Structural Color Modified Fabrics with Excellent Antibacterial Property

2021-11-02SHIXiaodi石小迪CAOXianxian曹贤贤DOURenmei窦仁美LUXihua鲁希华

SHI Xiaodi(石小迪), CAO Xianxian(曹贤贤), DOU Renmei(窦仁美), LU Xihua(鲁希华)

1 College of Chemistry, Chemical Engineering and Biotechnology, Donghua University, Shanghai 201620, China

2 Jinka Flooring Technology Co., Ltd., Shanghai 201806, China

Abstract: With the improvement of living standards, people are paying more and more attention to health problems. The antibacterial function of fabrics is therefore of great importance. The structural color(photonic crystal), which has been widely investigated and applied on fabric dyeing, contains a large number of hollow microstructure and functional groups, and is easy to be modified and functionalized. Therefore, an innovative way of endowing structural color dye on fabrics with antibacterial property was presented in this paper. The latex spheres and zinc pyrrolidone were co-assembled on polydopamine modified fabrics, antibacterial ion zinc pyrrolidone was therefore loaded into the pores of structural color dye, and brilliant antibacterial fabrics were successfully achieved. The existence of zinc pyrrolidone had little influence on the color saturation of brilliant structural color and meanwhile ensured the structural color dye excellent antibacterial effect. The antibacterial reduction rate of the antibacterial fabric reached 99.99%. Owing to the addition of polyurethane(PUA) coating on the surface of structural color, the fabric modified by the antibacterial structural color dye also presented good washing resistance, which showed great application possibility in functional textile and antibacterial fields.

Key words: functional structural color; antibacterial fabric; washing resistance

Introduction

With the improvement of living standards, people’s demands for fabrics are not only limited to warm-keeping, comfort or fashion, but also focus on special functionality, such as waterproof[1], anti-ultraviolet[2-3], antibacterium[4-5]and self-cleaning[6]. Therefore, investigation and development of multiple functional fabrics are becoming a popular trend[7-9]. Scientists all over the world are also dedicating lots of efforts into this research area. Huetal.[10]modified cellulose fabrics with a derivative of copper phthalocyanine by a dyeing method. The modified cellulose fabric possessed both antibacterium and anti-ultraviolet. Zengetal.[11]obtained superhydrophobic fabrics with non-iridescent structural color by spray-coating of the latex sphere emulsion, polyacrylate solution, and carbon black nanoparticles(NPs). Our group[12]also developed the functional structural color dye with excellent ultraviolet rays protection property, which was fabricated through the self-assembly of poly-(styrene-methyl methacrylate-acrylic acid)-avobenzone((P-(St-MMA-AA)-avobenzone) core-shell latex sphere on cotton fabrics. These special functions endow the fabrics broader application prospects.

Especially, due to the outbreak of COVID-19[13], people are paying more and more attention to health problems. The antibacterial function of fabrics, which can effectively inhibit the growth of bacteria and even kill bacteria in time, can effectively protect people from being attracted by bacteria. At present, the commonly used method for preparing the antibacterial fabric is loading antibacterial agents, including inorganic NPs[14]or organic photosensitive chemical groups[15], directly on the fabric. Aminlooetal.[16]synthesized zinc oxide NPs through a sonication method on 50/50 nylon/cotton(N/C) blend fabrics to achieve antibacterial purposes. Gaoetal.[17]obtained antibacterial cotton fabrics coated with silver NPs using polydopamine as an adhesive, and then coated with hydrophobic polydimethylsiloxane or polyimide. However, the direct modification of antibacterial ions on the fabric can easily fall off or penetrate into the skin and cause a series of health problems[18]. Structural color dye, which has been widely investigated in fabric dyeing[19], possesses lots of hollow structure[20]and functional groups[21], and is easy to be modified[22-26]. Therefore, it is possible to modify structural color dye on fabrics by antibacterial inorganic ions and endow fabrics excellent antibacterial property.

In this paper, monodispersed P-(St-MMA-AA) latex sphere emulsion was firstly prepared according to Ref. [27]. Zinc pyrrolidone[28-30]was then co-assembled with the monodispersed latex spheres on polydopamine pre-treated fabrics at constant temperature and humidity. Through the co-assembly of P-(St-MMA-AA) latex spheres and zinc pyrrolidone on polydopamine coated fabrics, antibacterial ion zinc pyrrolidone was therefore loaded into the pores of structural color dye, and brilliant antibacterial fabrics were successfully achieved. The existence of zinc pyrrolidone had little influence on the color saturation of brilliant structural color and meanwhile ensured the structural color dye excellent antibacterial effect. The structural color fabric was then immersed into mixture solution of urethane oligomer and photoinitiator[31], and was initiated polymerization by an ultraviolet lamp. The obtained polyurethane(PUA) coating can effectively fix the antibacterial agent zinc pyrrolidone on the surface of structural color to ensure its washing resistance and constant antibacterial property. Meanwhile the addition of PUA had little influence on the brilliant color of structural color on fabrics.

1 Experiments

1.1 Materials

Styrene(St), methyl methacrylate(MMA) and acrylic acid(AA) were purchased from Sinopharm Group, China. Sodium bicarbonate(NH4HCO3), sodium dodecyl benzenesul-fonate(SDBS), and ammonium persulfate(APS) were purchased from Beijing Chemical Works, China. Dopamine hydrochloride and tris(hydroxymethyl) aminomethane(THAM) were purchased from J&K Scientific Ltd., Beijing, China. Zinc pyrrolidone was purchased from Microban, Shanghai, China. The cotton fabric was purchased from Tianluo Textile Co., Ltd., Shaoxing, China. Deionized water(Direct-Q 3UV, Millipore) was used throughout the experiments.

1.2 Synthesis of monodispersed latex spheres

The P-(St-MMA-AA) latex spheres were synthesized according to the emulsion polymerization method. In brief, 0.5 g NH4HCO3,1.0 g AA, 1.0 g MMA and 19.0 g St were added into 100.0 g deionized water, then 20-30 mL C18H29NaSO3(1.0 g/L(H2O)) was added, and the mixed solution was stirred at 75 ℃ for 40 min. At a constant stirring rate, 16 mL APS(2.15 g/120 g(H2O)) was slowly added into the above reaction solution drop by drop, and the whole reaction process lasted for about 4 h. The reaction temperature increased to 80 ℃ for another 1 h to ensure the total polymerization of active monomer. The monodispersed latex spheres could be directly obtained without further purification.

1.3 Preparation of structural color fabrics with antibacterial property

The fabric was pre-treated by dopamine with different concentrations to ensure its great color rendering ability according to our previous research work[27]. Dopamine hydrochloride was dissolved in THAM buffer whose pH was 8.9. The concentration of dopamine was 0, 0.2, 0.5, 0.8, 1.0 and 1.2 mg/mL respectively. Dopamine hydrochloride was polymerized to black polydopamine on the fabric, making the fabric black. When the concentration of dopamine hydrochloride was 0.2 mg/mL, the original white cotton fabric turned to brown. When the concentration was above 0.8 mg/mL, the surface of the cotton fabric turned from dark brown to totally black. Therefore, the optimal concentration of dopamine hydrochloride was fixed to be 0.8 mg/mL to ensure the black background of fabrics and the high adhesion property of fabrics[27]. Firstly, zinc pyrrolidone was added into the P-(St-MMA-AA) latex sphere emulsion, and ultrasoniced for 30 min to ensure that they were homodispersed. The fabric pre-treated with dopamine hydrochloride was soaked in the above mixed emulsion at constant temperature and humidity to ensure the formation of antibacterial structural color. Then the fabric coated by structural color was slowly lifted up from the solution and dried. Finally, the structural color fabric with antibacterial function was obtained. The obtained structural color fabric was immersed in a mixed solution containing urethane oligomer and photoinitiator, and then the fabric was placed under an ultraviolet lamp with a wavelength of 365 nm to irradiate photopolymerization. By changing the particle size of the latex spheres, antibacterial structural colors with different colors could be obtained.

1.4 Antibacterial experiments

Antibacterial experiments were carried out according to Ref. [32]. Firstly, antibacterial fabric samples ((0.75±0.05) g) were cut into 5 mm×5 mm pieces, and then the sample was put in an autoclave(121 ℃, 103 kPa) for 15 min for sterilization. The antibacterial fabric sample and theEscherichiacoli(E.coil) inoculum suspension whose number of viable bacteria was 3×105-4×105CFU/mL were added into the 250 mL Erlenmeyer flask. The Erlenmeyer flask containing the sample was placed on a constant temperature shaker at temperature of(24±1)℃ and a speed of 250-300 r/min for about 1 min, and the number of bacteria was detected when the contact time was 0 and 18 h, respectively. The concentrations of viable bacteria were calculated according to

Y=(Wt-Qt)/Wt×100%,

whereYwas the bacterial reduction rate,Wtwas the average value of the viable bacteria concentration in the flask after 18 h shaking for the control samples, andQtwas the average concentration of viable bacteria in the flask after 18 h shaking for three bacterial samples.

1.5 Characterization

Microscopic morphology of samples was obtained by field emission scanning electronic microscopy(SEM)(JEOL JSM-4800, Japan). The chemical composition of the samples was captured by X-ray photoelectron spectroscopy(XPS)(AXIS Ultra DLD, Kratos, Japan). The reflectance spectra of structural color samples were obtained by an optic spectrophotometer(PG2000-Pro, IdeaOptics, China). The transmittance of the samples was detected by a UV-visible spectrophotometer(UV-1800, Shimadzu, Japan). Optical photos of structural color fabrics were captured by a camera(Nikon D90, Japan).

2 Results and Discussion

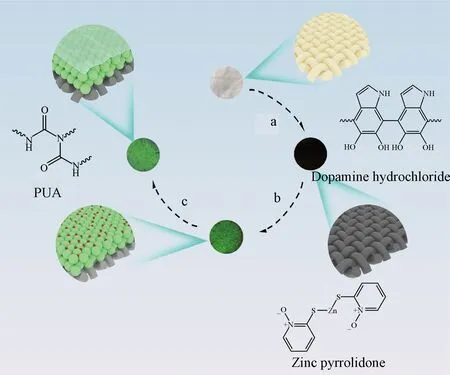

The preparation process of antibacterial structural color dye on fabrics is roughly shown in Fig. 1. The co-assembly of P-(St-MMA-AA) latex spheres and zinc pyrrolidone was achieved on polydopamine coated fabrics, antibacterial ions zinc pyrrolidone was therefore loaded into the pores of structural color dye, and brilliant antibacterial fabrics were successfully achieved. The pre-treatment of fabric substrate by dopamine-alkaline buffer solution greatly enhanced the interactions between the fabric and latex spheres because of the highly adhesive property of polydopamine[33]. Meanwhile, the structural color dye presented more brilliant color owing to the black background of polydopamine coating, which could adsorb scattered light inside photonic crystals(PCs) and improve the color brightness and contrast of structure color on the light-colored fabrics[27]. Zinc pyrrolidone was a commonly used antibacterial agent[34]endowing the brilliant structural color dye excellent antibacterial property on fabrics, and it was added into the monodispersed P-(St-MMA-AA) latex sphere emulsion and co-assembled with latex spheres at constant temperature and humidity on the pretreated fabric.

a—dopamine hydrochloride treatment;b—coating of structural color with zine pyrrolidone; c—PUA initiated by UV light.

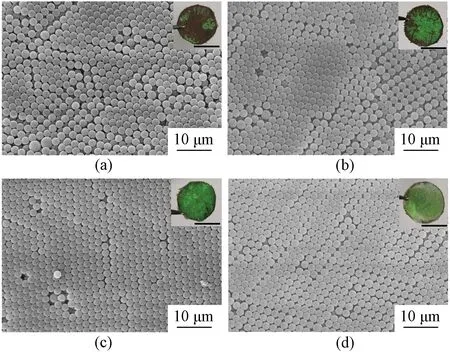

P-(St-MMA-AA) latex sphere emulsion was diluted into solutions with mass concentrations of 0.05%, 0.10%, 0.50%, and 1.00%, respectively. When the concentration of the latex spheres was less than 0.05%, the latex spheres were arranged loosely and the structural color could not cover the entire fabric(shown in Figs. 2(a) and 2(b)). As the concentration of latex spheres increased to 0.50%, the monodispersed latex spheres were arranged tightly and highly ordered, and the fabric presented brilliant structure color(shown in Fig. 2(c)). The further increase of latex sphere concentration(1.00%) resulted in the decrease of adhesion and mechanical strength of structure color, as well as dim structure color(shown in Fig. 2(d)). Therefore, the mass concentration of P-(St-MMA-AA) latex spheres was fixed to be 0.50%. The prepared structural color dye possessed excellent antibacterial property. After the self-assembly of latex spheres on the above treated fabric, certain amount of PUA oligomer and photoinitiator[35]was added to improve the interactions between zinc ions inside the structural color and the fabric, and the addition of proper amount of PUA had little influence on the brilliant color of structural color, as well as the excellent antibacterial property.

Fig. 2 SEM images of antibacterial structural color on fabrics with different concentrations of monodispersed latex spheres: (a) 0.05%; (b) 0.10%; (c) 0.50%; (d) 1.00%(insets were corresponding optical photos of structural color on fabrics, and the scale was 1 cm)

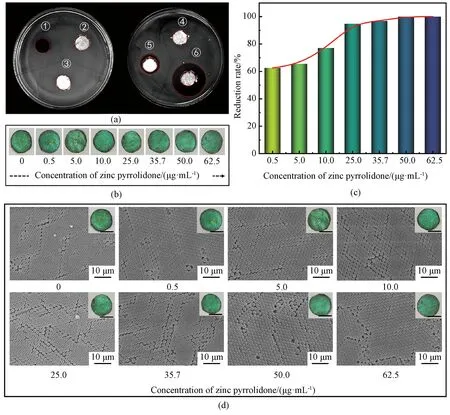

The antibacterial effect of antibacterial agents on fabrics was evaluated by using the agar plate counting method.E.coliwas used to confirm the antibacterial properties of fabrics[36]. Antibacterial experiments were carried out on cotton fabrics modified with polydopamine, structural color dye, zinc pyrrolidone and PUA coating. The qualitative analysis of the antibacterial properties of fabrics was carried out according to Ref. [37]. As shown in Fig. 3(a), the diameters of the inhibition zone of polydopamine-modified cotton fabrics(marked ①), polydopamine and structural color dye modified fabrics(marked ②), as well as polydopamine, structural color dye and PUA modified fabrics(marked ③ and ④) were zero. The diameter of the inhibition zone increased visibly when zinc pyrrolidone was added. When the concentration of zinc pyrrolidone was 10.0 μg/mL, the diameter of the inhibition zone was 18 mm(marked ⑤) and increased to 38 mm as the concentration of zinc pyrrolidone increased to 50.0 μg/mL(marked ⑥). Figure 3(a) proved that only after the addition of zinc pyrrolidone, structural color fabrics had antibacterial properties, and with the increase of the zinc pyrrolidone concentration, the diameter of the inhibition zone increased. It could be seen from Fig. 3(b) that the addition of zinc pyrrolidone had little influence on the color of the fabric. SEM was also applied to characterize the influence of zinc pyrrolidone on the microstructure of structural color dye. It was confirmed in Fig. 3(d) that the addition of certain amounts of zinc pyrrolidone had little influence on the ordered microstructure. In accordance with national standards, the vibration method was then used to quantitatively analyze the antibacterial properties of fabrics[32]. The corresponding bacterial reduction rate ofE.coliwas presented in Fig. 3(c). The trend indicated that with the increase of antibacterial agents, the reduction rate also increased. When the concentration of zinc pyrrolidone increased to 50.0 μg/mL, the concentration ofE.coliwas reduced by 99.99%.

Fig. 3 Antibacterial effect of antibacterial agents on fabrics: (a) inhibition zone; (b) optical pictures of structured colored fabrics with different zinc pyrrolidone concentrations; (c) reduction rate of fabrics with different zinc pyrrolidone concentrations; (d) SEM images of antibacterial structural color on fabrics with different concentrations of zinc pyrrolidone (insets were corresponding optical photos of structural color on fabrics, and the scale bar was 1 cm)

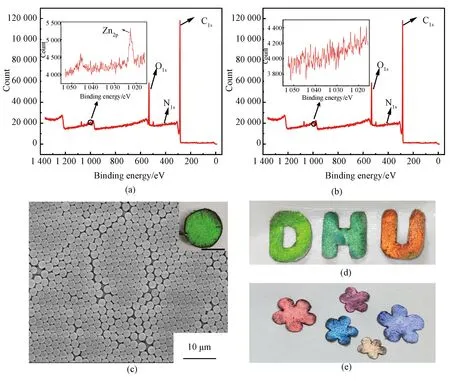

Then XPS characterization was applied to confirm the successful modification of antimicrobial agents. Samples modified by zinc pyrrolidone and the control sample without the addition of zinc pyrrolidone were characterized by XPS. The characteristic peak of Zn2pwas clearly observed in Fig. 4(a)[38], while it was not existed in the control sample as shown in Fig. 4(b). The results confirmed that zinc pyrrolidone was successfully modified on the fabric. Meanwhile, optical images were applied to confirm whether the addition of antibacterial agents had influence on the structural color or not. SEM was firstly applied to characterize the influence of zinc pyrrolidone on the microstructure of structural color dye. Figure 4(c) was the SEM image of structural color dye with zinc pyrrolidone loaded at a concentration of 50.0 μg/mL. It was clearly shown that the latex spheres were still tightly arranged in a highly ordered way. The optical photo in the inset of Fig. 4(c) also kept bright and high-saturation color, which was in consistent with the SEM images. Certain amount of PUA was added to improve the interactions between zinc pyrrolidone inside the structural color and the fabric. The addition of proper amount of PUA also had little influence on the brilliant color of structural color, as well as the excellent antibacterial property. By changing the particle size of the latex spheres, antibacterial structural colors with different colors and shapes could also be obtained as shown in Figs. 4(d) and 4(e), which proved the application possibility of structural color in brand logos and displays.

Fig. 4 Diagram and morphology of structural color fabrics: (a) XPS of fabrics with zinc pyrrolidone; (b) XPS of fabrics without zinc pyrrolidone; (c) SEM image of structural color dye loaded by zinc pyrrolidone on fabric(inset was the optical photo of antibacterial structural color on fabrics, with a diameter of 4 cm); (d) and (e) optical pictures of structural color dyed fabrics with different colors

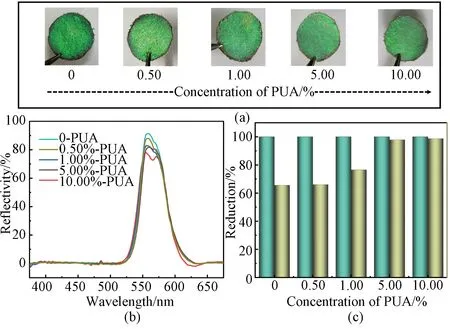

The best concentration of PUA was selected to improve the sustaining antibacterial reduction rate. The sustaining antibacterial reduction rate of antibacterial structural color fabric was quite necessary for its practical application. Therefore, antibacterial structural color fabric was placed in mixtures containing urethane oligomer and photoinitiator, and slowly lifted up to ensure the immersion of mixtures. Then a UV lamp with a wavelength of 365 nm was applied to initiate polymerization. It could be seen from Fig. 5(a) that the addition of certain amount of PUA had little influence on the structural color. When the concentration of PUA increased to 10.00%, the corresponding structural color still showed bright and high-saturated color. A fiber spectrophotometer was used to characterize the reflectance spectrum of structural color fabrics. The corresponding reflectivity of the fabric in Fig. 5(b) also slightly decreased. ThenE.coliwas used as the detection flora, and the influence of PUA on the antibacterial reduction rate of fabrics was tested after three cycles of washing treatment. The results were shown in Fig. 5(c). The antibacterial reduction rate before washing was 99.99%, but after three cycles of washing treatment, the antibacterial reduction rate dropped to 66.65% when the antibacterial agent was totally exposed. When the concentration of PUA was improved to 10.00%, the antibacterial reduction rate could be maintained at 98.87% after three cycles of washing. The results confirmed that the existence of PUA had good protection effect on the antibacterial effect of fabrics.

Fig. 5 Influence of PUA on antibacterial effect of fabrics: (a) optical pictures of structured colored fabrics with different concentrations of PUA; (b) reflection spectra of antibacterial structured color fabrics with different concentrations of PUA; (c) reduction rate of fabrics with different concentrations of PUA

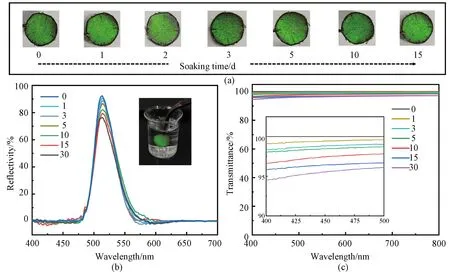

To testify the water resistance and washing resistance of the fabric, the fabric was directly immersed in deionized water. Figure 6(a) was the optical photos of the above fabrics which were soaked in deionized water for 1, 2, 3, 5, 10, and 15 d. The optical photos confirmed that the structural color of the fabric was well kept after being soaked in water for 15 d and the color still presented bright green and high color saturation. The corresponding reflectivity of the fabric in Fig. 6(b) also decreased slightly, which was in consistent with the result of the optical images. The corresponding deionized water with different soaking times was selected for the light transmittance test by a UV spectrophotometer. Results showed that, compared with the transmittance of pure water, the transmittance of deionized water solution soaked by fabrics decreased slightly. The results confirmed that the structural color fabric had excellent water resistance.

Fig. 6 Water resistance test of antibacterial structural color on fabrics: (a) optical images of fabrics immersed into deionized water solution for 0, 1, 2, 3, 5, 10 and 15 d; (b) corresponding reflection spectra of PCs after immersion; (c) transmittance spectra of corresponding deionized water solution after washing simulation

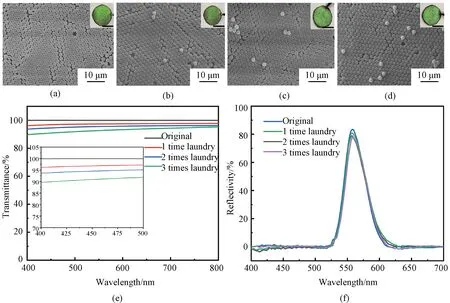

In order to meet the needs of daily life, it is very important for the fabric to have good washing resistance. The laundering process was simulated to determine the washing durability of the colored fabric by putting the fabric into canister rotating at 40 r/min for 15 min and 40 ℃. After three washing cycles, the structural color fabrics still retained their original bright colors. SEM images in Fig. 7 also confirmed the results. Compared with the original textile, after three washing cycles, the microstructure of structural color was barely destroyed and still in highly ordered arrangement. The water transmittance was slightly reduced as shown in Fig. 7(e). The reflectance of light was barely unchanged after three cycles of washing as shown in Fig.7(f). The results confirmed that the obtained antibacterial structural colored fabric had good washing resistance. The reason was that the combination effect of polydopamine and PUA greatly increased the interactions of the fabric, structural color dye and the antibacterial agent zinc pyrrolidone.

Fig. 7 Laundering resistance tests of fabrics loaded with antibacterial structure color: (a)-(d) optical images and corresponding SEM images of fabrics after laundering cycles; (e) transmittance spectra of corresponding water after washing simulation; (f) corresponding reflection spectra of antibacterial structural color after immersion

3 Conclusions

In this paper, structural color dye with excellent antibacterial property was successfully prepared and modified on fabrics. Due to the combination effect of polydopamine coating on fabrics and PUA on structural color coating, the interactions among the fabric, structural color dye and the antibacterial agent zinc pyrrolidone were greatly improved. The functional structural color dye endowed the fabric brilliant color, excellent antibacterial property as well as good washing resistance, which paved a new way for the applications of structural color and functional fabrics.

杂志排行

Journal of Donghua University(English Edition)的其它文章

- Axial Compression Properties of 3D Woven Special-Shaped Square Tubular Composites with Basalt Filament Yarns

- Parametric Effects on Length of Stable Section of Electrospinning Jet

- Preparation and Performance of Fluorescein Isothiocyanate-Labeled Fluorescent Starch and Polyvinyl Alcohol for Warp Sizing

- Effects of Magnolia denudata Leaf Litter on Growth and Photosynthesis of Microcystis aeruginosa

- Order Allocation in Industrial Internet Platform for Textile and Clothing

- Blockchain-Based Log Verification System for Cloud Forensics