水稻收获转运双机协同自主作业策略与试验

2022-11-13张闻宇张智刚罗锡文

张闻宇,张智刚,张 帆,丁 凡,胡 炼,罗锡文

·农业装备工程与机械化·

水稻收获转运双机协同自主作业策略与试验

张闻宇1,2,3,张智刚1,2,3,张 帆1,3,丁 凡1,3,胡 炼1,2,3,罗锡文1,2,3※

(1. 华南农业大学南方农业机械与装备关键技术教育部重点实验室,广州 510642;2. 岭南现代农业科学与技术广东省实验室,广州 510642;3. 广东省农业人工智能重点实验室,广州 510642)

针对水稻收获机与转运车双机协同自主作业环节多、粮食转运过程复杂等问题,该研究设计了一种基于有限状态机(Finite State Machine,FSM)的水稻收获机与转运车协同作业策略,分析了水稻收获机与转运车协同作业模式,建立有限状态机模型。首先,基于作业环节设计触发条件、评估方法和执行流程等基础模块;然后,根据双机协同的各项状态建立状态信息矩阵;最后,依据协同触发事件与状态转移的逻辑设计状态转移链。构建协同作业时分复用控制逻辑框架,并运用Stateflow软件进行仿真分析,为验证所设计策略的田间实际作业效果,搭建了履带式水稻收获转运双机协同试验系统,收获速度为0.8 m/s,收割幅宽1.9 m,共28条收获边,协同路径选择在短边的机耕道上,连续协同工作时间大于等于120 min,采用套圈路径自主收获0.7 hm2水稻,期间共进行6次自动协同转运作业,将所收获的粮食转运到卡车上。试验结果表明,该策略可以实现水稻收获/卸粮转运自主作业,收获效率为0.35 hm2/h,为实现水稻收获双机智能转运协同功能奠定了基础,可为水稻无人农场建设提供技术支持。

农业机械;水稻;收获;无人农场;转运;双机协同策略

0 引 言

水稻是主要粮食作物,保证水稻高产稳产保障国家粮食安全有重要意义。智能化机械生产能够减轻农业劳动强度、提高生产效率和质量[1-2]。水稻智能化收获作业复杂程度相对较高,涉及到定位测姿、路径跟踪、收获控制和协同转运等多个部分[3-5]。路径规划[6-7]和路径跟踪[8]是智能农机共性技术,国内外学者对农机直线跟踪进行了一系列研究,包括自适应纯追踪路径跟踪方法[9-11]、模糊控制方法[12]、复合循环鲁棒控制[13]、防侧翻适应控制算法[14]、虚拟阿克曼转向模型跟踪算法[15]和预瞄追踪模型算法[16],跟踪精度可达2.5 cm。

水稻收获时,由于收获机粮仓容量有限,收获机粮仓快满时需开至田边卸粮,影响了收获机自动作业效率。因此,研究水稻收获机与转运车的协同作业系统,采用智能转运车转运粮食可以有效提高收获机的作业效率。

国内外研究者对农机协同作业进行了相关研究。Noguchi等[17]提出了2种典型农机协同模式,一种是主机指定给从机作业目标,一是从机跟随主机作业。Iida等[18]研发了一农机自动跟随系统,采用超声波传感器控制随车的相对位置和偏角。白晓平等[19]提出了一种联合收获机群协同作业的控制方法,在1.0 m/s的速度下,车辆跟随平均跟踪误差为5.93 cm。张闻宇等[20]设计了纵向相对位置位速耦合控制器,实现了从机跟随卸粮,在1.0 m/s的速度下,收获机与运粮车相对纵向距离控制误差标准差为9.2 cm。王猛[21]建立了多农机协同作业静态任务分配模型,使作业成本降低了29.48%~55.00%。

曹如月等[22]提出了基于改进A*和Bezier曲线的多机协同全局路径规划,有效降低了转弯次数。宫金良等[23]提出一种复杂环境下异质农业机器人群的任务分配及全区域覆盖策略,4个试验机器人可以共同完成场地的覆盖,遍历重复率小于7%。姚竟发等[24]针对同种机型的协同进行了路径规划研究,以总作业时间和作业时长为综合优化目标,进行多机无冲突协同作业路径优化,矩形农田总作业时间和作业时长平均分别下降了2.45%、2.29%。翟志强等[25]提出一种面向主从跟随模式的多机协同作业导航路径规划方法,基于方向包围盒算法和分离轴定理建立农机安全状态检测模型,路径规划算法用时最小值为0.453 s、最大值为1.563 s、平均值为0.951 s,可为小麦、青贮收获等主从跟随式多机协同自主作业提供有效的全局作业路径。上述研究集中在弱耦合的多机空间协同路径规划,减少了作业时间和提高了覆盖率。多智能体协同在机器人领域也是研究的热点之一[26-32],对农机协同作业有借鉴作用。

上述协同研究大多集中于多机协同的协同精度控制方法和路径规划等,而农机协同作业系统中系统逻辑框架和协同控制策略是保证系统可靠性的关键。双机协同作业模式具有环节多、交互复杂等非顺序性特点,本文拟根据水稻收获双机协同作业需求,分析协同收获模式,建立系统有限状态机模型,基于该模型构建时分复用系统逻辑框架,并进行协同逻辑仿真验证和田间试验,以验证水稻收获转运双机协同自主作业策略的可靠性和实用性。

1 水稻收获智能转运双机协同模式

Noguchi等[17]将农机协同模式分为“GOTO”(定点协同)和“FOLLOW”(跟随协同)。水稻收获转运双机协同自主作业也可以按照粮食转运过程分为2种模式,模式1为召唤转运模式,模式2为随车转运模式。模式1是全程智能收获作业的基础,本文针对模式1多环节协同作业和控制的特点,并将模式1分为4个基本环节(Basic Elements,BE)的循环操作:

收获机自主收获环节1:收获机提高发动机转速、启动主离合和割台离合,跟踪预设收获路径,实现自主收获功能;

转运车等待召唤环节2:转运车根据规划的路径行驶到待协同路段,停车、等待收获机召唤。

收获机向转运车卸粮环节3:收获机到达待卸粮位,发送信号召唤转运车,转运车根据通讯信息实现召唤对位协同卸粮;

转运车卸粮环节4:转运车根据规划的路径驶往运粮卡车卸粮。

1、2和4为弱耦合环节,两车保持通讯各自完成自主规划作业任务。3为强耦合环节,收获机和转运车必须实现精准定位和协同作业。

针对水稻自主收获运粮协同作业的要求,制定智能协同流程,收获机首先根据规划路径出库下田,执行1自主收获,转运车随后出库,进入2在机耕道等待召唤,收获机基于粮仓状态停车召唤转运车,进入3协同卸粮,协同卸粮完成后收获机回到1继续收获,转运车行驶至田边道路进入4,完成卸粮后返回机耕道进入2等待收获机再次召唤。全部收获工作结束后收获机执行3将粮仓中的粮食卸至转运车中,然后自动驶回机库,转运车完成B后回库,最终完成智能协同作业。

2 收获转运双机协同过程建模

收获机与转运车智能协同作业包括自主作业和协同转运几个环节,本文根据协同模式将各个动作分为若干子状态,采用有限状态机(Finite State Machine,FSM)进行建模,有限状态机能够有效表示系统的各个状态和状态间转移关系,在商品生产和航天航空等领域广泛应用[33-34]。

根据收获机和转运车2个实体将系统分为2个模块状态机(Module State Machine,MSM),收获机为1,转运车为2。

2.1 状态机功能模块定义

收获转运双机协同模式状态机的组成部分包括:

1)触发器(State Generator,)。触发器为状态的外部触发输入,功能是触发状态转移。1的状态触发器包括:转运车对位完成信号G1,转运车驶离信号G2。2的状态触发器包括收获机就位信号G1,收获机卸粮结束信号G2。

2)评估器(State Assessor,)。评估器用于评估是否能进入状态。1的状态评估包括收获机粮仓满评估A1,收获机粮仓空评估A2,收获机直线跟踪质量评估A3,收获机目标路径状态评估A4;2的状态评估包括转运车粮仓满评估A1,转运车粮仓空评估A2,转运车直线跟踪质量评估A3,转运车目标路径状态评估A4。

3)执行器(State Executor,)。执行器为当前状态的执行任务,1的状态执行器包括收获状态执行器E1、召唤状态执行器E2和卸粮状态执行器E3。2的状态执行器包括对位状态执行器E1,等待状态执行器E2和卸车状态执行器E3。

4)确认器(State Verification,)。确认器用于确认当前状态的结果,1的状态确认器包括:收获机卸粮点就位确认V1、收获机卸粮完毕确认V2。2的状态确认器包括转运车与收获机对位成功确认V1、转运车与运粮卡车对位成功确认V2。

2.2 状态信息矩阵定义

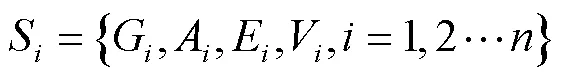

分别将收获机1和转运车2的触发器、评估器、执行器和确认器各部件组成系统状态矩阵,收获机状态矩阵为1、转运车状态矩阵为2,1包括收获路径和粮仓监控等信息,收获机的状态1表达式如下:

式中11为路径状态机,12为主离合状态机,13为割台离合状态,14为卸粮离合状态,15为粮仓监测状态,16为粮筒位置状态,17为定位定向状态,18为双机对位状态,19为发动机转速状态,110为车速状态,为收获机状态个数。

2包括转运路径和粮仓监控等信息,表达式如下:

式中21为路径状态机,22为卸粮离合状态,23为粮仓监测状态,24为粮筒位置状态,S为定位定向状态,26为运移对位状态,27为发动机转速状态,28为车速状态,为转运车状态个数。

上述每个状态都涉及触发器、评估器、执行器、确认器,集合关系式表达式为

11需要评估收获机是否在正常直线跟踪状态;收获作业时12、13、19和110按顺序结合主离合和割台离合加油门起步,停车等待时按则逆序操作。卸粮时14、15和16基于粮仓的状态先伸出粮筒、提高油门、结合卸粮离合,停止卸粮则逆序操作,18和19进行对位过程执行和评估。转运车除了没有主离合和割台离合状态机,其他的状态机功能与收获机相同。收获机和转运车状态集合如表1。

表1 收获机和转运车状态集合表Table 1 State parameter table of harvester and transport vehicle

注:E1为收获状态执行器,E2为召唤转运车状态执行器,E3为卸粮状态执行器,A1为收获机粮仓满评估器,A2为收获机粮仓空评估器,A3为收获机直线跟踪质量评估器,V1为收获机卸粮点就位确认器,V2为收获机卸粮完毕确认器,G1为转运车与收获机对位完成信号,G2为转运车驶离信号,E1为对位状态执行器,E2为等待状态执行器,E3为转运车卸粮状态执行器,A1为转运车粮仓满评估器,A2为转运车粮仓空评估器,A3为转运车直线跟踪质量评估器,V1为运粮车与收获机对位成功确认器,V2为转运车与运粮卡车对位成功确认器,G1为收获机就位信号,G2为收获机卸粮结束信号。

Note:E1is the state executor of harvest,E2is the state executor of calling transport,E3is the state executor of grain unloading,A1is the state assessor of harvester granary full,A2is the state assessor of harvester granary empty,A3is the state assessor of harvester line tracking quality,V1is the state verification of harvester in place unloading point,V2is the state verification of harvester finished grainunloading,G1is the state generator of transportalignment with harvest,G2is the state generator of transport leaving,E1is the state executor of alignment,E2is the state executor of waiting,E3is the state executor of the transport grain unloading,A1is the state assessor of transport granary full,A2is the state assessor of transport granary empty,A3is the state assessor of transport line tracking quality,V1is the state verification of alignment transport with harvest,V2is the state verification of alignment transport with grain transporting truck,G1is the state generator of harvester in place,G2is the state generator of harvest unloading over.

2.3 基本动作执行器

根据水稻收获转运协同作业过程中的操作,可以分为固定的执行流程:E1、E2、E3和E1、E2、E3。

E1顺序改变18、13、12、110和11的状态,使得收获机从停车模式进入收获1。

E2顺序改变110、18、12和13的状态,使得收获机从收获模式进入召唤等待,召唤转运车前来运粮。

E3分2组动作,E3_1开始卸粮和E3_2停止卸粮操作。

E1分2类功能,路径跟踪运移和协同对位。路径跟踪运移E1_1,沿21的规划路径进行路径运移。协同对位E1_2进行对位操作,E2使车辆从运移模式进入2。由于2卸粮系统与1相同,E3的功能和动作与E3相同,分为E3_1和E3_2。

2.4 协同作业状态转移链构建

根据4个基本环节设计状态机的状态转移链。1环节主要由执行器E1组成,2环节主要由执行器E2组成,3环节主要由执行器E2、E3和E1组成,4环节主要E3组成。1、2和4环节相对独立,3为强耦合环节。

当收获机1处于E1收获状态,A1评估如粮仓中的水稻储量达到阈值,1则按照11的规划在预定路径点上进入E2等待状态。同时V2确认到达指定位置,通过无线网络发送G1信号标志位至2转运车。如果2此时处于E2状态则进入E1执行,如果处于E3状态则完成卸粮后前往协同地点后经由E2转入E1执行。2执行E1,完成后,V1确认成功后发送G1触发1的E3卸粮执行。A2监测到如粮仓已经卸空则发送G2信号给2,接着1结束卸粮执行E1。此时2根据A2评估结果,如仓储达到阈值则进入E3卸粮流程,否则重新进入E2继续等待。E3依据A2判断粮空,然后依据路径规划到达协同位置进入E2。

依据上述流程设计水稻自动收获/卸粮转运双机协同的状态转移链,如图1所示。

注:M1为收获机状态机,M2为转运机状态机。

3 水稻自动收获/卸粮转运双机协同作业逻辑

3.1 逻辑框架设计

基于上文的双机协同模型、状态参数和状态转移链分别设计收获机和转运车的逻辑框架。

双机协同转运逻辑框架是双机协同模式从理论模型到技术实现的桥梁,其将路径跟踪控制系统、纵向对位控制算法、作业动作流程控制模块和自动卸粮模块等具体的技术细节进行有效整合,使得收获运粮系统能够在自主控制条件下完成水稻收获转运作业。

嵌入式导航驾驶控制器中同时有多个不同任务在运行,所以设计协同逻辑框架时采用时分复用模式,以主循环重复检索的方式为协同框架,收获机协同逻辑流程如图2a所示,转运车协同逻辑流程如图2b所示,该流程是由双机通讯所驱动的状态转移链流程,2组逻辑通过触发信号相互配合运行,实现水稻收获转运双机协同自主作业的功能。

3.2 协同逻辑时序仿真分析

仿真分析主要研究双机信号传递与协同逻辑框架的有效性,针对双机的顺序执行器进行了简化,引入延时替换车辆内部顺序执行器。采用MATLAB中的Stateflow建立仿真模型[34]。基于协同逻辑,设计收获机和转运车对应的Stateflow模型,分别为Harvester模块和Transfer模块。其中Output和Input分别代表模块当前状态的输出和下一时刻的状态输入,中间的延时函数Delay、Delay1代表执行的步骤所用的时间。2个模块之间通信信号包括G1、G1和G2触发器,传递方向如图3a所示,信号间的Delay2、Delay3、Delay4代表通讯延时。其中State表示农机当前状态,其他符号与上文定义一致。State的状态初始值都设为1,G1、G1和G2的信号初值都设为0,时序仿真结果如图 3b 和图3c所示,图中收获机和转运车的状态按照设计在1至4之间有序变化,如图3b1和2进入1和2,当1进入3,2进入3,3结束后,2进入4,1重回1,2结束4回到2,进入下一个循环。如图3c1进入3时发出G1信号召唤2,2就位后发出G1信号,卸粮结束1发出G2信号,进入下一个循环。试验结果表明收获转运流程逻辑框架有效。

图2 双机协同逻辑流程

注:收获机的状态1-4分别为Eh1、Eh2、Eh3_1和Eh3_2执行状态,转运车的状态1~6分别为Et1_1、Et2、Et1_2、Et3、Et3_1和Et3_2执行状态,输入1、输入2分别为收获机和转运车的输入状态,输出1、输出2分别为收获机和转运车的输出状态。

4 水稻自动收获/卸粮转运双机协同作业田间试验

4.1 双机协同导航试验系统

为验证水稻收获转运双机协同自主作业策略的实际作业效果和稳定性,构建了履带式水稻协同收获系统。收获协同系统包括履带式水稻收获机(潍柴雷沃重工RG70V4G-014)和履带式水稻转运车(潍柴雷沃重工RG70V4G-015),两机均采用全电控的底盘,主要参数如表2所示,具有线控的离合、割台、粮筒和履带行驶系统,采用CAN(Controller Area Network)总线发送线控协议报文。双机均安装双天线BDS定位系统(司南K726),定位信息获取频率为10 Hz,水平定位精度为±(10+1×10-6×)mm,其中为基站到移动站的距离(km)。水稻收获协同试验的双机通讯采用有人云的4/5G DTU(Data Transfer unit),型号为USR-G781,双工通讯串口透传频率为1 Hz,采用16位CRC(Cyclic Redundancy Check)校验设计串口通讯协议减少通讯误码率。导航控制模块与控制终端通过RS-232通讯;双机分别安装了导航控制终端(eAgri-800-RS)用于收获智能控制,通过CAN总线与双机的底盘电控单元(Electronic Control Unit,ECU)通讯。双机协同控制系统基于c语言运用Keil uVision5开发,协同策略逻辑嵌入其中,架构形式与文中逻辑流程一致,以双机之间通讯驱动状态转移。导航系统直线路径跟踪算法采用预瞄跟随控制方法[16]跟踪标准差小于5 cm,双机对位控制算法采用位置误差PID(Proportion Integration Differentiation)方法[20],纵向误差小于20 cm,控制系统结构和试验车辆如图4所示。

表2 收获机和转运车主要结构参数Table 2 Main structural parameters of harvester and transport vehicle

注:CAN为控制器局域网,RTK-GNSS为全球导航卫星定位系统实时动态测量技术。

4.2 水稻自动收获/卸粮转运双机协同作业试验设计与分析

试验设计:协同作业试验在华南农业大学增城试验基地进行。试验地长120 m,宽60 m,约0.7 hm2。由于本试验中没有安装粮仓位传感器,所以策略中的仓满、仓空采用产量预估和定时器计算确定,及时性和准确性不高,通过仿真验证符合逻辑运行需求。由于转运边是固定在机耕道上,必须完成收获一整圈才能卸粮转运。可以通过试验前一次长边的水稻收获量估算需要2圈进行转运。实际作业中一条长边作业大约可以收获20%粮仓容积的粮食,所以估算收获机快完成2圈作业时(4条长边收获)提前通知转运车做好转运准备。设计收获机和转运车先后从基地机库出发自主前往田间,收获机到田间后启动收获流程开始收获,收获速度设置为0.8 m/s。转运车在机耕道等待,按照所设计的协同作业策略,将收获的粮食转运到路边的运粮卡车中。整块农田收获完成之后,顺序回到机库中,图5为协同收获试验现场。

图5 增城试验基地水稻试验田智能收获试验现场

路径设计:按照试验计划,设计收获路径和转运路径。收获路径根据田块大小采用先收外圈再平行套圈的方式实现覆盖,收割路径幅宽设为1.9 m,共28条作业边,协同路径选择在短边的机耕道上。收获作业时短边行驶直线路径重合,转运车协同只需要规划1条复用的路径,在该条路径上前进或倒车就可以完成全田的粮食对位转运工作,具体转运点由收获机发出的坐标计算获得,都位于该路径上,协同路径如图6a所示。

试验分析:水稻收获试验中,智能收获机与转运车按照预定的路径完成协同作业流程,作业轨迹如图6b,图中的几处轨迹异常是因为数据记录通讯延时导致。规划了12组套圈路径,每2组转运一次,按照设计共进行了6次转运协同,图6c、6d和6e分别是记录的网络通讯逻辑触发信号G1、G2和G1按照预定逻辑先后正常触发,协同全过程对位准确,连续协同工作时间不少于120 min,完成协同收获作业并返回机库。试验表明水稻收获双机协同作业策略可以实现的水稻收获/卸粮转运自主作业,收获效率为0.35 hm2/h,能够为水稻智能覆盖收获协同作业提供支撑。

图6 水稻收获转运双机协同作业试验结果

5 结 论

针对水稻导航收获协同环节多、粮食需要转运等问题,本文设计了一种水稻收获机和转运车智能协同作业策略,将具体的技术进行了路径跟踪算法、协同对位算法、定位信息融合、通讯链路、底盘线控等技术按照策略有机组合,最终实现水稻收获机和转运车的智能化作业,具体论证如下。

1)建立了协同环节的有限状态机模型,构建了触发器、评估器、执行器和确认器模块,建立了收获转运环节的状态参数,定义了状态信息矩阵以表示各项状态的具体内容,结合该矩阵和基础模块设计了状态转移链,编制了协同逻辑框架。采用Stateflow仿真软件对协同逻辑框架进行了仿真验证。

2)构建了履带式水稻协同收获系统,制定了双机通讯协议,设计了水稻收获双机协同试验,包括作业流程和作业路径。进行田间水稻收获试验,收获速度为0.8 m/s,收割幅宽1.9 m,共28条收获边,协同路径选择在短边的机耕道上,连续协同工作时间大于等于120 min,采用套圈路径自主收获0.7 hm2水稻,期间进行了6次自动协同转运作业,将所收获的粮食转运到卡车上,试验结果表明,可以实现的水稻收获/卸粮转运自主作业,收获效率为0.35 hm2/h,状态信号正常,能够为水稻收获协同作业提供支撑。

由于现有系统中未安装粮仓传感器,所以策略中的仓满、仓空采用产量预估和定时器进行替换,及时性和准确性不高,未能实现策略中的所设计的全部功能。后期加入粮仓监测系统后可更好地实现收获策略。未来的研究可以将根据收获实际情况设计动态路径规划方法和融入随车转运模式2,将进2种模式相结合形成混合转运模式。基于粮仓传感器和已作业区域数据选择执行机耕道转运还是随车协同转运。当需要转运粮食时判断是否有可协同的安全空间可以使用,如果没有足够的空间,自动设置在机耕道定点转运。经过几圈收获作业后将随车转运空间腾出后,即可指定随车转运模式,提高效率的同时确保可行性。

[1] 罗锡文,廖娟,胡炼,等. 我国智能农机的研究进展与无人农场的实践 [J]. 华南农业大学学报,2021,42(6):8-17.

Luo Xiwen, Liao Juan, Hu Lian, et al. Research progress of intelligent agricultural machinery and practice of unmanned farm in China[J]. Journal of South China Agricultural University, 2021, 42(6): 8-17. (in English with Chinese abstract)

[2] 赵春江. 智慧农业的发展现状与未来展望[J]. 华南农业大学学报,2021,42(6):1-7.

Zhao Chunjiang. Current situations and prospects of smart agriculture[J]. Journal of South China Agricultural University, 2021, 42(6): 1-7. (in Chinese with English abstract)

[3] Aravind K R, Raja P, Manuel Pérez-Ruiz. Task-based agricultural mobile robots in arable farming: A review[J]. Spanish Journal of Agricultural Research, 2017, 15(1): 1-16.

[4] Han Shufeng, He Yong, Fang Hui. Recent development in automatic guidance and autonomous vehicle for agriculture: A review[J]. Journal of Zhejiang University(Agriculture and Life Sciences), 2018, 44(4): 381-391, 515.

韩树丰,何勇,方慧. 农机自动导航及无人驾驶车辆的发展综述[J]. 浙江大学学报(农业与生命科学版),2018,44(4):381-391,515. (in English with Chinese abstract)

[5] 兰玉彬,赵德楠,张彦斐,等. 生态无人农场模式探索及发展展望[J]. 农业工程学报,2021,37(9):312-327.

Lan Yubin, Zhao Denan, Zhang Yanfei, et al. Exploration and development prospect of eco-unmanned farm modes[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(9): 312-327. (in English with Chinese abstract)

[6] 周俊,何永强. 农业机械导航路径规划研究进展[J]. 农业机械学报,2021,52(9):1-14.

Zhou Jun, He Yongqiang. Research progress on navigation path planning of agricultural machinery[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(9): 1-14. (in Chinese with English abstract)

[7] 黄小毛,张垒,王绍帅,等. 凸多边形田块下油菜联合直播机组作业路径规划[J]. 农业机械学报,2022,53(1):33-40,150.

Huang Xiaomao, Zhang Lei, Wang Shaoshuai, et al. Path planning of rapeseed combine seeder in field of convex boundary[J]. Transactions of the Chinese Society for Agricultural Machinery, 2022, 53(1): 33-40, 150. (in Chinese with English abstract)

[8] 张漫,季宇寒,李世超,等. 农业机械导航技术研究进展[J]. 农业机械学报,2020,51(4):1-18.

Zhang Man, Ji Yuhan, Li Shichao, et al. Research progress of agricultural machinery navigation technology[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(4): 1-18. (in Chinese with English abstract)

[9] 张朝宇,董万静,熊子庆,等. 履带式油菜播种机模糊自适应纯追踪控制器设计与试验[J]. 农业机械学报,2021,52(12):105-114.

Zhang Chaoyu, Dong Wanjing, Xiong Ziqing, et al. Design and experiment of fuzzy adaptive pure pursuit control of crawler-type rape seeder[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(10): 105-114. (in Chinese with English abstract)

[10] 张智刚,罗锡文,赵祚喜,等. 基于Kalman滤波和纯追踪模型的农业机械导航控制[J]. 农业机械学报,2009,40(S):6-12.

Zhang Zhigang, Luo Xiwen, Zhao Zouxi, et al. Trajectory tracking control method based on kalman filter and pure pursuit model for agricultural vehicle[J]. Transactions of the Chinese Society of Agricultural Engineering, 2009, 40(S): 6-12. (in Chinese with English abstract)

[11] 张闻宇,丁幼春,廖庆喜,等. 基于SVR逆向模型的拖拉机导航纯追踪控制方法[J]. 农业机械学报,2016,47(1):29-36.

Zhang Wenyu, Ding Youchun, Liao Qingxi, et al. Pure pursuit control method based on SVR inverse-model for tractor navigation[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(1): 29-36. (in Chinese with English abstract)

[12] Gxa B, Mc A, Xh C, et al. Path following control of tractor with an electro-hydraulic coupling steering system: Layered multi-loop robust control architecture[J]. Biosystems Engineering, 2021, 209: 282-299.

[13] Hsiao Y C, Farzaneh K, Stavros G. V, et al. Developing and evaluating an autonomous agricultural all-terrain vehicle for field experimental rollover simulations[J]. Computers and Electronics in Agriculture, 2022, 194, 106735.

[14] Zhang L H, Zhang R R, Li L L, et al. Research on virtual Ackerman steering model based navigation system for tracked vehicles[J]. Computers and Electronics in Agriculture, 2022, 192, 106615.

[15] Aravind K R, Raja P, Manuel Pérez-Ruiz. Task-based agricultural mobile robots in arable farming: A review[J]. Spanish Journal of Agricultural Research, 2017, 15(1): 1-16.

[16] 王辉,王桂民,罗锡文,等. 基于预瞄追踪模型的农机导航路径跟踪控制方法[J]. 农业工程学报,2019,35(4):11-19.

Wang Hui, Wang Guimin, Luo Xiwen, et al. Path tracking control method of agricultural machine navigation based on aiming pursuit model[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(4): 11-19. (in Chinese with English abstract)

[17] Noguchi N, Will J, Reid J, et al. Development of a master- slave robot system for farm operations[J]. Computers & Electronics in Agriculture, 2004, 44(1): 1-19.

[18] Iida M, Kudou M, Ono K, et al. Automatic following control for agricultural vehicle[C]. Istanbul, Turkey, 6th International Workshop on Advanced Motion Control. Proceedings, 2000, 8494: 158-162.

[19] 白晓平,王卓,胡静涛,等. 基于领航-跟随结构的联合收获机群协同导航控制方法[J]. 农业机械学报,2017,48(7):14-21.

Bai Xiaoping, Wang Zhuo, Hu Jingtao, et al. Harvester group corporative navigation method based on leader-follower structure[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(7): 14-21. (in Chinese with English abstract)

[20] 张闻宇,张智刚,罗锡文,等. 收获机与运粮车纵向相对位置位速耦合协同控制方法与试验[J]. 农业工程学报,2021,37(9):1-11.

Zhang Wenyu, Zhang Zhigang, Luo Xiwen, et al. Position-velocity coupling control method and experiments for longitudinal relative position of harvester and grain truck[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(9): 1-11. (in Chinese with English abstract)

[21] 王猛. 农机多机协同作业任务分配关键技术研究[D]. 北京:中国农业机械化科学研究院,2021.

Wang Meng. Research on Key Technologies on Farm Task Allocation for Multi-Machine Cooperative Operation[D]. Bei jing: Chinese Academy of Agricultural Mechanization Sciences, 2021. (in Chinese with English abstract)

[22] 曹如月,张振乾,李世超,等. 基于改进A*算法和Bezier曲线的多机协同全局路径规划[J]. 农业机械学报,2021,52(S):548-554.

Cao Ruyue, Zhang Zhenqian, Li Shichao, et al. Multi-machine cooperation global path planning based on A-star algorithm and bezier curve[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(S): 548-554. (in Chinese with English abstract)

[23] 宫金良,王伟,张彦斐,等. 基于农田环境的农业机器人群协同作业策略[J]. 农业工程学报,2021,37(2):11-19.

Gong Jinliang, Wang Wei, Zhang Yanfei, et al. Cooperative working strategy for agricultural robot groups based on farmland environment[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(2): 11-19. (in Chinese with English abstract)

[24] 姚竟发,滕桂法,霍利民,等. 联合收割机多机协同作业路径优化[J]. 农业工程学报,2019,35(17):12-18.

Yao Jingfa, Teng Guifa, Huo Limin, et al. Optimization of cooperative operation path for multiple combine harvesters without conflict[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(17): 12 -18. (in Chinese with English abstract)

[25] 翟志强,王秀倩,王亮,等. 面向主从跟随协同作业的导航路径规划方法[J]. 农业机械学报,2021,52(S):542-547.

Zhai Zhiqiang, Wang Xiuqian, Wang Liang, et al. Collaborative path planning for autonomous agricultural machinery of master-slave cooperation[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(S): 542-547. (in Chinese with English abstract)

[26] Jin Y, Wei SQ, Yuan J, et al. Hierarchical and stable multiagent reinforcement learning for cooperative navigation control[J]. IEEE Transactions on Neural Networks and Learning Systems( Early Access ), 2021, 9(19): 1-14.

[27] Gxa B, Mc A, Xh C, et al. Path following control of tractor with an electro-hydraulic coupling steering system: Layered multi-loop robust control architecture[J]. Biosystems Engineering, 2021, 209: 282-299.

[28] Valery P, Lyudmila V, Inna N, et al. The problem of choice of optimal technological decisions on harvester control[J]. MATEC Web of Conferences, 2018, 226: 1-6

[29] Wang H L, Yao Z X, Guo Y H. Collaborative control of unmanned underwater vehicles[J]. Journal of Physics: Conference Series, 2021, 1887(1): 1-5.

[30] 朱良麒,丁力平,陈文亮,等.-Shape算法双机器人协作工作空间研究[J]. 机械设计与制造杂志社,2021(10):267-271,278.

Zhu Liangqi, Ding Liping, Chen Wenliang, et al. The study of dual-robot cooperative workspace based on α-shape 3d reconstruction theory[J]. Machinery Design & Manufacture, 2021(10): 267-271, 278. (in Chinese with English abstract)

[31] 牛作硕,宫金良,张彦斐. 基于多路线追踪的机器人局部路径规划与实验[J]. 计算机应用与软件,2022,39(1):60-64.

Niu Zuoshuo, Gong Jinliang, Zhang Yanfei. Robot local path planning and experriment based on multi-path tracking[J]. Computer Application and Software, 2022, 39(1): 60-64. (in Chinese with English abstract)

[32] Liu L Y, Liu Q Y, Song Y, et al. A collaborative control method of dual-arm robots based on deep reinforcement learning[J]. Applied Sciences, 2021, 11(4): 1-16.

[33] 孙鹏,谭玉玺,汤磊. 基于有限状态机的作战实体模型行为规则可视化建模[J]. 指挥控制与仿真,2015,37(2):27-30.

Sun Peng, Tan Yuxi, Tang Lei. Visual modeling of combat entities behavior model rules based on finite state machine[J]. Command Control & Simulation, 2015, 37(2): 27-30. (in Chinese with English abstract)

[34] 闻霞,任雯,赖森财,等. 基于有限状态机模型的全自动烫印机控制系统设计[J]. 工程设计学报,2020,27(6):771-780.

Wen Xia, Ren Wen, Lai Sencai, et al. Design of control system of automatic hot stamping machine based on finite state machine model[J]. Chinese Journal of Engineering Design, 2020, 27(6): 771-780. (in Chinese with English abstract)

Cooperative autonomous operation strategy and experiment of the rice harvester together with a rice-transporting vehicle

Zhang Wenyu1,2,3, Zhang Zhigang1,2,3, Zhang Fan1,3, Ding Fan1,3, Hu Lian1,2,3, Luo Xiwen1,2,3※

(1.,,,510642,; 2.,510642,; 3(),510642,)

Many links and complex cooperative operations have posed a great challenge to the autonomous harvesting between rice harvester and transfer vehicle. In this study, a cooperative operation strategy was designed for the autonomous rice harvester and transfer vehicle using Finite State Machine (FSM). The cooperative mode was then divided into four links: independent harvesting, waiting for calls, cooperative truck unloading grain, and transportation. An FSM model was also established to construct the basic components of a collaborative harvesting state machine. After that, the state information matrix was defined to design the specific flow of basic action execution, including the harvester starts harvesting, stops harvesting, starts unloading grain and stops unloading grain. The transfer vehicle was then driven at the waiting point to cooperate with the alignment, then to start or stop grain unloading. As such, the state transition chain of collaborative work was constructed to clarify the transition relationship and trigger conditions between the states in the process of collaboration. The cooperative control logic framework involved the harvester and transfer vehicle, according to the state transition chain architecture. Stateflow tool was selected to simulate and verify the compiled logic framework in the MATLAB platform. The sequential execution was also simplified to introduce the timing and signal transmission delay of internal execution. The simulation results show that the states of the harvester and transfer vehicles were transferred orderly, particularly with the correct conversion of the trigger signal. The test results also show that the control logic strategy performed better for cooperative harvesting. A crawler-type rice collaborative harvesting system was constructed to verify the actual operating performance of the logic strategy, including the crawler rice harvester (Weichai Lovol Heavy Industry RG70V4G-014) and crawler rice transfer vehicle (Weichai Lovol Heavy Industry RG70V4G-015). Among them, the two intelligent agricultural machines adopted the fully electronically controlled chassis with the wire-controlled clutch, header, grain cylinder, and crawler driving system. The dual antenna BDS positioning system (Sina K726) was also equipped, where the data transfer unit (USR-G781) was used in the communication between two computers in the fixed-point cooperative experiment of rice harvesting. The 4/5 G Data Transfer Unit (DTU) with human cloud was adopted at the same time. The autonomous control module was communicated with the control terminal through RS-232. A Self-control terminal (eAgri-800-RS) was installed in the two computers for the harvesting self-control, which communicated with the chassis Electronic Control Unit of the two computers through CAN bus. The software system was developed by Keil uVision 5. The linear path tracking was adopted to follow the model control in the navigation system. The two-computer alignment control was adopted to deal with the position error PID. The collaborative system test was carried out in the Zengcheng Experimental Base of South China Agricultural University. The harvester and transfer vehicle were designed to independently work in the field from the hangar of the base. Specifically, the harvesting speed and width were set at 0.8 m/s, and 1.9 m, respectively. The continuous cooperative working time was not less than 120 min. About 0.7 hm2of rice were automatically harvested by the ferrule path. Six operations of the automatic cooperative transfer system were carried out to transfer the grain to the truck during this period. The transfer truck waited on the tractor road, and then transferred the harvested grain to the roadside truck, according to the designed fixed-point cooperative operation strategy. The harvester and transfer vehicle returned to the hangar in sequence after harvesting the whole farmland. The harvest and transportation path were also designed in the test plan. Among them, the specific harvesting path was designed to cover the field, where the outer ring was harvested first and then parallel rings, according to the size of the field. The cooperative path was selected on the short-side tractor road. A balance was obtained on the short-side straight-line paths of the harvesting operation. The transfer vehicles only needed to plan a reusable path. The grain alignment transfer work was completed to advance or reverse this path in the whole field. The specific transfer points were calculated from the coordinates issued by the harvester, all of which were located on this path. Consequently, the fixed-point cooperative operation was also realized using the autonomous harvester and the transfer vehicle, according to the predetermined path. The logic signals were successively recorded to normally trigger during network communication under the predetermined logic framework in the test. The whole cooperative process was aligned accurately to successfully complete the fixed-point cooperative harvesting operation and return to the hangar. Therefore, the cooperative operation strategy of double machines for rice harvesting was effective and reliable under the configuration, and the harvesting efficiency was 0.35 hm2/h. The finding can also provide strong support for the cooperative operation of autonomous full coverage harvesting in rectangular rice regions.

agricultural machinery; rice; harvesting; unmanned farm; transport; cooperation strategy between harvester and transfer vehicle

10.11975/j.issn.1002-6819.2022.15.001

S147.2

A

1002-6819(2022)-15-0001-09

张闻宇,张智刚,张帆,等. 水稻收获转运双机协同自主作业策略与试验[J]. 农业工程学报,2022,38(15):1-9.doi:10.11975/j.issn.1002-6819.2022.15.001 http://www.tcsae.org

Zhang Wenyu, Zhang Zhigang, Zhang Fan, et al. Cooperative autonomous operation strategy and experiment of the rice harvester together with a rice-transporting vehicle[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2022, 38(15): 1-9. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2022.15.001 http://www.tcsae.org

2022-03-30

2022-06-06

国家重点研发计划项目(2021YFD2000602);智慧农场技术与装备集成应用模式与数字化展示(2130106);广东省基础与应用基础研究基金项目(2019A1515111152)

张闻宇,博士,讲师,研究方向为精准农业、无人农场关键技术、农业机械智能控制。Email:zhangwenyu@scau.edu.cn

罗锡文,教授,中国工程院院士,研究方向为农业机械化、电气化和自动化。Email:xwluo@scau.edu.cn