噬菌体保鲜技术在预制菜中的应用研究进展

2023-05-13冯珊红钟乐程萍肖乃玉张雪琴肖更生周锦贤

冯珊红,钟乐,程萍,肖乃玉,张雪琴,肖更生,周锦贤

噬菌体保鲜技术在预制菜中的应用研究进展

冯珊红,钟乐,程萍,肖乃玉,张雪琴,肖更生,周锦贤

(1.仲恺农业工程学院 轻工食品学院,广州 510225;2.广东省高校中央厨房绿色制造开发中心,广州 510225;3.农业农村部岭南特色食品绿色加工与智能制造重点实验室,广州 510225)

综述噬菌体保鲜技术在预制菜中的应用研究,为预制菜的食品安全保障和噬菌体的应用研究提供依据。本文以预制菜的食品安全为出发点,就预制菜进行分类,重点对动植物源食材的噬菌体生物防控的应用研究进行讨论。分析表明,噬菌体在预制菜中的应用具有广泛的应用前景和价值。噬菌体可以有效地控制预制菜中的食源性细菌污染、保持食品品质并延长货架期。为提高噬菌体的抗菌效果,可以从噬菌体的浓度、稳定性及其与物理保鲜方法或生物、化学保鲜剂结合等方面考虑。为实现噬菌体在预制菜中的广泛应用,还需提高噬菌体的筛选效率和稳定性,并制定相应的标准和规范,以提高消费者的可接受程度,促进噬菌体在国内市场的推广和应用。因此,使用噬菌体保鲜技术不仅能够延长预制菜的货架期、提高食品安全性,还能为食品行业带来更多的发展机遇。

噬菌体;预制菜;食源性细菌;生物防控

预制菜是以畜禽、水产品、果蔬等农产品为原料,配以各种辅料,经预加工而成的成品或半成品菜肴,分为即食、即热、即烹、即配[1]。随着经济社会发展,对食品工业提出了新的要求,餐饮行业的连锁化和规模化发展趋势显著,外卖市场和团餐业务需求强劲,为预制菜行业带来了快速发展的机遇,预制菜因保质期长、食用方便等特点广受青睐[2]。但预制菜对食品的新鲜度和安全性要求高[3],例如,肉类食品富含蛋白质、脂肪等营养成分,易受微生物的侵染,造成食品腐败;果蔬经过去皮、切分等加工手段会导致组织细胞损伤、代谢反应急剧活化及微生物污染,造成褐变、萎蔫、黄化、腐烂等品质劣变现象[4-5]。食源性细菌污染一直是食品加工过程中需要注重的关键问题之一。据数据显示,美国居民因食用感染产志贺毒素的大肠杆菌的生菜和李斯特菌的金针菇分别导致240人和36人患病[6-7],以致大量新鲜农产品被召回,造成重大粮食损失。因此预制菜的加工、储运环节需要严格把控,以抑制食源性细菌并保证食品安全。

为延长预制菜的货架期,需要从生产端消除食源性细菌的影响,常用的保鲜技术有:物理方法,即超高压、辐照、冰温冷藏、气调包装等[8-12];化学方法,即无机盐、有机酸及其盐类等[13-16];生物方法,即壳聚糖、植物精油、乳酸链球菌素(Nisin From,Nisin)、纳他霉素、溶菌酶等[17-22]。这些常规方法已在食品保鲜中长期实施,其中生物保鲜技术有很大的发展空间,被认为是一种可持续、安全和环保的选择,具有天然、无毒、可降解的特点。为提高预制菜的质量,减少杀菌带来的品质下降,噬菌体杀灭食源性细菌的方式受到国内外研究学者的广泛关注[23]。噬菌体具有特异性强、裂解效果好、可持续发挥作用等优点,虽然噬菌体与宿主菌共进化会降低噬菌体的有效性,但也会导致噬菌体在不同宿主细胞中有更广泛、更针对性的遗传多样性,从而提高了噬菌体在不同环境下的适应性和生存能力[24]。

本文围绕预制菜,将其分为生鲜肉制品、熟肉制品以及果蔬类。阐述了在预制菜领域中噬菌体控制食源性细菌的研究应用进展,涵盖了噬菌体在食品检测领域的应用。为保障预制菜的食品安全和噬菌体制剂的研发提供依据。

1 噬菌体特性

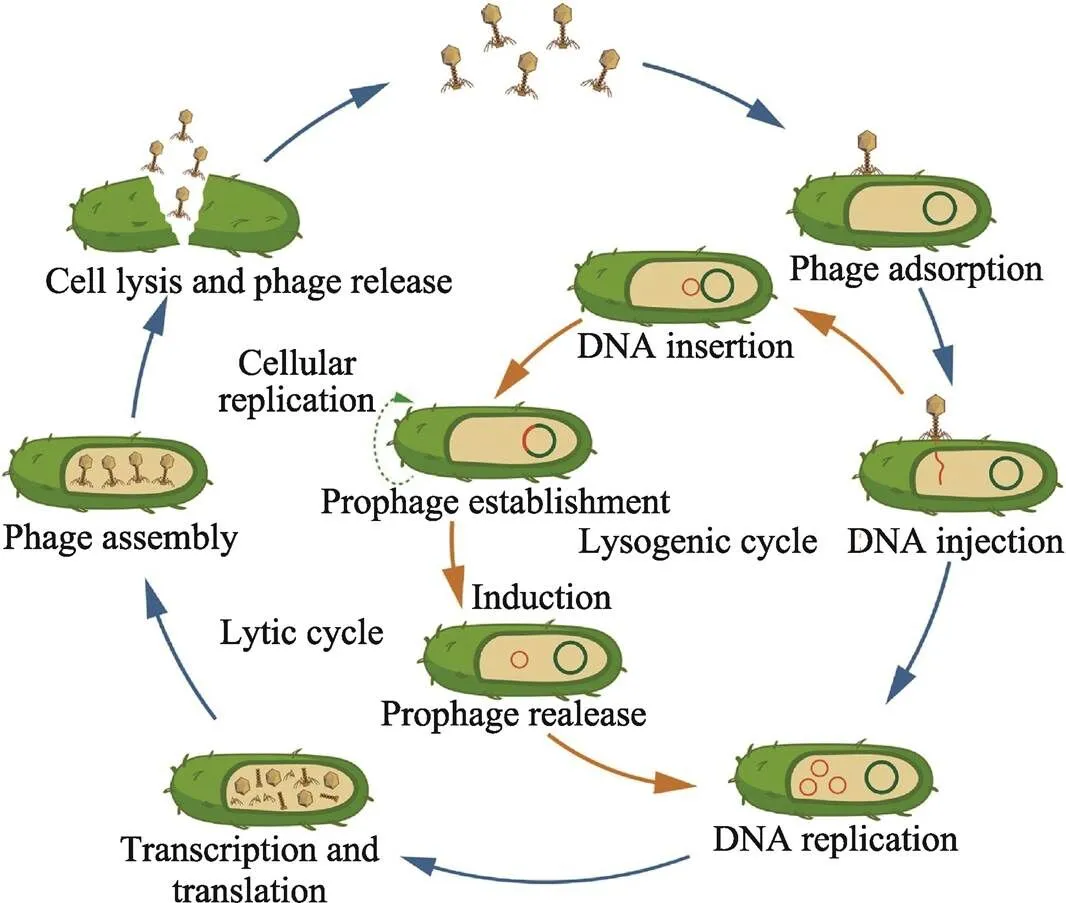

噬菌体是地球上最多样化的生命形式,其数量是细菌的104倍,在环境中无处不在,能够裂解目标细菌,对食品中的病原菌具有高效的杀灭作用,并且是一种非化学性的杀菌,对人体健康无不良影响[25-27]。作为细菌的天敌,噬菌体可以通过裂解复制循环或溶源循环在宿主细菌内裂解或溶源化,分别称为裂解性噬菌体和温和性噬菌体(图1)[28]。早在20世纪20年代就已提出噬菌体疗法[29],但抗生素的出现导致人们忽略对噬菌体治疗的深入研究,随着抗生素耐药性的上升,噬菌体疗法再次成为人们关注的焦点,被认为是预防或治疗耐药细菌感染的潜在工具。噬菌体治疗已得到世界各地的认可,在动植物治疗、食品、医药等领域研究广泛,并已有获得美国食品药监局认证的噬菌体产品,用于控制肉类及家禽产品的食源性细菌[30]。

噬菌体的发现及其在食品中的应用,为抑菌剂的种类增添了新的选择,提供了一种安全、高效且具有强大靶向性的生物抑菌剂[31]。总结起来,不同的保鲜技术有不同的特点,归纳见表1。

图1 噬菌体的裂解和溶源循环

2 噬菌体在生鲜肉制品的应用研究

生鲜肉类营养丰富,自由水含量较高,pH为5.7~6.5,这些条件都有利于微生物的生长繁殖[32]。最常见的是细菌感染,例如沙门氏菌、霍乱弧菌等,这些细菌可能会导致食物中毒和肠道感染等疾病。有研究证实噬菌体可用于抑制碎牛肉、牛肉片、猪肉、鸡肉的大肠杆菌、沙门氏菌以及单核增生李斯特杆菌的污染[33-40],均有显著的抑菌效果。

表1 噬菌体保鲜技术与常规保鲜技术的对比

Tab.1 Comparison between phage preservation technology and conventional preservation technology

预制菜生鲜肉的冷链贮藏过程中引入特定的噬菌体可以抑制细菌的生长,从而减少细菌污染的风险。Abhisingha等[41]将噬菌体鸡尾酒用于减少冷藏期间鸡肉上的沙门氏菌,在−20 ℃仍有一定的抑制效果;钱蓓蕾等[42]在0、4 ℃条件下将噬菌体作用于感染李斯特氏菌的虾仁24 h后,发现细菌死亡率均可达到99.9%;Xu等[43]将噬菌体作用于受污染的三文鱼片和扇贝,在4 ℃贮藏7 d后可将鼠伤寒沙门氏菌的数量降低至检测限以下。为了最大限度地发挥噬菌体的作用,可采用协同应用的方式。比如,在有氧、真空或气调(CO2和O2的体积分数分别为95%和5%)环境下,可以增强噬菌体制剂对牛肉、鸡胸肉中的大肠杆菌和沙门氏菌的抑制效果[44-45]。将噬菌体与Nisin、山梨酸钾组合处理污染沙门氏菌的冷鲜猪肉[46],与有机酸结合处理鸡肉中的肠炎沙门氏菌[47],与月桂酸精氨酸乙酯(Lauroyl Arginate Ethyl Ester,LAE)联合抑制鸡胸肉中的单核增生李斯特菌[48],均能提高整体的抑菌效果。

在食品保鲜中,噬菌体与材料结合可赋予食品包装材料抑菌性能,但噬菌体在应用过程中受到环境因素的影响,其活性容易降低,Cui等[49]研发了脂质体包裹噬菌体的壳聚糖膜,增加噬菌体的稳定性和成活率,其包封率可达(57.66±0.12)%。包裹噬菌体的脂质体应用于人工污染的牛肉,带正电荷的脂质体与带负电荷的细菌结合,噬菌体通过脂质体的缓释性进入牛肉表面,吸附裂解大肠杆菌O157:H7;为提高噬菌体的感染效果,噬菌体还可以固定于聚己内酯膜(Polycaprolactone,PCL)、乳清蛋白膜(Whey Protein Concentrate,WPC)上抑制生鲜肉上大肠杆菌O157:H7的生长[50-51],使噬菌体更容易与目标细菌接触。亦有将几种噬菌体制成噬菌体鸡尾酒用于生鲜肉托盘吸水衬垫,有效解决微生物污染和水分流失的问题[52],保持生鲜肉的滋味和质量。

噬菌体作为生物保鲜剂,通过其对细菌的特异性感染,可广泛应用于防控猪肉、牛肉、羊肉及海鲜等预制菜生鲜肉制品中的食源性细菌。此外,噬菌体还可喷涂或清洗生鲜肉加工设备,如切块机、切片机、绞肉机等,以抑制食源性细菌的生长繁殖,从而减少加工设备的微生物污染。

3 噬菌体在熟肉制品的应用研究

熟肉制品富含脂肪、蛋白质等营养物质,极易在加工、运输、销售等环节受到微生物(单核增生李斯特菌、大肠杆菌、沙门氏菌等)的污染[53]。例如低温肉制品的热处理温度低,可能残留一些耐热微生物[54],或在贮藏、销售期间因微生物存在而将蛋白质分解为生物胺[55],导致肉制品品质下降、货架期缩短。从预制菜熟肉制品的加工流程来看,噬菌体可用于原料、操作空间减菌化,以及包装、保鲜、杀菌等加工过程的细菌防控。

在食品保鲜时,噬菌体的浓度是影响抑菌效果的重要因素,如果浓度太低,可能无法控制细菌的数量。Soffer等[56]将不同剂量的ShigaShield™噬菌体制剂用于去除腌牛肉熟食、烟熏三文鱼、预煮鸡肉等食物中的志贺菌,发现最大剂量的(2×107或9×107PFU/g)噬菌体制剂可使细菌总数减少90%。Perera等[57]以不同浓度的ListShield噬菌体处理烟熏鲑鱼中的单核增生李斯特氏菌,较高浓度的噬菌体使细菌数减少了90%。Sirdesai等[58]将浓度为107PFU/cm2和5×107PFU/cm2的PhageGuard S噬菌体用于抑制培根中的沙门氏菌,细菌减少量分别为1.3 lg(CFU/cm2)和0.8 lg(CFU/cm2)。除了使用适量的噬菌体外,还可在使用噬菌体时采取额外的控制措施,如真空包装、添加抗氧化剂等,以确保食品的安全性。Devlieghere等[59]研究了噬菌体P100对冷藏真空包装的熟火腿中单核细胞增生李斯特菌生长的影响,熟火腿经过噬菌体处理后的28 d和42 d将细菌数保持在低于或等于1 CFU/g。Radford等[60]在聚乳酸膜上添加含A511噬菌体的黄原胶涂层,研究对预烹饪的火鸡胸脯肉片上的沙门氏菌和李斯特菌的抑制效果,其细菌数减少量可分别达到1.30、6.31 lg(CFU/cm2)。Figueiredo等[61]将噬菌体P100与Nisin用于抑制猪肉火腿片的李斯特菌,72 h后细菌数减少了3 lg(CFU/cm2)。Khashayar等[62]将6种噬菌体制成新型噬菌体鸡尾酒用于熟鸡胸肉中抑制志贺菌,与对照样品相比,7 d后的细菌减少数达到99%。除此之外,Park等[63]将筛选出的耐热噬菌体在66 ℃鸡胸肉加工条件下,经过30 min处理,其噬菌体依然保持100%的存活率,证明了耐热噬菌体可用于低温肉制品的微生物防治。研究表明,噬菌体在实际加工中具有显著的效果,Perera等[57]将噬菌体应用于实际的烟熏三文鱼加工厂,发现ListShield噬菌体处理的鱼片均未检出单核细胞增生李斯特氏菌。由此可见,噬菌体在预制菜熟肉制品的食源性细菌防控中具有潜在价值,对目标细菌进行抑制的同时并不会对食品原有的口感和质量产生不良影响。

4 噬菌体在果蔬制品的应用研究

预制菜产品种类丰富,大多为肉类预制菜,而果蔬类预制食品种类很少,其中的原因包括果蔬深加工技术和开发新产品思路的受限。为保证果蔬类预制菜的新鲜度和营养性,鲜切产品将成为果蔬市场的新趋势[64],给人们带来更佳的消费体验。预制菜的鲜切果蔬从采摘、加工、包装、运输到销售过程中都可能被微生物污染,导致果蔬的微生物种群发生变化,从而产生腐败、变质等现象[65]。为提高消费者对鲜切果蔬产品的信任度,迫切需要一种新型生物控制剂,抑制鲜切果蔬上的食源性细菌生长并延长货架期,提供健康安全的产品[66-67]。噬菌体作用于鲜切果蔬后不会改变其营养特性或风味,但能够增强果蔬制品的抗微生物效果,有利于提高其贮运和销售过程的安全性[68]。

预制菜的鲜切果蔬种类丰富,直接制成凉拌沙拉或生食会增加感染食源性致病菌的风险。为有效降低食物中毒的风险,可以采用措施减少鲜切果蔬的微生物污染[69]。表2列举了不同途径筛选出的噬菌体应用于鲜切果蔬的案例。

表2 筛出的噬菌体在鲜切果蔬的应用

Tab.2 Application of screened phage in fresh-cut fruits and vegetables

噬菌体在鲜切果蔬上的应用仍存在一些局限性。首先是pH值的影响,柑橘、西瓜等的pH通常在4.0左右,而噬菌体的pH稳定范围为6.0~9.0,这种环境下,噬菌体可能会失去活性;其次,果蔬表面通常会形成微生物生物被膜,这种生物被膜通常由多种微生物组成,能够增强细菌在果蔬表面的黏附能力和生长速率,降低噬菌体的抑菌效果。

许多研究表明,将噬菌体与其他抑菌剂结合使用,可以有效抑制鲜切果蔬中微生物的生长。Oladunjoye等[79]将噬菌体和蔗糖单月桂酸酯用于抑制鲜切胡萝卜上的单核增生李斯特氏菌,储存6 d后细菌数减少2.17~4.00 lg(CFU/cm2)。Boyacioglu等[80]将噬菌体与气调(O2、CO2、N2的体积分数分别为5%、35%、60%)结合用于抑制绿叶蔬菜(菠菜、绿叶莴苣、长叶莴苣)的细菌感染,其细菌减少量分别为3.08、3.89和4.34 lg(CFU/cm2)。Hong等[81]则是将噬菌体与细菌拮抗剂G. asaii联合使用测试对哈密瓜片上的李斯特氏菌的抑制效果,发现两者混合使用将李斯特氏菌数减少了6 lg(CFU/cm2)。Oladunjoye等[82]将噬菌体和磷酸三钠(Tri-Sodium Phosphate,TSP)应用于感染单核细胞增多性李斯特菌的鲜切番茄和西瓜上,噬菌体–TSP使番茄、甜瓜的细菌减少数分别为1~2 lg(CFU/cm2)、2~5 lg(CFU/cm2)。Oliveira等[83]将包裹噬菌体的食用乳清分离蛋白(Whey Protein Isolation,WPI)涂层用于感染了大肠杆菌的圣女果和切片苹果,发现相比于对照组,含有噬菌体的WPI涂层减少的活菌数为1~3 lg(CFU/cm2)。Cui等[84]用噬菌体和冷氮等离子体处理生菜、黄瓜和胡萝卜上的大肠杆菌O157:H7生物被膜,冷氮等离子体可以破坏细菌生物被膜的结构,使其失去生物黏附的能力,加上噬菌体的杀菌效果,可以将大肠杆菌的数量降低到不可检出的水平。总体而言,噬菌体与物理、化学方法结合应用于鲜切果蔬,可以达到保证果蔬卫生安全和延长果蔬保鲜期的双重效果,具有广阔的应用前景和发展潜力。

5 结语

预制菜行业正处于发展期,面临着食品安全方面的挑战。一方面,预制菜的食材原料存在微生物污染的风险;另一方面,预制菜在运输、贮藏过程由于冷链运输、配送速度不达标而导致菜品腐败变质、口味不佳等。噬菌体用于预制菜保鲜时,与化学、物理杀菌方式不同,噬菌体能够在被污染的食品中快速繁殖和扩散,并裂解宿主菌,从而达到杀菌的目的。其杀菌过程不会释放化学物质或能量,因此噬菌体不会对食品的质量、味道和营养产生负面影响。

虽然噬菌体保鲜技术在预制菜方面有显著优势,但是在工业化应用上仍存在局限。首先,噬菌体易受外界环境(高温、酸性环境、低水分活度)干扰失去活性、特异性强导致宿主谱窄;其次,噬菌体的应用多为喷洒、浸泡和涂层,与包装材料结合的研究较少;最后,若噬菌体进行工业化生产,必须在监管机构批准的良好生产规范(Good Manufacturing Practice,GMP)下制定具体的生产指南,为噬菌体产品制定质量和安全标准。

整体而言,噬菌体在预制菜行业有很大的应用前景,并且其在肉类、果蔬等食品中的研究应用都取得了良好效果。噬菌体生物控制不应该被认为是其他保鲜技术的替代品,而是作为一种提高食品安全性的额外工具。提高噬菌体的稳定性、安全性和消费者的接受度,进而推动我国噬菌体产品的研发进程,促进噬菌体制剂工业化生产。

[1] 赵靓琳. 预制菜行业现状及问题研究[J]. 现代营销(经营版), 2021(9):146-147.

ZHAO Liang-lin. Research on the Present Situation and Problems of Prefabricated Vegetable Industry[J]. Marketing Management Review, 2021(9): 146-147.

[2] 张玉荣. 预制菜, 乡村振兴的新产业大产业[J]. 小康, 2022(14): 18-23.

ZHANG Yu-rong. Prefabricated Vegetables, a New Industry for Rural Revitalization[J]. Xiaokang, 2022(14): 18-23.

[3] 曾耀锐, 邹玉洁, 卢贤钿. 供应链视角下 “宅经济” 预制菜发展现状及前景分析[J]. 中国储运, 2022(11): 189-190.

ZENG Yao-rui, ZOU Yu-jie, LU Xian-dian. Analysis on the Development Status and Prospect of "House Economy" Prefabricated Vegetables from the Perspective of Supply Chain[J]. China Storage & Transport, 2022(11): 189-190.

[4] 贾艳艳. 预制菜现状、质量安全与展望研究[J]. 中国食品工业, 2022(17): 54-57.

JIA Yan-yan. Research on the Present Situation, Quality, Safety and Prospect of Prepared Vegetables[J]. China Food Industry, 2022(17): 54-57.

[5] 柳青, 陈晓琪, 黄广学, 等. 鲜切果蔬品质控制技术研究进展[J]. 食品研究与开发, 2022, 43(6): 217-224.

LIU Qing, CHEN Xiao-qi, HUANG Guang-xue, et al. Progress on Research into Quality Control Technology for Fresh-Cut Fruit and Vegetables[J]. Food Research and Development, 2022, 43(6): 217-224.

[6] BOTTICHIO L, KEATON A, THOMAS D, et al. Shiga Toxin-Producing Escherichia coli Infections Associated With Romaine Lettuce-United States, 2018[J]. Clin Infect Dis, 2020, 71(8): 323-330.

[7] CDC. Outbreak of Listeria infections linked to enoki mushrooms[C]. Atlanta: CDC, 2020.

[8] PARK D H, JUNG J G, JUNG B R, et al. Changes in Salmon () Flesh Quality Following Ultra-High Pressure Treatment and 30 d of Chilled Storage[J]. Journal of Food Science, 2015, 80(1): 142-146.

[9] NIKULINA E O, IVANOVA G V, KOLMAN O I, et al. Research of the Influence of Vacuum Packaging on the Quality and Safety of Meat Semi-Finished Products[J]. IOP Conference Series: Earth and Environmental Science, 2021, 677(3): 032066.

[10] 赵磊, 王丹, 马越, 等. 短波紫外线照射对鲜切黄瓜片品质的影响[J]. 食品工业, 2019, 40(5): 205-209.

ZHAO Lei, WANG Dan, MA Yue, et al. Effect of Ultraviolet C Irradiation on the Quality of Fresh Cut Cucumber Slices[J]. The Food Industry, 2019, 40(5): 205-209.

[11] SHEN Xu, ZHANG Min, DEVAHASTIN S, et al. Effects of Pressurized Argon and Nitrogen Treatments in Combination with Modified Atmosphere on Quality Characteristics of Fresh-Cut Potatoes[J]. Postharvest Biology and Technology, 2019, 149: 159-165.

[12] UKUKU D O, GEVEKE D J, CHAU L, et al. Microbial Safety and Overall Quality of Cantaloupe Fresh-Cut Pieces Prepared from Whole Fruit after Wet Steam Treatment[J]. International Journal of Food Microbiology, 2016, 231: 86-92.

[13] DUBAL Z B, PATURKAR A M, WASKAR V S, et al. Effect of Food Grade Organic Acids on Inoculatedandin Sheep/Goat Meat Stored at Refrigeration Temperature[J]. Meat Science, 2004, 66(4): 817-821.

[14] MOHAN A, POHLMAN F W. Role of Organic Acids and Peroxyacetic Acid as Antimicrobial Intervention for ControllingO157: H7 on Beef Trimmings[J]. LWT - Food Science and Technology, 2016, 65: 868-873.

[15] IRKIN R, DEGIRMENCIOGLU N, GULDAS M. Effects of Organic Acids to Prolong the Shelf-Life and Improve the Microbial Quality of Fresh Cut Broccoli Florets[J]. Quality Assurance and Safety of Crops & Foods, 2015, 7(5): 737-745.

[16] SANGSUWAN J, RATTANAPANONE N, RACHTANAPUN P. Effect of Chitosan/Methyl Cellulose Films on Microbial and Quality Characteristics of Fresh-Cut Cantaloupe and Pineapple[J]. Postharvest Biology and Technology, 2008, 49(3): 403-410.

[17] VENKATACHALAM K, LEKJING S. A Chitosan-Based Edible Film with Clove Essential Oil and Nisin for Improving the Quality and Shelf Life of Pork Patties in Cold Storage[J]. RSC Advances, 2020, 10(30): 17777-17786.

[18] HE Li, ZOU Li-kou, YANG Qian-ru, et al. Antimicrobial Activities of Nisin, Tea Polyphenols, and Chitosan and their Combinations in Chilled Mutton.[J]. Journal of food science, 2016, 81(6): 1466-1471.

[19] CEGIELSKA-RADZIEJEWSKA R, SZABLEWSKI T, RADZIEJEWSKA-KUBZDELA E, et al. The Effect of Modified Lysozyme Treatment on the Microflora, Physicochemical and Sensory Characteristics of Pork Packaged in Preservative Gas Atmospheres[J]. Coatings, 2021, 11(5): 488.

[20] CHEN Chen, HU Wen-zhong, ZHANG Rui-dong, et al. Levels of Phenolic Compounds, Antioxidant Capacity, and Microbial Counts of Fresh-Cut Onions after Treatment with a Combination of Nisin and Citric Acid[J]. Horticulture, Environment, and Biotechnology, 2016, 57(3): 266-273.

[21] OLADUNJOYE A O, SINGH S, IJABADENIYI O A. Biocontrol of Listeria Monocytogenes ATCC 7644 on Fresh-Cut Tomato () Using Nisin Combined with Organic Acids[J]. Food Science and Biotechnology, 2016, 25(5): 1491-1496.

[22] 范飞, 陈玉鹏, 周洁, 等. ε–聚赖氨酸盐酸盐改性PVA/LDPE 复合薄膜对砀山梨保鲜效果[J]. 北方园艺, 2022(5): 97-103.

FAN Fei, CHEN Yu-peng, ZHOU Jie, et al. Fresh-Keeping Effect of Ε-Polylysine Hydrochloride Modified PVA/LDPE Composite Film on Dangshan Pears[J]. Northern Horticulture, 2022(5): 97-103.

[23] 孙新城, 胡旭阳, 许素月, 等. 噬菌体裂解酶在食品安全领域的研究进展[J]. 食品安全质量检测学报, 2021, 12(24): 9415-9421.

SUN Xin-cheng, HU Xu-yang, XU Su-yue, et al. Research Progress of Phage Lyase in the Field of Food Safety[J]. Journal of Food Safety & Quality, 2021, 12(24): 9415-9421.

[24] MIAO E A, MILLER S I. Bacteriophages in the Evolution of Pathogen–Host Interactions[J]. Proceedings of the National Academy of Sciences of the United States of America, 1999, 96(17): 9452-9454.

[25] COBIÁN GÜEMES A G, YOULE M, CANTÚ V A, et al. Viruses as Winners in the Game of Life[J]. Annual Review of Virology, 2016, 3: 197-214.

[26] WITTEBOLE X, DE ROOCK S, OPAL S M. A Historical Overview of Bacteriophage Therapy as an Alternative to Antibiotics for the Treatment of Bacterial Pathogens[J]. Virulence, 2014, 5(1): 226-235.

[27] CULOT A, GROSSET N, GAUTIER M. Overcoming the Challenges of Phage Therapy for Industrial Aquaculture: A Review[J]. Aquaculture, 2019, 513: 734423.

[28] YANG Yu-fan, DU Hu, ZOU Geng, et al. Encapsulation and Delivery of Phage as a Novel Method for Gut Flora Manipulation in Situ: A Review[J]. Journal of Controlled Release, 2023, 353: 634-649.

[29] SLOPEK S, DURLAKOWA I, WEBER-DABROWSKA B, et al. Results of Bacteriophage Treatment of Suppurative Bacterial Infections. Ⅱ. Detailed Evaluation of the Results[J]. Archivum Immunologiae et Therapiae Experimentalis, 1983, 31(3): 293-327.

[30] HUANG Yuan-ling, WANG Wen-hui, ZHANG Zhi-hao, et al. Phage Products for Fighting Antimicrobial Resistance[J]. Microorganisms, 2022, 10(7): 1324.

[31] HAGENS S, LOESSNER M J. Bacteriophage for Biocontrol of Foodborne Pathogens: Calculations and Considerations[J]. Current pharmaceutical biotechnology, 2010, 11(1): 58-68.

[32] 尹德凤, 张莉, 张大文, 等. 生鲜肉类产品中腐败细菌研究[J]. 农产品质量与安全, 2018(3): 21-29.

YIN De-feng, ZHANG Li, ZHANG Da-wen, et al. Study on Spoilage Bacteria in Fresh Meat Products[J]. Quality and Safety of Agro-Products, 2018(3): 21-29.

[33] ABULADZE T, LI Man-rong, MENETREZ M Y, et al. Bacteriophages Reduce Experimental Contamination of Hard Surfaces, Tomato, Spinach, Broccoli, and Ground Beef byO157: H7[J]. Applied and Environmental Microbiology, 2008, 74(20): 6230-6238.

[34] TOMAT D, MIGLIORE L, AQUILI V, et al. Phage Biocontrol of Enteropathogenic and Shiga Toxin-Producingin Meat Products[J]. Frontiers in Cellular and Infection Microbiology, 2013, 3: 20.

[35] SEO J, SEO D J, OH H, et al. Inhibiting the Growth of Escherichia Coli O157: H7 in Beef, Pork, and Chicken Meat Using a Bacteriophage[J]. Korean Journal for Food Science of Animal Resources, 2016, 36(2): 186-193.

[36] SHEBS-MAURINE E L, GIOTTO F M, LAIDLER S T, et al. Effects of Bacteriophages and Peroxyacetic Acid Applications on Beef Contaminated with Salmonella during Different Grinding Stages[J]. Meat Science, 2021, 173: 108407.

[37] KIM S, KIM B S, BAI J, et al. Antibacterial κ-Carrageenan/Konjac Glucomannan-Based Edible Hydrogel Film Containing Salmonella Phage PBSE191 and Its Application in Chicken Meat[J]. LWT, 2023, 180: 114707.

[38] ÖZGÜL A D, HAMZA A, ZELIHA Y. Biocontrol of Salmonella Enteritidis on Chicken Meat and Skin Using Lytic SE-P3, P16, P37, and P47 Bacteriophages[J]. LWT, 2020, 137: 110469.

[39] ISHAQ A, EBNER P D, SYED Q A, et al. Employing List-Shield Bacteriophage as a Bio-Control Intervention forfrom Raw Beef Surface and Maintain Meat Quality during Refrigeration Storage[J]. LWT, 2020, 132: 109784.

[40] YANG S, SADEKUZZAMAN M, HA S D. Reduction ofon Chicken Breasts by Combined Treatment with UV-C Light and Bacteriophage ListShield[J]. LWT, 2017, 86: 193-200.

[41] ABHISINGHA M, DUMNIL J, PITAKSUTHEEPONG C. Efficiency of Phage Cocktail to Reduce Salmonella Typhimurium on Chicken Meat during Low Temperature Storage[J]. LWT, 2020, 129: 109580.

[42] 钱蓓蕾, 徐捷, 顾润润, 等. 噬菌体对虾仁中单核细胞增生李斯特菌的抑制效果[J]. 食品与发酵工业, 2011, 37(12): 62-65.

QIAN Bei-lei, XU Jie, GU Run-run, et al. Effects of Phage Treatment on Growth and Survival of Listeria Monocytogenes in Shrimp Meat[J]. Food and Fermentation Industries, 2011, 37(12): 62-65.

[43] XU Dong-qin, JIANG Yan-hua, WANG Lian-zhu, et al. Biocontrol ofTyphimurium in Raw Salmon Fillets and Scallop Adductors by Using Bacteriophage SLMP1[J]. Journal of Food Protection, 2018, 81(8): 1304-1312.

[44] SHEBS E L, LUKOV M J, GIOTTO F M, et al. Efficiency of Commercial Bacteriophages on Stec O157: H7 Populations in Beef Kept under Vacuum and Aerobic Conditions[J]. Meat and Muscle Biology, 2019, 3(2): 131.

[45] SUKUMARAN A T, NANNAPANENI R, KIESS A, et al. Reduction ofon Chicken Breast Fillets Stored under Aerobic or Modified Atmosphere Packaging by the Application of Lytic Bacteriophage Preparation SalmoFreshTM1[J]. Poultry Science, 2016, 95(3): 668-675.

[46] WANG Chang-bao, YANG Jie, ZHU Xiao-yu, et al. Effects ofBacteriophage, Nisin and Potassium Sorbate and Their Combination on Safety and Shelf Life of Fresh Chilled Pork[J]. Food Control, 2017, 73: 869-877.

[47] PELYUNTHA W, VONGKAMJAN K. Combined Effects ofPhage Cocktail and Organic Acid for ControllingEnteritidis in Chicken Meat[J]. Food Control, 2022, 133: 108653.

[48] YANG S, SADEKUZZAMAN M, HA S D. Treatment with Lauric Arginate Ethyl Ester and Commercial Bacteriophage, Alone or in Combination, Inhibitsin Chicken Breast Tissue[J]. Food Control, 2017, 78: 57-63.

[49] CUI Hai-ying, YUAN Lu, LIN Lin. Novel Chitosan Film Embedded with Liposome-Encapsulated Phage for Biocontrol ofO157: H7 in Beef[J]. Carbohydrate Polymers, 2017, 177: 156-164.

[50] CHOI I, YOO D S, CHANG Y, et al. Polycaprolactone Film Functionalized with Bacteriophage T4 Promotes Antibacterial Activity of Food Packaging Toward[J]. Food Chemistry, 2021, 346: 128883.

[51] TOMAT D, SOAZO M, VERDINI R, et al. Evaluation of an WPC Edible Film Added with a Cocktail of Six Lytic Phages Against Foodborne Pathogens such as Enteropathogenic and Shigatoxigenic[J]. LWT, 2019, 113: 108316.

[52] GOUVÊA D M, SANTOS MENDONÇA R C, LOPEZ M E S, et al. Absorbent Food Pads Containing Bacteriophages for Potential Antimicrobial Use in Refrigerated Food Products[J]. LWT - Food Science and Technology, 2016, 67: 159-166.

[53] 吴玲玲, 李艳芬, 邱正勇, 等. 2015年河南省预包装熟肉制品生产加工过程的污染状况调查[J]. 卫生研究, 2017, 46(5): 834-836.

WU Ling-ling, LI Yan-fen, QIU Zheng-yong, et al. Investigation on Pollution Status of Prepackaged Cooked Meat Products in Henan Province in 2015[J]. Journal of Hygiene Research, 2017, 46(5): 834-836.

[54] Lei Li. The Harm of Microorganisms in Low Temperature Meat Products and Its Control Technology[C]// 2018 International Conference on Medicine, Biology, Materials and Manufacturing (ICMBMM 2018). Francis Academic Press, 2018: 112-115.

[55] 戴莹, 宋海勇, 吴曦, 等. 肉制品中生物胺的形成、检测和控制研究进展[J]. 肉类研究, 2020, 34(11): 89-97.

DAI Ying, SONG Hai-yong, WU Xi, et al. Recent Progress in the Formation, Detection and Control of Biogenic Amines in Meat Products[J]. Meat Research, 2020, 34(11): 89-97.

[56] SOFFER N, WOOLSTON J, LI Man-rong, et al. Bacteriophage Preparation Lytic for Shigella Significantly Reduces Shigella Sonnei Contamination in Various Foods[J]. PloS one, 2017, 12(3): 0175256.

[57] PERERA M N, ABULADZE T, LI Man-rong, et al. Bacteriophage Cocktail Significantly Reduces or EliminatesContamination on Lettuce, Apples, Cheese, Smoked Salmon and Frozen Foods[J]. Food Microbiology, 2015, 52: 42-48.

[58] SIRDESAI S, ERACLIO G, PETERSON R, et al. Efficiency of Phage Intervention on Salmonella Kill on Lean Pork, Pork Trim and Bacon[J]. Meat and Muscle Biology, 2018, 2(2): 157.

[59] DEVLIEGHERE F, VERMEIREN L. Efficacy of Phage P100 on L. Monocytogenes in Refrigerated Vacuum Pack-aged Cooked Ham[J]. Fleischwirtschaft, 2019, 99: 92-95.

[60] RADFORD D, GUILD B, STRANGE P, et al. Characterization of Antimicrobial Properties ofPhage Felix O1 andPhage A511 Embedded in Xanthan Coatings on Poly(lactic acid) Films[J]. Food Microbiology, 2017, 66: 117-128.

[61] FIGUEIREDO A C L, ALMEIDA R C C. Antibacterial Efficacy of Nisin, Bacteriophage P100 and Sodium Lactate Againstin Ready- to-Eat Sliced Pork Ham[J]. Brazilian Journal of Microbiology, 2017, 48(4): 724-729.

[62] KHASHAYAR S, ZHANG Li-li, SOLEIMANI D A, et al. Effective Control of Shigella Contamination in Different Foods Using a Novel Six-Phage Cocktail[J]. LWT, 2021, 144: 111137.

[63] PARK H, KIM J, KIM M, et al. Development of New Strategy Combining Heat Treatment and Phage Cocktail for Post-Contamination Prevention[J]. Food Research International, 2021, 145: 110415.

[64] ANSAH F A, AMODIO M L, COLELLI G. Quality of Fresh-Cut Products as Affected by Harvest and Postharvest Operations[J]. Journal of the Science of Food and Agriculture, 2018, 98(10): 3614-3626.

[65] 丛聪, 袁玉玉, 王丽丽, 等. 噬菌体在食品应用中的安全性[J]. 国外医药(抗生素分册), 2019, 40(5): 410-419.

CONG Cong, YUAN Yu-yu, WANG Li-li, et al. The Safety of Bacteriophage in Food Applications[J]. World Notes on Antibiotics, 2019, 40(5): 410-419.

[66] GIANNAKOUROU M C, TSIRONI T N. Application of Processing and Packaging Hurdles for Fresh-Cut Fruits and Vegetables Preservation[J]. Foods, 2021, 10(4): 830.

[67] LEVERENTZ B, CONWAY W S, ALAVIDZE Z, et al. Examination of Bacteriophage as a Biocontrol Method foron Fresh-Cut Fruit: A Model Study[J]. Journal of Food Protection, 2001, 64(8): 1116-1121.

[68] LÓPEZ-CUEVAS O, MEDRANO-FÉLIX J A, CASTRO-DEL CAMPO N, et al. Bacteriophage Applications for Fresh Produce Food Safety[J]. International Journal of Environmental Health Research, 2021, 31(6): 687-702.

[69] 张元嵩, 金昌海, 杨振泉. 噬菌体源天然抑菌剂在中央厨房食品安全控制中的应用[J]. 美食研究, 2021, 38(3): 67-74.

ZHANG Yuan-song, JIN Chang-hai, YANG Zhen-quan. Application of Bacteriophages from Natural Antimicrobial Agents on Controlling Food Quality and Safety in Central Kitchen[J]. Culinary Science Journal of Yangzhou University, 2021, 38(3): 67-74.

[70] 杨园平, 潘旬, 雷智栋, 等. 鲜切苦菊、生菜和紫甘蓝上假单胞菌的分离鉴定及其噬菌体的初步筛选[J]. 现代食品科技, 2022, 38(1): 126-133.

YANG Yuan-ping, PAN Xun, LEI Zhi-dong, et al. Isolation and Identification of Pseudomonas Spp.from Fresh-Cut Chrysanthemum, Lettuce, and Purple Cabbage and Preliminary Screening of Their Phages[J]. Modern Food Science & Technology, 2022, 38(1): 126-133.

[71] ZHOU Wen-yuan, SUN Si-fan, ZHANG Yuan-song, et al. Isolation and Characterization of a Virulent Bacteriophage for ControllingEnteritidis Growth in Ready-to-Eat Mixed-Ingredient Salads[J]. Journal of Food Protection, 2021, 84(9): 1629-1639.

[72] 张羽嘉, 薛宇, 高璐, 等. 小肠结肠炎耶尔森氏菌噬菌体的分离鉴定及在鲜切蔬菜中的靶向抑菌作用[J]. 美食研究, 2019, 36(2): 43-47.

ZHANG Yu-jia, XUE Yu, GAO Lu, et al. Isolation and Identification of Yersinia Enterocolitica Phage and Its Antibacterial Effect in Fresh-Cut Vegetables[J]. Culinary Science Journal of Yangzhou University, 2019, 36(2): 43-47.

[73] 龙门, 詹歌, 金双潮, 等. JS25噬菌体生物特性及对食品中致病菌的生物防治[J]. 农业工程学报, 2016, 32(22): 303-308.

LONG Men, ZHAN Ge, JIN Shuang-chao, et al. Biological Properties of Bacteriophages and Biocontrol Ofstaphylococcus Aureus in Foods[J]. Transactions of the Chinese Society of Agricultural Engineering, 2016, 32(22): 303-308.

[74] ISLAM M S, ZHOU Yang, LIANG Lu, et al. Application of a Broad Range Lytic Phage LPST94 for Biological Control of Salmonella in Foods[J]. Microorganisms, 2020, 8(2): 247.

[75] LUO Dan-dan, LI Cheng-si, WU Qing-ping, et al. Isolation and Characterization of New Phage vB_CtuP_A24 and Application to ControlSPP. in Infant Milk Formula and Lettuce[J]. Food Research International, 2021, 141: 110109.

[76] SHAHIN K, BAO Hong-duo, ZHU Shu-jiao, et al. Bio-Control of O157: H7, and Colistin-Resistant MCR-1-PositiveUsing a New Designed Broad Host Range Phage Cocktail[J]. LWT, 2022, 154: 112836.

[77] EL-DOUGDOUG N K, CUCIC S, ABDELHAMID A G, et al. Control ofNewport on Cherry Tomato Using a Cocktail of Lytic Bacteriophages[J]. International Journal of Food Microbiology, 2019, 293: 60-71.

[78] WITTE S, HUIJBOOM L, KLAMERT S, et al. Application of Bacteriophages EP75 and EP335 Efficiently Reduces Viable Cell Counts ofO157 on Beef and Vegetables[J]. Food Microbiology, 2022, 104: 103978.

[79] OLADUNJOYE A O, OYEWOLE S A, SINGH S, et al. Prediction ofATCC 7644 Growth on Fresh-Cut Produce Treated with Bacteriophage and Sucrose Monolaurate by Using Artificial Neural Network[J]. LWT - Food Science and Technology, 2017, 76: 9-17.

[80] BOYACIOGLU O, SHARMA M, SULAKVELIDZE A, et al. Biocontrol of Escherichia Coli O157: H7 on Fresh-Cut Leafy Greens[J]. Bacteriophage, 2013, 3(1): 24620.

[81] HONG Y P. Combining of Bacteriophage and G. Asaii Application to Reduce L. Monocytogenes on Fresh-Cut Melon under Low Temperature and Packing with Functional Film[J]. Journal of Food and Nutrition Sciences, 2015, 3(1): 79.

[82] OLADUNJOYE A O, SINGH S, IJABADENIYI O A. Trisodium Phosphate Enhanced Phage Lysis ofGrowth on Fresh-Cut Produce[J]. LWT, 2017, 86: 312-317.

[83] OLIVEIRA M, ⅥÑAS I, COLÀS P, et al. Effectiveness of a Bacteriophage in Reducingon Fresh-Cut Fruits and Fruit Juices[J]. Food Microbiology, 2014, 38: 137-142.

[84] CUI Hai-ying, BAI Mei, YUAN Lu, et al. Sequential Effect of Phages and Cold Nitrogen Plasma AgainstO157: H7 Biofilms on Different Vegetables[J]. International Journal of Food Microbiology, 2018, 268: 1-9.

Research Progress on Application of Phage Preservation Technology in Prepared Vegetables

FENG Shan-hong, ZHONG Le, CHENG Ping, XIAO Nai-yu, ZHANG Xue-qin, XIAO Geng-sheng,ZHOU Jin-xian

(1. College of Light Industry and Food Engineering, Zhongkai University of Agriculture and Engineering, Guangzhou 510225, China; 2. Guangdong Province University Central Kitchen Green Manufacturing Development Center, Guangzhou 510225, China; 3. Lingnan Special Food Green Processing and Intelligent Manufacturing Key Laboratory, Ministry of Agriculture and Rural Affairs, Guangzhou 510225, China)

The work aims to summarize the application of phage preservation technology in prepared vegetables, and to provide a basis for food safety protection of prepared vegetables and application research of phage. Based on the food safety of prepared vegetables, the prepared vegetables were classified, and the application of phage biological prevention and control of animal and plant-derived ingredients was mainly discussed. The analysis showed that the application of phage in prepared vegetables had a wide application prospect and value. Phage could effectively control food-borne bacterial contamination in prepared vegetables, maintain food quality and extend shelf life. In order to improve the antibacterial effect of phage, it could be considered from the concentration and stability of phage and its combination with physical preservation methods or biological and chemical preservatives. To realize the wide application of phage in prepared vegetables, it is necessary to improve the screening efficiency and stability of phage, and formulate corresponding standards and norms to improve the acceptability of consumers and promote the popularization and application of phage in the domestic market. Therefore, the use of phage preservation technology can not only extend the shelf life of prepared vegetables and improve food safety, but also bring more development opportunities for the food industry.

phage; prepared vegetables; food-borne bacteria; biological prevention and control

TS201.6

A

1001-3563(2023)09-0028-09

10.19554/j.cnki.1001-3563.2023.09.004

2023−03−02

2021年“广东省科技大专项”河源市科技计划项目(2021006)

冯珊红(1999—),女,硕士生,主攻抗菌保鲜。

钟乐(1984—),男,博士,副教授,主要研究方向为功能包装材料。

责任编辑:曾钰婵