Influence of momentum ratio control mode on spray and combustion characteristics of a LOX/LCH4 pintle injector

2022-05-24RuiZHOUChibingSHEN

Rui ZHOU,Chi-bing SHEN

Science and Technology on Scramjet Laboratory,College of Aerospace Science and Engineering,National University of Defense Technology,Changsha 410073,China

1 Introduction

Spray and combustion characteristics of an oxidantcentered liquid oxygen/liquid methane (LOX/LCH)pintle injector under different momentum ratio control modes are studied by numerical simulation.Results show a high total momentum ratio(TMR)can be good for boosting overall combustion efficiency.Either an increase in LOX injection pressure drop or a reduction in LCHpressure drop can increase the TMR and pro‐mote the diffusion of the high-temperature zone along the length direction of the combustion chamber,and in engineering applications,the flame distribution can be changed by adjusting the TMR.LCHatomizes faster,the contact area of oxygen on the combustion chamber wall is larger,and the range of the lowtemperature zone in front of the pintle tip is smaller when the TMR is 1.37,compared with TMR of 0.62.Four high-temperature peaks are formed on the central line passing through the apex of the pintle tip in the combustion chamber width direction since an arcshaped shear flame develops.Vortices can promote flame stability by extending the mixing time of the gases,thus preventing the development of high tem‐perature in the combustion chamber head and at the pintle tip.Also a 3D spray structure of the pintle in‐jector contributes to its good combustion stability.

It is a key technology to realize thrust control of a liquid rocket engine through throttling(Zhang,1984;Preclik et al.,2005;Casiano et al.,2010).A variable area injector,namely the pintle injector,has received extensive attention in recent years due to its deep throttling capability(Fang and Shen,2017;Zhou et al.,2020).Parameter design of a pintle injector mainly in‐cludes the width of the annular slit,the hole structure,the block factor(BF),the ratio of the diameter of radial holes to the pintle tip circumference,the skip distance,the distance from the axial film injection area to the impinging point,and the TMR.TMR is the ratio of the momentum of the radial jet to the momentum of the axial film(Dressler and Baue,2000;Dressler,2006).

At present,there are studies on pintle injectors with different propellant combinations.Austin and Heister(2002) and Austin et al.(2005) studied a 666.67 N thrust class pintle engine with hydrogen peroxide and a nontoxic,hypergolic miscible fuel,and concluded that a fuel-center pintle was preferred and that a hemispherical pintle structure can allow fuel flowing through the pintle to alleviate heat energy accumu‐lation.Bedard et al.(2012) designed a LOX/LCHpintle injector.Their study introduced a novel sys‐tem for natural gas liquefaction to supply cryogenic fuel,and a fuel film cooling method was used to keep the chamber walls at a low temperature.Payri et al.(2016) used a pintle injector for a diesel engine as a way of conducting injection rate shaping strategy,and the results showed that the spray velocity was less impacted.Son et al.(2017) conducted a nu‐merical simulation study on a fuel-centered LOX/methane pintle injector and found that a wide flame cone angle can contribute to forming a pair of large vortices at the pintle tip,which effectively enhance combustion performance.Lee et al.(2021)used water and air as simulants to obtain spray angle and drop‐let size of a pintle injector in different skip distance conditions.Considering the deviation in each case,an appropriate skip distance was recommended for different throttling conditions.

It can be concluded that the current research on pintle injectors lacks studies on the spray and com‐bustion characteristics of a LOX/LCHpintle injector.To ensure the safety of the later test,numerical simula‐tion is used in this paper to study the spray and com‐bustion characteristics of a LOX/LCHpintle injector in different momentum ratio control modes,so as to facilitate engineering applications.

2 Simulation domain and cases

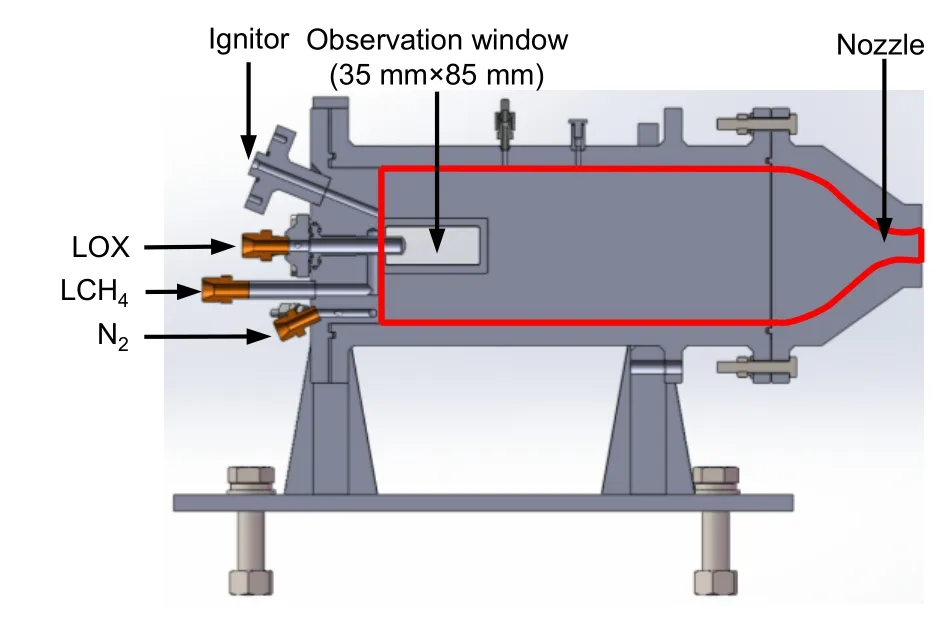

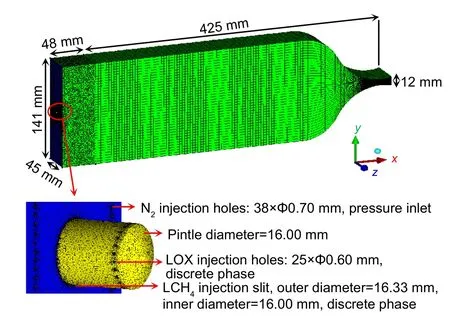

The test piece is shown in Fig.1.The simulation domain is the area of the test piece within red lines,and the area was meshed as shown in Fig.2.One part where pintle extends into the combustion chamber is complicated and was divided by non-structural grids with axial length of 48 mm.The other part of the com‐bustion chamber,including the nozzle,has a regular structure and was divided by structural grids with axial length of 425 mm.Thex

coordinate represents axial length,they

coordinate represents height,and thez

coordinate represents width.Holes near the observation windows on both sides of combustion chamber are used to inject normal temperature nitrogen to prevent the observation windows from bursting,and to estab‐lish the desired combustion chamber pressure quickly.

Fig.1 Test prototype of the simulation object.References to color refer to the online version of this figure

Fig.2 Simulation setup

Standardk-ε

turbulence model was used to simu‐late flow.It is suitable for high Reynolds number tur‐bulence.Discrete-phase two-way coupling model was used to calculate droplet evaporation.Non-premixed eddy dissipation model was performed to calculate the fast combustion reaction.To ensure stability of the simulation,results were calculated in a steady condi‐tion,assuming that the spray and combustion processes are instantaneously stable,and that the combustion time of the later test will not exceed 0.5 s.The nozzle outlet boundary condition is the pressure outlet.The nitrogen inlet boundary condition is the pressure inlet,and its pressure drop remains the same in all cases.LOX and LCHinlet boundary conditions are set through discrete phase model (DPM),in which the customized initial injection particle size of the liquid phase was calculated by a theoretical Sauter mean di‐ameter (SMD) prediction proposed by Dombrowski and Johns(1963).By calculation,the SMD of LOX is 16 μm and the SMD of LCHis 8 μm.Table 1 shows simulation cases of the LOX/LCHpintle injector,where ∆p

is the LCHinjection pressure drop,v

is the LCHinjection velocity,m

is the LCHinjection mass flow rate,∆p

is the LOX in‐jection pressure drop,v

is the LOX injection velocity,m

is the LOX injection mass flow rate,P

is the com‐bustion chamber pressure,andc

is the overall com‐bustion efficiency calculated by rocket propulsion analysis.Case 1 is a basic condition,based on which,cases 10-1 and 10-4 obtain the same small TMR by reducing the LOX injection pressure drop and increas‐ing the LCHinjection pressure drop,respectively,while cases 10-2 and 10-3 obtain the same large TMR by increasing the LOX injection pressure drop and reducing the LCHinjection pressure drop,respec‐tively.It can be concluded that,despite the changingmodes of the TMR,high TMR conditions have high combustion chamber pressure and can achieve high overall combustion efficiency through strong impinge‐ment and rapid mixing.3 Simulation results and discussion

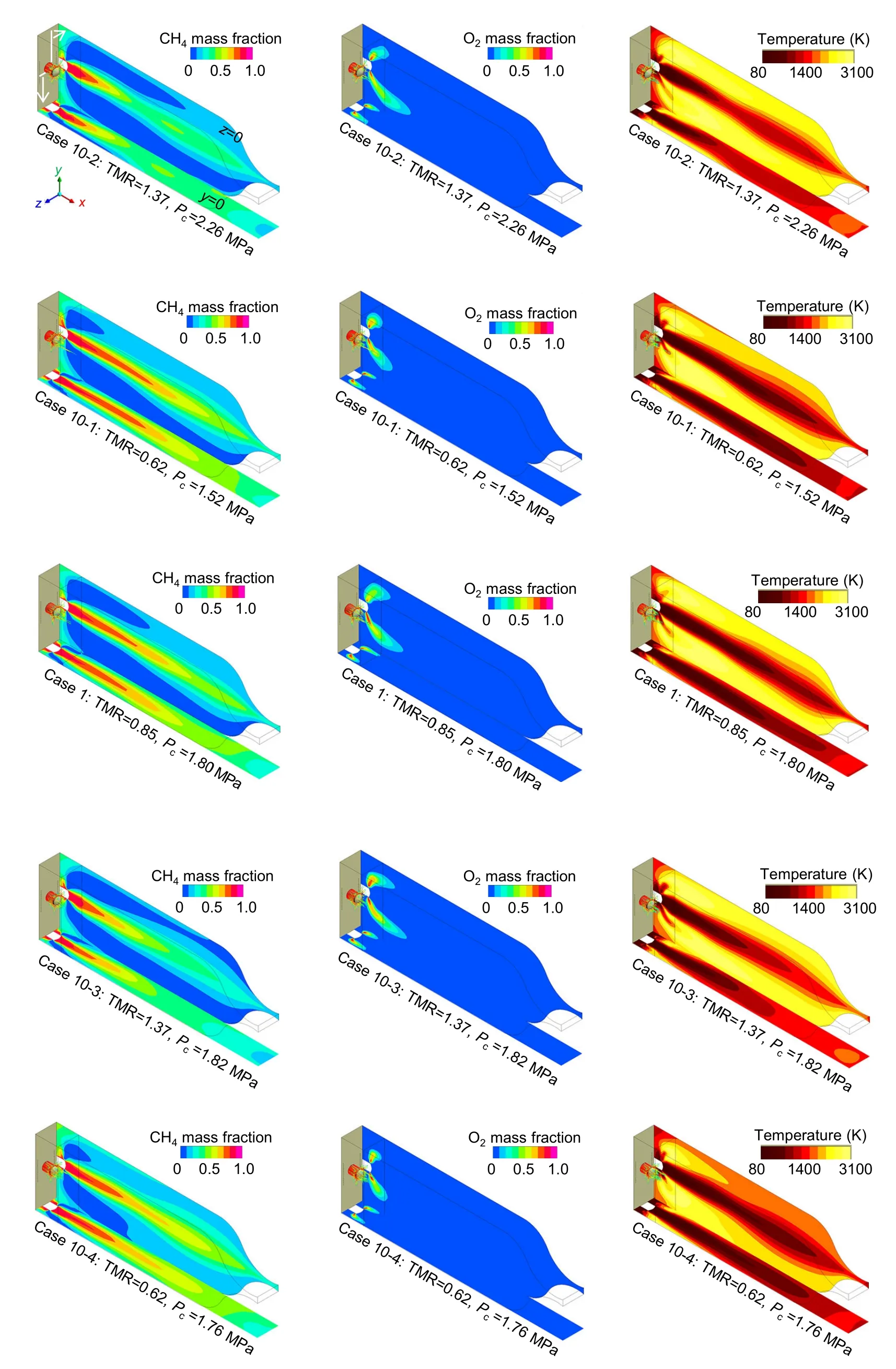

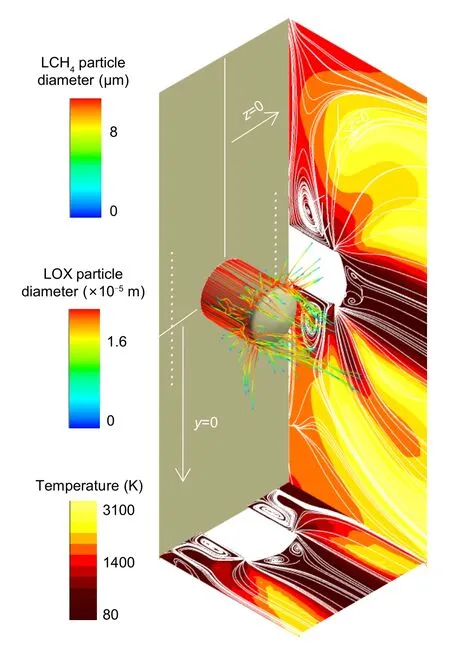

Fig.3 shows the contours of methane,oxygen,and temperature on central planes in the width direc‐tion (y

=0) and the length direction (z

=0) in different momentum ratio control modes.The results were pro‐cessed in computational fluid dynamics post model(CFD-Post).The colored lines around the pintle dem‐onstrate the liquid-phase trajectory.It can be summa‐rized that in small TMR cases (TMR=0.62),the LOX injection pressure drop is smaller than that of LCH,which means small radial inertia,contributing to a small oxygen distribution area,while large axial iner‐tia can be helpful by amassing methane in front of the pintle tip.This is good for preventing ablation of the pintle tip since the methane temperature in this region is relatively low,and this low-temperature zone in front of the pintle tip diffuses further along the axial direction than it does in high TMR cases(TMR=1.37).In high TMR cases (TMR=1.37),with LOX hitting the combustion chamber wall,vaporizing,and spread‐ing axially along the combustion chamber wall,the contact area of oxygen on the combustion chamber wall is obviously large.That is not conducive to pro‐tection of the combustion chamber wall from oxida‐tion in engineering applications.A high-temperature zone diffuses along the axial direction of the com‐bustion chamber with increased TMR.In engineer‐ing,the flame distribution area can be controlled by changing the TMR.High TMR leads to a strong mo‐mentum exchange effect with a large spray area,ex‐tending the residence time of high-temperature mixed gases,and increasing the energy release rate.Thus,the flame diffuses and the high-temperature zone is large,which is not beneficial in reducing combustion cham‐ber length.A small TMR can effectively shorten the combustion chamber flame distribution area.

Fig.3 Methane contour,oxygen contour,temperature contour,and liquid phase trajectory (colored lines) in different omentum ratio control modes.References to color refer to the online version of this figure

In particular,Son et al.(2020) divided the oxygen/methane combustion flames of a pintle injector into a shear-layer type and a tip-attached type.It can be concluded that flames in the five cases in this paper belong to the shear-layer type.This flame type does not attach to a specific wall in the combustion cham‐ber,which is an advantage for thermal protection.

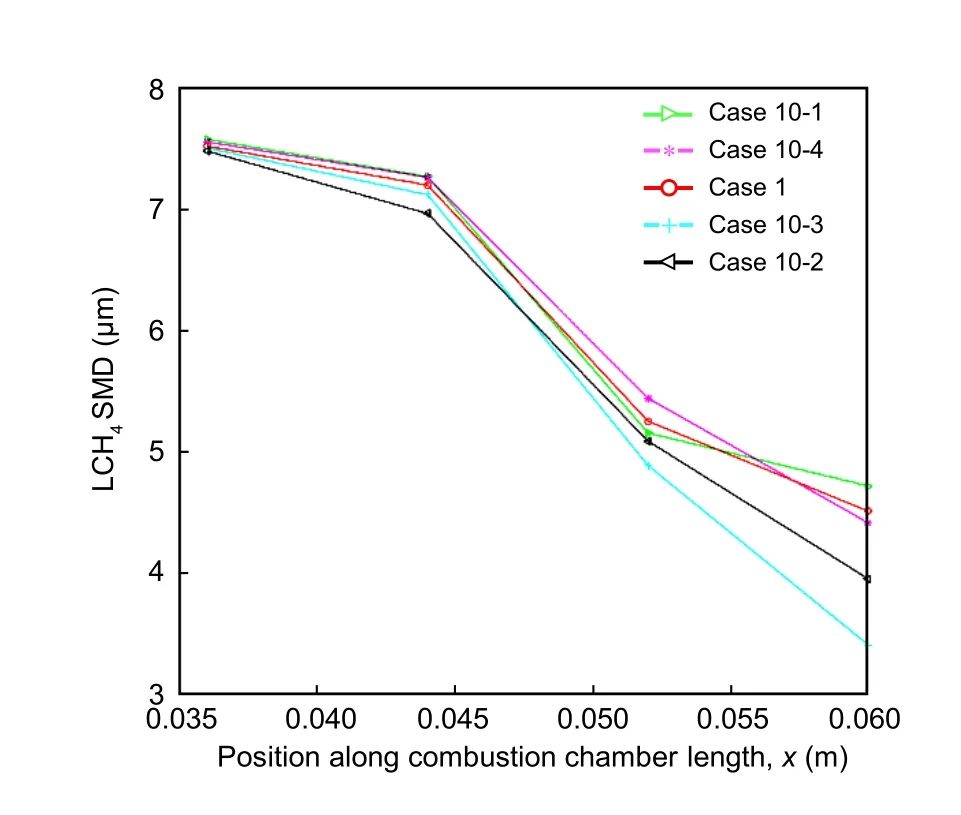

Fig.4 demonstrates LCHSMD distribution along the combustion chamber length in different momen‐tum ratio control modes.It can be seen that,as the LOX injection pressure drop gradually increases,TMR increases from 0.62 (green line) to 0.85 (red line) to 1.37 (yellow line).With the TMR=1.37,the LOX injection pressure drop is larger than the LCHinjection pressure drop.LOX has strong inertia,and LCHhas a weak guiding effect on LOX in the axial direction.The tendency of LOX to hit LCHvertically is obvious with more LOX penetrating through LCHand enhancing atomization,resulting in a small LCHSMD and a large diameter gradient.When the LCHinjection pressure drop gradually increases,TMR de‐creases from 1.37(blue line)to 0.85(red line)to 0.62(purple line).Similarly,when TMR=1.37,LOX has strong inertia,and more LOX can penetrate through LCH,thus leading to a small LCHSMD and a large diameter gradient.Meanwhile,highP

(comparing five cases,cases of TMR=1.37 also have higherP

)can be another factor boosting LCHevaporation rate by dramatically changing its initial physical state when LCHis injected into the combustion chamber.In sum‐mary,LCHatomizes faster under conditions of higher TMR.

Fig.4 LCH4 SMD distribution along the combustion chamber length in different momentum ratio control modes

Fig.5 shows the average pressure distribution in the central plane along the combustion chamber length in different momentum ratio control modes.Oscillation higher thanP

is caused by impact of pro‐pellants,occurring at impinging point.Oscillation lower thanP

is caused by phase transition of the propellants.Overall,P

can remain stable at the tar‐get pressure in each case.Spatial 3D spray of pintle injector enables energy to diffuse in all directions in time,which makes it possible to have good combus‐tion stability.

Fig.5 Average pressure of central plane along the combustion chamber length in different momentum ratio control modes

The pintle injector demonstrates a typical flow field structure in the near pintle field.Fig.6 shows the contour of temperature,streamlines,and discrete phase trajectory in the combustion chamber head in case 1.The areas where vortices are located are low-temperature regions,indicating that a vortex can strengthen mix‐ing and promote flame stability by prolonging the continuous contact time of mixed gases,effectively preventing a high temperature from developing in the combustion chamber head and at the pintle tip.

Fig.6 Temperature contour,streamlines,and discrete phase trajectory in the combustion chamber head in case 1.References to color refer to the online version of this figure

4 Conclusions

Through simulation,the influence of momentum ratio on spray and combustion characteristics in an oxidant-centred LOX/LCHpintle injector is obtained.This has value for engineering applications.The main conclusions are as follows:

1.High TMR can be helpful for achieving highc

with strong impact of propellants and good mixing.In particular,LCHvaporizes faster and contributes to faster chemical combustion under conditions of TMR=1.37,and concentrates less at the pintle tip,compared with the conditions of TMR=0.62.2.Flame develops from the place where two pro‐pellants are in contact.As the mixing process increases,the surface area of the flame increases,forming an arcshaped shear flame.

3.The spray structure of a pintle injector presents a 3D distribution,which is beneficial for diffusing energy rapidly,thus creating good combustion stability.

4.Vortices can promote flame stability by ex‐tending the mixing time of gases,and effectively prevent high temperature from developing in the com‐bustion chamber head or at the pintle tip.

Acknowledgments

This work is supported by the National Natural Science Foundation of China (Nos.11572346 and 12072367) and the Natural Science Foundation of Hunan Province (No.2020JJ4666),China.

Author contributions

Rui ZHOU wrote the manuscript.Chi-bing SHEN guided the work of this paper.

Conflict of interest

Rui ZHOU and Chi-bing SHEN declare that they have no conflict of interest.

杂志排行

Journal of Zhejiang University-Science A(Applied Physics & Engineering)的其它文章

- Recycling Bayer and sintering red muds in brick production:a review

- An analytical investigation of the collapse of asymmetrically corroded pipes under external pressure

- Vertical temperature gradients of concrete box girder caused by solar radiation in Sichuan-Tibet railway

- Numerical study on ethylene-air continuous rotating detonation in annular combustors with different widths

- Effect of the micro vortex generator on the characteristics of vaporized RP-3 kerosene combustion in supersonic flows