Nanosecond laser preheating effect on ablation morphology and plasma emission in collinear dual-pulse laser-induced breakdown spectroscopy

2022-11-17NaLI李娜EdwardHAREFAandWeidongZHOU周卫东

Na LI(李娜),Edward HAREFA and Weidong ZHOU(周卫东)

Key Laboratory of Optical Information Detection and Display Technology of Zhejiang,Zhejiang Normal University,Jinhua 321004,People’s Republic of China

Abstract Focus-offset collinear dual-pulse laser-induced breakdown spectroscopy is designed and used to investigate the laser ablation and spectral intensity with an aluminum alloy sample.The laser crater morphologies and ablation volumes were measured.An inter-pulse time delay dependent ablation efficiency on a nanosecond laser-heated sample was observed,which was similar to the trend of spectral intensity versus inter-pulse time delay in the delay time less than 3 μs.Based on the observation,the nanosecond pulse laser preheating effect on subsequent second laser ablation and signal enhancement is discussed,which will be helpful for understanding the ablation and signal enhancement mechanism in the standard collinear DP-LIBS technique.

Keywords:enhancement mechanism,laser ablation,crater morphology,target preheating

1.Introduction

Laser-induced breakdown spectroscopy(LIBS),an atomic emission spectroscopy technique,has been widely investigated due to its unique features,including simple sample preparation,fast and simultaneous multi-element detection,rapidin situanalyses,etc[1,2].As the detection capability and sensitivity of traditional single-pulse(SP)LIBS are not good enough for real analytical application,many methods for enhancing the signal intensity of LIBS have been proposed[2],such as a spark or glow discharge enhanced LIBS[3-5],spatial and magnetic confined LIBS[6-8],microwave-assisted LIBS[9,10],sample preheating[11,12]and dual-pulse(DP)LIBS[13,14]etc.Among these methods,the DP-LIBS technique has attracted much more attention due to its advantages of simple instrument requirement and convenient operation.

In the standard collinear DP-LIBS,two nanosecond pulse laser beams are coaxial and incident perpendicularly on the sample surface with identical focus points,and both produce ablation with a certain inter-pulse time delay.As an effective and completive signal enhancement technique for SP-LIBS,understanding the basic enhancement mechanisms is highly desirable.To date,a great effort has been devoted to elucidating the mechanisms that yield the signal enhancement in collinear DP-LIBS[13-24].In general,double pulse LIBS increases the ablation and plasma volume,affects the plasma expansion rates,temperature and ion density in the plasma kernel,and extends the decay time of plasma emissions.All these factors are mixed together to affect the line intensities of LIBS.Specific to the role of the first pulse,it causes on one hand a temporary rise of the target surface temperature,and changes the physical properties of the target material.On the other hand,it forms a plasma plume and shock wave(SW)that produces a transient change in the local atmospheric conditions,leading to the better transmission and coupling of radiant energy[19],and the varying fluid dynamics of the plasma[18,22].These two effects cooperate to increase the coupling of the second pulse energy with the target surface,so that the total mass ablated is larger than that in the case of a single pulse of the same total energy[25,26].However,it is difficult to quantify the relative contributions of physical properties(sample temperature,surface texturing,etc)changes and ambient rarefaction to increase ablation efficiency.To our knowledge,no one work in the literature achieved this quantification.

As we all know,laser surface treatment will increase the temperature of the sample,change the physical properties of the sample,and leave some irregular patterns on the surface after cooling.Obviously,after being preheated by the first pulse laser,the increase in temperature and the change of physical properties of the target material surface will make the subsequent laser ablation easier in the standard collinear DPLIBS configuration.To know the relative contributions of the preheating effect of the first laser would be helpful for understanding the mechanism of signal enhancement in standard collinear DP-LIBS.Long pulse laser heating effect with a pulse width of 60 μs had been investigated recently by Cuiet alin their non-standard collinear long-short DP-LIBS[15].An inter-pulse time delay-dependent ablation and signal enhancement are observed,with a maximum ablation and line intensity at 30 μs inter-pulse time delay.The optimized time delay is just in the middle of long pulse duration,which is very different from that observed in standard collinear DPLIBS with two nanosecond laser pulses[27,28].

In this work,a focus-offset collinear dual-pulse laserinduced breakdown spectroscopy(FOC-DP-LIBS)was proposed and used to investigate the laser ablation process and signal enhancement in collinear DP-LIBS.In the FOC-DPLIBS technique,the two-laser focuses are a few millimeters away along the laser pulse incident direction.This will make the first pulse have a larger radiation area on the sample surface than the second ablation pulse,which is different from that in standard collinear DP-LIBS configuration.Meanwhile,when using the first laser with relatively low laser energy,the first laser cannot generate laser plasma,but only heat,melt and modify the sample surface.To some extent,it leads to an increase in ambient air temperature around the sample.The inter-pulse time delay dependent FOC-DP-LIBS spectroscopy and the morphologies of laser craters were recorded under a low first laser energy condition.Good consistency of ablation volume and spectral intensity was observed in the delay time of less than 3 μs.Based on the results,an inter-pulse timedependent nanosecond laser preheating effect on subsequent laser ablation and spectral intensity enhancement was derived.

2.Experimental

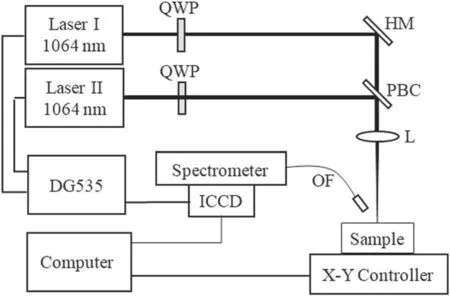

The schematic diagram of the experimental setup used for the FOC-DP-LIBS configuration is shown in figure 1.Two Q-switched Nd:YAG lasers operated at 1064 nm with a pulse width of 15 ns(FWHM)are used here.Both lasers were operated at 1 Hz for the experiments described here.In the experiment,the first laser energy was fixed at 9 mJ which has a flat beam profile,while the second laser energy was kept at 36 mJ but with a Gaussian profile.Both laser beams were combined and aligned in a collinear configuration by a polarizing beam combiner(PBC).The focal points of the twolaser beams are well separated and have a spatial offset of about~7 mm.The produced craters have a diameter of~300 μm for the second laser and~600 μm for the first laser,and if firing the first laser with low energy of 9 mJ,no obvious plasma emission can be generated by the first laser.The FOCDP-LIBS plasma emission was coupled into an optic fiber by a quartz lens,and then delivered through the fiber to the entrance slit of a Czerny-Turner spectrograph(Andor Shamrock SR-303i),equipped with an ICCD(Andor iStar)detector.

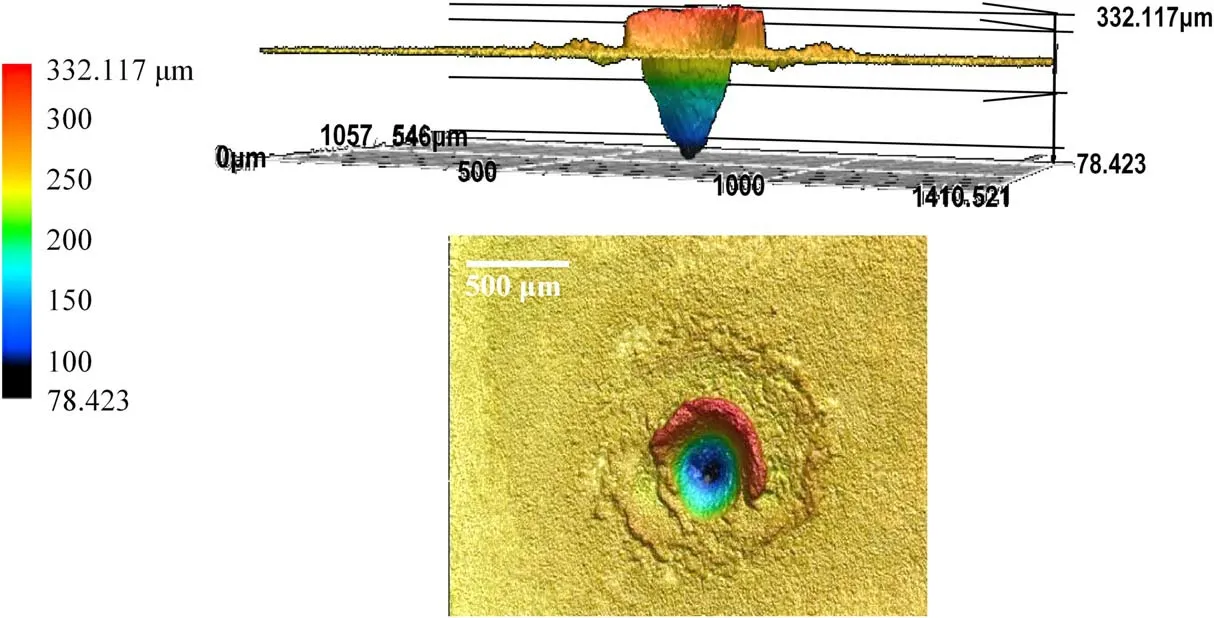

Laser pulses and data acquisition were externally synchronized by a pulse delay generator(Stanford Instruments Model DG535),which allows a wide range of delay times between two-laser pulses to be selected with minimal jitter.The time delay between laser pulses varied from 50 ns up to 24 μs in this study.The gate delay of ICCD was 0.6 μs after the second laser pulse to minimize the initial continuum Bremsstrahlung emission,which has been optimized for SPLIBS analysis in our previous investigation.The data integration time of the ICCD detector was kept at 1 μs for all measurements and an average of 20 shots was taken as a measured spectrum to reduce shot-to-shot variations.For each experiment condition,10 measured spectra were taken.The mean and the associated standard deviation were then calculated over those 10 measurements.The line Al I 394.40 nm was used for analysis.Each crater was taken after 200 successive laser shots.The size and shape of craters were determined by using a laser confocal microscope(model VK250,from KEYENCE).Figure 2 is a typical 3D diagram of a crater measured by VK250,the crater was formed in the FOC-DP-LIBS experiment.It can be seen from the side view that the crater is an inverted cone.A three-dimensional profile of the craters can be observed and measured.The values of the crater depth and diameter can be provided directly by microscope VK250,and then the ablated mass volume can be estimated and derived.

Figure 1.Schematic diagram of FO-DP-LIBS.QWP:Quarter wave plate,HM:Higher reflection mirror,PBC:Polarizer beam combiner,L:Lens,OF:Optical fiber.

Figure 2.Typical 3D image of a crater on aluminum alloy by FOC-DP-LIBS.

A certified aluminum alloy analytical sample(No.5093)from the Chinese National Institute of Metrology was used in this study.The sample surface was polished and carefully cleaned before experiments.AnX-Ytranslation platform is used to move the sample horizontally and get the spectra at different sample locations.

3.Results and discussion

3.1.Inter-pulse time delay dependent ablation crater

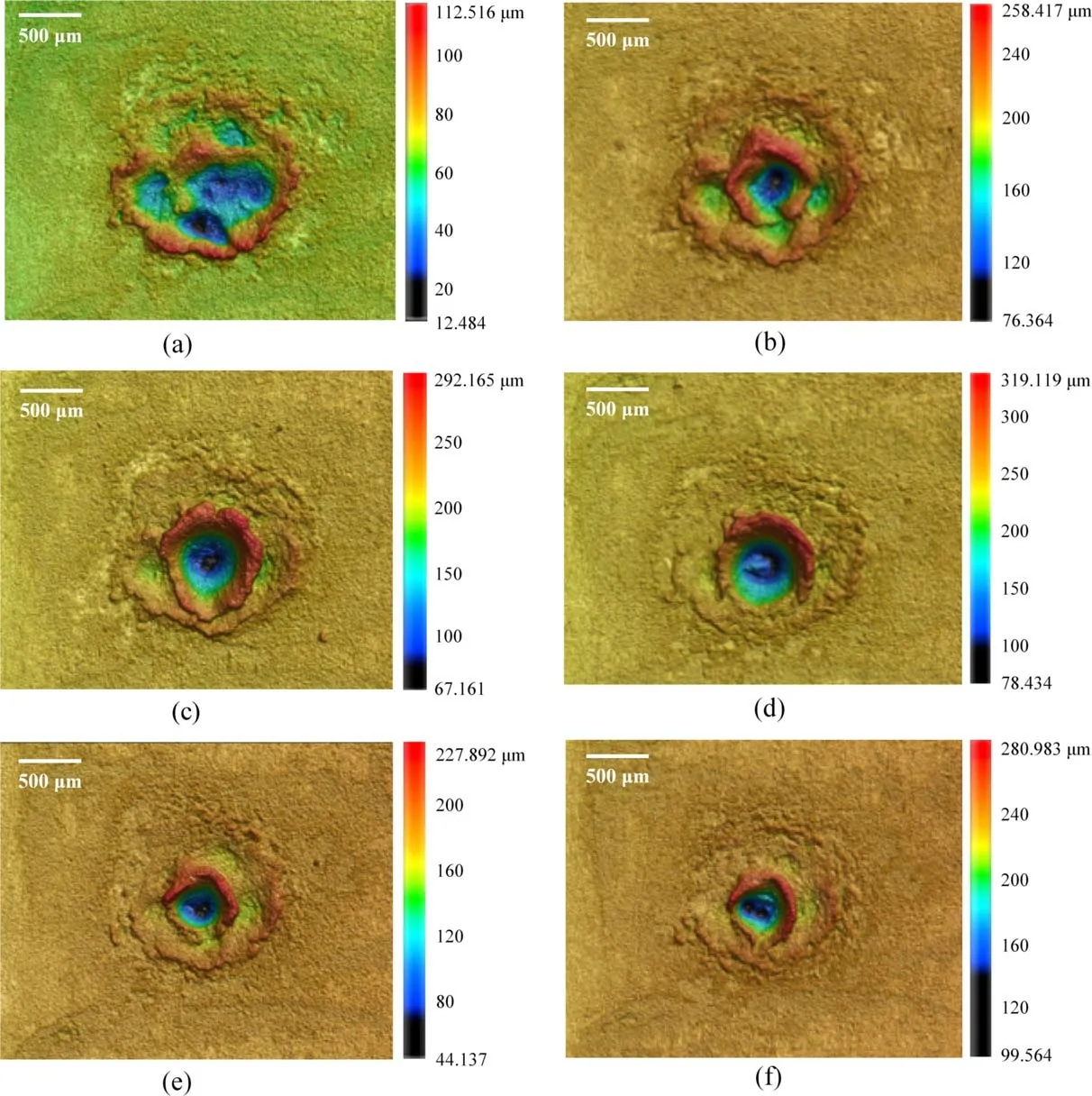

Figure 3 is the morphologies of laser craters at different interpulse time delays.Each crater was formed after 200 successive dual-pulse laser shots with a laser energy ratio of 9 mJ/36 mJ.It can be seen that,when the inter-pulse time delay is small,an irregular ablation profile is generated.It is known that,with the radiation of a nanosecond pulse laser in SP-LIBS,the target temperature rises rapidly in a short time and maintains the molten state in the early time of laser firing.After 300-400 ns,the temperature decreases rapidly and solidifies gradually,and then reaches room temperature after about~1 μs[29,30].In FOC-DP-LIBS,the first laser energy density is designed to be lower than the ablation threshold,it cannot ablate sample and generate plasma.It may only heat the aluminum alloy and form a molten metal layer on the sample surface.With the firing of a subsequent second laser,a shark wave appears as well,which will push away the melted metal on the surface,leading to an irregular laser crater at a short inter-pulse time delay,typically shorter than 500 ns.With the increase in time delay,the molten metal layer gradually solidifies and forms a microstructure on the surface.Meanwhile,a heated layer forms on the aluminum alloy surface,which has a thermal smoothing effect on the area where the thermal conductivity of the aluminum alloy is not uniform.The heated layer is also conducive to the diffusion and absorption of second laser energy,and so in favor of ablation[31].Therefore,regular craters,i.e.an inverted conical ablation profile,gradually forms after sample cooling and surface curing at~900 ns or longer inter-pulse time delay.The ablation volume(both depth and diameter)of the craters reaches the maximum at the time delay of 1.8 μs.Further increasing the time delay,the central depth,and diameter of the ablation profile slowly decrease,indicating that with the increase of time delay,the influence of first laser heating on second laser ablation weakens gradually.

Figure 3.Typical laser crater morphologies at different inter-pulse time delays.(a)500 ns,(b)900 ns,(c)1.2 μs,(d)1.8 μs,(e)4 μs,(f)13 μs.

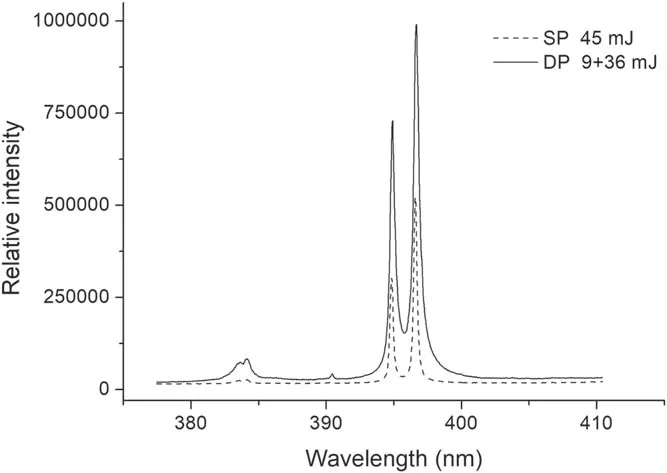

Figure 4.Al I 394.40 nm/396.15 nm obtained by FOC-DP-LIBS at 1.8 μs inter-pulse delays and single-pulse LIBS with the same total energy.

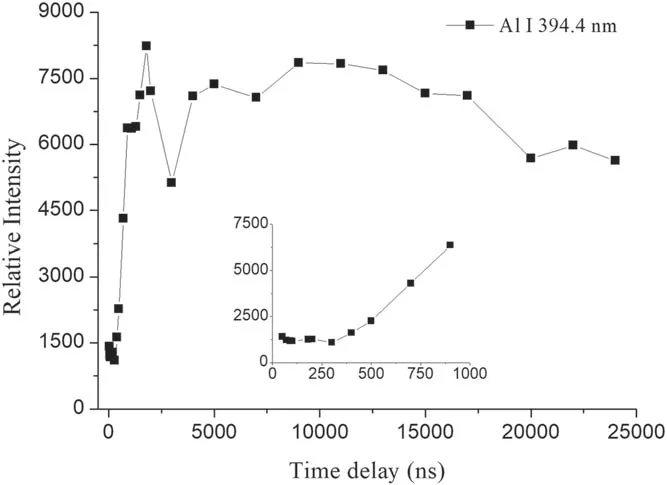

Figure 5.The Al I 394.4 nm line intensities at different inter-pulse time delays.The enlarged graph is the intensity variation within 50-900 ns time delay.

3.2.Inter-pulse time delay dependent line intensity

The typical emission spectra of aluminum alloy acquired by FOC-DP-LIBS with an inter-pulse time delay of 1.8 μs and laser energy ratio of 9/36 mJ are shown in figure 4,along with the single-pulse LIBS with the same total energy(45 mJ).The integrated intensity ratios of DP-LIBS/SP-LIBS are 3.35 for line Al I 394.40 nm and 2.25 for line Al I 396.15 nm,respectively.For comparison,the ablated mass volumes of DP-LIBS and single-pulse LIBS with the same total energy were measured and a ratio of 2.97 was derived.Although the low-energy first nanosecond laser does not ablate the sample and generate plasma emission in FOC-DP-LIBS,it will obviously change the temperature,surface morphology,and optical properties of the ablated material,and the first laser pulse will change the temperature of the ambient environment as well.These changes will affect the coupling of the second laser with the aluminum alloy and lead to signal enhancement.

After the sample and surrounding gas are heated by nanosecond laser radiation,the time-varying physical properties of the material and the ambient gas,as well as the coupling effect of the second laser pulse on the aluminum alloy,determine that the inter-pulse delay has a great influence on the signal enhancement.Figure 5 is the variation of spectral intensities of aluminum atomic spectral lines(Al I 394.4 nm)with the inter-pulse time delay between two laser pulses.It can be seen that,when the time delay is less than 500 ns,the signal intensity is obviously lower than that with other time delays.The first laser pulse with a small laser energy density may only heat the aluminum alloy and generate a molten layer on the sample surface in a short delay time and this molten layer surface only existed in a short time after the first laser firing.This molten layer is easy to be pushed and sputtered away by the second pulse laser bombardment and leaves an irregular crater,as shown in figure 3.A mirror-like molten surface has a higher optical reflectivity,which will prevent the absorption and ablation of the subsequent laser pulse,resulting in weak spectral line intensity and poor ablation efficiency.

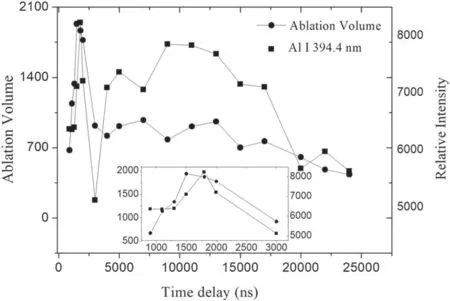

Figure 6.Crater volume and signal intensity of Al I 394.4 nm as a function of the inter-pulse time delay.

When the time delay is within the range of 500 ns-3 μs,signal intensity increases sharply in the delay range of 500-900 ns,reaches the maximum at about 1.8 μs,and then decreases until about 3 μs.The signal intensity increases again,remains relatively stable at 10 to 13 μs,and then decreases gradually.

After a time delay of 500 ns,the melted layer will gradually solidify and texture the surface.The softened and textured metal surface will be conducive to light absorption and the coupling effect between the sample and the second laser pulse,resulting in an increase in signal intensity and ablation efficiency.After a longer delay time of 13 μs,the sample temperature gradually decreases to the normal ambient value,and the signal intensity also decreases.It should be pointed out that,an obvious signal increase is observed in the time delay range between 3 and 10 μs after the signal decrement from the maximum.The phenomenon has not been observed in traditional collinear DP-LIBS.But different from the signal intensity,the ablation volume does not have an obvious increase at this time delay range,as shown in figure 5 later,indicating that the signal intensity increment is not due to the increase of ablated material in the time delay between 3 and 10 μs.Note that during this time delay phase,due to the thermal diffusion and heat exchange between the sample and the surrounding air after the first laser radiates the sample,the atmospheric condition around the sample will change transiently and finally re-balance.The high-temperature ambient gas will reduce the energy exchange of plasma with the surrounding gas,which is conducive to the expansion and emission of the second laser plasma[32,33].The signal enhancement observed in the time delay between 3 and 10 μs is likely caused by this phenomenon.

Based on the laser crater depth and diameter,the ablated mass volume at each inter-pulse time delay was derived,with the results shown in figure 6.If the inter-pulse time delay dependents ablation volume and spectral line intensity curves are put together,as shown in figure 6 as well,an obvious correlation between the ablation mass and spectral line intensity is observed,except in the delay range from 3 to 10 μs.When the inter-pulse time delay is less than 900 ns,no regular ablation crater was formed and the crater volume cannot be calculated and discussed here.At a time delay between 900 ns and 1.8 μs,the laser ablation volume continues to increase until the ablation volume reaches a maximum of 1.8 μs,which is roughly consistent with the varying trend of spectral intensity.At time delay in the range of 1.8-3 μs,both the volume and intensity decrease simultaneously,and their varying trend of them is consistent as well.The consistency of ablation volume and signal intensity observed here shows that the enhancement of spectral intensity is determined by the enhancement of ablation mass in FOC-DPLIBS in the time delay range of 900 ns-3 μs.This basically depends on the physical process of rapid heating and melting of the material surface after being irradiated by a low-energy nanosecond laser,then cooling and shaping through thermal diffusion,and finally changing its surface morphology.Previously,the LIBS line intensity enhancement in a preheated aluminum target had been investigated by Sanginéset al[11],both the crater volume and line intensities were found to be dependent on the temperature of a preheated sample,and a crater volume dependent line intensities were found.No correlation between the line intensity and the measurement electron temperature was observed,and the emission enhancement was assigned to an increment of the ablated mass in their study.The crater volume-dependent line intensity found here in inter-pulse time delay range from 900 ns to 3 μs probably may mean a similar enhancement mechanism.The disagreement of the varying trend between line intensity and ablated volume in the time delay range of 3-10 μs probably was caused by a hot ambient gas,which benefits the second laser plasma expansion and reduces its energy losses,but cannot significantly affect the second laser ablation.

4.Conclusion

In summary,a FOC-DP-LIBS was proposed and used to investigate the nanosecond laser heating effect of laser ablation and plasma emission on an aluminum alloy sample.An irregular laser crater and low signal intensity were observed at a shorter inter-pulse time delay.While further increasing the interpulse time delay,an inverted conical regular crater can be formed,along with an inter-pulse time delay-dependent laser craters and ablation volume.In addition,consistency of ablation volume and spectral intensity versus inter-pulse time delay was found in the time delay of less than 3 μs,indicating that the signal enhancement is almost determined by ablated mass in the nanosecond pulse laser-heated sample in this time delay range.The observed inter-pulse delay-dependent ablation volume and signal intensity are consistent with the physical process,that is,the material surface is rapidly heated and melted after being irradiated by the low-energy first laser,then cooled and shaped by thermal diffusion,and finally changed its surface morphology.Due to heat diffusion and formation of high-temperature ambient gas,spectral line intensity increases again after 3 μs inter-pulse time delay.The nanosecond laser heating effect on subsequent laser ablation and spectral intensity enhancement was then been derived.The result obtained here will be helpful for further understanding the laser ablation and signal enhancement mechanism in the standard collinear DP-LIBS technique.

Acknowledgments

This study was supported by National Natural Science Foundation of China(No.61975186).

ORCID iDs

猜你喜欢

杂志排行

Plasma Science and Technology的其它文章

- Interaction of an unwetted liquid Li-based capillary porous system with high-density plasma

- Understanding the changing mechanism of arc characteristics in ultrasound-magnetic field coaxial hybrid gas tungsten arc welding

- An equivalent model of discharge instability in the discharge chamber of Kaufman ion thruster

- Comparative study of pulsed breakdown processes and mechanisms in self-triggered four-electrode pre-ionized switches

- Investigation of stimulated growth effect using pulsed cold atmospheric plasma treatment on Ganoderma lucidum

- Discharge and jet characteristics of gliding arc plasma igniter driven by pressure difference