新型准零刚度果蔬运输隔振系统设计

2022-09-21铁世萃王花兰

铁世萃,王花兰

新型准零刚度果蔬运输隔振系统设计

铁世萃1,王花兰2

(1.青海交通职业技术学院,西宁 810000;2.兰州交通大学,兰州 730070)

为避免果蔬在运输过程中因振动造成损伤,导致价值下降,基于准零刚度隔振技术,提出一种采用紧凑、高效的弹簧–滚轮–滚珠负刚度机构的新型果蔬运输隔振箱装置。首先,基于弹簧–滚轮–滚珠负刚度机构与垂向正刚度弹簧并联的方式设计准零刚度果蔬运输隔振系统结构;其次,分析其静力学特性,推导该非线性隔振装置的刚度特性;最后,在果蔬运输系统模型运动微分方程基础上建立Simulink仿真模型,研究在C级路面激励下,该新型运输隔振系统的动态隔振特性。研究结果表明,通过合理的结构参数设计,该隔振装置在平衡点附近将具有高静态刚度、低动态刚度的准零刚度特性。在C级路面激励下,该新型运输隔振系统的振动位移峰的峰值相较于对应线性系统的衰减约29.3%,加速度均方根值衰减约97.3%。设计合理的新型果蔬运输系统的隔振效率优于对应的线性隔振系统的。

果蔬运输;准零刚度;隔振设计;非线性

果蔬类农产品在农村经济中占有重要地位,是乡村产业结构调整和我国实施乡村振兴战略的重要环节[1-2]。果蔬类农产品的流通必然需要物流运输,而物流运输过程中长时间的振动是导致果蔬机械损伤的重要原因,我国每年有大量的水果和蔬菜由于机械损伤而导致价值降低甚至丢弃[3-5]。高性能的果蔬运输隔振设计具有重要的研究价值和良好的应用前景[6-7]。

线性隔振装置由于具有结构简单、性能可靠等诸多优点,被广泛应用于各类隔振实践中。为了实现更高的隔振性能,必然要求线性隔振装置具有更低的刚度,然而这也会导致弹性元件的大变形和稳定性下降。准零刚度具有优异的高静态刚度、低动态刚度(HSLD)特性,不仅可以可靠地支撑果蔬等货物,而且可以实现对小幅振动的高性能隔振,是一种优良的果蔬运输隔振方案。

准零刚度隔振系统通常是在正刚度机构的基础上并联等大小的负刚度机构获得,准零刚度系统往往具有很低的动刚度,从而获得很低的固有频率和起始隔振频率[8-9]。目前,准零刚度隔振系统已经广泛应用于飞行器振动测试[10]、高性能制造[11-12]、液体输送管[13]等诸多领域。笔者在之前的研究中采用三弹簧并联的方式实现了准零刚度果蔬运输隔振系统[14],然而,三弹簧并联的准零刚度结构占用的空间较大[15-16],不利于准零刚度果蔬运输隔振的广泛应用。为此文中基于弹簧–滚轮–滚珠负刚度机构与正刚度并联的结构开展改进设计,提出一种新型、紧凑的准零刚度果蔬运输隔振系统。

1 准零刚度隔振装置结构设计

2 准零刚度隔振装置的静力学分析

2.1 力–位移关系

令果蔬车架位移1与车身位移2的相对位移为12=1−2,通过图1a可以看到,准零刚度隔振装置的恢复力12与12有以下的分段非线性关系:

图1 新型准零刚度果蔬运输隔振系统简图

图2 不同预压缩量下的力–位移关系

2.2 准零刚度隔振装置的刚度特性

表1 几何非线性果蔬运输隔振装置结构参数

Tab.1 Structural parameters of the vibration isolation device for fruit and vegetable transportation with geometric nonlinearity

图3 不同预压缩量下的刚度–位移关系

3 果蔬运输车建模与动力学分析

3.1 基于Simulink的果蔬运输车的动力学建模

根据图1a和式(1)建立准零刚度隔振装置的Simulink模型,见图4。

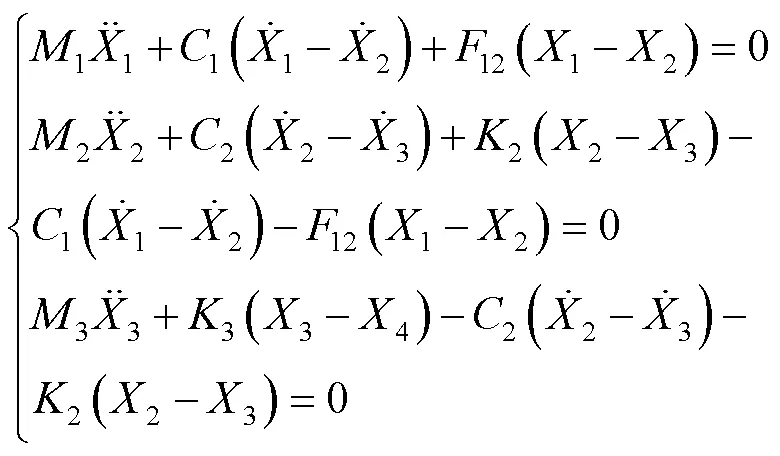

根据图1b和第2节的分析,具有准零刚度果蔬运输车四分之一车模型的动力学方程可以描述为:

根据式(8)建立准零刚度果蔬运输车的仿真模型,见图5。

3.2 准零刚度果蔬运输车的隔振特性研究

图4 准零刚度隔振装置的Simulink模型

图5 准零刚度果蔬运输车的Simulink模型

图6 滤波白噪声路面不平度模型

图7 C级路面激励下果蔬车架的振动响应

表2 采用不同隔振装置的果蔬运输车的振动响应对比

Tab.2 Comparison of vibration response of fruit and vegetable transport vehicle with different vibration isolation devices

4 结语

文中提出了一种基于弹簧–滚轮–滚珠负刚度机构的新型紧凑、高效的果蔬运输隔振系统。对隔振系统的刚度分析表明,该结构的刚度与振动位移是典型非线性关系,通过合理地设计结构参数,该装置在平衡位置附近表现为高静态刚度、低动态刚度的准零刚度特性。在推导果蔬运输车四分之一车模型微分方程的基础上,采用Simulink建立了新型果蔬运输隔振系统模型,研究了在C级路面激励下,该新型运输隔振系统的动态隔振特性。仿真分析结果表明,对于C级路面激励,该新型果蔬运输车在全频段大幅优于对应的线性运输系统,其振动位移响应峰峰值、均方根值均显著小于对应的线性运输系统的,其加速度响应的峰峰值、均方根值更是大幅度小于对应的线性运输系统的。

[1] 范蕊. 长春国爱农场有机果蔬营销策略研究[D]. 长春: 吉林大学, 2020: 6-42.

FAN Rui. Research on Marketing Strategy of Organic Fruits and Vegetables in Changchun Guoai Farm[D]. Changchun: Jilin University, 2020: 6-42.

[2] 杨杰, 王灵玲, 鲁雨轩. 我国果蔬产业冷链物流运输研究[J]. 粮食科技与经济, 2020, 45(4): 80-81.

YANG Jie, WANG Ling-ling, LU Yu-Xuan. Research on Cold Chain Logistics Transportation of Fruit and Vegetable Industry in China[J]. Grain technology and economy, 2020, 45(4): 80-81.

[3] 周然, 苏树强, 李云飞. 果蔬运输振动频谱检测分析及对水果损伤的研究[J]. 包装工程, 2007, 28(10): 76-79.

ZHOU Ran, SU Shu-qiang, LI Yun-fei. Analysis of Truck Vibration and Damage to Huanghua Pears during Transport[J]. Packaging Engineering, 2007, 28(10): 76-79.

[4] 李光, 王子蕊, 宋海燕. 苹果运输包装振动损伤预测方法的研究[J]. 振动与冲击, 2018, 37(8): 251-256.

LI Guang, WANG Zi-rui, SONG Hai-yan. Prediction of Vibration Damage of Apples in Transportation Package[J]. Journal of Vibration and Shock, 2018, 37(8): 251-256.

[5] 昌玥, 范佳雯, 卢文静, 等. 猕猴桃减振包装在模拟运输中的使用效果[J]. 保鲜与加工, 2017, 17(5): 14-19.

CHANG Yue, FAN Jia-wen, LU Wen-jing, et al. Effects of Anti-Vibration Package in Simulated Transportation of Kiwifruit[J]. Storage and Process, 2017, 17(5): 14-19.

[6] 王芳, 魏星, 魏巍, 等. 果蔬运输受振动·冲击作用研究进展[J]. 安徽农业科学, 2015, 43(26): 326-329.

WANG Fang, WEI Xing, WEI Wei, et al. Research Progress on Transport Vibration and Impact Damage of Fruit and Vegetable[J]. Journal of Anhui Agricultural Sciences, 2015, 43(26): 326-329.

[7] 赵芸, 马少博, 胡云峰, 等. 运输过程中振动对蔬菜品质的影响[J]. 天津农业科学, 2018, 24(5): 75-79.

ZHAO Yun, MA Shao-bo, HU Yun-feng, et al. Effect of Vibration during Transportation on the Quality of Vegetables[J]. Tianjin Agricultural Sciences, 2018, 24(5): 75-79.

[8] 孟令帅. 新型准零刚度隔振器的设计和特性研究[D]. 北京: 中国人民解放军军事医学科学院, 2015: 2-18.

MENG Ling-shuai. Design and Characteristics Analysis of the Novel Quasi-Zero Stiffness Isolator[D]. Beijing: Academy of Military Medical Sciences, 2015: 2-18.

[9] VIRGIN L, SANTILLAN S, PLAUT R. Vibration Isolation Using Extreme Geometric Nonlinearity[J]. Journal of Sound and Vibration, 2007, 315(3): 721-731.

[10] MOLYNEUX W. The Support of an Aircraft for Ground Resonance Tests: A Survey of Available Methods[J]. Aircraft Engineering and Aerospace Technology, 1958, 30(6): 160-166.

[11] ZHU Tao, CAZZOLATO B, ROBERTSON W S P, et al. Vibration Isolation Using Six Degree-of-Freedom Quasi-Zero Stiffness Magnetic Levitation[J]. Journal of Sound and Vibration, 2015, 358: 48-73.

[12] 王亚威. 基于非线性准零刚度的精密机床隔振器性能研究[D]. 洛阳: 河南科技大学, 2017: 2-32.

WANG Ya-wei. Study on Performance of Precision Machine Tool Vibration Isolator Based on Nonlinear Quasi-Zero Stiffness[D]. Luoyang: Henan University of Science and Technology, 2017: 2-32.

[13] DING Hu, JI Jin-chen, CHEN Li-qun. Nonlinear Vibration Isolation for Fluid-Conveying Pipes Using Quasi-Zero Stiffness Characteristics[J]. Mechanical Systems and Signal Processing, 2019, 121: 675-688.

[14] 应玉萍, 王花兰. 基于几何非线性的果蔬运输隔振系统设计[J]. 包装工程, 2020, 41(19): 153-158.

YING Yu-ping, WANG Hua-lan. Design of Vibration Isolation System for Fruit and Vegetable Transportation Based on Geometric Nonlinearity[J]. Packaging Engineering, 2020, 41(19): 153-158.

[15] 王心龙. CRSM准零刚度隔振器的非线性隔振特性及实验研究[D]. 长沙: 湖南大学, 2015: 3-26.

WANG Xin-long. On Nonlinear Vibration Isolation Characteristics and Experimental Research of a Quasi-Zero-Stiffness Isolator with CRSM[D]. Changsha: Hunan University, 2015: 3-26.

[16] 妥吉英, 邓兆祥, 张河山, 等. 准零刚度振动传感系统[J]. 吉林大学学报(工学版), 2019, 49(1): 24-29.

TUO Ji-ying, DENG Zhao-xiang, ZHANG He-shan, et al. Quasi-Zero-Stiffness Vibration Sensor System[J]. Journal of Jilin University (Engineering and Technology Edition), 2019, 49(1): 24-29.

[17] 余志生. 汽车理论[M]. 2版(修订本). 北京: 机械工业出版社, 1990: 230-260.

YU Zhi-sheng. Automobile Theory[M]. Beijing: China Machine Press, 1990: 230-260.

[18] 张进秋, 黄大山, 姚军. 车辆悬架系统振动控制[M]. 北京: 国防工业出版社, 2020: 38-46.

ZHANG Jin-qiu, HUANG Da-shan, YAO Jun. Vibration Control of Vehicle Suspension System[M]. Beijing: National Defense Industry Press, 2020: 38-46.

[19] GB 7031—86, 车辆振动输入——路面平度表示方法[S].

GB 7031—86, Vehicle Vibration Input—Expression Method of Road Roughness[S].

Design of a New Quasi-zeroStiffness Vibration Isolation System for Fruit and Vegetable Transportation

TIE Shi-cui1,WANG Hua-lan2

(1.Qinghai Communications Technical College, Xining 810000, China;2.Lanzhou Jiaotong University, Lanzhou 730070, China)

The work aims to propose a new fruit and vegetable transportation vibration isolation box device with compact and efficient spring-roller-ball negative stiffness mechanism based on the quasi-zero stiffness vibration isolation technology, so as to avoid the damage and value decline caused by vibration in fruit and vegetable transportation. Firstly, the structure of vibration isolation system of quasi-zero stiffness for fruit and vegetable transportation was designed based on the parallel connection of spring-roller-ball negative stiffness mechanism and vertical positive stiffness spring; Secondly, the static characteristics were analyzed, and the stiffness characteristics of the nonlinear vibration isolation device were deduced; Finally, based on the motion differential equation of the fruit and vegetable transportation system model, a Simulink simulation model was established to study the dynamic vibration isolation characteristics of the new transportation vibration isolation system under level-C road excitation. The research results showed that the vibration isolation device may have the quasi-zero stiffness with high static stiffness and low dynamic stiffness near the balance point through reasonable design of structure parameters.Compared with the corresponding linear system, the peak to peak value of vibration displacement and the RMS value of acceleration of the new transportation vibration isolation system decreased by 29.3% and 97.3% respectively under level-C road excitation. The vibration isolation efficiency of the new fruit and vegetable transportation system with reasonable design is superior to that of the corresponding linear vibration isolation system.

fruit and vegetable transportation; quasi-zero stiffness; vibration isolation design; nonlinearity

TB485.3;TH113.1

A

1001-3563(2022)17-0102-07

10.19554/j.cnki.1001-3563.2022.17.013

2021–10–31

中国物流学会研究课题(2021CSLKT3—158)

铁世萃(1985—),女,本科,讲师,主要研究方向为物流运输。

王花兰(1969—),女,博士,教授,主要研究方向为城市交通、物流运输。

责任编辑:曾钰婵