Volatile Components and Antitumor Activity of Ganoderma lucidum Spore Oil and Its Molecular Distillation Components

2023-02-21MengxueSUNLiyingNIYuhongHUANGBinWANGMingZHANGChaoMAMaoyuWU

Mengxue SUN, Liying NI, Yuhong HUANG, Bin WANG, Ming ZHANG, Chao MA, Maoyu WU*

1.Jinan Fruit Research Institute, All China Federation of Supply & Marketing Co-operatives, Jinan 250014, China; 2.College of Life Science, Yangtze University, Jingzhou 434022, China

Abstract [Objectives]To compare the effects of molecular distillation on the flavor and antitumor activity of Ganoderma lucidum spore oil.[Methods]G. lucidum spore oil was separated and purified by molecular distillation technology, and the volatile components of different components of molecular distillation were analyzed by gas chromatography-ion mobility spectrometry(GC-IMS)technology.Human liver carcinoma cells(HepG2), human breast cancer cells(MCF-7), and human cervical cancer cells(Hela)were selected as the tumor cell lines to be tested, and the cell viability was detected by the MTT assay.[Results]Molecular distillation effectively reduced small molecular substances produced by oil oxidation in G. lucidum spore oil, such as heptanal, octanal, linalool, hexanal, E-2-octanal, 3-ethylpyridine, etc. Among the heavy components, the content of esters was relatively high, mainly including ethyl levulinate, ethyl crotonate, and amyl butyrate.The MTT cytotoxicity test indicated that G. lucidum spore oil and its molecular distillation components had certain inhibitory effects on the growth of three tumor cells, and G. lucidum spore oil crude oil had the most significant antitumor activity.G. lucidum spore oil crude oil, heavy component, and light component had the most significant antitumor activity on HepG2 cells, followed by MCF-7 cells, and the weakest antitumor activity on Hela cells.The quality of G. lucidum spore oil became higher after molecular distillation, and the rancid smell was reduced, and molecular distillation had little effect on the antitumor activity of G. lucidum spores.[Conclusions]Molecular distillation technology can be applied to the refining of G. lucidum spore oil to improve product quality.

Key words Ganoderma lucidum spore oil, Molecular distillation, Gas chromatography-ion mobility spectrometry(GC-IMS), Principal component analysis(PCA), Antitumor activity

1 Introduction

Ganodermalucidumis a fungus of the genusGanodermain the family Polyporaceae of Basidiomycetes with high medicinal value[1], also known as mushroom of immortality, Shenzhi, Mulingzhi, and Zhicao,etc.It has the effects of invigorating qi and calming the nerves, relieving cough and relieving asthma, and is a commonly used traditional Chinese medicine for nourishing and strengthening, reinforcing healthy qi and securing the root[2].Physicians of all ages listed it as the top grade for health preservation.There are rich varieties ofG.lucidumresources in the world, mainly distributed in China, the Korean Peninsula and Japan, and are cultivated in East China, Southwest China, Jilin, Shanxi, Taiwan, Henan, Hainan, Guangxi, Guizhou and other regions[2].Both the mycelium spores and fruiting bodies ofG.lucidumhave medicinal properties[3].The main active components are polysaccharides, peptidoglycan and triterpenes,etc.These biologically active components make it have various physiological functions such as immune activity, antitumor, anti-aging, anti-virus and hypolipidemic[4-5].G.lucidumspore oil is a lipid active component extracted from broken spores by supercritical CO2extraction technology, and is a collection of active components ofG.lucidumspores.It is rich in triterpenoids, sterols and unsaturated fatty acids, so it has a wider range of physiological activities[6], such as resisting tumor[7], improving immunity[8-9]and protecting nerves[10]and so on.

G.lucidumspore oil, as one of the functional components ofG.lucidum, has great development value, and the research on its quality and function at home and abroad is getting more and more in-depth.In recent years, with the improvement of people’s living standards and health awareness, health products based onG.lucidumspore oil have gradually entered people’s field of vision.However,G.lucidumspore oil contains less antioxidant substances and is prone to oxidative rancidity[11], which affects its taste and quality.Therefore it needs to be refined to reduce the acid value.Although the chemical alkali refining or physical refining deodorization technology in the traditional oil industry can effectively reduce the acid value and peroxide value, it has certain limitations.For example, the high acid value of oil results in a large amount of alkali added in chemical alkali refining, and the alkali saponifies a large amount of neutral oil during the neutralization of free fatty acids, resulting in a low oil refining yield.Physical refining uses steam distillation to deacidify, and high temperature will greatly damage the trace components and affect the quality of the oil.G.lucidumspore oil is precious and scarce, its physiologically active components are easily destroyed at high temperature.Thus, ordinary oil deodorization methods cannot be used to reduce the peroxide value and acid value ofG.lucidumspore oil.

Molecular distillation is a special liquid-liquid treatment process.It is separated based on the difference in the mean free path of different molecular motions in the mixture components.It is very good for natural substances with high boiling point, high viscosity, heat sensitivity and easy oxidation[12].With reference to the optimal molecular distillation refining process obtained from previous studies, we used GC-IMS technology to analyze the volatile components of molecularly distilledG.lucidumspore oil.We explored the effects of molecular distillation on the anticancer activity ofG.lucidumspore oil, aiming to provide a theoretical reference for the quality improvement and high-value utilization ofG.lucidumspore oil.

2 Materials and methods

2.1 Materials and reagentsG.lucidumspore oil(Fujian Xianzhilou Biological Science and Technology Co., Ltd., China); MEM medium(Wuhan Boster Biological Technology Co., Ltd., China); phosphate buffer PBS(Beijing Solarbio Science & Technology Co., Ltd., China); fetal bovine serum(Gibeo Company, USA); 0.25% EDTA-trypsin(Genomcell, China); Dimethylsulfoxide(DMSO)and CCK-8(Sigma, USA); T25 culture bottle, 96-well cell culture plate(Corning Company, USA); human liver cancer cell line HepG2, human cervical cancer cell line Hela, and human breast cancer cell line MCF-7(Wuhan Procell Life Science&Technology Co., Ltd., China).

2.2 Instruments and equipmentVKL70-5 molecular distillation instrument(VTA, Germany); BSC-1500IIA2-X Biological Safety Cabinet(Shandong Biobase Medical Instrument Company, China); Heraeus BB15 carbon dioxide incubator(Heraeus, Germany); inverted microscope CKX53(OLYMPUS, Japan); Multiskan FC microplate reader, Countess II cell counter(Thermo Fisher, USA); FlavourSpec®flavor analyzer(equipped with CTC automatic headspace sampler, Laboratory Analytical Viewer(LAV)analysis software, Reporter plug-in, Gallery Plot plug-in, Dynamic PCA plug-in and Library Search qualitative software, GAS company, Germany).

2.3 Experimental methods

2.3.1Molecular distillation.The distillation was carried out with reference to the previous process optimization parameters of molecular distillation refiningG.lucidumspore oil[13].The feed amount was 20 g, the distillation temperature was 200 ℃, the injection rate was 2 mL/min, the scraper speed was 160 r/min, and the condensation temperature was 50 ℃.G.lucidumspore oil was measured from the feeder at 2 mL/min and then entered the molecular distillation device, and was evenly distributed on the evaporation surface under the high-speed rotation of the wiper at 160 r/min.The evaporation surface was precisely controlled by heat conduction oil at 200 ℃.The raw material was heated on the evaporation surface, and under high vacuum conditions, the volatile components were condensed into liquid by the condenser in the middle, and flowed into the light component collection bottle along the condenser.The less volatile components flowed into the heavy component collection bottle along the inner wall of the distillation cylinder.In order to prevent volatiles from entering the vacuum system, a cold trap must be installed on the pipeline, and the pressure of the molecular distillation system should be maintained at 1.8-2.9 Pa.

2.3.2GC-IMS analysis.(i)Headspace sampling conditions.Weighed 2 g of the sample to be tested, placed it in a 20 mL headspace sample bottle, sealed it, and incubated at 80 ℃ for 30 min before injecting the sample.The temperature of the injection needle was 85 ℃, the injection volume was 100 μL, and each group of samples was measured 3 times in parallel.(ii)GC-IMS conditions.FS-SE-54-CB-1 column(15 m×0.53 mm), incubation speed 500 r/min, column temperature 60 ℃, carrier gas N2, IMS temperature 45 ℃, run analysis time 20 min.Carrier gas flow gradient setting: the initial flow rate was 2 mL/min and kept for 2 min; linearly increased to 10 mL/min within 2 to 10 min; linearly increased to 100 mL/min within 10 to 20 min and then stopped.The linear voltage(electric field intensity)in the tube was 400 V/cm; the radiation source was β-ray(tritium, 3H); positive ion mode.

2.3.3Cytotoxicity test.(i)Preparation ofG.lucidumspore oil solution.Took about 10 mg ofG.lucidumspore oil, precisely weighed, put it in a 15 mL centrifuge tube, and dissolved it with 10 mL of DMSO to obtain aG.lucidumspore oil sample solution with a concentration of 10 mg/mL.(ii)Cell seeding.HepG2, MCF-7, and Hela cells were subcultured separately.When the growth density of the cells reached 70%-80%, they were digested with 0.25% trypsin and subcultured.HepG2 and Hela cells were diluted to 1×105cells/mL with MEM medium containing 10% FBS, and MCF-7 cells were diluted to 1×105cells/mL with medium containing 10% FBS and 0.01 mg/mL insulin, and seeded in 96-well cell culture plates.At least 3 replicate wells were set up for each concentration, 100 μL per well, and cultured at 37 ℃, 5% CO2for 48 h.Then used 3-4 mL of complete medium, blew it evenly with a pipette gun, and subcultured according to the cell density of 1∶2-1∶3, and the cell viability was obviously enhanced after subculture to 2-3 passages.The cells at this time can be subjected to the next cytotoxicity test.(iii)Detection of cell viability by MTT assay.The HepG2 cells were diluted to 5×104cells/mL with culture medium, and the cells were inoculated into 96-well plates according to the addition amount of 1×104cells per well.At the same time, a blank control group(complete culture medium), a negative control group(cell suspension + complete culture medium)and a test sample group(cell suspension + sample)were set.After injecting samples, the 96-well plate was placed in a 5% CO2cell incubator at 37 ℃ for 24 h.Added different concentrations of samples to be tested(0.1-5.0 mg/mL), placed in 5% CO2, 37 ℃ cell culture incubator for 20 h, precisely weighed 5 mg MTT and dissolved in 1 mL PBS, and stored in the dark.Before use, filtered through a 0.22 μm microporous membrane, added 20 μL of 5 mg/mL MTT solution to each well of a 96-well plate, and cultured for 4 h.Aspirated the culture medium in the wells, washed twice with PBS buffer, added 100 μL of DMSO to each well, shook on a shaker for 10 min, and fully dissolved the crystals.The absorbance(ODvalue)of each well was measured at a wavelength of 570 nm on a microplate reader, and the cell viability(%)was calculated according to Formula(1).

Cell viability(%)=[ODof sample goup-ODof blank group]/[ODof negative control-ODof blank group]×100%

(1)

3 Results and analysis

3.1 Effect of molecular distillation on the volatile components ofG.lucidumspore oil

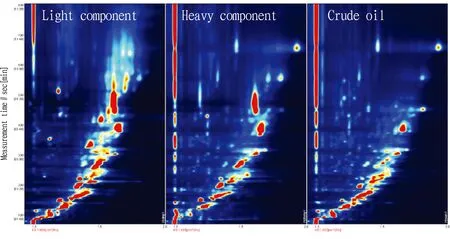

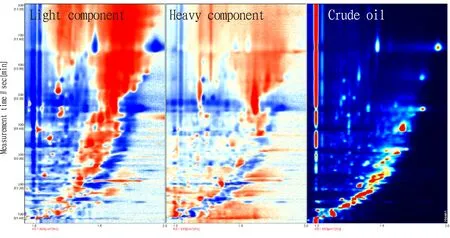

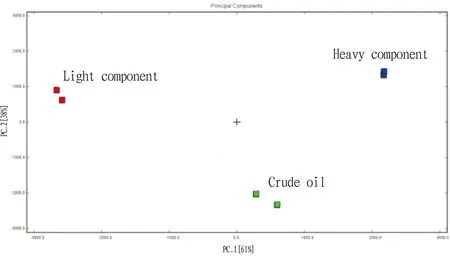

3.1.1Difference analysis of volatile components.The two-dimensional spectrum of the volatile components of the distillation product analyzed by GC-IMS is shown in Fig.1.A red vertical line at the abscissa 1.0 is the normalized reaction ion peak.Spots of different colors and sizes are distributed near the reactive ion peak, and each spot represents a volatile organic compound.The depth of the color represents the concentration of the substance, and the darker the color, the greater the concentration of the substance[14].The spectrum intuitively reflects the differences in the types and contents of volatile components in different components of molecular distillation.The spectra of crude oil samples were selected as a reference, and the spectra of light components and heavy components were subtracted from the reference to obtain the difference diagram of different fractions(Fig.2).In the spectrum after subtraction, substances with the same content were offset as white, red indicates that the content of the substance was higher than that of crude oil, blue indicates that the content of the substance is lower than that of crude oil, and the darker the color, the greater the difference.From Fig.2, it can be seen that the volatile components of crude oil and its products after molecular distillation are quite different, indicating that molecular distillation will significantly affect the flavor ofG.lucidumspore oil.With the aid of LAV software, we conducted PCA analysis on the volatile components of different components ofG.lucidumspore oil, and used PC1 and PC2 to plot the score map(Fig.3).The contri bution rate of the first principal component PC1 was 61%, the contribution rate of the second principal component PC2 was 38%, and the cumulative contribution rate of PC1 and PC2 was 99%.The samples of different components were clearly separated in the figure, the samples of light components were gathered on the right side of the figure, and the samples of heavy components were gathered on the left side of the figure.The distance between the two groups was far, there was no crossover between samples, so the difference was large.

Fig.1 GC-IMS comparison of volatile components of Ganoderma lucidum spore oil

Fig.2 GC-IMS difference diagram for volatile components of Ganoderma lucidum spore oil

Fig.3 PCA score chart for volatile components of Ganoderma lucidum spore oil

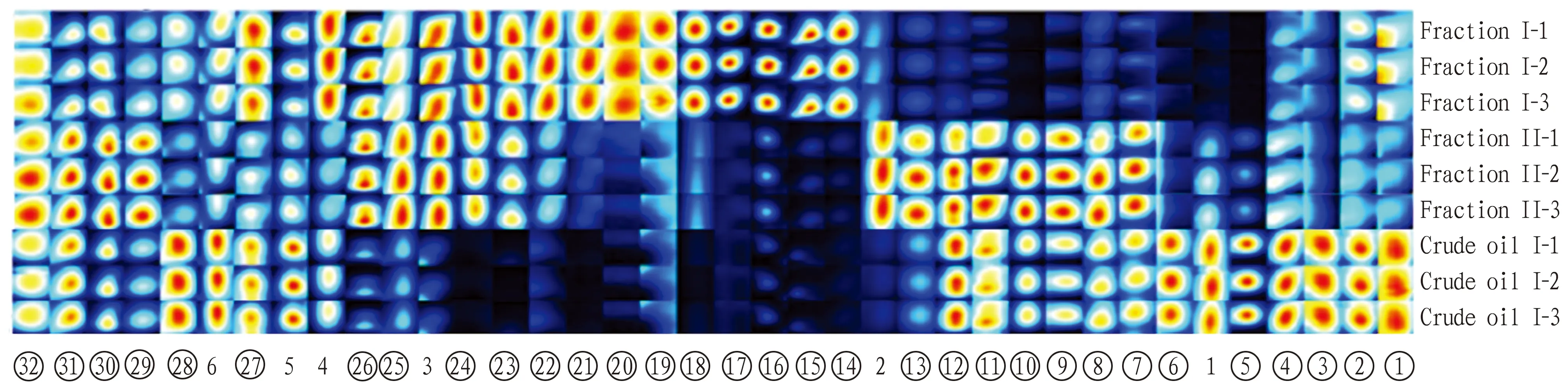

3.1.2Comparative analysis of volatile components ofG.lucidumspore oil.Fig.4 illustrates the ion peak gallery of VOCs with obvious changing rules screened by the built-in Gallery Plot plug-in of the LAV software that comes with the Flavour Spec system.The qualitative analysis results of VOCs inG.lucidumspore oil are shown in Table 1.A total of 38 volatile components were detected in the sample, and 32 were qualitative.Among them, there were 8 kinds of aldehydes, 7 kinds of esters, 4 kinds of ketones, 4 kinds of alcohols, 4 kinds of alkenes, and 3 kinds of others(1 kind of ethers, 1 kind of pyridines, and 1 kind of pyrrolines), and 6 kinds of compounds were not identified.As indicated in Fig.4, the samples of different components showed obvious differences.Some volatile substances are shared, mainly 1-pentanol, 2-Heptanone, Isobutyl isobutyrate, Ethyl(E)-2-hexenoate, Ethyl acrylate, 2-Butanone and other substances.Molecular distillation has a high degree of vacuum, low heating temperature, and heat-sensitive substances are not easily damaged.AfterG.lucidumspore oil is refined through molecular distillation, and the components with different molecular mean free paths are separated to a certain extent[15].The obtained light phase components have different composition and content from the heavy components.Most of the small molecular substances are concentrated in the light phase, mainly including heptanal, octanal, linalool, hexanal, E-2-octanal, 3-ethylpyridine,etc.Studies have shown that the pathways for the formation of volatile components in vegetable oils mainly include Maillard reactions and lipid oxidation.Maillard reaction produces furan, pyrazine, pyrrole,etc., and lipid oxidation produces small molecular aldehydes, ketones and other harmful substances[16].The research results show that aldehydes mainly exist in light components, and aldehydes are the characteristic volatile substances produced by fat oxidation, and they are mainly the products of unsaturated fatty acid free radical reaction.The unsaturated fatty acid ofG.lucidumspore oil will be oxidized and decomposed during storage, the oil will undergo oxidation reaction, and the quality ofG.lucidumspore oil will also deteriorate to a large extent.Saturated fatty acids with lower boiling points and some biologically active components in oil are also easy to decompose at high temperature, and are more distilled to the condenser together with light components to be removed.The results show that molecular distillation can effectively remove small molecular components of oxidative rancidity, which is consistent with previous research results[13].Among the heavy components, the content of esters and other substances is relatively high, mainly including ethyl levulinate, ethyl crotonate, and amyl butyrate.Esters can have a positive impact on the odor profile of vegetable oils and have a mild effect on the overall odor of vegetable oils[17].The content of 2-pentylfuran and(Z)-β-ocimene in the heavy components is higher.Terpenes are important components of plant volatile oils, and those with low threshold values are aroma substances, which are often used as components in medicines and spices, and contribute to the smell ofG.lucidumspore oil.Moreover, olefin compounds are generally less or not detected in various vegetable oils, and some terpene hydrocarbon compounds are beneficial to human health[18].Headspace gas chromatography-ion mobility spectrometry(HS-GC-IMS)analysis showed that after molecular distillation, most of the small molecular substances were concentrated in light components, and molecular distillation had a significant impact on the volatile components ofG.lucidumspore oil.As a result, the flavor of the two components is quite different, and the quality ofG.lucidumspore oil becomes higher after molecular distillation, and impurities and rancidity are reduced, forming a new unique flavor.

Note: Components of ①②③… are listed in Table 1.

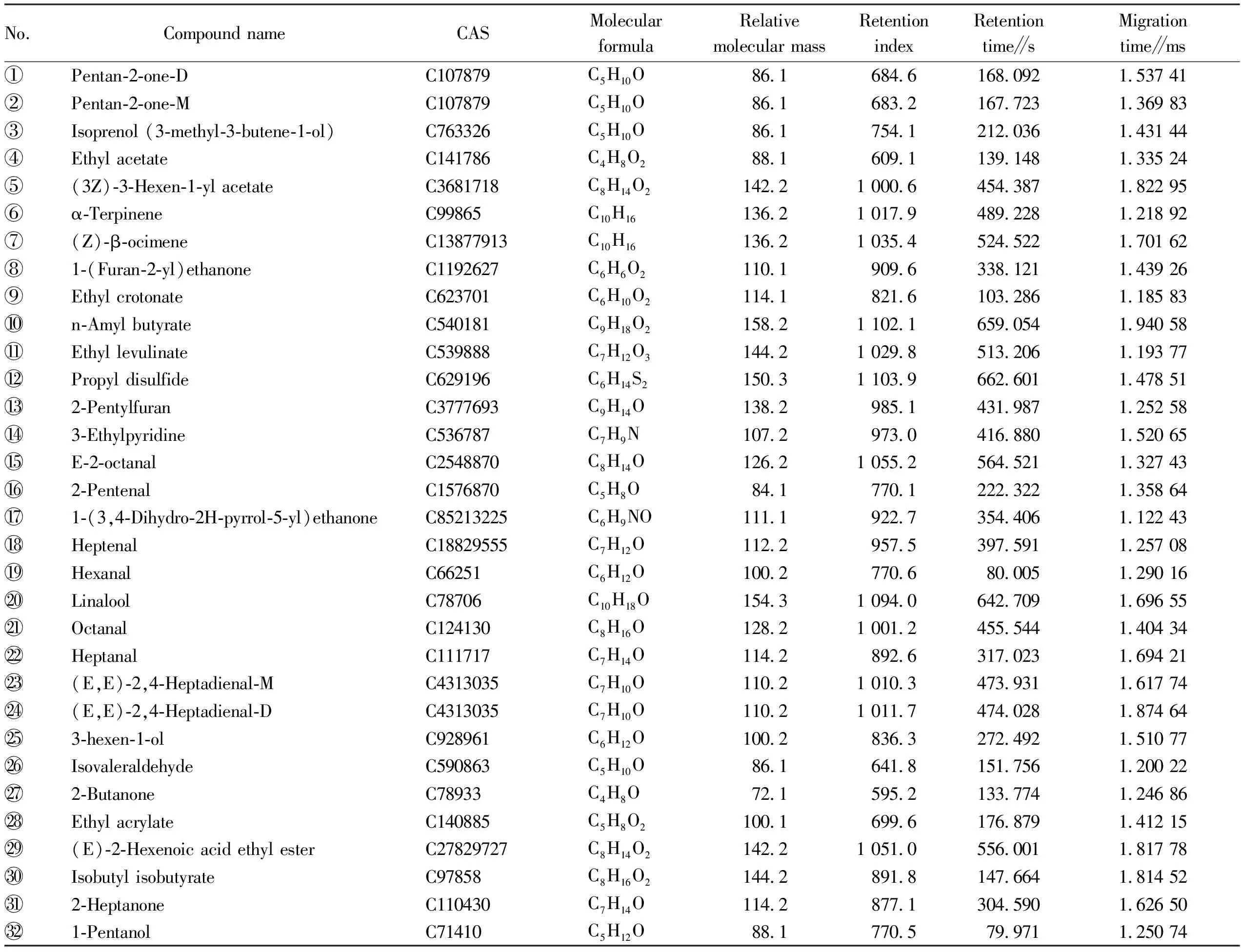

Table 1 Volatile components of Ganoderma lucidum spore oil

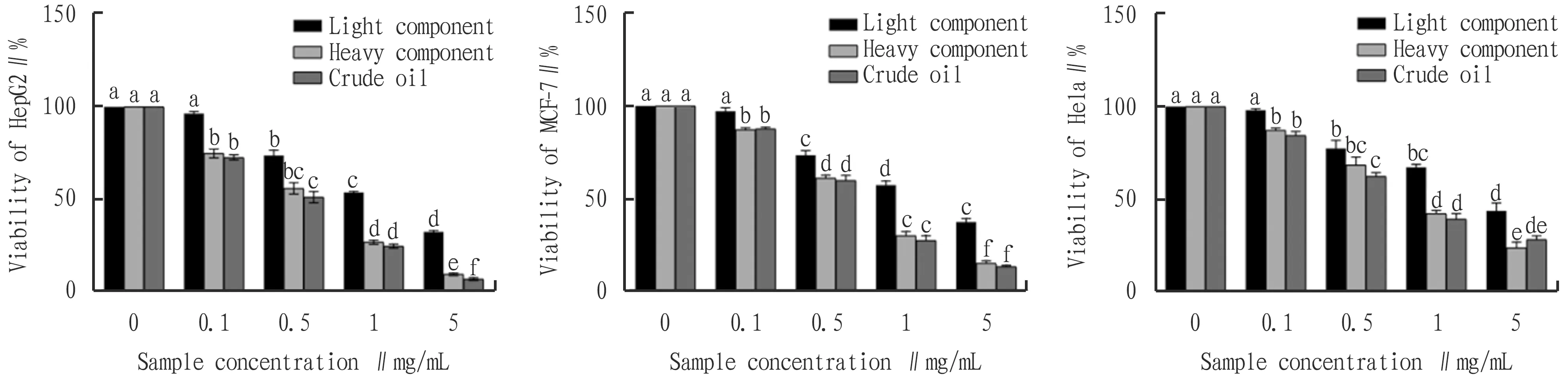

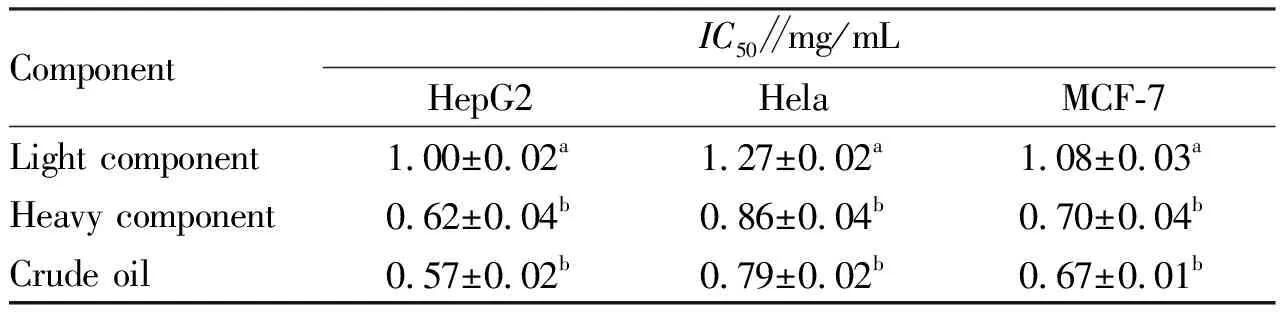

3.2 Detection of cell viability by MTT assayAs indicated in Fig.5, after 24 h of culture for three kinds of tumor cells(HepG2, MCF-7, Hela), the MTT results showed that with the increase ofG.lucidumspore oil sample concentration, the cell survival rate showed a downward trend, showing a dose-dependent manner.Crude oil, heavy component and light component samples all showed good inhibitory effects on the three types of cells.The three components were the most toxic to HepG2 cells, followed by MCF-7 cells, and the least toxic to Hela cells.In addition, at different sample concentrations, the order of the inhibitory ability ofG.lucidumspore oil crude oil and distilled fractions to HepG2, MCF-7, and Hela cells was: crude oil > heavy components > light components.Comparing theIC50of the three kinds of cells against the three different components(Table 2), theIC50ofG.lucidumspore oil crude oil against HepG2, MCF-7, and Hela was the lowest(0.57±0.02, 0.79±0.02, and 0.67±0.01 mg/mL, respectively), followed by heavy components(0.62±0.04, 0.86±0.04, and 0.70±0.04 mg/mL, respectively).The results showed that the viability ofG.lucidumspore crude oil on tumor cells was slightly lower than that of the heavy component, which may be because the molecular distillation temperature caused damage to the antitumor active components inG.lucidum, Studies have shown that the triterpenoids inG.lucidumare very unstable at high temperatures and are easily affected by temperature, resulting in a decrease in their content[19].Besides, after molecular distillation, when the sample concentration increased to 5 mg/mL, the viability of the HepG2, MCF-7, Hela tumor cells in the heavy component group was 9.21±0.73%, 15.03±0.25%, and 23.70±3.08%, respectively, significantly higher than that in the light component group(32.22±0.80%, 37.30±0.89%, and 43.71±4.22%, respectively), indicating that most of the active components inG.lucidumspore oil were concentrated in the heavy components, and molecular distillation had little effect on the antitumor active components of the heavy components compared with crude oil.

Fig.5 Effects of Ganoderma lucidum spore oil on viability of HepG2, MCF-7, Hela cells

Table 2 Cytotoxicity of Ganoderma lucidum spore oil to HepG2, MCF-7, Hela cells

4 Conclusions

In this experiment, we studied the flavor and antitumor activity ofG.lucidumspore oil before and after molecular distillation.Based on gas chromatography-ion mobility spectrometry(GC-IMS)technology, we analyzed the volatile flavor components of molecular distillation products, a total of 38 volatile components were detected in the sample, and 32 components were identified.Among them, there are 8 kinds of aldehydes, 7 kinds of esters, 4 kinds of ketones, 4 kinds of alcohols, 4 kinds of alkenes, and 3 kinds of others(1 kind of ethers, 1 kind of pyridines, and 1 kind of pyrrolines).Experimental results show that molecular distillation can effectively reduce small molecular substances produced by oxidation of oil inG.lucidumspore oil, such as: heptanal, octanal, linalool, hexanal, E-2-octanal, 3-ethylpyridine,etc.The content of esters in the heavy components is higher, the impurities and rancidity are reduced, and it has a unique flavor.The MTT cytotoxicity test found thatG.lucidumspore oil and its distilled components had a certain inhibitory effect on the growth of the three tumor cells.Specifically, the effect on HepG2 cells was the most significant, followed by MCF-7 cells, and Hela cells were the weakest.In addition, crude oil and heavy components showed good inhibitory effects on the three types of cells, indicating that molecular distillation had little effect on the antitumor activity ofG.lucidumspore oil.In summary, molecular distillation technology can be applied in the refining ofG.lucidumspore oil to reduce its impurities and rancidity, improve flavor and improve product quality.

杂志排行

Asian Agricultural Research的其它文章

- Research on Practice Problems and Strategies for Professional Master’s Degree Candidates for Agriculture

- Reform and Exploration of Integrating "Service Learning" into the Teaching of Pathogenic Biology of Aquatic Animals to Help Rural Revitalization

- Review on Land Ecosystem Health Assessment

- Promoting the Empowerment of Science and Technology to Ensure Food Safety Production: A Case Study of Huizhou City

- High-quality Development Path of Henan Agriculture and Rural Areas Empowered by Digital Inclusive Finance

- Technical Efficiency of "Master Switch" in Widening the Human Living Space by Fenlong Tillage