Magneto-hydrodynamic simulation study of direct current multi-contact circuit breaker for equalizing breaking arc

2023-03-06BowenJIA贾博文JianwenWU武建文ShuLI李枢HaoWU吴昊XiangjunPENG彭向军JianDAI戴健andRuangCHEN陈儒盎

Bowen JIA(贾博文),Jianwen WU(武建文),Shu LI(李枢),Hao WU(吴昊),Xiangjun PENG (彭向军),Jian DAI (戴健) and Ruang CHEN (陈儒盎)

1 Systems Engineering Institute,Academy of Military Sciences,Beijing 100071,People’s Republic of China

2 School of Automation Science and Electrical Engineering,Beihang University,Beijing 100083,People’s Republic of China

Abstract This work is based on a direct current (DC) natural current commutation topology,which uses load-carrying branch contacts carrying rated current and multiple sets of series arcing branch contacts in parallel to achieve circuit breaking.The proposed topology can meet the new requirements of higher voltage DC switches in aviation,aerospace,energy and other fields.First,a magneto-hydrodynamic arc model is built using COMSOL Multiphysics,and the different arc breaking characteristics of the arcing branch contacts in different gas environments are simulated.Then,a voltage uniformity coefficient is used to measure the voltage sharing effect in the process of dynamic interruption.In order to solve the dispersion of arcing contact action,a structural control method is adopted to improve the voltage uniformity coefficient.The uniform voltage distribution can improve the breaking capacity and electrical life of the series connection structure.

Keywords:DC circuit breaker,voltage uniformity coefficient,MHD modelling,uniform-voltage regulation method

1.Introduction

Direct current (DC) power supply systems have been widely used in the aerospace,urban rail traction,ship power system and new energy industries due to their outstanding advantages such as good system stability,good load characteristics and simple control [1-3].However,the further development of medium and low voltage DC power supply systems to a higher voltage level needs a breakthrough in DC breaking technology and the development of environment-resistant and lightweight DC switchgear.In recent years,high voltage DC power supply systems with a rated voltage of 270 V have been used in modern multi-electric and all-electric aircraft.Similarly,in the field of aerospace,solar power stations have been demonstrated to provide the largest power supply for spacecraft [4].In the future,the power supply of commercial power stations will reach GW level,and adopting high voltage power supply systems will become an important direction of future space technology development [5,6].In the fields of urban rail traction,new energy vehicles and the new generation of ship power distribution systems,the trend is for developing the voltage level of DC systems to several kV and above,and medium voltage DC power supply systems at kV level have become the focus for development.It can be predicted that high voltage and large capacity DC power supply systems will be fully applied in military and civil fields in the future[7,8].

For the protection of DC high voltage levels,the large capacity DC contactor is a key device that plays the role of connecting,carrying and breaking the normal circuit,and its breaking characteristics are important factors restricting the performance of its system.In principle,the high voltage DC circuit breaker is generally composed of three branches: the load-carrying branch (main branch),the transfer (breaking)branch and the energy absorbing branch[9].Because there is no current zero crossing point in the DC arc,a special method is needed to extinguish the arc [10,11].The following methods can be adopted [12,13]: increasing the arc voltage by using multiple groups of near-pole voltage drop,increasing the electric field intensity of the arc column and lengthening the arc,and forcing the current to cross zero by using a forced branch,etc.

Therefore,on the premise of meeting the demand for high voltage and large current DC breaking,this paper firstly proposes a DC natural commutation contactor topology and designs a prototype,which can maintain a low on-state voltage drop when carrying rated current.When breaking the circuit,the asynchronous contact realizes the natural transfer of current,and the arcing contact with high voltage breaking ability completes the breaking of the circuit.Then,based on the Gas Discharge Plasma Database (GPLAS,www.plasmadata.net/index),a two-dimensional magneto-hydrodynamic(MHD) arc model is built by using COMSOL Multiphysics software to simulate the breaking characteristics of multicontact arcs in series under different background atmospheres.Considering a 1 atm hydrogen environment[14],the dynamic voltage sharing characteristics of arcs under different mechanical action dispersions are studied by designing different initial arc temperature values.Finally,a structural control method is adopted to make the arc voltage of each contact achieve dynamic uniformity in the breaking process,which improved the breaking capacity and switching electrical life.

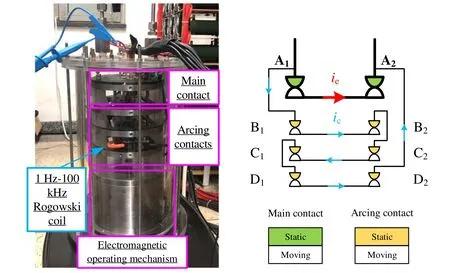

2.Principle and modeling of the current commutation voltage sharing breaking

The contact structure of a DC natural commutation contactor consists of two parts: the load-carrying branch carries rated current,and the arcing branch breaks the circuit.The loadcarrying branch and arcing branch are parallel in structure.The assembled contactor prototype and internal current distribution are shown in figure 1.Under the rated condition,a large proportion of the current flows through the load-carrying branch,which limits the improvement of the contact voltage drop and solves the problem of rated temperature rise under large DC current.On contact structure,the moving contacts of the load-carrying branch and the arcing branch are installed on the same electromagnetic operating mechanism,but the design of contacts overtravel is different.The contact overtravel of the load-carrying branch is smaller than that of the arcing branch,so that the main contacts are first opened during the breaking process,and the arcing contacts can still maintain a good circuit conduction state.When breaking the circuit,the internal circuit current will naturally commutate in the contactor.Under certain conditions,the main contact does not ignite an arc during the commutation process.After commutation,the arc voltage can be improved by the sealed gas environment.

2.1.Hypotheses

As a kind of high temperature plasma which is in a state close to thermodynamic equilibrium,the movement process of an arc can be described by an MHD model during arc extinction.In this paper,the arc MHD model includes the following assumptions.(1)The arc ignition and electrode opening process are ignored,that is,the process of arc extinguishing is simulated under the condition that the opening distance and the initial temperature of the arc are determined.(2)The research object is a macro-neutral Newtonian fluid,and the flow property is weakly compressible.(3) The viscous dissipation and isobaric expansion in the energy equation are neglected.(4) The magnetic field produced by displacement current and arc current is ignored.The movement of the arc depends on the magnetic field generated by the permanent magnet.

2.2.Geometry of the MHD model

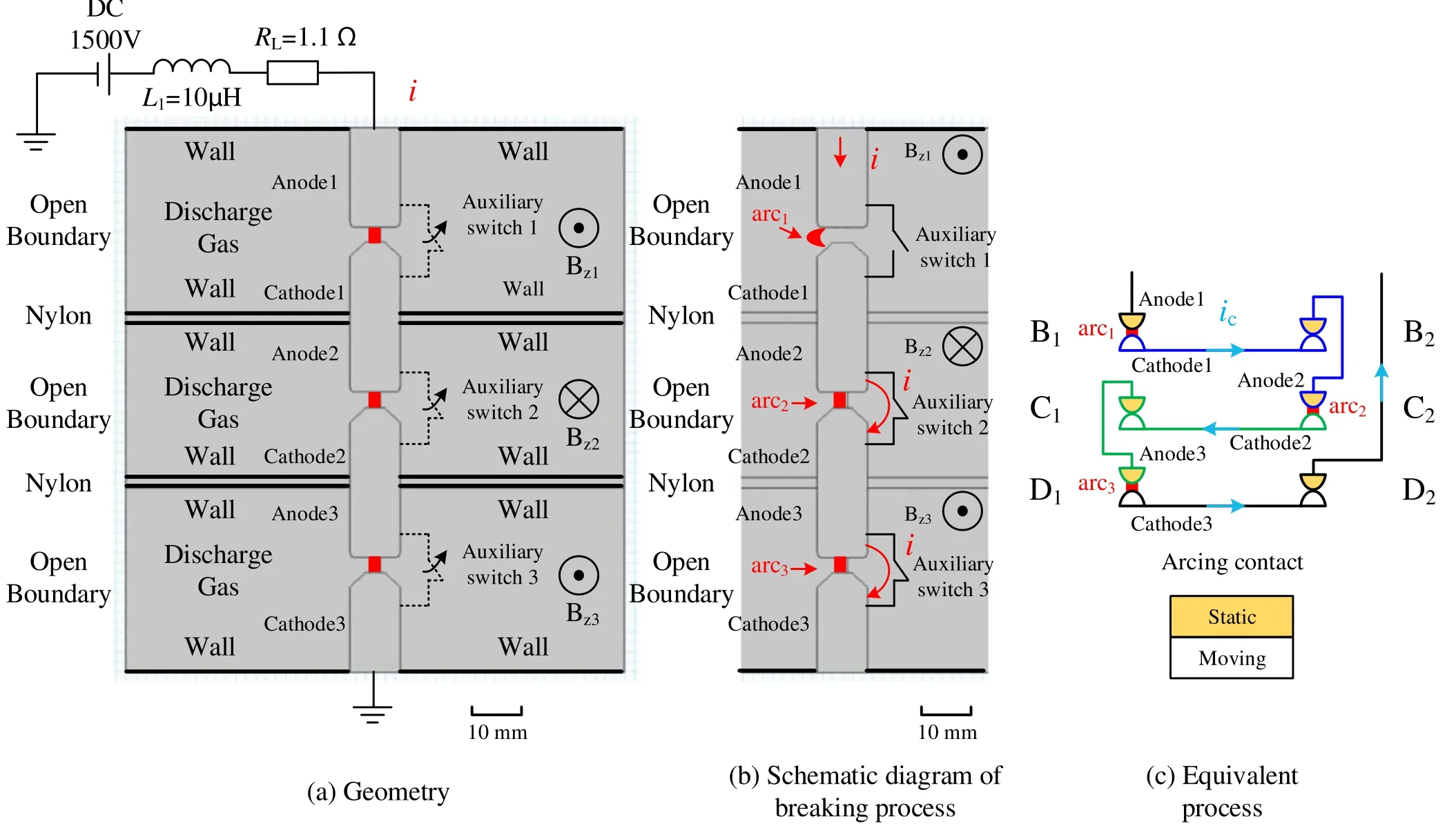

Figure 2 shows the geometry of the arc MHD model built using COMSOL Multiphysics and the equivalent process of the model.The voltage,current,derivative of current over time,electrical potential,velocity field,pressure and temperature are calculated by using the electrical circuit,electrical current,laminar flow and heat transfer in fluids interface nodes.The thermal flow and the heat transfer in fluids are coupled through the non-isothermal flow interface,and the electrical current and heat transfer in fluids are coupled through the equilibrium discharge head source interface,where the heat source components consider enthalpy transport and Joule heating.

Figure 1. The assembled contactor prototype and internal current distribution.

Figure 2. Geometry and equivalent process of the MHD model.

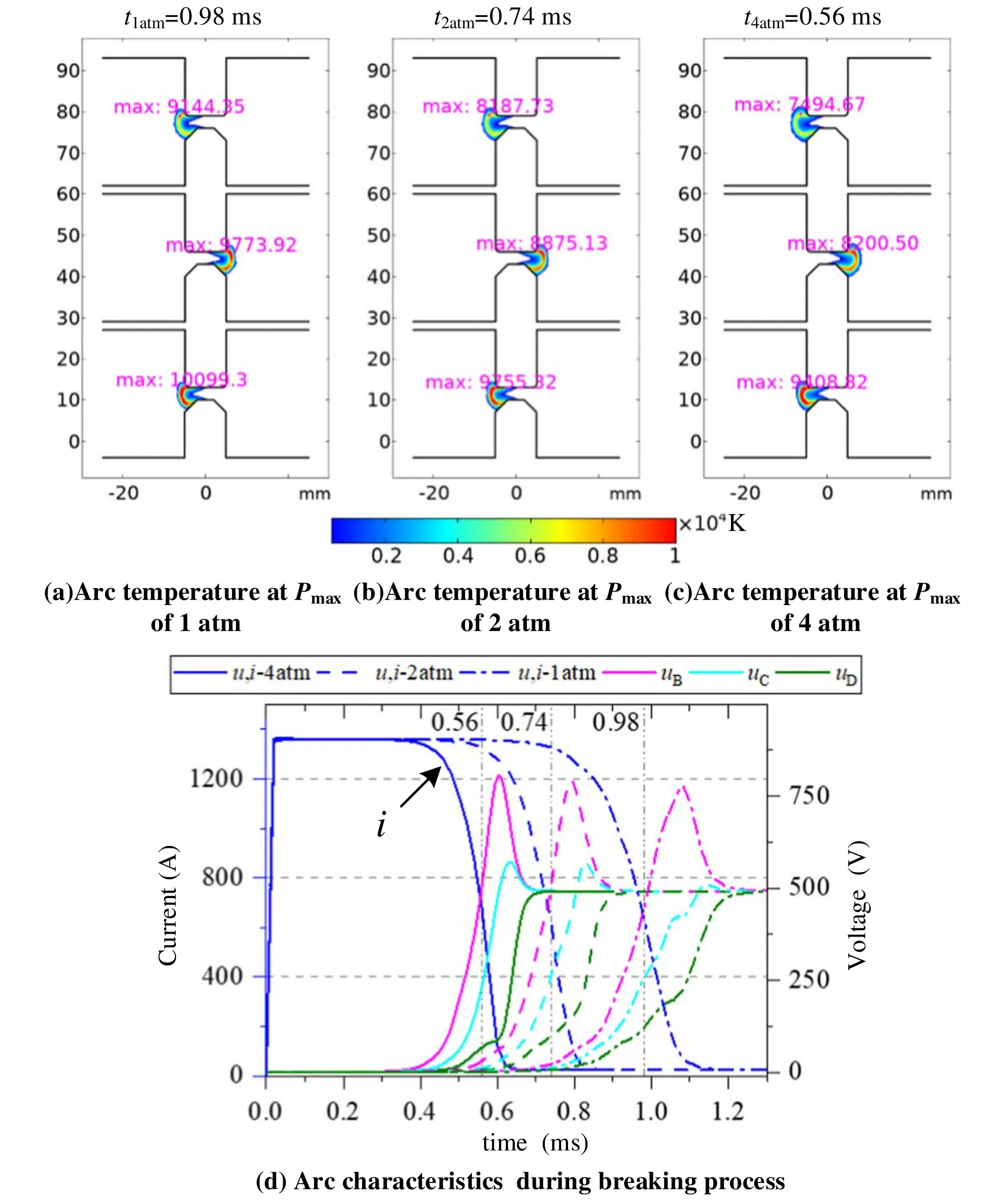

Figure 3. Simulation results for arc temperature in H2.

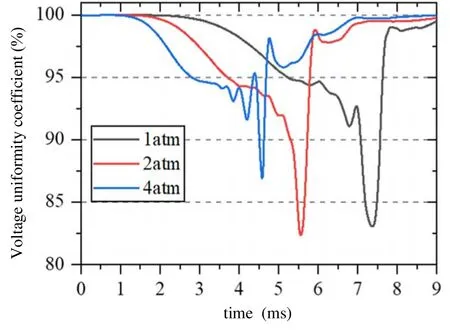

Figure 4.Dynamic voltage sharing coefficients of multi-contact arcs under different gas pressures in H2.

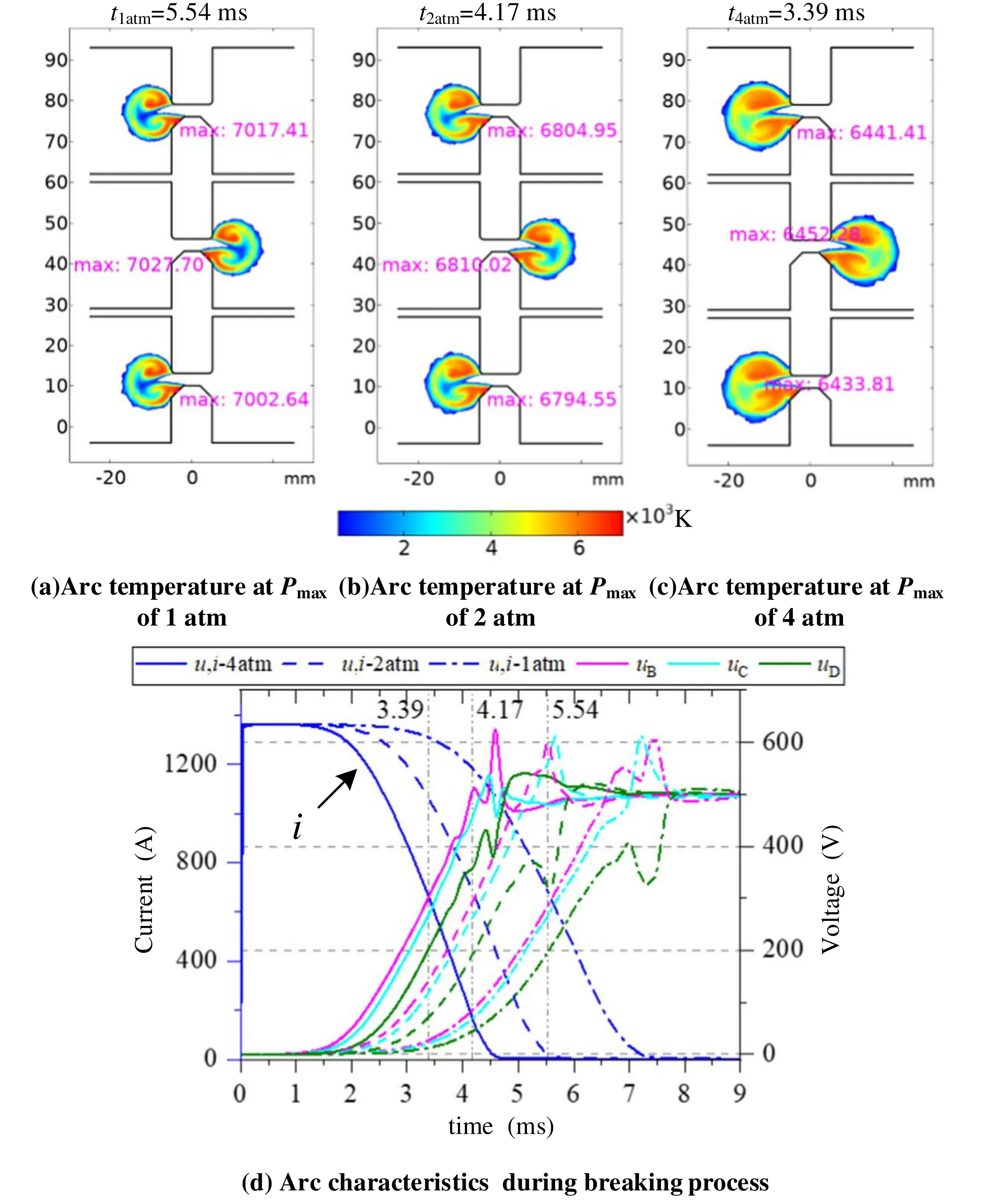

Figure 5. Simulation results for arc temperature in N2.

Figure 6.Dynamic voltage sharing coefficients of multi-contact arcs under different gas pressures in N2.

Figure 7. Simulation results for arc temperature in H7N3.

Figure 8.Dynamic voltage sharing coefficients of multi-contact arcs under different gas pressures in H7N3.

Figure 9.The simulation results for dynamic voltage sharing under structural control.

Figure 10.Voltage sharing breaking effect under magnetic field regulation.

Due to the symmetry of the structure,the arcs between B1,C1and D1contacts are mirror antisymmetric to those between B2,C2and D2contacts,so the model can be further simplified.The equivalent process of the cathode and anode terminals is as follows.The static and moving contacts of B2,C1and D2in figure 1 are regarded as equipotential,that is,the contacts are kept in contact and no arc is generated.Anode1 and Cathode1 are equivalent to the static and moving contacts of B1respectively,Anode2 and Cathode2 are equivalent to the static and moving contacts of C2respectively,Anode3 and Cathode3 are equivalent to the static and moving contacts of D1respectively,and the equipotential part can be considered to be equivalent to a cylindrical conductor.Since the simplified simulation model corresponds to half of the supply voltage,the external circuit is equivalent to a 1500 V DC power supply,10 μH equivalent line inductance,and 1.1 Ω load resistance.

The MHD geometric model contains three independent discharge gas regions separated by nylon.The physical parameters of the discharge gas are determined using GPLAS.A magnetic field perpendicular to the plane direction is applied to the three discharge areas,and the magnetic induction intensity is expressed asBz1,Bz2andBz3.In order to realize the reverse motion of the adjacent arc,Bz2is opposite to the other two magnetic fields.At the initial time of the simulation,the geometric dimension of the arc is set as 2 mm in diameter and 3 mm in length.The initial temperature isT0_arc1,T0_arc2andT0_arc3.In the MHD model,the magnetic induction intensity is set to 50 mT.The arc initial temperature is set to 13 000 K.In the simulation model,an auxiliary switch is connected at both ends of the contact at different positions,as shown in figure 2(a).Auxiliary switches are used to form different arc motion conditions.In the simulation model,these auxiliary switches are connected in parallel to the gaps at different positions through the‘terminal’interface in the ‘electric circuit’ module.When the auxiliary switch is closed,since the on-state resistance of the auxiliary switch is much smaller than that of the arc,the current in the circuit will flow through the auxiliary switch,and the arc between the electrodes will not move because there is nearly no current.As shown in figure 2(b),Auxiliary Switch 1 is opened and the currentiin the circuit will flow through arc1,resulting in a movement trend under the magnetic field.The time when large current flows into the arc is changed by setting the opening time of the auxiliary switch.The opening sequence of the three auxiliary switches is set respectively to make the arc move at different times under the action of the Lorentz force,resulting in unbalanced voltage.In the simulation model,the opening times of the auxiliary switches are set as 100 μs and 200 μs.Subsequently,the cooled gas gradually recovers its insulation characteristics to complete the circuit disconnection.

2.3.Governing equations

The evolution of an arc plasma is the result of the interaction of gas dynamics and an electromagnetic field.According to MHD theory,the Navier-Stokes equation and energy conservation equation can be used to calculate the flow characteristics of the arc extinction process[15,16].According to the mass conservation equation,the arc plasma should satisfy the mass continuity theorem,as shown in equation (1).

where ρ is the plasma mass density,kg m-3;u is the velocity vector,m s-1.

The velocity distribution of the arc plasma is obtained by solving the momentum equation(Navier-Stokes equation),as shown in equations (2) and (3)

wherepis the plasma pressure,Pa; μ is the viscosity,kg(m·s)-1; J is the current density,A m-2; B is the magnetic induction intensity of arc blowing,T.I in equation (2) is a unit matrix of order 3.

The dynamic temperature distribution in the interrupter can be obtained by calculating the energy conservation equation through the coupling of multiple physical interfaces,as shown in equations (4)-(6).

whereCpis the specific heat at constant pressure,J(kg·K)-1;kis the thermal conductivity,W (m·K)-1;Tis the plasma temperature,K.kBis Boltzmann’s constant; the variableqin lower case is the elementary charge,equal to 1.602 × 10-19C; σ is the electrical conductivity,S m-1.In order to obtain the further change of arc plasma temperature at low temperature,the minimum value of electrical conductivity is set in the physical parameters of the arc extinguishing medium.σminequals 0.02 S m-1,and the corresponding cutoff temperatureTcutoffis 4500 K.

2.4.Boundary settings

For the wall condition in the model,the no-slip condition is selected,with a no-slip wall where the fluid velocity relative to the wall velocity is zero [17].For a stationary wall that means that u = 0.The open boundary condition describes a boundary in contact with a large volume of fluid,and fluid can both enter and leave the domain on boundaries with this type of condition.

3.Simulation research and analysis

3.1.Simulation of dynamic voltage sharing under the same initial conditions

In this section,under the same initial conditions,MHD modeling and simulation are carried out using the gas physical parameters of H2,N2and H2-N2(7:3 mixture ratio,represented by H7N3) in the plasma database under different gas pressures,and the simulation results of voltage distribution during the interruption process are obtained.In order to define the effect of dynamic voltage sharing in the process of breaking,a normalized voltage uniformity coefficientkis used in this work,as shown in equation (7).

wherenis the number of arcing contacts,which is 3 in this paper;u i(t)is the arc voltage between theith contacts;(t)is the average voltage of all arcing contacts at the current time;is the static expected voltage sharing value.

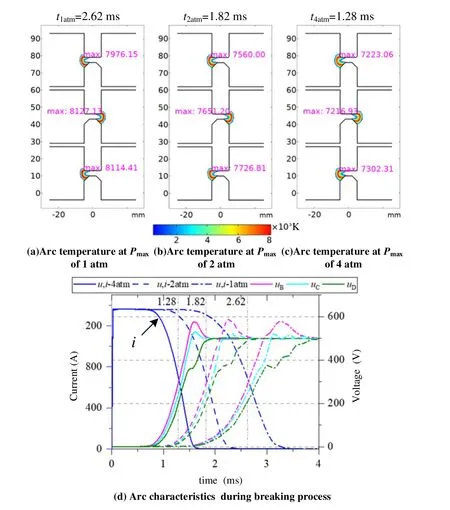

The simulation results for arc temperature under different pressures in the H2environment are shown in figure 3.The solid lines in the figure represent the arc current and the arc voltage at different positions(using three colors to distinguish the positions) under the 4 atm condition,the dashed lines indicate the arc current and the arc voltage at different positions under the 2 atm condition and the dot-dashed line indicates the arc current and the arc voltage at different positions under the 1 atm condition.

According to the simulation results,H2has a good arc extinguishing effect,and the total arcing time is less than 1.22 ms at three pressure points.In particular,the arcing conditions at the maximum power point (Pmax) under each pressure point are marked in figures 3(a)-(c).The arc is elongated under the action of a magnetic field.When the arc voltage increases,the current gradually decreases,and the insulation performance of the gas medium is restored,which realizes the circuit breaking.In addition,when the gas pressure increases,the arc burning time will be decreased correspondingly,and the arc temperature atPmaxis decreased at the same time.

Dynamic voltage sharing coefficients of multi-contact arcs under different gas pressures in the H2environment are shown in figure 4.Due to the short arcing time,the voltage of each contact is uneven during the breaking process,and the minimum value of the voltage uniformity coefficient is less than 70%.The overvoltage between some contacts is high,so the energy absorbing element should be considered properly.

The simulation results for arc temperature atPmaxunder different pressures in the N2environment are shown in figure 5.Unlike in H2,the arcing time in N2increases significantly,ranging from 4.94 to 7.8 ms.The arc temperature at the maximum power point of the arc increases slightly with the arcing time.Similarly,the overvoltage between some contacts is also high,so the energy absorbing element should be considered properly.

As shown in figure 6,dynamic voltage sharing coefficients of multi-contact arcs under different gas pressures in N2can also be maintained at about 85%.The effect of arc dynamic voltage sharing is obvious.

In view of the high overvoltage problem of a single gas in the circuit breaking process,H7N3 is selected as the arc extinguishing medium to study the breaking characteristics and voltage sharing characteristics of a mixed gas.The simulation results for arc temperature atPmaxunder different pressures in an H7N3 environment are shown in figure 7.

Compared with the single component gas,the arcing time of the mixed gas is closer to that of the H2environment,ranging from 1.87 to 3.79 ms.The arc temperature at the maximum power point of the arc is slightly lower,and the dynamic voltage sharing coefficients of the multi-contact arc under different gas pressures in H7N3 have been significantly improved,as shown in figure 8.The voltage uniformity coefficient is about 90%,and it is less affected by gas pressure.In the same way,the overvoltage of the mixed gas arc is obviously lower than that of the single gas arc.

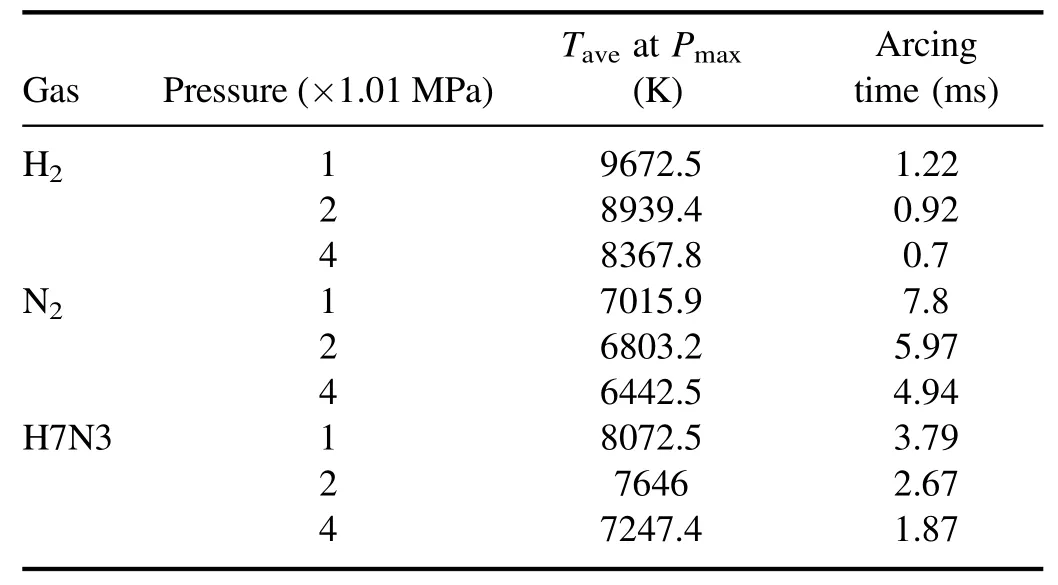

Table 1.The arcing characteristics under the same initial conditions.

Under the same initial conditions,table 1 summarizes the arcing characteristics of arc extinguishing media under different gas pressures,including the average temperature at the moment of maximum arc power and the arcing time.

3.2.Equalizing breaking process regulated by structure

In this section,research on the voltage equalizing breaking of structural regulation is carried out for an H7N3 arc extinguishing medium under 4 atm.Because of the mechanical dispersion of the opening process,the arc energy between different contacts is not average in the initial stage of arc ignition.

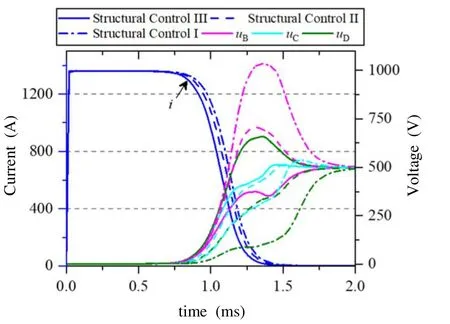

In the simulation process,three structural regulation methods are designed to study the effect of voltage equalizing breaking.Different auxiliary switch breaking intervals are set as follows.Structural control I:100 μs and 200 μs;structural control II:50 μs and 100 μs;and structural control III: 30 μs and 60 μs.The initial temperature of the arc at different positions is set asT0_arc1=T0_arc2=T0_arc3= 13 000 K,and the magnetic induction is set asBz1=Bz2=Bz3= 50 mT.Based on the above simulation conditions,the simulation results for dynamic voltage sharing under structural control are shown in figure 9.

According to figure 9,it can be seen that under the condition of the same arc blowing magnetic induction intensity,the first arc always bears a higher voltage during the dynamic breaking process; the contact breaking time sequence istB<tC<tD.The uneven arcing energy will lead to a difference in contact material ablation,which acts against improving the electrical life of the switchgear,and also limits the breaking capacity.The dynamic voltage sharing coefficients of multi-contact arcs under different structural control methods are shown in figure 10.

According to the simulation results,three kinds of structural control method can affect the dynamic voltage sharing during the breaking process.However,there is a reasonable structural control range for making the voltage uniformity coefficient reach a higher level.When the contact breaking interval is set from 100 μs/200 μs to 50 μs/100 μs,the voltage uniformity coefficient increases from 44.5% to 76.5%.When the contact breaking interval is set from 50 μs/100 μs to 30 μs/60 μs,the voltage uniformity coefficient increases from 76.5% to 83.8%.

4.Conclusions

In this work,based on a proposed topology of a DC natural commutation contactor,the voltage sharing breaking simulation of series multi-contact asynchronous breaking is carried out using MHD theory.It can be concluded that:

(1) Based on the MHD theory,a simulation model of three series multi-contact breaking processes is established.Using H2,N2,and H2-N2mixed gas as the arc extinguishing medium,the arc simulation studies under different gas pressure conditions are carried out and the arc characteristics under different gas types are obtained.

(2) Under the same initial conditions,the arc dynamic voltage uniformity characteristics between different contacts under a series of gas parameters are obtained.Considering the uneven voltage distribution caused by series multi-contact asynchronous breaking,a structural control method is proposed,and a normalized dynamic voltage uniformity coefficient is used to obtain the dynamic voltage sharing effect after regulation.

(3) In view of the mechanical dispersion of the opening process,there is a reasonable structural control range to make the voltage uniformity coefficient reach a higher level.The voltage uniformity coefficient is increased from 44.5% to 76.5% when the contact breaking interval is set from 100 μs/200 μs to 50 μs/100 μs,and correspondingly from 76.5% to 83.8% when the contact breaking interval is set from 50 μs/100 μs to 30 μs/60 μs.

Acknowledgments

This work is supported by National Natural Science Foundation of China(No.51977002).This manuscript is recommended by the Third International Symposium on Insulation and Discharge Computation for Power Equipment (IDCOMPU2021).The physical parameters of the discharge gas were determined by GPLAS (www.plasma-data.net/index).

猜你喜欢

杂志排行

Plasma Science and Technology的其它文章

- Efficient combination and enhancement of high-power mid-infrared pulses in plasmas

- Realization of Te0>10 keV long pulse operation over 100 s on EAST

- Solving Poisson equation with slowingdown equilibrium distribution for global gyrokinetic simulation

- Experimental studies of cusp stabilization in Keda Mirror with AXisymmetricity (KMAX)

- BITS: an efficient transport solver based on a collocation method with B-spline basis

- Comparing simulated and experimental spectral line splitting in visible spectroscopy diagnostics in the HL-2A tokamak