Tailoring Photonic-Engineered Textiles with Butterfly-Mimetic Tertiary Micro/Nano Architectures for Superior Passive Radiative Cooling

2023-03-22HongyuGuoTinyeNiuJinyongYuXueliWngYngSi

Hongyu Guo, Tinye Niu, Jinyong Yu,b, Xueli Wng,b,*, Yng Si,b,*

a State Key Laboratory for Modification of Chemical Fibers and Polymer Materials, College of Textiles, Donghua University, Shanghai 201620, China

b Innovation Center for Textile Science and Technology, Donghua University, Shanghai 201620, China

Keywords:Biomimetic materials Personal thermal management Textiles Passive radiative cooling

ABSTRACT People could potentially mitigate heat discomfort when outdoors by combining passive radiative cooling(PRC) strategies with personal thermal management techniques.However, most current PRC materials lack wearing comfort and durability.In this study,a microarray technique is applied to fabricate the tailoring photonic-engineered textiles with intriguing PRC capability and appealing wearability.The developed radiative cooling textiles (RCTs) demonstrate appropriate air-moisture permeability, structural stability, and extended spectroscopic response with high sunlight reflectivity (91.7%) and robust heat emissivity(95.8%)through the atmospheric transparent spectral window(ATSW).In a hot outdoor cooling test, a skin simulator covered by the RCTs displays a temperature drop of approximately 4.4 °C at noon compared with cotton textiles.The evolution of our mimetic structures may provide new insights into the generation of wearable, thermal-wet comfortable, and robust textiles for exploring PRC techniques in personal thermal management applications.

1.Introduction

With global warming,heat waves are occurring more frequently and with greater intensity[1].Approximately a third of the global population is already exposed to conditions that involve necessary outdoor physical activities and industrial operations, leading to heat stress[2,3].Heat stress not only has physiological and psychological consequences, but also diminishes industrial worker productivity, and in extreme cases, results in immeasurable suffering and loss of life [4].Hence, personal thermal management (PTM)—a strategy that could efficiently regulate the body’s microclimate to ensure thermal comfort in outdoor conditions, is critical [5,6].Active cooling methods are prevalently employed for PTM, which primarily relies on a bulky compression cooling system that consumes substantial amounts of energy and requires access to electricity.A solution to these challenges, however, lies in passive radiative cooling (PRC), which achieves spontaneously cooling through the spectral responsiveness of materials [7].Although recent research has yielded various PRC material designs of PRC materials, including metamaterials [8,9], multilayer dielectrics[10-12],porous media[13-16],and their composites[17,18],there is still much work to be done.The majority of these materials lack flexibility, exhibit weak air-moisture permeability, and possess inadequate durability, rendering them unsuitable for direct use in PTM [6].Therefore, it is highly important to produce a flexible PRC material with outstanding wearability for regulating the microclimate of the human body in outdoor settings [19-21].

A systematic design of the PRC textiles requires the optimization of two important characteristics: high sunlight reflectivity(Rsolar; the wavelength (λ) of 0.3-2.5 μm) [22,23] and strong heat emissivity through the atmospheric transparent spectral window(εATSW; λ of 8-13 μm) [24-27].Meeting the two of these requirements with a single component remains a significant challenge,necessitating the construction of multi-layer composite structures[28-30].Therefore, the hierarchical woven fabrics and multi-layer nanofibrous membranes [31-34], which have acceptable optical properties and adequate PRC properties, make up the majority of the recently disclosed PRC materials for PTM.However,two issues hindered the practical use of cutting-edge PRC textiles: ①The stacking of multi-layer structures reduces the textiles’ airmoisture permeability, making them less comfortable to wear and causing sweat to condense;and ②the weak bonding fastness between the layers of textiles makes it prone to separation during washing and prolonged wearing, resulting in poor durability.We concluded that the predicted answer to these issues is the deliberate development of monolayer PRC textiles.For this principle, we investigated the reported PRC features and were significantly enlightened by the monolayer wing with the fascinating photonic structure of the Sericinus montelus(S.montelus);due to its delicate hierarchical porous structures and intrinsic material characteristics, the wing has a broadband sunlight reflection and great heat dissipation through the atmospheric transparent spectral window(ATSW) [35-39].We thus reason that constructing butterflymimetic monolayer PRC textiles using high mid-infrared (MIR)emittance materials holds great promise for achieving superior PRC properties and wearability in outdoor settings.

Herein,we present a microarray technology to develop tailoring photonic-engineered textiles with butterfly-mimetic structures for effective personal outdoor PRC.An ideal extended spectroscopic response (λ of 0.3-13 μm) is directly provided by the fine tertiary micro/nano structures.The monolayer textiles with through-holes offer gas and water transport channels, ensuring adequate airmoisture permeability while maintaining structural stability.Thus,the resulting radiative cooling textiles(RCTs)exhibit the integrated properties of ideal extended spectroscopic response(Rsolarof 91.7%and εATSWof 95.8%), desirable air permeability, adequate water vapor transmittance,and structural robustness,which are promising candidates for exploring PRC techniques in PTM applications.

2.Material and methods

2.1.Materials

Polyethylene terephthalate (PET) textile was purchased from Gaoyi Yongsheng Textile Co.Ltd.(China).Cellulose triacetate(CTA; polymer), isopropanol, and ammonia were provided by Shanghai Aladdin Biochemical Technology Co.Ltd.(China).CH2Cl2and bromoform were purchased from Shanghai Macklin Biochemical Co.Ltd.(China).SiO2nanoparticles(NPs)were provided by Jingjiang Tonggao Chemical Co.Ltd.(China).Specimen of S.montelus was provided by Shanghai Qiuyu Biotechnology Co.Ltd.(China).

2.2.Preparation of RCTs

We first introduced SiO2NPs to the water in a predetermined quantity(0.5 wt%)and ultrasonically dispersed them for 4 h.Then,the PET textile was immersed in the SiO2NPs dispersion liquid before being stirred and dried.The textile was then completely immersed in the CTA solution (2.3 wt%) in CH2Cl2,and pressure was then applied to drive the liquid into the aperture gap of the textiles.After 30 min,it was quickly transferred to a static humidity (75% ± 2%) environment constructed with a saturated sodium chloride solution.Breath figures formed when moisture touched the cool substrate.After the solvent and condensed water have completely evaporated, orderly homogenous pores are created on the surface.

2.3.Characterization

Xenon lamp (CEL-HXF300-T3; Shanghai Liyi Biotechnology,China) was used to test the cooling performance of S.montelus.Scanning electron microscopy (SEM; VEGA 3 LMU; Tescan, Czech Republic) was used to examine the morphology.The finitedifference time-domain (FDTD) was used to simulate the optical properties of different structures.Ultraviolet (UV)-visible (Vis)-near infrared (NIR) spectrophotometer (UV3600 PLUS; Shimadzu,Japan) and the Fourier transform infrared spectrometer (NEXUS-670; Thermo Fisher Scientific, USA) were used to determine the optical properties.A homemade test box was used to test direct thermal measurements (Supplementary method in Appendix A).A one-dimensional steady-state heat transfer model (Supplementary method) was carried out to calculate the cooling demand of different textiles.A tensile tester (HD026N-300; Nantong Hongda,China)was used to analyze the tensile strength and elongation.To demonstrate the softness of the RCTs, we conducted the bending rigidity tests on the bending rigidity tester (LLY-01; Laizhou Electronic,China).The water vapor transmission(WVT)rate was determined using a textile moisture permeability testing device(YG601H; Ningbo Textile Instrument, China), the air permeability was determined using an air-permeability tester (YG461E; Dongguan Bolade,China),and the hydrophilicity was tested by the contact angle tester (SL150; KINO, USA).The infrared thermal images were taken with an infrared camera (315; FOTRIC, China).The Martindale abrasion tester (YG401-6; Shaanxi Changling Textile,China), washing machine (Y089D; Wenzhou Fangyuan, China),and Dynamic mechanical analyzer (Q850; TA Instruments, USA)were used to investigate the durability of the textiles.

3.Results and discussion

3.1.Biomimetic structure design and fabrication

S.montelus, a butterfly species that lives in East Asia, has two seasonal morphs with fascinating PRC functions for individual thermal regulation [35,40,41].Due to the carefully constructed hierarchical pores on the wing scale,S.montelus exhibits structural whiteness with broadband sunlight reflectance (Fig.1(a)).After 30 min of xenon lamp irradiating (700 W·m-2), the temperature differential (ΔT) between the two regions (white and black) of the wing reached about 8.7 °C, indicating the high sunlight reflectivity of the white parts(Fig.S1(a)in Appendix A).Simultaneously,as illustrated in Fig.S1(b) in Appendix A, we discovered that the wing scale changed from being opaque structurally to almost transparent when it was submerged in the bromoform (a liquid that matches the index of chitin).These findings suggested that the wing’s peculiar microstructure,known as structural whiteness,is responsible for its broad spectrum reflectance.Furthermore,SEM was used to explore the microstructures of the wing scale at several angles.As represented in Fig.1(a) and Fig.S2 in Appendix A,the delicate hierarchical porous structure of the wing scale contained bulges with multiple arrayed micro-pores,raised ridges that run parallel to the pedestal,and grooves that were arranged alongside the ridges.Meanwhile, benefiting from the major component(chitin) of the wing scale with high MIR-absorbance, the wing exhibited high emissivity in ATSW [33].Taking inspiration from this fascinating natural photonic structure,we designed monolayer PRC textiles based on three criteria:①The textiles must be able to effectively reflect sunlight that reduces solar energy gain; ②the textiles must exhibit high emittance through ATSW that evaluates radiative heat loss; and ③the textiles should possess high airmoisture permeability and structural stability.The first two requirements are satisfied by constructing delicate tertiary micro/nano architectures with strong Mie’s scattering and multiple reflections using high εATSWmaterials (CTA and SiO2NPs) [23],which were illustrated to be high MIR absorption/emission materials due to the vibration of C-O bonds [6,27] and Si-O bonds [21].To fulfill the third criterion,we successfully assembled the surface of the tailoring microstructure by microarray technique to robustly embed fine photonic architectures into textiles.

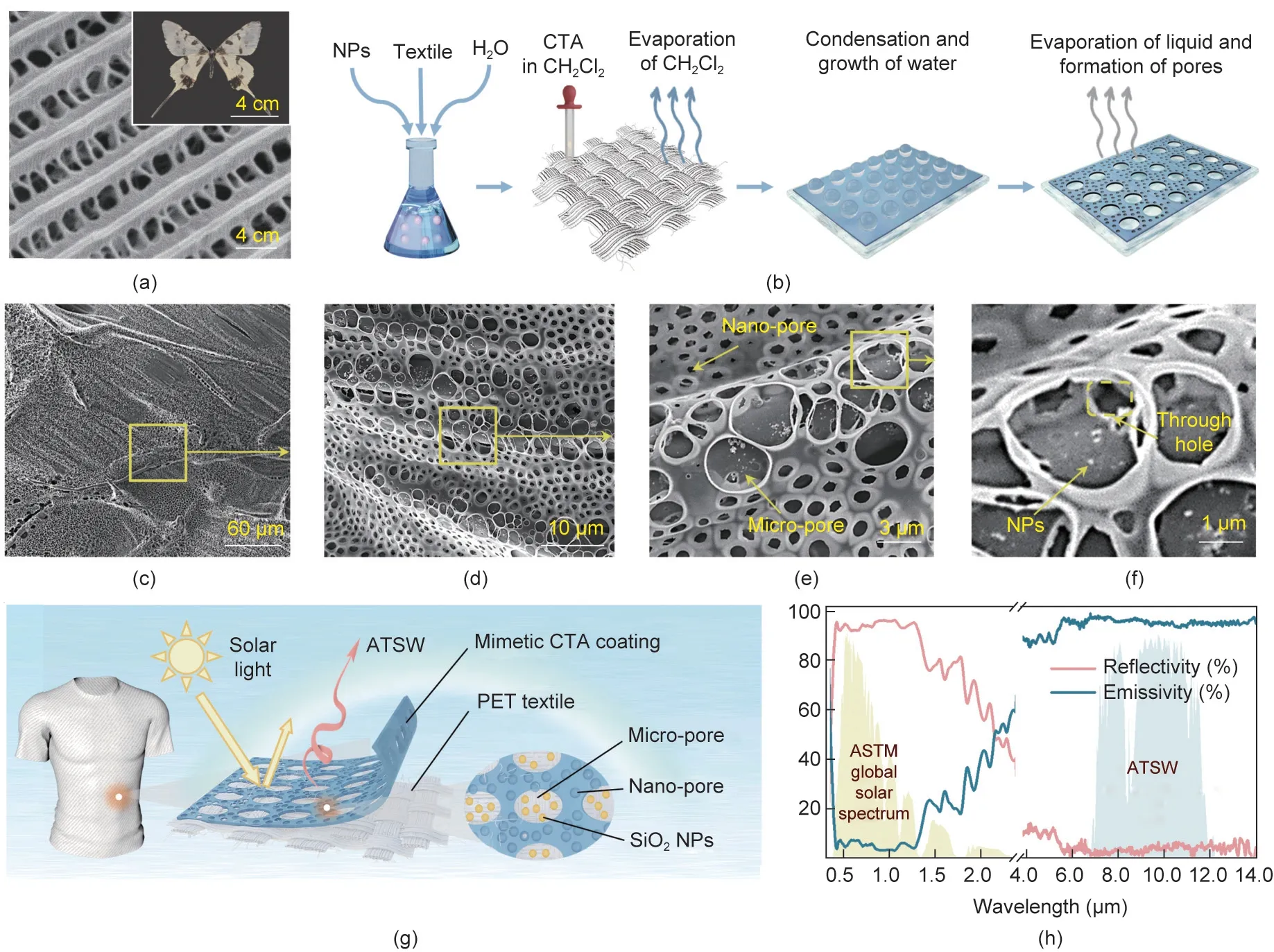

Fig.1.(a)SEM image of S.montelus’wing.The insert shows a photograph of S.montelus.(b)Schematic illustration of the preparation process of the RCTs.(c-f)Morphologies of RCTs with tertiary micro/nano architectures at different magnifications.(g) Schematic illustration of the working principle of the RCTs.(h) Spectral reflectivity and emissivity of the RCTs against normalized American Society for Testing and Materials (ASTM) 1.5 global solar spectrum and the ATSW transmissivity, respectively.

As demonstrated in Fig.1(b), RCTs were fabricated using the static breath figure patterning method, a microarray technique(Supplementary method).The microarray technique started with immersion and ultrasonic of commercial twill PET textiles in SiO2NPs dispersion.Upon drying in air,the dried PET-SiO2textiles were fully soaked into the prefabricated CTA casting solution, and pressure was applied to impose the liquid into the aperture gap of the textiles(Fig.S3 in Appendix A).After 30 min,the textile was quickly moved to a static high-humidity environment.The evaporation of the volatile dissolvent (CH2Cl2), which encourages the condensation and expansion of water droplets,is to blame for a considerable drop in surface temperature.The ΔT between the substrate surface and the droplets gradually diminished and finally disappeared once the substrate surface was entirely covered by the droplets.After the evaporation of CH2Cl2and condensed water,the film finally formed with arranged pore arrays using droplets as a template.Eventually,the bio-inspired tertiary micro/nano architectures formed on the PET textiles,which contain the micro-pores(with an average diameter (davg) of 2.84 μm) arranged on the fibers, nano-pores (davgof 586 nm) ordered between the fibers, and SiO2NPs (davgof 165 nm) randomly distributed throughout the textile structures(Figs.1(c)-(f)).The resulting textiles with a thickness of(582 ± 51) μm presented a desirable extended spectroscopic response (Rsolarof 91.7% and εATSWof 95.8%) benefitting from the tailoring photonic structure,which could effectively lower the solar energy absorption and evaluate the heat emission to the outer space through ATSW (Figs.1(g) and (h)).The photographs of the RCTs, untreated PET textiles, and commercial cotton textiles for comparison were shown in Fig.S4 in Appendix A.

3.2.Optical performance optimization

To promote the PRC properties of the textiles by multi-level structural design and material selection[6],we simulated the optical parameter of the tailoring structures(Fig.2(a)and Supplementary method).Over the wavelength of 0.3-2.5 μm,a material could substantially scatter the light wave with a wavelength near the diameter of the components (particle or pore size) according to Mie’s scattering theory [23].To forecast the scattering ability of the dielectric particles based on their refractive index, the FDTD method was used (Fig.S5 in Appendix A).We estimated and demonstrated that the SiO2NPs with a particle size of 200 nm could scatter most of the sunlight over the wavelengths of 0.3-0.55 μm.Analogously, the scattering property between 0.55 and 2.5 μm was also simulated by evenly distributing holes of various sizes on a 4 μm×4 μm×2 μm CTA pedestal.Since the scattering ability of different apertures varies with wavelength, we proved that the apertures of 0.6 and 3.0 μm could efficiently scatter the Vis and NIR light, respectively.Furthermore, CTA and SiO2were illustrated to be high MIR absorption/emission materials due to the vibration of C-O bonds[6,27]and Si-O bonds[21],which could cooperate to enhance the heat exchange with the cold outer space through ATSW.

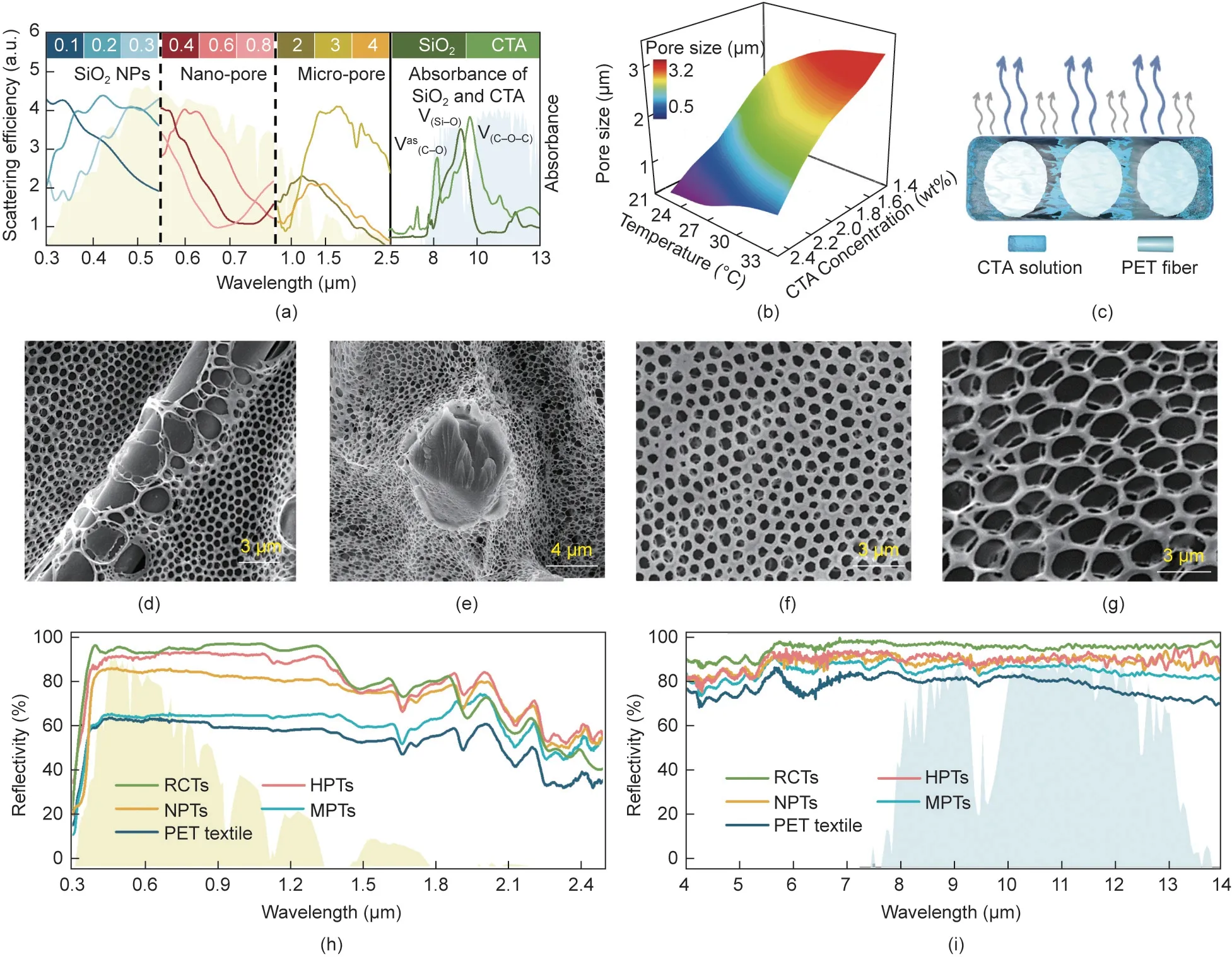

Fig.2.(a) Simulated scattering efficiency of microstructure (SiO2 NPs, nano-pores, and micro-pores) and MIR absorbance of CTA and SiO2.(b) Relationship between the average pore size and the formation parameters(temperature and CTA concentration).(c)Forming mechanism schematic of the hierarchical porous structure.(d)SEM image of the hierarchical porous textiles (HPTs).(e) Cross-sectional SEM image of the HPTs.(f) SEM image of the homogenous nano-porous textiles (NPTs).(g) SEM image of the micro-porous textiles (MPTs).(h) Spectral reflectivity against normalized ASTM 1.5 global solar spectrum.(i) Spectral emissivity against the ATSW transmissivity.

By varying the forming temperature and CTA concentration,we explored the pore size fluctuation in order to accurately build the optimal structure(Fig.2(b)and Fig.S6 and Supplementary discussion in Appendix A).It is interesting to note that,in contrast to earlier studies[42,43],our material had a multi-level porous structure caused by the unevenness of the textile surface.The forming schematic diagram shown in Fig.2(c) and Supplementary discussion indicated that the shallow thickness of the CTA solution on the top of fibers (blue arrows) resulted in faster evaporation rates of CH2Cl2and an earlier emergence of water droplet templates.Thus,with early condensation and longer growth times of water droplets, the micro-pores formed orderly on the top of each fiber.On the contrary, the slower evaporation rate of CH2Cl2between the fibers enabled the formation of several layers of nano-pores(Figs.2(d) and (e), and Fig.S7 in Appendix A).As illustrated in Figs.2(f)and (g), and Fig.S8 in Appendix A, we also constructed orderly homogenous pores with average apertures of 0.53-3.21 μm on the textiles.In the meanwhile, by adjusting the preparation settings,we were able to regulate the CTA coverage area and SiO2concentrations (Figs.S9 and S10, and Supplementary discussion in Appendix A).The optical properties of the different porous structural textiles were illustrated in Figs.2(h) and (i), and Fig.S11 in Appendix A,namely RCTs,HPTs, homogenous NPTs,homogeneous MPTs, and untreated PET textiles.Due to full spectrum Mie’s scattering and multiple reflections, the RCTs exhibited an Rsolarof 91.7%, whereas the Rsolarof HPTs marginally decreased to 88.7%,especially in the UV-Vis wavelength region, as a result of the absence of SiO2NPs.For the textiles with homogeneous porous CTA, the Rsolarof NPTs falls to 81.2%, whereas the Rsolarof MPTs drastically decreases in the UV-Vis wavelength band due to the monolayer micro-porous structure.Moreover, in order to further clarify the reasons for the increase in reflectivity, we normalized the reflectance results against the weight and thickness of the PET substrates (Supplementary discussion, Fig.S12, and Table S1 in Appendix A).According to the emission spectra, all five textiles exhibited high thermal emittances through the ATSW.The ATSW emissivity rises from 80.2% to 95.8% with the addition of CTA and SiO2NPs, demonstrating that the intrinsic characteristics of the materials had a great impact on εATSW.

3.3.Spectrum response mechanism analysis

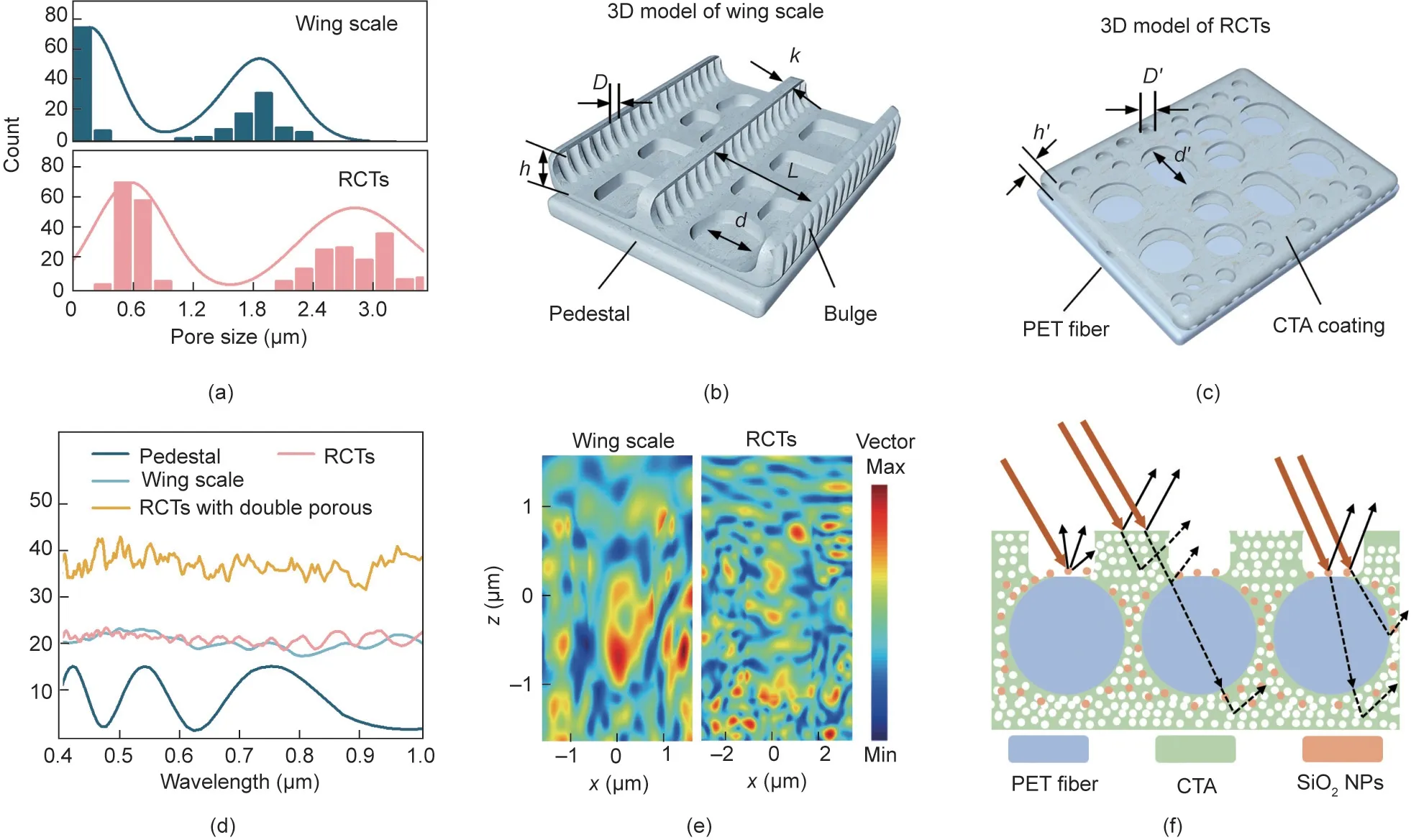

Fig.3.(a) Pore size distributions of the wing scale and the RCTs.(b) Simplified 3D simulation model of the wing scale of S.montelus.h: thickness of ridge; d: diameter of micro-pores;D:width of nano-pores;L:width of the grooves;k:width of ridge.(c) Simplified 3D simulation model of the RCTs.h’:thickness of CTA;d’:diameter of micropores;D’:diameter of nano-pores.(d)Simulated spectra reflectivity of different structures.(e)The distribution of Poynting vectors on cross sections of wing scale and RCTs under 700 nm.(f) Reflectance mechanism schematic of the RCTs.

Numerically,we analyzed the relationship between microstructure and optical properties to infer the mechanism of the desired spectrum response.The wing scale of S.montelus presented broadband sunlight reflectance, which is attributed to the delicate hierarchical porous structure of the wing scale contains bulges with numerous arrayed micro-pores(davgof 1.81 μm),raised ridges that run parallel to the pedestal, and grooves that are arranged alongside the ridges (davgof 0.17 μm).Similarly, the pore diameters of the RCTs, which had a bimodal distribution centered between 0.6 and 2.8 μm, suggest that a comparable optical mechanism may exist (Fig.3(a)).The FDTD simulation began with the simplified three-dimensional (3D) model constructions of the wing scale and RCTs as shown in Figs.3(b) and (c), originating from the SEM image (Fig.S13(a) in Appendix A).As shown in Figs.S13(b)and (c) in Appendix A, the CTA porous structures had been fabricated on the surface of PET fibers with the micro-pores and the nano-pores.As corroborated by the simulated optical parameters, the pedestal possessed the same width as that of a wing scale’s groove (L), which showed a weak reflectance during the wavelength between 0.4 and 1 μm.Due to multiple scattering,the reflectance dramatically increased to more than 20% with the introduction of the bulge structures, while the reflectance of RCTs with a double porous structure also increased to approximately 36% (Fig.3(d)).In order to visually observe the scattering of light,we presented the simulated Poynting vectors of the two structural models under the incident light (λ of 700 nm).Poynting vector,which represents the energy flux density vector in the electromagnetic field, indicates the energy passing through the vertical unit area per unit of time[35].As shown in Fig.3(e),the Poynting vector of our RCTs showed more erratic and abundant hotspots than that of the wing scale, which indicated a more dispersive scattering direction of light.Based on our characteristics of the microstructures and calculations of the optical properties, we presented our assumption of the reflectance mechanism of RCTs in Fig.3(f) and Fig.S13(b).The hierarchical pores of RCTs yield a broad spectrum of apertures, leading to pronounced Mie’s scattering; while the abundant longitudinal nanopore configurations and SiO2NPs within the substance engender multiple light reflections.Consequently, the RCTs demonstrate exceptional sunlight reflectivity.

3.4.Direct cooling performance and wearability

To estimate the direct radiative cooling performance of the RCTs, we carried out a continuous outdoor measurement of temperature and cooling demand (CD) under a clear sky in Shanghai,China on the August 5 and 10, 2022.As shown in Fig.4(a) and Fig.S14 and Supplementary method in Appendix A,the RCTs were placed in a homemade device elevated to a height above the ground of 0.7 m to lessen the effects of thermal convection and conduction during the direct cooling experiment (Supplementary method), we also tested the sun intensity with a pyranometer.Promisingly, under a relative humidity of 38% and average solar irradiance intensity of approximately 810 W·m-2at noon, the ΔT of the simulator surface covered by RCTs reached approximately 4.4, 3.5, and 2.0 °C compared with that of the commercial cotton textiles, PET textiles, and ambient respectively during peak sun irradiation between 11:00 and 15:00 (Fig.4(b)).As a result, the CD of RCTs was about 174 W·m-2less than cotton.The increased value of CD implied that additional cooling energy was necessary to uphold a steady body temperature of 34 °C in human beings,indicating improved thermal comfort in hot outdoor environments.Meanwhile,during the cooling test of a whole day,the average temperature drop reached 2.8°C(Fig.4(c)).Therefore,our RCTs possessed an adequate cooling performance, which was comparable with that of the previously reported textiles [6,27].Moreover,we assessed the temperatures of the body surface covered by RCTs and cotton textiles using an infrared thermal imager.The ΔT reached approximately 2.8 °C after 30 min of sun exposure,demonstrating the cooling properties in practical wearing situations (Fig.4(d)).

RCTs have great wearability in addition to their desirable cooling capabilities,which was important for direct application to PTM.Mechanical testing revealed that our RCTs could withstand a tensile stress of 1158 N and a strain of 11%, which was significantly better than those of cotton textiles,as shown in Fig.4(e).The swelling of the original fiber would be the cause of the decrease in strength and elongation, and the overall material felt slightly harder after treatment.To further test the comfortability of RCTs,we conducted an air permeability test, which was a measurement of the capacity to permit air to pass when a specific pressure is applied.Under the pressure drop of 100 Pa, the air permeability of the RCTs (grammage of (221.7 ± 11.6) g·m-2, the thickness of(582± 51)μm),untreated PET textiles(grammage of (214.5± 5.4)g·m-2, the thickness of (531 ± 16)μm), and cotton textiles (grammage of (201.9 ± 2.1)g·m-2, the thickness of (481± 32)μm)were 45.3, 47.3, 49.1 mm·s-1, respectively, as shown in Fig.4(f).Meanwhile, the WVT rate of the RCTs was 4744 g·m-2·d-1, indicating little sweat condensation and great moisture comfortability(Fig.S15 in Appendix A).Furthermore,we conducted the moisture absorption test, water resistance experiment, and contact angle measurements on RCTs,untreated PET textiles,and cotton textiles to further demonstrate the wearability of our materials (Figs.S16,S17, and Supplementary discussion in Appendix A).Besides, softness was a key factor for the wearability and comfortability of radiative cooling textiles.As shown in Figs.S18(a) and (b) in Appendix A, the bending rigidity of the RCTs, untreated textiles,and cotton textiles was 10.6, 8.1, and 2.7 mN·cm, respectively.The softness of RCTs was lower than that of untreated PET textiles due to the porous structure filled between the fibers and yarns,but RCTs could still be twisted with fundamental wearable potential(Fig.S18(c) in Appendix A).

The importance of durability is often underestimated,yet durability remains a crucial requirement for PRC textiles.To test the durability of the RCTs, we performed abrasion resistance testing on the Martindale abrasion tester [19], as shown in Fig.S19 in Appendix A.Compared with untreated PET and cotton textiles,the RCTs showed even better resistance to abrasion, which was demonstrated by the lower mass reduction of 2.15% and undetectable surface damage.The mass reduction of RCTs was on account of the slight destruction of tertiary architectures.Attributed to the strong interfacial adhesion of PET and CTA,the CTA film critically reduced the frictional force on the single fiber during abrasion and effectively inhibited the extraction of fibers from yarn/textile structures.Furthermore, we measured the Rsolarand εATSWof RCTs after 10 000 abrasion cycles to further demonstrate the abrasion resistance (Fig.S20 in Appendix A).Because of the slight destruction of tertiary architectures, the Rsolarand εATSWwere decreased by 6.3% and 3.3%, respectively.In addition, the mass of RCTs was slightly decreased by 1.2%, while the Rsolarand εATSWexhibited almost no degradation after 10 000 bending cycles(Figs.S21 and S22 in Appendix A).The RCTs showed excellent bending resistance because of the adequate tenacity and bending recovery of CTA.Moreover, after 50 washing cycles, the mass of RCTs decreased by 1.9%, while the Rsolarand εATSWdecreased by 8.9%and 2.7%respectively(Figs.S23 and S24 in Appendix A).When compared to those of cutting-edged PRC textiles, which were considered to be promising candidates for exploring PRC in temperature-regulating wearable applications, RCTs offered the appropriate passive radiative cooling ability and wearability.

4.Conclusions

In summary, we developed a facile and adaptable pathway for the fabrication of photonic-engineered PRC textiles via the microarray technique.The tailoring tertiary micro/nano architectures of the resulting textiles endowed excellent extended spectroscopic response (Rsolarof 91.7% and εATSWof 95.8%) which yields a temperature drop of approximately 4.4 °C compared to the commercial cotton textiles in the practical cooling properties measurement.Additionally, the robust monolayer design with a throughhole structure of RCTs provided channels for the transport of air and moisture, leading to a desirable air permeability of 45.3 mm·s-1and water vapor transmittance of 4744 g·m-2·d-1,while preserving structural stability and facile service.Our biomimetic design and the development of the monolayer photonicengineered textiles provided a versatile platform for exploring PRC materials in PTM applications for personal thermal control that effectively save energy.

Acknowledgments

This work was supported by the Ministry of Industry and Information Technology, the National Development and Reform Commission of the People’s Republic of China, the Fundamental Research Funds for the Central Universities (2232020A-06), the Science and Technology Commission of Shanghai Municipality(20QA1400500, 21130750100, and 22dz1200102), and Huo Yingdong Education Foundation (171065).

Compliance with ethics guidelines

Hongyu Guo, Tianye Niu, Jianyong Yu, Xueli Wang, and Yang Si declare that they have no conflict of interest or financial conflicts to disclose.

Appendix A.Supplementary date

Supplementary data to this article can be found online at https://doi.org/10.1016/j.eng.2023.07.019.

杂志排行

Engineering的其它文章

- Global Top Ten Engineering Achivements 2023

- 2023 Global Engineering Fronts

- Will Massive Appetite for Minerals Stall Clean Energy Transition?

- Optical Microscopy Advances Reach Sub-Nanometer Resolution

- International Correlation Research Program: Cross-Fault Measurement for Earthquake Prediction

- A Systematic Perspective on Communication Innovations Toward 6G