A review on solidification of alloys under hypergravity

2023-03-30FngjieYouXinboZhoQunzhoYueYuefengGuJihuiWngHongbinBeiZeZhng

Fngjie You, Xinbo Zho,b,*, Qunzho Yue,**, Yuefeng Gu,b, Jihui Wng,c,Hongbin Bei, Ze Zhng,b

a Institute of Superalloys Science and Technology, School of Materials Science and Engineering, Zhejiang University, Hangzhou, 310027, China

b State Key Laboratory of Silicon and Advanced Semiconductor Materials, Zhejiang University, Hangzhou, 310027, China

c Polytechnic Institute, Zhejiang University, Hangzhou, 310027, Zhejiang, China

Keywords:Hypergravity Solidification Alloys Grain refinement Convection Segregation

A B S T R A C T A comprehensive and integrated review of the hypergravity field applied to solidifying alloys is provided.The hypergravity field refers to an environment in which the acceleration of gravity is more significant than the gravitational acceleration through rotation, resulting in significant changes in the solidification behavior of the alloy.The convection mode of the melt is closely related to the level and direction of hypergravity.Obvious floatation or sedimentation of solutes and crystals of different densities is induced.Columnar-to-equiaxed transition, grain refinement, and gradients in composition and microstructure are readily available under hypergravity.Furthermore, the nucleation and growth of crystals and their migration under enhanced convection are gradually revealed through simulations and in-situ observations.This review aims to summarize the universal law of the effect of the hypergravity field on the composition distribution and microstructure evolution of alloys during solidification.Based on the development of hypergravity equipment and characterization methods, it is expected to broaden the theoretical framework of hypergravity solidification.To provide a theoretical reference for developing new solidification processes and high-performance materials.

1.Introduction

In recent years,the need to generate high-performance materials has driven the improvement of traditional processes and the exploration of new technologies.Among them,the application of the hypergravity field provides an additional degree of freedom for materials processing.By enhancing melt flow,heat and mass transfer during solidification[1],the hypergravity field affects nucleation and growth of crystals, thus changing microstructure and properties.Firstly, the theoretical framework of solidification can be extended by coupling the hypergravity field,temperature field and solute field.The melting point and solid solubility of the alloy may change due to the pressure of centrifugal force and Coriolis force [2].Second, unstable structures under conventional conditions may exist in the hypergravity field,allowing the development of materials with unique properties.Under the action of hypergravity, the composition and structure show a continuous gradient distribution in space,so that the material has the desired properties in a specific region[3,4].Taking Al/Al2O3composite tubes as an example, Al2O3particles were distributed in a gradient along the direction of hypergravity [5].The area in the outer layer had higher mechanical properties and wear resistance, and was suitable for the automotive field.Based on the characteristics of hypergravity solidification,it is possible to develop new preparation technologies with energy saving and high throughput.

The mass transfer and micro-mixing of the multiphase flow were strongly enhanced due to the high-speed rotation of the liquid phase in the hypergravity field [1,6,7].Therefore, hypergravity technology has attracted wide interest in separation, absorption, rectification, nanoparticle preparation of materials and so on [8-10].The solidification of alloys is a common but complex process.The microstructures and thermophysical properties in liquid metals, nucleation of crystals, microstructure evolution, and solute segregation [11], which have received much attention,can undergo unexpected changes in hypergravity fields.Details of the multiphase flow motion during solidification in the hypergravity field are provided in the early centrifugal casting.However,heating and centrifugation processes are separated in most centrifugal casting technologies, and a deep understanding of the interaction between the hypergravity field and the solidification is far from being realized [12].Based on fully understanding the effect of hypergravity,the relationship between hypergravity,temperature,microstructure and properties is established by regulating melt flow,heat and mass transfer,and liquid-solid interface morphology.At the same time,the construction of the special hypergravity equipment platform, as well as the development of the corresponding characterization technology and calculation method are urgently needed.This review aims to summarize the phenomenon and mechanism of hypergravity technology in solidification and discuss the challenges and prospects for future development.

2.Hypergravity technology

2.1.Principle of hypergravity technology

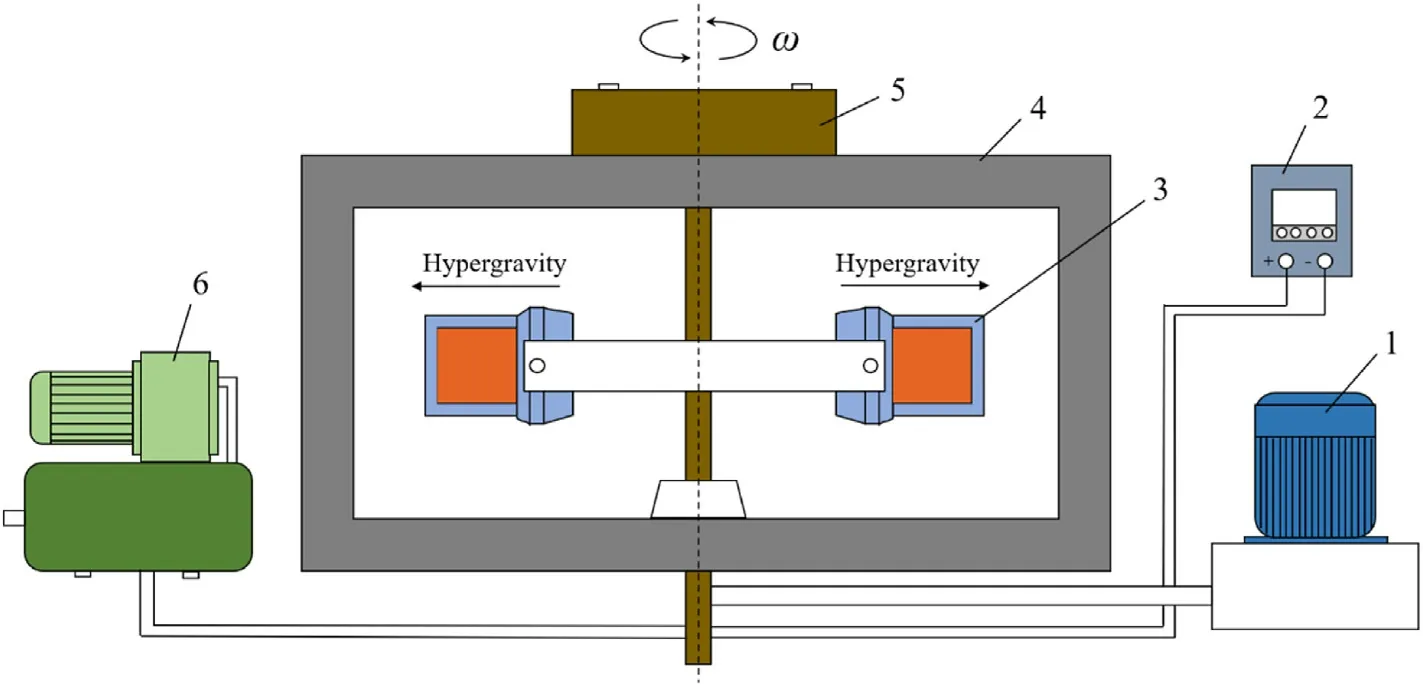

Hypergravity refers to the force(including gravitation and repulsion)on an object in an environment where the acceleration of gravity is much larger than the gravitational acceleration [1].The principle of hypergravity technology is to facilitate the unique flow behavior of fluid in a multiphase system to enhance the mass transfer and micro-mixing process greatly.It is possible to simulate a hypergravity environment on the earth by generating a centrifugal acceleration environment through high-speed rotation.The rotation equipment that implements a hypergravity environment is called “hypergravity” (HiGee).The HiGee can process liquid-gas, liquid-solid two-phase media and even gas-liquid-solid three-phase media according to different requirements.And due to the characteristics of enhanced mass transfer and micro-mixing, the hypergravity technology has broad application prospects in various fields.Take the liquid-solid reaction in HiGee as an example(Fig.1),the solidification of alloys in the hypergravity field can be realized in a special bucket.Therefore, the influence of hypergravity and temperature on the solidification microstructure of alloys are gained.

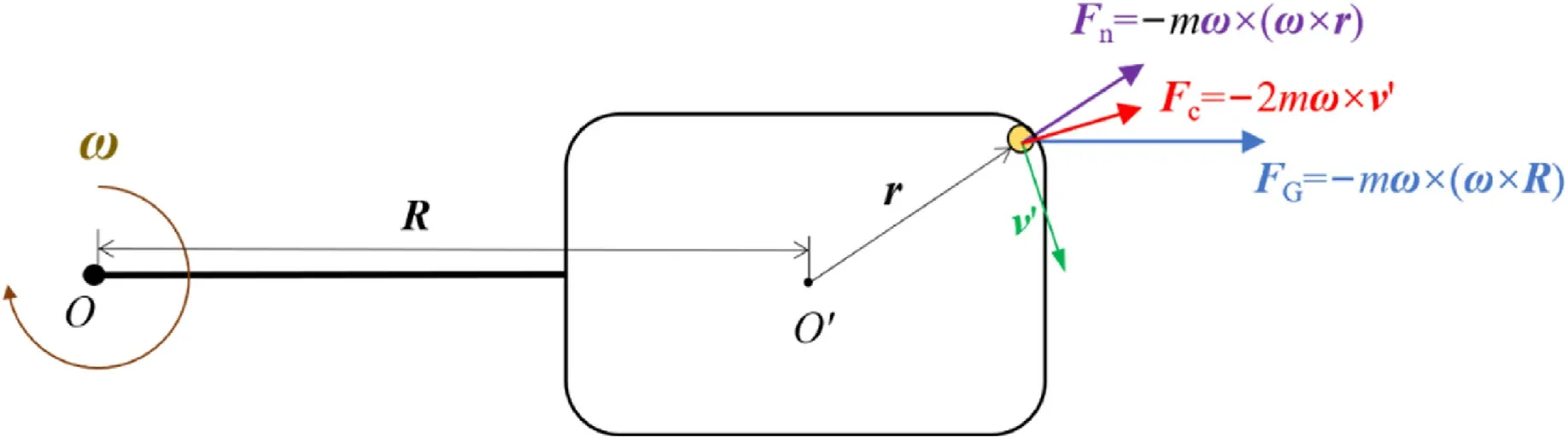

The ideal hypergravity acceleration is a constant value, but the hypergravity field obtained by high-speed rotation was curved and uneven [13-15].The governing equation of a moving particle in HiGee running at a constant rotational speed via Eq.(1)[16]:

where m is the mass of the particle,F is the external force,here refers to terrestrial gravity, ω is the rotational angular velocity vector, R is the rotation radius vector between the rotation axis O and the center of the experimental chamber O',r is the position vector between the position of the particle and O',v′is the velocity vector of the particle relative to the experimental chamber.The linearly-distributed hypergravity is - mω×(ω × R), which is the focus of this review.The nonlinearly-distributed centrifugal force is - mω×(ω × r).In addition,the particle moving in hypergravity equipment would also be affected by the Coriolis force, -2mω×v′,proportional to its movement speed,that is,the Coriolis effect[17].The external force F is small relative to hypergravity, so it is neglected in the experiment.Experimental results were usually complex and unclear because Coriolis acceleration and nonlinearly-distributed centrifugal acceleration were affected by equipment size and testing parameters[18,19].The schematic diagram of the force on the particle in a HiGee running at a constant speed is shown in Fig.2.This review focuses on the influence of hypergravity on the solidification of alloys.

The intensity of the hypergravity field is evaluated by the gravity coefficient G, which is the ratio of centrifugal acceleration to normal gravitational acceleration via Eq.(2):

where G is the gravity coefficient,g is the gravitational acceleration,N is the rotating speed.The increase of G results from the increase of N and R,leading to the change of motion mode of matter.The core scientific challenge facing hypergravity research is how to quantitatively characterize the threshold of the hypergravity effect and construct the corresponding characterization methods.

2.2.History of hypergravity technology

The application of centrifugal fields in the industry has a history of more than 100 years and the research of centrifugal fields in enhancing mass transfer began to attract industry's attention in the late 1970s.The rotating device with a rotor filled with high specific surface area materials such as glass beads,wire mesh and poly tetra fluoroethylene fibers was first proposed by Ramshaw et al.of the Imperial Chemical Industries(ICI)in 1979 to promote mass transfer among the phases[20].And in the following years, several new patents called “HiGee” [21-23] were published.Since then, hypergravity technology has aroused widespread interest in academia and industry.In 1983, ICI [24] reported for the first time that an industrial-scale HiGee apparatus was used for the separation of ethanol and isopropanol and benzene and cyclohexane, and it had successfully operated for thousands of hours,which was proved to be the feasibility of this technology in industrial applications.

In the early development of hypergravity technology, including separation [8,25,25-28], wastewater treatment [29] and gas purification[30], mainly focused researchers' attention.The liquid overcomes the surface tension under the action of enormous shearing force, strengthening the mass transfer,which benefits the separation process.In 1994,hypergravity technology was creatively applied to prepare nanoparticles,which opened up a new field of hypergravity technology application[31].The hypergravity technology can prepare nanomaterials with controllable particle size and small particle distribution.In addition to inorganic materials such as calcium carbonate, the synthesis of nanocomposites and nanomedicine can also apply hypergravity technology[32].Compared with traditional industrial equipment,the HiGee has the advantages of high efficiency, low cost, small equipment size, maintenance and easy operation, which are very useful for industrial applications such as metallurgy,energy, medicine and environment, etc.

Fig.1.Schematic diagram of HiGee: 1, rotation controller; 2, temperature controller; 3, experiment chamber; 4, housing; 5, lifting controller; 6, vacuum system.

Fig.2.Schematic diagram of the force on the particle in a HiGee.

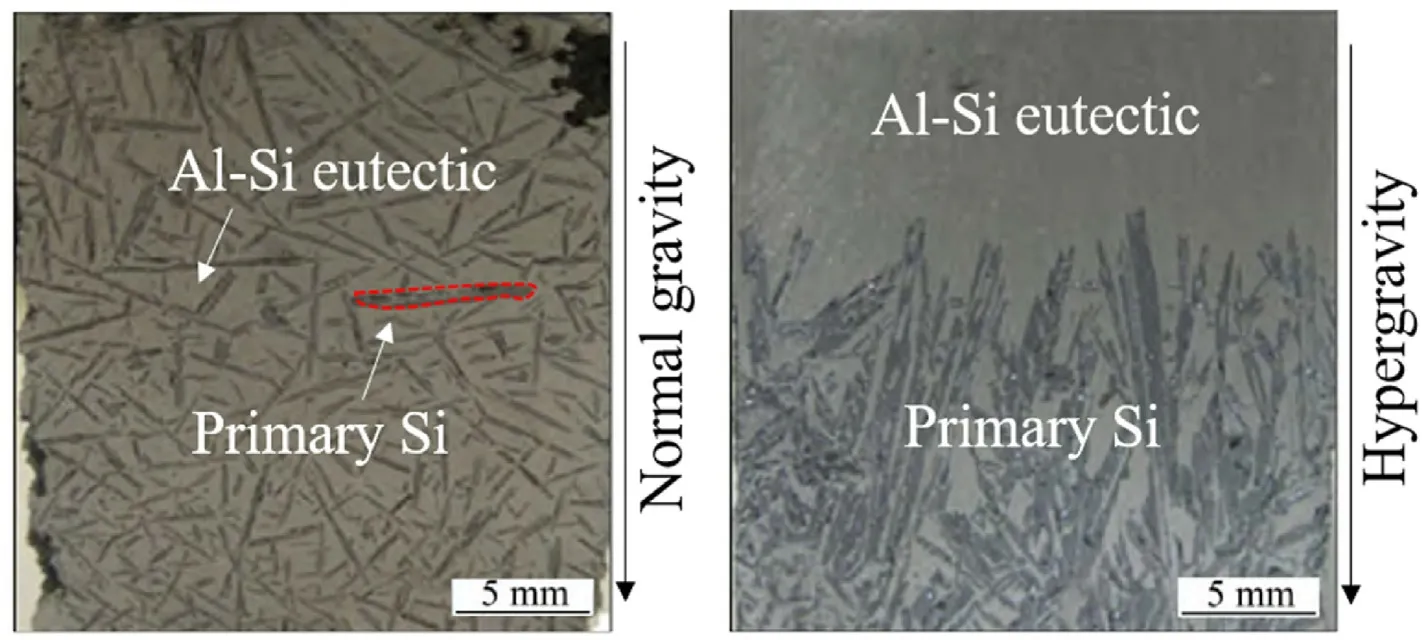

In metallurgy,hypergravity technology is applied to purify melt and improve solidification microstructure.The influence of buoyancy in the hypergravity field is greatly enhanced, causing the relative movement among phases with different densities.Primary phases or inclusions will be concentrated on one side under hypergravity to achieve purification.The primary Si with a purity of more than 99.9%was obtained from the Al-Si melt at G=403 for 3 h and T=1473 K(Fig.3)[33].Song et al.[34]investigated the removal of inclusions in the aluminum melt in the hypergravity field and found the removal efficiencies exceeded 90%at G≥50, t = 2 min and T = 973 K.However, these previous results of separation under hypergravity were mainly based on the presence of solute gradients or secondary phases (crystals, inclusions, etc.) in the high-temperature melt [35].Stronger hypergravity may be required to separate solutes of different densities from the homogeneous melt.

In addition, centrifugal casting is a hypergravity technology widely applied in industrial production.The alloy castability can be improved by pouring the liquid metal into a rotating mold.More importantly, functionally graded materials with gradually changing properties can be prepared by mixing the second phase with molten metal.Rajan et al.[36]synthesized Al356-SiC composites at about 60 g using horizontal centrifugal casting equipment (Fig.4a).SiC particles were distributed in a continuous gradient from the outer to inner periphery of the casting(Fig.4b and c).The maxmium of 45 vol% SiCp in the outer periphery enhanced the surface hardness and wear resistance.However, it is still difficult to directly relate the hypergravity field and the solidification microstructure, especially the influence of the mold, such as mold size,material, preheating temperature, etc., must be taken into account.In recent years, with the development of numerical simulations, in-situ observations, and hypergravity equipment, discussions on the thermodynamics and kinetics of the hypergravity solidification process have become more in-depth[37,38].

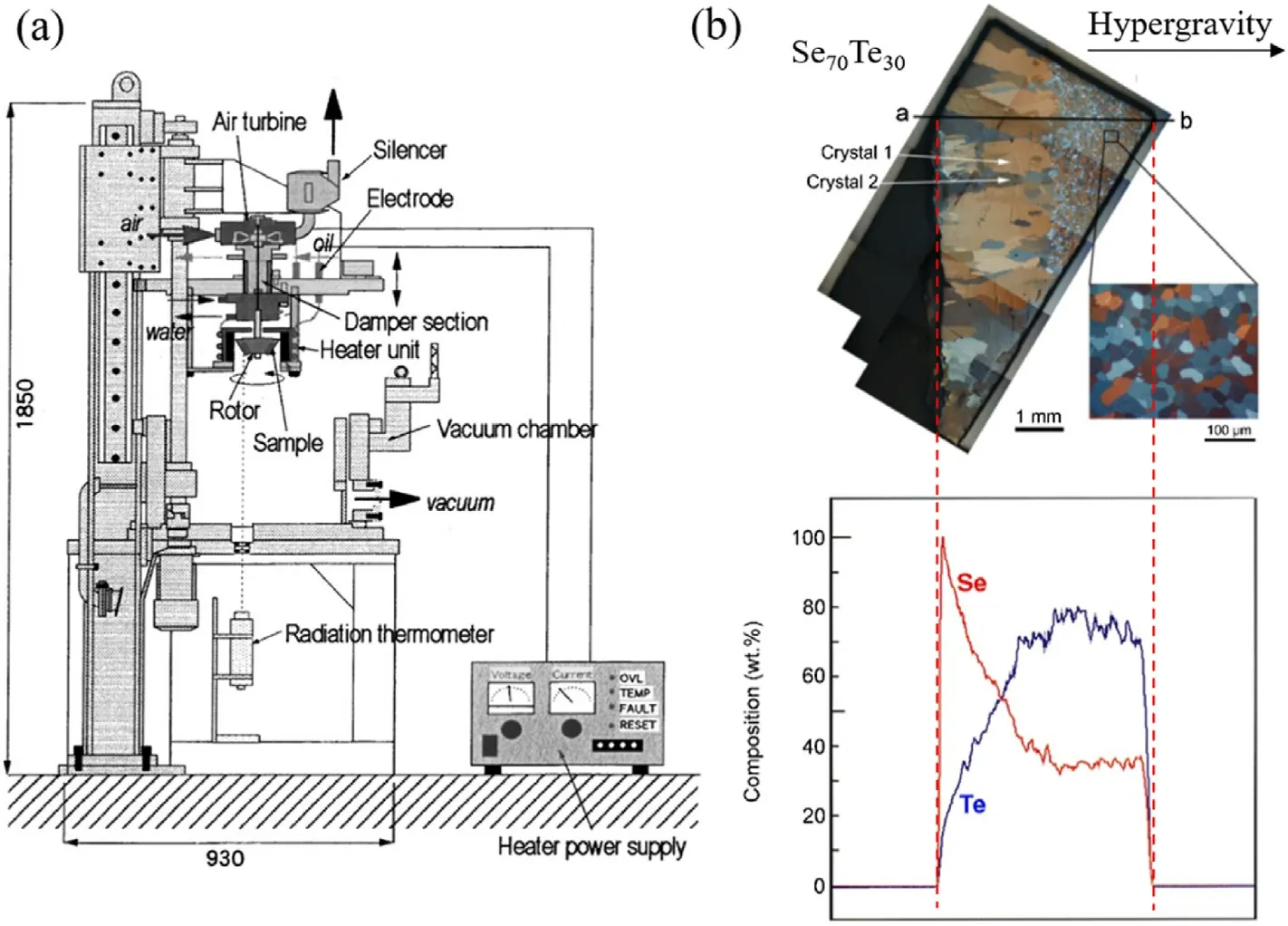

In addition to solidification,a linear gradient structure along the direction of gravity could be formed in the solid under an ultra hypergravity field of over 106g level, via the equipment shown in Fig.5a[40-42].A hypergravity field of about 106g was applied to Se70Te30at a temperature of 533 K for 100 h,and the resulting grains and composition were shown in Fig.5b[41].The grains of started materials with a size of 1-2 μm were replaced by coarse grains (several millimeters long and hundreds of microns wide)in low gravity regions and small grains(tens of microns) in hypergravity regions.Composition gradients also appeared in low gravity regions along the direction of hypergravity.Hypergravity-induced diffusion occurred when the gravitational potential was comparable to the chemical potential,and seemed to be related to the behavior of vacancies [43]: the level of hypergravity acting on different positions of the sample differs, and the resulting vacancy concentration is diverse.Vacancies moved to low gravity regions and deposited there to increase the values of the diffusion coefficients.Meanwhile, as the direction of gravity changes, the interdiffusion coefficient may be smaller than that under normal gravity.

In general, hypergravity technology has achieved excellent results after decades of development.Due to the unique characteristics of enhanced mass transfer and micro-mixing, the application of hypergravity technology in various fields will bring great benefits.At present,there are still many phenomena and mechanisms of solidification in the hypergravity field waiting to be revealed,and the specialized equipment needs to be improved.As a new external field intensification technology,hypergravity technology has great potential and advantages for application in the solidification of alloys.

Fig.3.Si purification from Al-Si melt by hypergravity technology [33].

Fig.4.Centrifugal cast functionally graded Al356-SiC metal matrix composites [36]: (a) horizontal centrifugal casting equipment; (b) schematic diagram of continuously graded microstructure [39]; (c) graded distribution SiC particle from the outer edge; (d) variation in hardness from the outer edge.

Fig.5.(a) Schematic diagram of the hypergravity equipment [42]; (b) gradients in composition and microstructure [41].

3.Solidification structure in hypergravity fields

Most of the alloys are prepared by liquid-solid phase transformation.Researchers can adjust the solidification structure of the alloy by controlling the solidification structure of the alloy to obtain castings with excellent properties.External fields, such as electric current [44], magnetic field[45]and ultrasonic field[46]have already received extensive attention from researchers due to their influence on the solidification structure.As a kind of external field, the hypergravity fields can also affect the solidification structure of the alloy, especially the grain size,solute redistribution, microstructure morphology and graded microstructure.

3.1.Microstructure morphology

The buoyancy-driven convection is dramatically modified under the effect of the hypergravity field.The result is reflected in the solidification structure, such as the columnar-to-equiaxed transition (CET), eutectic morphology and dendrites in the mushy zone (details in Chapter 4.2),which in turn leads to changes in the properties of the alloy.

In the solidification structure of as-cast alloys,fine-grained equiaxed structures usually lead to materials with a more homogeneous composition field and isotropic mechanical properties.During the solidification process,columnar crystals tend to transform into equiaxed crystals under the action of hypergravity.Therefore,it is necessary to have a clear grasp of the process and mechanism of CET.The microstructure of as-cast Cu-11 wt%Sn under different hypergravity fields is shown in Fig.6 [47].Developed dendrites existed in the normal gravity field in Fig.6a.When the gravity coefficient reached 100, coarse dendrites and equiaxed crystals coexisted, and both the primary and secondary dendrite sizes decreased,as shown in Fig.6b,indicating that CET has occurred.As the gravity coefficient continued to increase in Fig.6c and d, the equiaxed crystal grains tended to be spherical and the size was further reduced while the grain boundaries were gradually clear.

The proposed mechanisms of equiaxed grain formation in a normal gravity field can be grouped into the direct heterogeneous nucleation of equiaxed grains in the bulk liquid and the detachment of dendrites fragments from grains nucleated and growing from the mold walls[48].Considering the significant influence of the hypergravity field on the solidification microstructure, modification of these mechanisms is needed and the details will be discussed together with grain refinement in the next section.

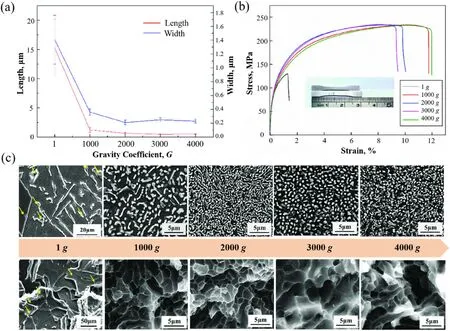

Eutectic structure is an important phase in the solidification microstructure, which always affected by the hypergravity field.The morphology of the Pb-Sn eutectic varied with the level of gravity [49]:lamellar eutectic at 1 g,15 g and cellular dendrite at 5 g,10 g.Yang et al.[50]reported the eutectic cementite in the hypergravity field was refined compared with that in a normal gravity field.Gan et al.[51]investigated the effects of hypergravity fields(3000 g)and modifiers on eutectic Si in etched Al-Si alloys as shown in Fig.7.The needle-shaped eutectic Si under a normal gravity field were refined into fine bars under an enhanced hypergravity field.Moreover, the synergistic effect of hypergravity and modifiers has been observed to have a much stronger refinement effect on eutectic Si than a single effect.Furthermore,the size and organization of eutectic Si under different hypergravity fields are shown in Fig.8a and c [52].All four hypergravity fields refined the eutectic Si, significantly increasing tensile strength and elongation(Fig.8b).The typical brittle fracture occurred on the fracture surface under normal gravity(Fig.8c),and the crack sources were concentrated in primary Si and eutectic Si.Under hypergravity, a large number of dimples on the fracture surface of the sample indicated the occurrence of ductile fracture,and the cracks propagated along the Si/Al interface due to a large amount of refined and uniformly distributed eutectic Si.For polycrystalline Cu-0.5Sn alloy, as the hypergravity coefficient increases to 1000, the continuous refinement of grains led to the simultaneous increase of strength and plasticity [53].All in all, the refinement of the solidification structure by the hypergravity field provides a way to improve the strength and plasticity of the alloy at the same time.The research on the mechanical properties and mechanism of alloys in the hypergravity field still needs to be completed.

3.2.Grain refinement

As the significant phenomenon of alloy solidification, the grain refinement of castings has been widely reported previously [54].Zhao et al.[55] used the Bridgman technique to study the eutectic Pb-Sn solidified under different gravity levels and found that as the gravity coefficient increased, the size of the eutectic cell decreased.The trend of grain refinement is related to the level of gravity:only change the gravity level,when the gravity coefficient is small,the degree of grain refinement is low but the rate of change with gravity is large.Compared with no centrifugation, the average grain diameter of Cu-based alloy decreased from 88-125 μm to 44-62 μm when the centrifugal speed was 100 r·min-1[56].As the gravity coefficient increases,the grain size continues to decrease but at a slower rate.The grain diameter of Al-Ni-Cr alloy reached the minimum value under the gravity coefficient of G = 3000 and larger grain size was observed under a larger intensity of hypergravity field [57].

In the meantime,the studies on the refinement mechanism have not yet reached a unified conclusion.Investigation of the published papers reveals that there are four possible mechanisms contributing to the grain refinement during solidification under a hypergravity field,including the change of nucleation free energy mechanism [58], the change of hydrostatic pressure mechanism [59], the dendrite fragments mechanism[60,61], and the "Crystal Rain" mechanism [47,62].These mechanisms work at different stages of solidification and different gravity levels, as shown in Fig.9.

Fig.6.Microstructure of as-cast Cu-11 wt%Sn in normal gravity and hypergravity fields: (a) G = 1; (b) G = 100; (c) G = 300; (d) G = 600 [47].

Fig.7.Microstructure and distribution of the eutectic Si in Al-Si alloys [51].

Fig.8.Microstructure and tensile properties of Al-Si alloys in hypergravity fields: (a)length and width of eutectic Si;(b)tensile stress-strain curve;(c) solidification microstructure and tensile fracture surface [52].

Fig.9.Grain refinement mechanisms in hypergravity fields: non-experimental results in blue areas; experimental results in orange areas.

The change of nucleation free energy occurred under a hypergravity field,according to the calculation results[62].The large intensity of the hypergravity (more than 50000 g) was enough to create a significant solubility difference between the two sides of the droplet in the melt,relating to the static pressure difference generated by the hypergravity field [63].Under the assumption that the change of nucleation free energy was due to the increase in hydrostatic pressure, Zhao et al.[61]calculated ΔGG, the change of nucleation Gibbs free energy caused by hypergravity(less than 1000 g)and compared the value with the value of ΔGV,the solid-liquid difference of Gibbs free energy per unit volume.The result demonstrated that the absolute value of ΔGGis much smaller than ΔGV,which indicates the change of nucleation rate caused by ΔGGis not significant enough to achieve the grain refining at low gravity.

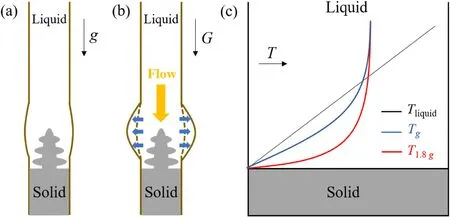

The explosive nucleation of Al-20 wt%.Cu alloys was observed when the gravity level increased rapidly from 1 g to 1.8 g, which meant the natural convection requiring a longer response time was not the formation mechanism [59].The enhanced gravity led to an increase in hydrostatic pressure, which then caused the crucible at the solid-liquid interface to deform (Fig.10a and b).Finally, the solute-poor liquid flowed towards the columnar front, resulting in constitutional undercooling (Fig.10c) [59].Equiaxed dendrites were easier to form and promote grain refinement in this case.The material's strength,toughness,fatigue resistance,and hardness can thus be optimized.

However, both previous mechanisms have limitations: changes in nucleation free energy had a significant effect on grain size only at extremely high levels of gravity (more than 104g), and this cannot explain grain refinement at low levels of gravity.The hydrostatic pressure mechanism described the explosion nucleation under extremely low gravity(1.8 g),but the experimental results were affected by the material of the crucible,and it is difficult to explain the solidification in a stronger gravity field.Moreover,most of the HiGees cannot reach the gravity level of 105g,so a more general mechanism is needed.

By contriving casting conditions,the fragments produced by dendrite fragmentation are potent nucleation seeds, and then grain refinement appears.This process can be enhanced under external fields, such as electromagnetic stirring [64] and ultrasound [65].The strong influence of gravity level on dendrite fragmentation has been directly observed[59,66], but evidence of how dendrites are affected under a large hypergravity field is still lacking.Based on the effect of forced convection on dendrites,the author hypothesized that dendrite fragmentation in the hypergravity field was mainly related to the remelting of dendrites,shearing effect of forced convection on dendrites,and the stability of the connection between dendrites and branches [67].Driven by forced convection in the hypergravity field, the solute-rich liquid was transported to the dendrite root in the mushy zone,which lowered the melting point of the solid-liquid interface and led to the remelting of the dendrite root [68,69].The initial fragment, which was less dense than the surrounding liquid,was transported to the columnar front as it grew.In this process, the fragment consumed the solvent atoms from the interdendritic liquid,leading to the enrichment of solutes and the formation of a self-reinforcement process [68].In addition, dendrite fragments may arise from the impact of enhanced convection on dendrites.The maximum liquid velocity was 5 mm/s at 20 g(0.1 mm/s at 1 g),according to the simulation [70].However, even at 10 mm/s, the shear force exerted by forced convection on the dendrite root did not reach 1%of the yield stress[71].Therefore,this mechanism may play an important role in higher hypergravity fields.Thirdly, the faster the growth rate of a dendrite, the more fragile the junction between the dendrite and branches was and the easier it was to break[72,73].It has been reported that the dendrite growth rate was strongly affected by gravity level[74].In short,these mechanisms depended on the strength and orientation of hypergravity fields and solute fields, for which there is limited information.

Fig.10.Variation of liquid undercooling ahead of the solid-liquid interface due to fluid flow induced by the change in hydrostatic pressure in the melt with respect to hypergravity [59].

Considering the actual solidification condition, the coexistence of free-chill crystals and the dendrite fragments mechanism proposed by Chang et al.[60] seems to be more reasonable.As heat transfer was promoted at the position close to the cold mold[75],a large number of crystals nucleated due to large undercooling.Subsequently, under the combined action of the severe convection and turbulence produced by the hypergravity field, the crystals detached from the mold wall, and were broken or remelted into fragments into the flowing melt,resulting in lots of nuclei.

The dendrite fragmentation mechanism explained the origin of the nuclei under larger hypergravity.However, it was found that the application of the hypergravity field at different stages of solidification could cause the position of the fine grain zone to shift.Therefore,it is necessary to explore the movement of grains in the hypergravity field.Yang et al.[47,62] reported the “Crystal Rain” mechanism in the early stage of solidification was the main reason for grain refinement and focused on the movement of crystals in the melt.The radial velocity of particles in viscous liquid under centrifugal force,Vr,can be expressed according to Stokes’law[76]:

where d is the diameter of the particle;ρland ρpare the densities of the liquid and particle; G is the gravity coefficient; g is the gravitational acceleration;η is the apparent viscosity.

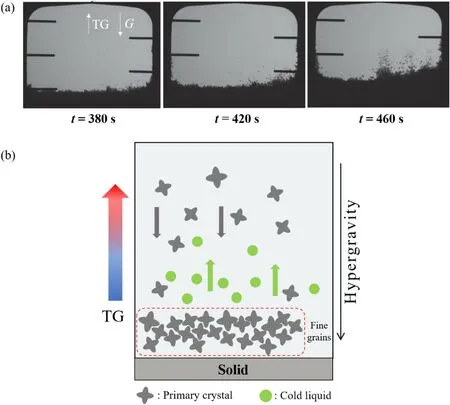

Therefore,obvious floatation or sedimentation of crystals appears in a hypergravity field due to the large gravity coefficient.The solidification of the Neopentylglycol-(D)Camphor alloy in a hypergravity field of 10 g was observed by in-situ optical systems(Fig.11a)[77].The direction of hypergravity is downward,and the constant temperature gradient(TG)is upward.When crystallization began, the sedimentation of denser primary crystals immediately occurred along the direction of hypergravity.Correspondingly, the lighter liquid in the region of strong hypergravity moved in the opposite direction.Since this liquid was cooler than the surroundings,many crystals nucleated close to the initial region,leading to a self-reinforcing process, as shown in Fig.11b.Grain refinement in hypergravity fields occurred at an early stage in solidification,as shown in Fig.12b and c [62].The coarse grains shown in Fig.12a and d indicated the solidification structure could not be refined at the complete liquid stage or the completely solidified stage under a hypergravity field.At the end of solidification,due to possible density changes between the solid and liquid, the crystals tended to move in the opposite direction.However,the large fraction of solid and established dendrite connections prevented the crystals from moving freely.

Fig.11.(a) in-situ images of the solidification of the Neopentylglycol-(D)Camphor alloy at 10 g [77]; (b) schematic diagram of “Crystal Rain” mechanism.

Fig.12.Macrostructures of Al-8wt%Cu alloy after applying a hypergravity field of G =800 at different solidification stages [62]: (a)at the high-temperature liquid stage; (b)starts at the onset of solidification and ends when the solid fraction reaches 20 wt%;(c)starts once the solid fraction reaches 80 wt% and ends when solid fraction reaches 100 wt%; (d) at the completely solidified stage.The red frame is the fine crystal area.

As a complex process, grain refinement may be caused due to fixed mechanism or a synergistic effect of several mechanisms in a specific environment.The change of nucleation free energy mechanism had a significant effect only in the ultra-large hypergravity field, which required the HiGee with a higher rotational speed or a longer arm length.The crucible limits the degree of grain refinement in the hydrostatic pressure mechanism.And the violent and complex convection seemed to be more influential in the hypergravity field.In addition, the modifiers may distribute homogeneously under hypergravity, leading to stronger grain refinement, but details of the mechanism are lacking [51,78].We believe that the dendrite fragments mechanism and the "Crystal Rain"mechanism play a major role in the hypergravity field.Both explained the origin and movement of grains in the early stages of solidification.Most current research focuses on binary or ternary alloys and the appearance of larger grains under a larger hypergravity field lacks theoretical support.The development of HiGee and corresponding characterization methods also limits further research.Therefore,in-depth research is still needed to give decisive evidence for these grain refinement mechanisms.

3.3.Graded microstructures

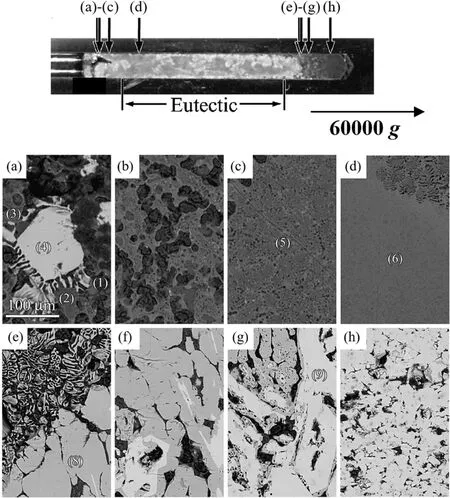

Graded materials have gradual composition and microstructure in a certain direction,leading to a gradient in performance.Chemical vapour deposition (CVD) [79], thermal spray [80], laser deposition [81] and many other methods have been successfully used to prepare gradient materials, and the hypergravity field can also play the same role.In a hypergravity field of 60000 g,the microstructure of metallic glass with a composition of Mg56Al30Li7Cu7appeared clear stratification along the direction of hypergravity [82]: In the low gravity regions (Fig.13a and b)), the microstructure was mainly dominated by primary phases with low density.In the middle of the sample (Fig.13c and d)), ternary and binary eutectics made up the majority of the sample (70% of the total volume).Heavy Cu-rich microstructures dominated those regions under hypergravity(Fig.13e-h).The solidification sequence can be determined by applying the hypergravity field to the solidification of the alloy,therefore it is used to explore the influence of various elements on the eutectic temperature and provide guidance for developing new bulk metallic glasses[82,83].

4.Convection and segregation in hypergravity fields

4.1.Convection mode

The solidification of the alloy and the melt flow are strongly coupled,which is reflected in the solute discharged during the primary crystal crystallization process may induce solute convection, which in turn can affect the solute redistribution in the boundary layer and the mushy zone[84,85].Therefore, a clear understanding of the interaction between convection and solidification plays a very important role in controlling the microstructure of the metal, which can control the properties of the final casting.The influence of convection under the earth's gravity on the solidification structure has been extensively studied, as well as the microgravity experiments[38,86].The flow pattern of the melt exhibits different behaviors under enhanced gravity.The results can be characterized by a dimensionless number,the Rayleigh number Ra[87]:

where b is the resultant acceleration(vectorial sum of gravitational acceleration and centrifugal acceleration);α is the thermal volumetric expansion coefficient;ΔT is the temperature gradient;h is the height of the columnar melt;ν is the kinematic viscosity;κ is the thermal diffusivity.Considering that the small tilting angles between the gravitational acceleration and centrifugalaccelerationhadlittle effecton Ra[88],the variationtrendof Ra was consistent with the magnitude of centrifugal acceleration.Therefore,according to formulas(2)and(4),Ra was demonstrated significant positive correlation with the gravity coefficient G.No flow occurred with a small Ra by adjusting the resultant acceleration b to varify Ra.The onset of steady flow was observed when Ra exceeded the critical value Raa1.With Ra increasing,temperature fluctuations and unsteady convection were found when Ra reached the second critical value Raa2.The steady laminar flow appeared again as Ra continued to increase,eventually convection became unstable at very high values of Ra[87].

Fig.13.Optical micrograph and backscattered SEM images of Mg56Al30Li7Cu7 taken from different regions.(1):(Li,Mg)solid solution,(2):(Mg,Li)solid solution,(3):primary Al12Mg17,(4): primary Al49Mg37Cu14,(5): Cu-poor binary eutectic, (6):fine ternary eutectic, (7):Cu-rich coarse binary eutectic, (8):primary Al49Mg37Cu14,(9): primary Al9Mg7Cu4 [82].

In the directional solidification experiment, convection could be divided into parallel convection and anti-parallel convection according to the relative direction of gravity and temperature gradient.However,parallel convection was always unstable, resulting in a high degree of mixing and reduced segregation[89].Anti-parallel convection was more stable, but the radial temperature gradient could cause convection to induce macro-segregation[89-91].These melt flows are subject to centrifugal acceleration and Coriolis acceleration, which have long been studied in the growth of crystals in centrifugal systems [92].Unlike centrifugal forces which enhanced buoyant convection,there was still no unified conclusion about the effect of Coriolis force on convection.In anti-parallel convection,the Coriolis force was the cause of radial solute homogenization and contributed to flow instability at higher centrifugal speeds.On the other hand, Coriolis force had a stabilizing effect on convection in parallel convection [93].The Rossby dimensionless number Ro is the ratio of inertia and Coriolis force,describing the degree to which the system is affected by the Coriolis force, and is defined as follows[94]:

Table 1 The value of Rossby number Ro and parameters ω,Uref at different gravity levels[94].

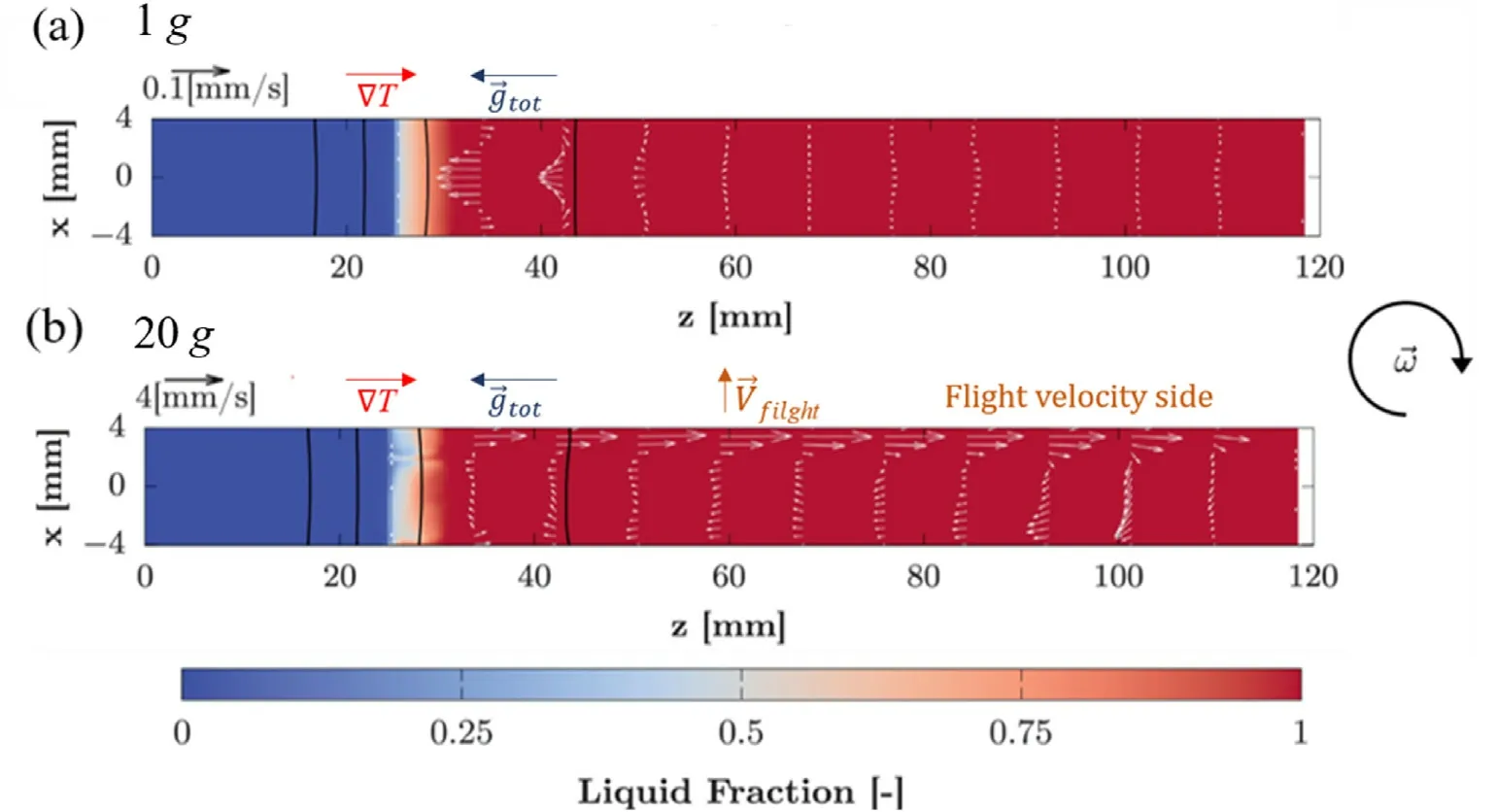

where Uref, ω, L are the reference velocity, magnitude of the centrifuge angular velocity,and characteristic length.The reference velocity Urefis the average of the maximum velocity in the main plane of study at various instants.Under all experimental conditions, the Rossby number Ro≪1 as shown in Table 1,indicated that the Coriolis force completely determined the convection mode.Fig.14 indicates the deflection effect of Coriolis force on liquid flow clearly.The thermal buoyancy induced by the temperature gradient explained the convection mode in the normal gravity field,as shown in Fig.14a.Driven by the violent solute buoyancy in case 20 g,the solute-rich liquid was deflected to the flight velocity side by Coriolis force and returned to the mushy zone on the opposite side(see Fig.14b) forming a large circulation.However, the results of the nondimensional consideration [95] indicated that the ratio of Coriolis force to buoyancy force depended on the length of the centrifugal arm and had nothing to do with the centrifugal speed.The completely symmetrical convection at the gravity level from 1 g to 20 g suggested that the Coriolis force did not affect the fluid flow significantly.

4.2.Dendrite growth in the mushy zone

The convection mode in the scale of the entire sample length in the hypergravity field has been discussed in the previous section.Furthermore, the interaction of the convection and the microstructure in the mushy zone in different gravity conditions lead to changes in the dendrite growth,which is usually studied under directional solidification conditions.

When an axial hypergravity field was applied,the different directions of the gravityvector causeddifferent solute migration directions,resulting in differences in dendrite morphology and primary dendrite arm spacing(PDAS).In addition,the migration process was also related to the relative density of the solute.Taking the Ti-Al alloy as an example,when the direction of the gravity vector was parallel to the solidification direction(also thedirectionof dendritegrowth),Themeltflow movedfromthefully liquid region to the dendrite tips in the mushy zone[74,96],as shown in Fig.15 (+5 g, +15 g), which was defined as the downward convection.When the direction of the gravity vector was anti-parallel to the solidification direction (-1 g to -5 g in Fig.15), the convection moved in the opposite direction, which was defined as upward convection.Faster average velocity occurred in upward convection, which was unstable.When the gravity level was between-5 g and-15 g,the convection situation was more complicated,with the evolution of branched structures.

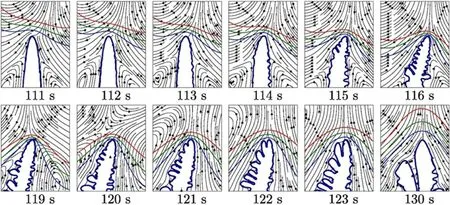

The results also revealed that convection could affect the tip velocity by controlling the thickness of the boundary layer.In downward convection, the increased gravity level meant a smaller boundary layer thickness and a larger concentration gradient,resulting in faster dendrite growth.Similarly,the increased gravity level in upward convection led to a slower tip velocity.In addition,the PDAS was found to be increasing in the case of downward convection.As for upward convection, the unstable convection induced tip splitting,and the branched structures led to a decrease in PDAS.Fig.16[72]details the tip splitting process of a single dendrite.It should be noted that the adjustment of the dendrite growth direction and the number of splitting events increased with the increase of gravity level and convective velocity.It is worth mentioning that for the Al-Cu alloy, the effect of gravity on PDAS obtained by in-situ experiments and numerical simulation was different [90,97].Therefore,the dendrite growth under hypergravity fields needs more strong evidence to verify the simulation results, especially the directional solidification experiments.

4.3.Macrosegregation in hypergravity fields

Macrosegregation refers to the change of composition on the length scale of the casting size,and this phenomenon originates from the mass transfer process in the solidification process [85,98-101].The mass transfer process is affected by the coupling of multiple mechanisms such as thermosolutal convection due to density change caused by the coupling of temperature and composition, solid fragments movement and forced convection caused by external fields[102].Increased gravity intensified the mass transfer process and strengthened the macrosegregation.Fernˊandez et al.[94] found the segregation channels enriched with aluminum appeared on the flight velocity side (Fig.17)due to the deflection effect of the Coriolis force in the hypergravity field.There are three possible mechanisms to explain the macrosegregation phenomenon under hypergravity as following.

Fu et al.[103] believed that atomic clusters with different densities were formed in the melt.Under the action of centrifugal force, these atomic clusters moved to both ends respectively along the centrifugal force axis and were enriched.However,the size of atomic clusters in the melt was extremely small, usually at the nanometer level [104,105].Yang et al.[106] assumed the Cu atomic clusters in the Al-Cu alloy as particles and calculated the movement of the Cu atomic clusters in a hypergravity field of 1000 g according to Stokes’ law.This assumption ignored the effect of Brownian motion and assumed that the atomic clusters were stable.Even so,the Cu atomic cluster with a diameter of 1 nm only moved 1.241 μm after 25 min,which was a very small distance relative to the entire sample length.Therefore, the atomic clusters mechanism was not the main cause of macrosegregation.

The movement of primary crystals under intensified convection in the hypergravity field might also cause macrosegregation [107].Regarding the preparation of eutectic Al-Al2Cu by a centrifugal in-situ method, it was found that although there was a gradient microstructure,the primary Al and Al2Cu phases did not exist [3].Yang et al.[62] assumed that in high-concentrated Al-Cu alloys (Al-11 wt%Cu and Al-15 wt%Cu) and low-concentrated Al-Cu alloys (Al-4.5 wt%Cu), the primary Al phases could move in the opposite direction.However, the solute Cu in alloys with different compositions were segregated on the same side of the sample.These results indicated that the movement of primary crystals in the hypergravity field could not explained the macrosegregation's appearance.

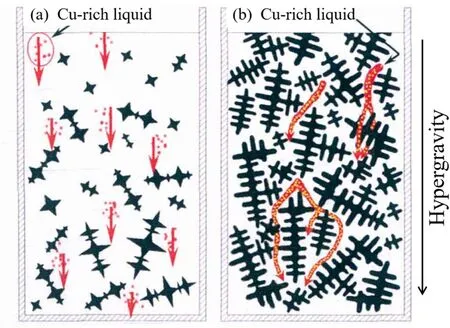

Studies[8,108]proved that liquids tended to form regions rich in one solute and another, regardless of the existence of a hypergravity field.When studying Al-Al2Cu alloys [3], it was believed that Cu-rich and Al-rich regions might appear in the melt during the early stage of solidification with hypergravity field.These areas with different densities from the main melt were separated under centrifugal force,resulting in a composition gradient before the crystallization of the primary phase.This kind of macrosegregation, named “gravity segregation”, was caused by the density difference of the liquid phase and mainly occurs in the early and middle stages of solidification,as shown in Fig.18a.

At the end of solidification, the dendrite network was extremely developed, and only a small amount of liquid remained in the interdendritic zone, so the gravity segregation mechanism was no longer applicable.Under the normal gravity field,the liquid has a high viscosity at this stage and is blocked by dendrites, so it is very difficult to move.However, the liquid existed in the form of film, filament and droplet in the hypergravity field [109,110].Thus, it could pass through the tiny gaps in the interdendrite, as shown in Fig.18b, resulting in “channel segregation”.Yang et al.[25,106] found that only applying a hypergravity field at the end of solidification could also lead to macrosegregation and provided evidence that hypergravity could promote liquid flow in porous media.However, the appearance of channel segregation wasn't observed in the Cu-Sn alloy,possibly due to the grain refinement and the difference in liquid viscosity[47].

5.Summary and perspective

Fig.14.Evolution of the liquid velocity pattern in the main plane of study in the fully liquid region at the solidification time t =200 s for the case: (a) 1 g; (b) 20 g (adapted from Ref.[94]).The main plane consists of the flight velocity vector, V→flight,and the total apparent gravity vector, g→tot (sum of centrifugal acceleration and the gravitational acceleration).Temperature contours in black: 1400, 1450, 1500 and 1550 °C,respectively.The temperature gradient is denoted as ∇T and the centrifuge angular velocity as ω.

Hypergravity technology has been an important field intensification technology in recent decades.High-speed rotation generates a hypergravity field during solidification,which induces obvious changes in the solidification structure of alloys.According to the simulation and experimental results, a deeper understanding of this phenomenon has emerged, and excellent performance of alloys is obtained.This article summarizes the research status of solidification of alloys in the hypergravity field, and the conclusions can be expressed as follows:

1.The columnar-to-equiaxed transition (CET) will appear in the directional solidification experiment under hypergravity, and grain refinement is obvious in the hypergravity field.Grain refinement is the result of the coupling of multiple mechanisms in different situations,of which the mechanism of"Crystal Rain"seems most likely to play a major role.

2.The formation of macrosegregation seems to be closely related to the movement of solute-rich regions under convection in a hypergravity field.It is called "gravity segregation" in the early solidification and"channel segregation"in the middle and late periods of solidification.The macrosegregation becomes more serious as the intensity of the hypergravity field increases,leading to gradient structures.

3.The direction and intensity of the hypergravity field significantly affect the behavior of melt convection during solidification.The melt forms a large circulation in the scale of the entire sample under the coupled action of centrifugal force and Coriolis force.However, the effect of Coriolis force is still inconclusive.

4.Dendrites exhibit different growth patterns in hypergravity fields,such as growth rate and dendrite arm spacing, depending on the convection mode.

Although there have been many valuable studies on solidification under hypergravity, considering the complex interaction of liquid-solid phase change under hypergravity, many unclear scientific and engineering questions remain to be explored as follows.

1.There is a lack of intuitive and ingenious characterization methods for the formation of microstructures and the evolution of convection mode under strong gravity levels(over 100 g).

2.There is no quantitative understanding of the solidification mechanism in the hypergravity field, which makes it difficult to precisely control the microstructure through hypergravity fields.

3.The development of simulation models can well explain the convection of melt and the evolution of the dendrite-scale structure under hypergravity.However, the existing models are two-dimensional,thus the development of three-dimensional models is expected to give a more consistent result with the experimental phenomenon.4

.Most of the existing research stops at hypergravity's effect on the solidification structure.“How to transition from structure to properties” is a question worth considering.

Fig.16.Evolution of a dendrite tip for -5 g [96].Streamlines in black and Al concentration isolines in red (48.8 at.%), green (48.9 at.%), blue (49 at.%).

Fig.17.Relative aluminum segregation×100%for different gravity levels:(a)5 g;(b)10 g;(c)15 g;(d)20 g〈C〉and C0are the averaged solute concentration and nominal composition.Contours at 〈C〉 = C0in black.totis illustrated in Fig.14 [94].

Fig.18.Schematic diagram of (a) gravity segregation mechanism and (b) channel segregation mechanism in the hypergravity field [106].

5.Mass transfer results such as macroscopic segregation and accelerated crystal growth in hypergravity fields are achievable.However, the effect of convective modes on the mechanism of mass transfer processes (e.g.,atomic diffusion)requires more in-depth investigation.

6.The development of more advanced hypergravity equipment can help researchers eliminate other factors and obtain accurate solidification theory.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

This work was jointly supported by the National Natural Science Foundation of China (51988101), the Key Basic Research Program of Zhejiang Province(2020C01002),and the Fundamental Research Funds for the Central Universities(226-2022-00050).

杂志排行

Progress in Natural Science:Materials International的其它文章

- Research progress of composite cathode materials for Solid oxide fuel cells

- Improving mechanical properties of Mg-Sn alloys by co-addition of Li and Al

- Multi-stimuli bilayer hydrogel actuator for remotely controllable transportation of droplets

- The formation and temperature stability of microemulsion emulsified by polyoxyethylene ether surfactant

- Towards high-efficiency of hydrogen purification in metal hydride

- Research advances on electrode materials for solid oxide electrolysis cells