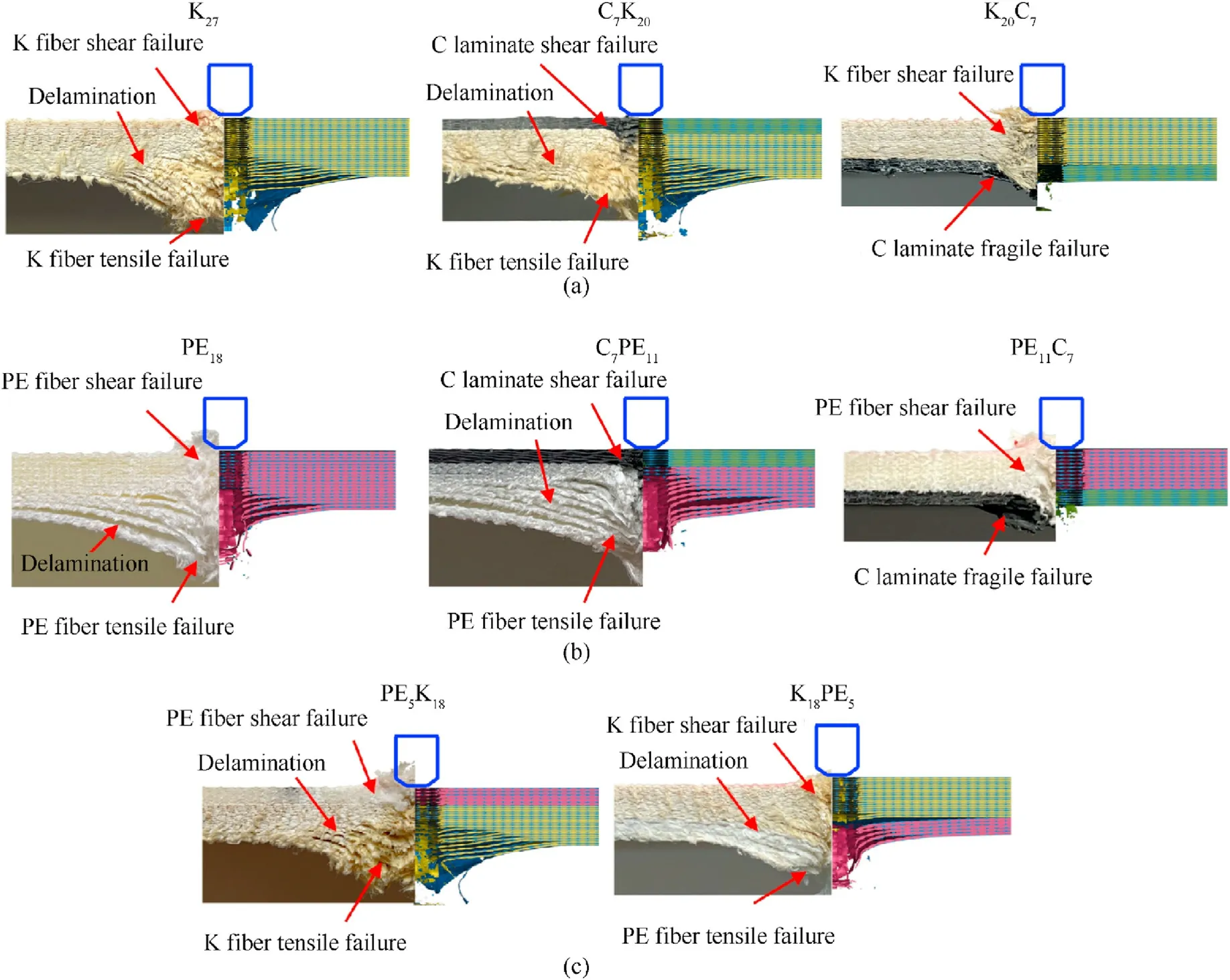

4.5.Ballistic damage evolution

4.5.1.Group of C/K combination

Fig.9 shows the comparison of the ballistic penetration evolution for K27,C7K20and K20C7under the striking velocity of 500 ± 10 m/s.At the initial stage of 0-16 μs,caused by the initial contact between the chisel-nosed head of projectile and the hybrid laminates,the stress distribution region appears directly under the projectile upon impact and the kinetic energy of the projectile transfers into different components of the composites.The shear failure and matrix cracking dominate the penetration process in the stage,no matter in carbon layers (C7K20) or Kevlar layers (K20C7).Subsequently,there is a difference in damage modes about 40 μs,the tensile failure,large deformation,delamination,and matrix cracking are observed as major failure modes for the K27and C7K20.The vast amount of energy is absorbed by the kind of tensile failure and plastic deformations.In contrast,there is no delamination and deformation about 40 μs in the K20C7,the plastic deformation of Kevlar layers at the front is hindered by the back carbon layers barrier.The hybrid laminates of the K20C7dominate the shear failure and matrix cracking in the stage.The main energy absorption mechanism of the K20C7in this stage is the carbon fiber fracture and matrix cracking,and the energy absorption for the carbon layer’s deformation can be neglected due to the low extension of the brittle materials.As the penetration progresses(40-90 μs),the delamination length(~20 mm)for the K27and C7K20is much larger than the length of the damage zone,and the stress distribution inplane of the back layers is very large.This indicates that the deformation and delamination provided a large energy dissipation during impact.Hence,it could be discovered that the ballistic performance at the front side mainly depends on intrinsic material properties such as shear resistance,but at the back side,it depends upon the hybrid structures and material properties.

Fig.9.Comparisons of ballistic penetration evolution of K27,C7K20 and K20C7 (Vs =500 ± 10 m/s).

Fig.10 plots the variation of velocity and acceleration concerning the times in the FEA.The acceleration shows an approximately linear increase sharply in the initial stage of 0-4 μs,with 0 μs corresponding to the instant of projectile impact with composite panels.The acceleration is attributed to the resistance from the fiber breakage and matrix cracking at the contact surface between the projectiles and composites.Subsequently,the peak acceleration is observed in 5-16 μs,and the maximum acceleration of C7K20is higher than that of K20C7and K27.This suggests that the high compressive and shear strengths of carbon fiber at the front side provide higher resistance to the projectile penetration.The velocity of the projectile shows declines rapidly,which is consistently associated with the acceleration increase in 5-16 μs.Then the acceleration curves express different trends after reaching the peak value.The acceleration curves of the K20C7and K27have a similar trend,those have decreased in 16-40 μs,the fluctuation indicates the asynchronous fracture of the different components in the composites.However,the C7K20shows a plateau with a higher absolute value in the stage of 16-40 μs,it plays an important role to decelerate the projectile.After 40 μs,the change in the acceleration gives a decline and decreases to zero around 90 μs.

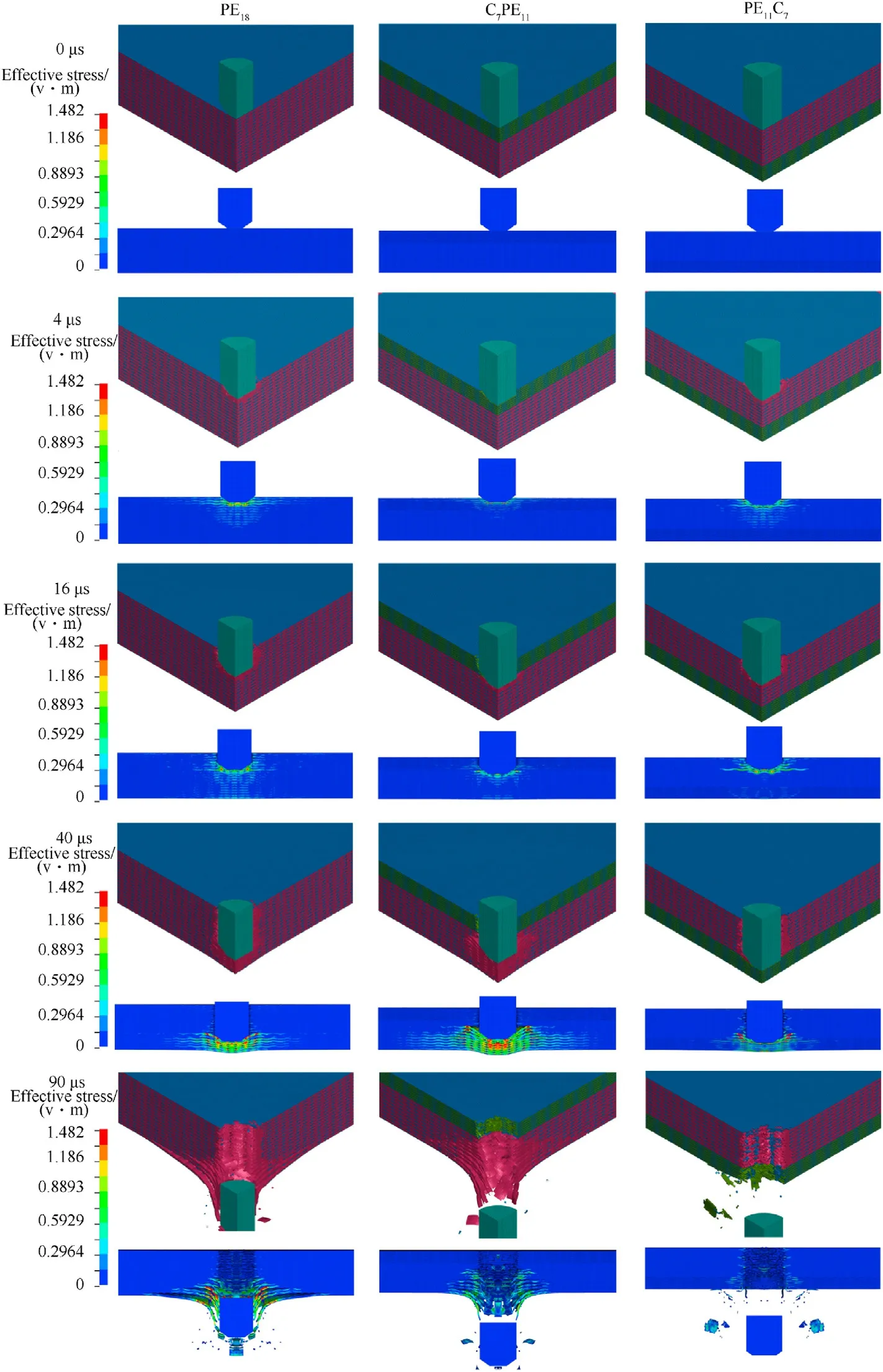

4.5.2.Group of C/PE combination

Fig.11 gives the damage evolution of PE18,C7PE11and PE11C7under the strike velocity of 500 ± 10 m/s.From Fig.10,the penetration damage mechanism varies with the penetration depth,the major damage at the front layers is due to shear and compression failure,the damage at the back layers is mainly due to tension failure and delamination of the C7PE11and PE18.But the PE11C7indicates that the shear failure is the dominant failure mode on both sides.These observations are similar to the group of C/K combination.However,there is a decrease inEV50andEadfor the C7PE11and PE11C7than the non-hybrid specimens.The decrease of the C7PE11could be attributed to that the carbon laminates are fragile materials with high stiffness,and UHMWPE laminates are flexible materials,a transverse deformation of flexible materials is much easier than that of fragile materials.Consequently,the UHMWPE layers at the back side cannot provide sufficient support in the impact direction,which leads to a decrease in constraint force from the back UHMWPE layers.This indicates that the appropriate balance of stiffness and flexibility is necessary between different materials.Moreover,the introduction of a redundant amount of carbon fiber could also reduce the ballistic resistance due to the carbon is an inferior ballistic material to the UHMWPE in impact resistance and specific strength.As for the PE11C7,the UHMWPE layers at the front side have failed to provide sufficient resistance force to decelerate the projectiles because of the low compressive and shear strengths of the UHMWPE materials.Further,the decrease may account for the high bending stiffness of the carbon layers at the back,which suppresses the delamination and fiber stretching of the UHMWPE layers,thus resulting in the reduction of the energy absorption capacity.As a result,the PE11C7exhibits the minimum ballistic resistance.

Fig.11.Comparisons of ballistic penetration evolution of PE18,C7PE11,and PE11C7 (Vs =500 ± 10 m/s).

Fig.12 shows the velocity vs.time history and acceleration vs.time history of PE18,C7PE11and PE11C7.From Fig.12,the acceleration curve shows a higher absolute value for the C7PE11than that of the PE18and PE11C7in 0-16 μs,the carbon layers at the front side provide a higher deceleration effect.However,the peak value of the PE18appears quite higher than that of the C7PE11and PE11C7in 16-40 μs,and the PE11C7has the lowest absolute value of the acceleration.It indicates that the addition of carbon layers results in a decrease in its ballistic resistance.In addition,the lack of appropriate deformation and delamination of the PE11C7also reduced the deceleration effect.

Fig.12.Velocity vs.time history and acceleration vs.time history of PE18,C7PE11 and PE11C7 (Vs =500 ± 10 m/s).

4.5.3.Group of PE/K combination

Fig.13 shows the temporal evolution of the penetration process for the K27,PE5K18,and K18PE5at the strike velocity of 500±10 m/s.These composite specimens failed in a progressive manner,and the penetration process could be broadly identified into two stages.Firstly,the fibers experienced compressive and shear stress under the projectile within the first 16 μs,which was accompanied by fibers shear failure and matrix crack.Secondly,the fiber stretching and delamination occurred after the time around 16 μs.This indicates that the stress between projectiles and targets decreases with a decrease in the impact velocity of the projectiles.It changes the failure modes from shear failure to tension failure.According to the above results,the K18PE5provides the higherEV50as well as theEad.This can be explained that the Kevlar layers at the front in the hybrid laminates offered excellent mechanical properties against shear or compression failure,and the high tensile strength of UHMWPE fibers in the back side provided significant stretching and deformability during ballistic impacts,allowing the UHMWPE layers to absorb more kinetic energy.Furthermore,Kevlar layers exhibited larger transverse deformations under impact,which results in an improved failure simultaneity between the Kevlar layer and UHMWPE layer.It can provide a better synergistic effect to dissipate the impact energy from projectiles and result in improved ballistic impact resistance.

Fig.13.Comparisons of ballistic penetration evolution of K27,PE5K18 and K18PE5(Vs =500 ± 10 m/s).

Fig.14 shows the velocity vs.time history and acceleration vs.time history of the PE5K18and K18PE5under the strike velocity of 500±10 m/s.The K18PE5shows two distinct peak values around 10 μs and 30 μs.The penetration resistance of the K18PE5could be improved by adding UHMWPE layers at the back side.The transverse deformation in the UHMWPE layer was the greatest compared with Kevlar and carbon fiber layers at the back side.This greatest deflection of the back layer that provided much larger penetration resistance.Moreover,stress gradient arising from bending and shearing would be relieved when the Kevlar layers are in the front side due to the lower bending support from the back layers.Therefore,a larger penetration resistance could be attained with this hybrid scheme.As a result,The Kevlar/UHMWPE hybrid laminates with UHMWPE layers as the back face exhibited a higher capacity for decelerating projectile.In contrast,the acceleration curve of the PE5K18is similar to that of the K27.These results indicate that the addition of UHMWPE layers in the front shows a negligible influence on ballistic resistance.

Fig.14.Velocity vs.time history and acceleration vs.time history of K27,PE5K18 and K18PE5 (Vs =500 ± 10 m/s).

5.Conclusions

The ballistic penetration damages of carbon,Kevlar and UHMWPE plain-woven hybrid laminates have been evaluated with ballistic impact tests and finite element analysis (FEA).Effects of fabric hybrids on ballistic impact damages have been analyzed from comparisons of impact damages and energy absorptions between the tests and FEA.The main conclusions are listed as follows.

(1) The ballistic test combined with the FEA gives an efficient method to study ballistic penetration damage mechanisms for hybrid composite laminates.

(2) The ballistic performance is sensitive to the fiber combinations and laminate stacking sequence.It was found that the UHMWPE/Kevlar hybrid laminates with Kevlar layers as the front face exhibits the highest energy absorption capacity and higher ballistic limit.The carbon/Kevlar hybrid laminates with carbon layers as the front face also shows an improvement in energy absorption capacity and ballistic limit.While the carbon/UHMWPE hybrid laminates with UHMWPE layers as the front face displays the minimum energy absorption capacity.

(3) The ballistic penetration damages morphology indicated that even though fiber combinations and laminate stacking sequences of the hybrid laminates changed,the front damage morphology remained almost the same for all the hybrid scheme.And it changed for back face of the hybrid laminates.

(4) Penetration mechanisms of the hybrid laminates showed that the front layers tend to fail in shear,followed by fiber breakages,matrix crack and interlayer along the penetration path.The Kevlar or UHMWPE layer at back face displayed fiber stretching and tension failure,such damage modes were benefit for energy absorption under ballistic penetration.

(5) The hybrid structures affected the ballistic resistance in penetration process according to the FEA results.When carbon laminates place on the striking face,the absolute value of peak acceleration is higher than the other.And positioning UHMWPE layers on the back hybridized with Kevlar layers can also achieve a higher deceleration effect.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

杂志排行

Defence Technology的其它文章

- Numerical simulation of flow field characteristics and theimprovement of pressure oscillation of rotating detonation engine

- The dynamic response of a high-density polyethylene slow-release structure under launching overload

- Adaptive saturated tracking control for solid launch vehicles in ascending based on differential inclusion stabilization

- Comparative investigations of ternary thermite Al/Fe2O3/CuO and Al/Fe2O3/Bi2O3 from pyrolytic,kinetics and combustion behaviors

- Impact point prediction guidance of ballistic missile in high maneuver penetration condition

- Deep learning-based method for detecting anomalies in electromagnetic environment situation