Experimental investigation of rigid confinement effects of radial strain on dynamic mechanical properties and failure modes of concrete

2021-10-26PengfeiLiuXiopingZhouQihuQin

Pengfei Liu,Xioping Zhou,b,*,Qihu Qin

a School of Civil Engineering,Chongqing University,Chongqing 400044,China

b School of Civil Engineering,Wuhan University,Wuhan 430072,China

c PLA University of Science and Technology,Nanjing 210007,China

Keywords:Strain rate effect Multiaxial loading Dynamic peak axial stress Thermo-activated mechanism Dynamic increase factor

ABSTRACT In this study,to confirm the effect of confining pressure on dynamic mechanical behavior and failure modes of concrete,a split Hopkinson pressure bar dynamic loading device was utilized to perform dynamic compressive experiments under confined and unconfined conditions.The confining pressure was achieved by applying a lateral metal sleeve on the testing specimen which was loaded in the axial direction.The experimental results prove that dynamic peak axial stress,dynamic peak lateral stress,and peak axial strain of concrete are strongly sensitive to the strain rate under confined conditions.Moreover,the failure patterns are significantly affected by the stress-loading rate and confining pressure.Concrete shows stronger strain rate effects under an unconfined condition than that under a confined condition.More cracks are created in concrete subjected to uniaxial dynamic compression at a higher strain rate,which can be explained by a thermal-activated mechanism.By contrast,crack generation is prevented by confinement.Fitting formulas of the dynamic peak stress and dynamic peak axial strain are established by considering strain rate effects(50–250 s-1)as well as the dynamic confining increase factor (DIFc).

1.Introduction

Concrete is a typical construction and building material in civil engineering.Practical concrete structures and their subcomponents may experience multiaxial compressive stress states,which have an advantageous effect on their bearing capacity [1].It is important and necessary for concrete,which accurately evaluates the mechanical property and deformation mechanism under complex stress (biaxial or triaxial) conditions for the engineering design and controlling the construction costs.The dynamic strength of concrete increases with increasing strain rate,implying that concrete is a typical rate-dependent material [2–6].Dynamic loading is frequently encountered in concrete structures,such as earthquakes,the vibration of vehicles,impact loads,blasting loads and so on.Therefore,the dynamic behavior of concrete is an important topic in practical engineering,especially considering the role of confining pressure and the strain rate effect [7,8].

Many researchers have studied the confining action of concrete,including experimental investigations [9–14],theoretical analysis[15–19],and numerical simulations [20–23].These works have aided the understanding of the confining effects on the strength,deformation,and failure mechanism of concrete.Gran et al.[24]investigated the dynamic behaviors of concrete considering confinement;the results of which showed the dynamic strength to increase by 30%–40% and the elasticity modulus to increases by about 60% compared with the quasi-static condition around the strain rate of 5 s-1.A common recognition is that concrete undergoes brittle failure behaviors under low confined conditions.In contrast,concrete typically shows ductile features and failure associated with ductile fracture under high confined conditions [25].Christensen et al.[26] developed the dynamic experiments of concrete-like material under a confined condition.Zeng et al.[27] and Yan et al.[28] developed the MTS set-up to explore the compression behavior of concrete materials at a low strain rate.The compressive mechanical properties and failure mechanism of concrete were investigated with the maximal confinement of 650 MPa [29,30].Such previous investigations mainly focused on dynamic loads with low strain rate effects,while high dynamic loading effects have been rarely investigated,even though concrete structures are often subjected to multiaxial dynamic loads at a high strain rate [31,32].As such,the dynamic mechanical behavior of concrete requires urgent attention with particular consideration of the confining effects at high strain rates.

Previous studies have proved that the dynamic mechanical response of concrete materials strongly depends on the loading rate [5].In fact,the strain rate effect of concrete materials was demonstrated as early as 1917 by Abrams [33] via a compressive experiment.Following this,more works have been conducted to improve the understanding of the dynamic behavior of concrete[34–36] and concrete-like materials [37,38],such as cement [39–41],rock [42,43],coal [44],ceramic [45],soft soils [46],and sand[47].To perform dynamic experiments of brittle materials (such as concrete,cement,and rock) under high strain rate conditions,a split Hopkinson pressure bar(SHPB)set-up has been extensively applied,as shown in Fig.1.The achievements of both dynamic compression characteristics [48,49] and dynamic tension properties of concrete have been performed.Experimental models have been developed to explore the properties of concrete under uniaxial dynamic loading,in which the dynamic strength increasing with the increase of strain rate has been found [50,51].The dynamic properties of concrete material depend not only on strain rate but also on confining pressure.However,it is challenging to realize the combination of high dynamic loads and confining stress in SHPB experiments.Currently,there are two common methods for SHPB experiments:hydrostatic pressure loading and metal sleeve confining(displacement boundary condition).The confining pressure range of the metal sleeve can be achieved by the thickness of the sleeve.Compared with the hydrostatic pressure method,the metal sleeve confining experiment is easily executed in the SHPB test,without any special testing devices required.Furthermore,metal sleeve confining experiments can realize the high confining pressure in which hydrostatic pressure testing is difficult to achieve due to the special requirements of sealing.

A series of dynamic compression tests of concrete were performed by SHPB under confined conditions (metal sleeve) and unconfined conditions to investigate the dynamic mechanical behaviors at high strain rate and high confining pressure state.To explore the confining pressure effects of concrete concerning the stress loading condition,two types of specimens (confined specimens and unconfined specimens) were prepared with the same materials cured under the same condition.The confined concrete specimen was obtained by a metal sleeve jacketing.The SHPB loading device was used to provide dynamic stress for the concrete specimens at strain rates ranging from 50 to 250 s-1.The dynamic behaviors of concrete including the dynamic axial stress evaluation,dynamic peak lateral stress,strain rate effect,peak axial strain,and confining effects on the strain rate mechanism are analyzed in detail.The failure pattern of specimens is discussed to help understand the dynamic behaviors of concrete under both confined and unconfined conditions.Finally,a linear fitting was established for the dynamic increase factor(DIF)and dynamic confining increase factor (DIFc) of concrete under confining pressure action.

2.Experimental procedures

2.1.Specimen materials

The cement applied in this investigation is P.O 42.5.Concrete specimens were made of potable water,river sand(fine aggregate),and natural coarse aggregates(3.35–8.00 mm).The composition of concrete specimen is cement,water,sand,and aggregate,and the corresponding ratio is 4.0:1.8:4.8:8.0.The unconfined specimens were prepared by PVC pipe (Φ51× 51 mm).The confined specimens were cast in cylindrical metal sleeves (inner diameter:Φ51× 51 mm).All specimens were kept in a concrete maintainer with a saturated condition for up to 28 d.It is noteworthy that a release agent was used inside the metal sleeves before the casting.The concrete specimens were slightly and frequently moved to avoid the sleeve sticking together during the curing stage.The goal was to realize a specimen closely combined in the confining sleeve and to lubricate the gap between the specimen and the inner part of the sleeve,which is important for the multiaxial loading in the SHPB experiment.To eliminate other factors as possible,the specimens under confined and unconfined conditions were made by the same materials(cement,aggregate,etc),cured in the same condition and experienced the same curing period.The purpose of these preparations was to investigate the confining effects of concrete under dynamic loading conditions while avoiding other influential factors.

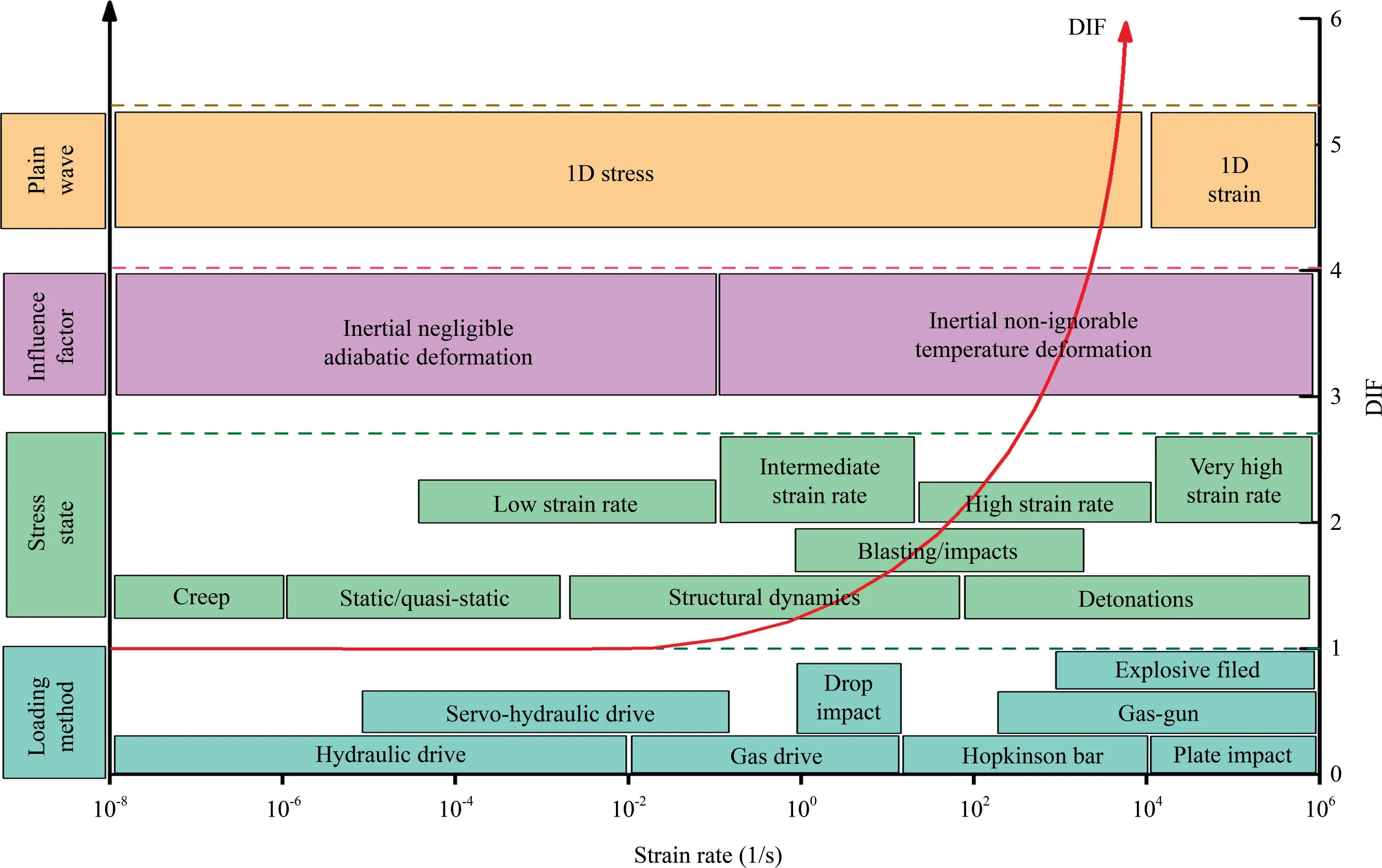

Fig.1.Stress state and experimental methods at different strain rates.

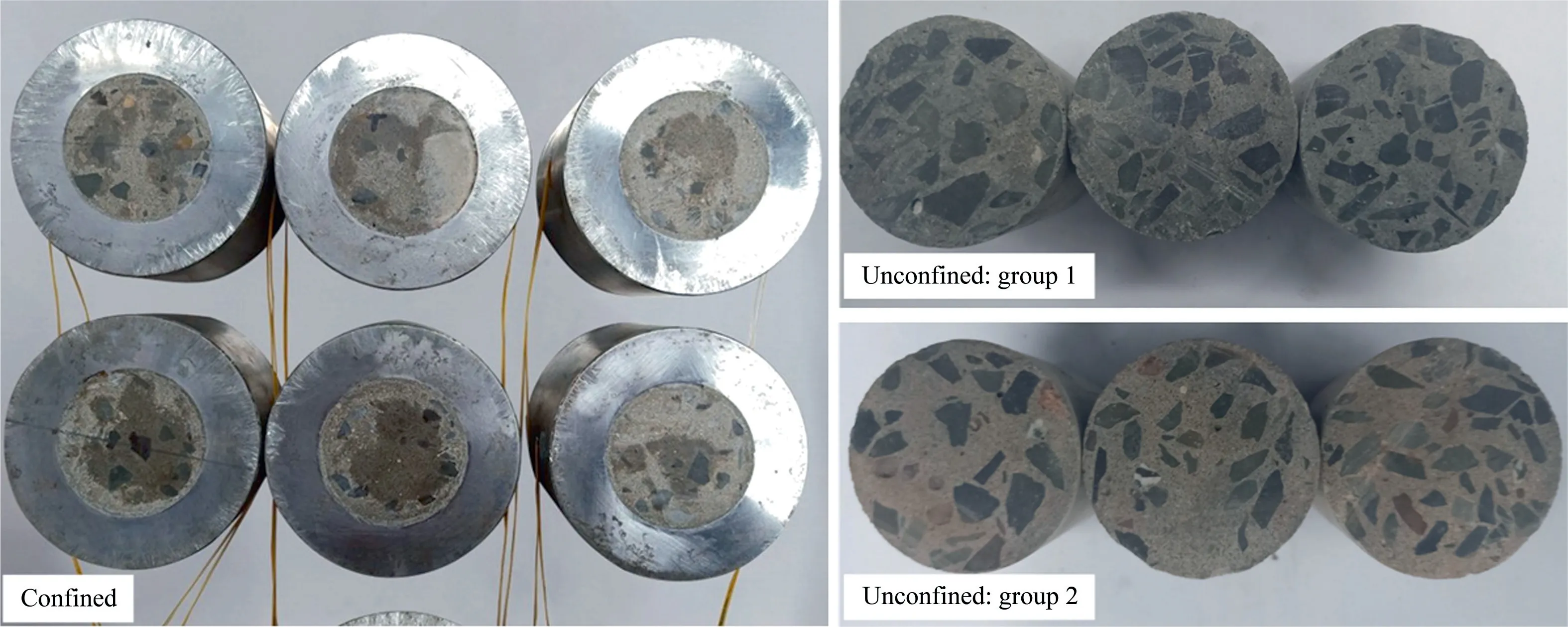

A specimen cylinder size of Φ51× 51 mm was designed to accommodate the diameter of the dynamic loading device,and it is the suggested size for dynamic compression in SHPB experiments[52].As shown in Fig.2,the typical confined and unconfined specimens were used in this study.The physical parameters of the concrete specimens are listed as follows:the average mass density and P wave velocity are 2250 kg/m3and 4510 m/s,respectively,and the average uniaxial compressive strength (UCS) is 38 MPa.To reduce the experimental scatter of results,two specimens were conducted for each strain rate under the confined condition (little error of repeated testing data),and three specimens were conducted for each strain rate under the unconfined conditions.All the concrete testing specimen ends are flat to 0.02 mm and parallel to within 0.05 mm.

2.2.Dynamic loading set-up

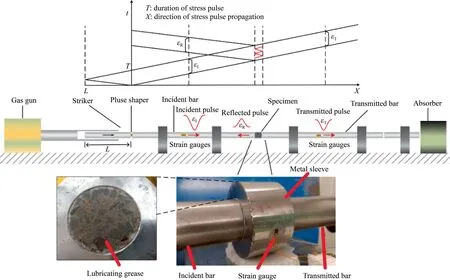

The SHPB set-up (Φ=50 mm) was applied to conduct the dynamic compressive tests,as shown in Fig.3.The dynamic loading device comprises a gas gun,a short cylindrical striker(L=0.5 m),and three high-strength cylindrical maraging metal bars (an incident bar (2.5 m),a transmitted bar (2.5 m),and an absorber bar (1.0 m)).The bars have a density of 7800 kg/cm3,an elastic modulus of 210 GPa,and a P wave velocity of 5.2 km/s.Dynamic stress equilibrium must be reached to obtain reliable SHPB experimental results [53].A red copper disc (Φ11× 1 mm)is attached to the impact end of the incident bar for dynamic compression tests of brittle materials to overcome the sharp rise of the incident pulse caused by the high-speed impact of the striker at a high strain rate [54].Lubricating grease is applied between the specimen and metal bars to reduce the radial friction effects under impact loading.

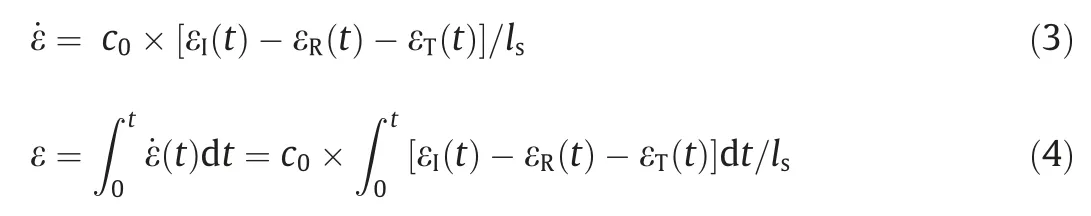

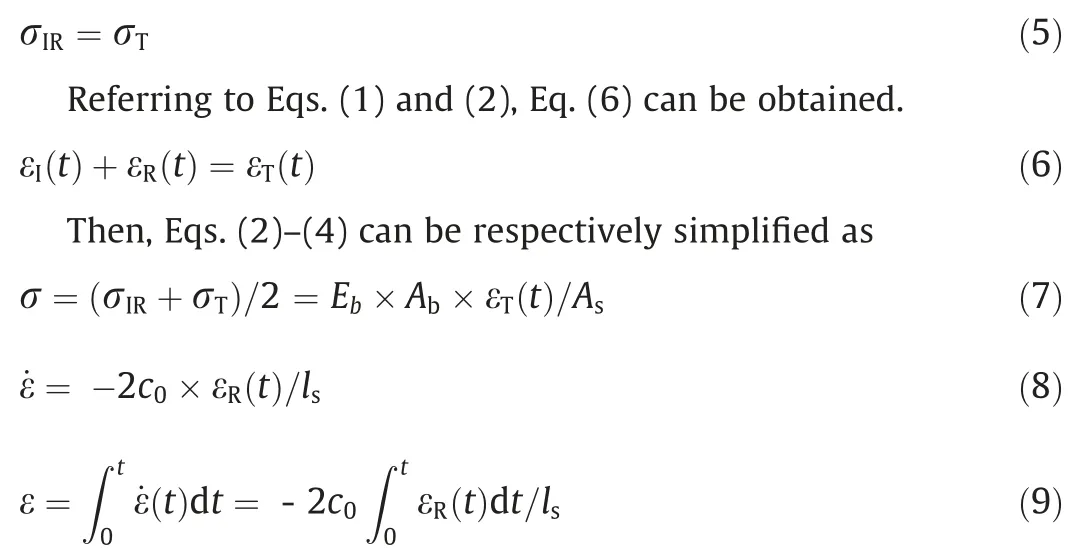

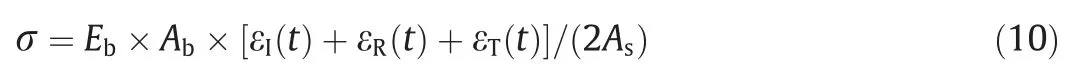

Based on the one-dimensional (1D) wave propagation theory,the dynamic stress (σ) of the testing specimen can be obtained as follows [55].

where εI(t),εT(t),and εR(t) are the incident,transmitted,and reflected strain signals measured on metal bars,respectively;σIRand σTthe loading stresses at two ends of a specimen;tthe time of stress loading;Asthe cross-sectional area;.ε andlsthe strain rate and the length of the specimen,respectively;andc0,Eb,andAbthe elastic wave speed,Young’s modulus,and cross-sectional area of the cylindrical metal bar,respectively.

Basic theoretical assumptions in the SHPB experiment are that equilibration of loading stress (strain) and uniform deformation of the specimen is reached during the dynamic impacts.Consequently,the stress equilibration of the specimen can be defined as

If the dynamic stress of the specimen is not in perfect equilibrium,it can be calculated as follows.

Under the confined condition,the assessment of dynamic axial stress,strain rate,and axial strain in the loading direction can be obtained by the same method as that in the case of uniaxial loading[3].The lateral confining pressure applied on the concrete specimen is achieved by the metal sleeve,as shown in Fig.4.The inner diameter of the confining sleeve is a little larger than that of the cylindrical maraging metal bars (incident bar and transmitted bar) to avoid impact damage between the bars and sleeve.Under dynamic axial compression loads,both specimen and the metal sleeve expand in the radial direction before failure of the specimen as a result of Poisson’s ratio of the specimen.Two strain gauges are installed on the metal sleeve to record the dynamic radial response signals.Before the beginning of the experiment,the testing specimen should be lubricated to cut down the contact friction between testing specimen and metal sleeves.It is noted that the yield stress of the metal sleeve is strong enough to undergo elastic deformations during dynamic loadings.Based on the above assumptions,the lateral confinement can be obtained by the pulse measured from sleeves.From the thick-walled cylinder theory,the lateral confining pressure can be written as [56]

Fig.2.Typical confined and unconfined concrete specimens.

Fig.3.Schematic of the SHPB device and confined specimen.

Fig.4.Assembly of confined concrete specimens.

whereqcis the lateral confining pressure of specimen;andri,ro,Ec,and εcthe inner radius,outer radius,elastic modulus,and strain signal of the confining metal sleeve,respectively.

3.Experimental results

The dynamic compression experiments of concrete were executed under unconfined and confined conditions by the SHPB device.To compare confining effect at similar strain rate condition(50–250 s-1),the experimental results from five strain rates (50–250 s-1) under the unconfined condition as well as from seven strain rates (75–225 s-1) under the confined condition are presented in this study.The strain rate,dynamic stress evolution,peak strain,DIF,DIFc,dynamic peak lateral stress,failure patterns,and mechanism of the typical concrete specimen are discussed under both unconfined and confined conditions to consider the confining effect.

3.1.Unconfined experimental results

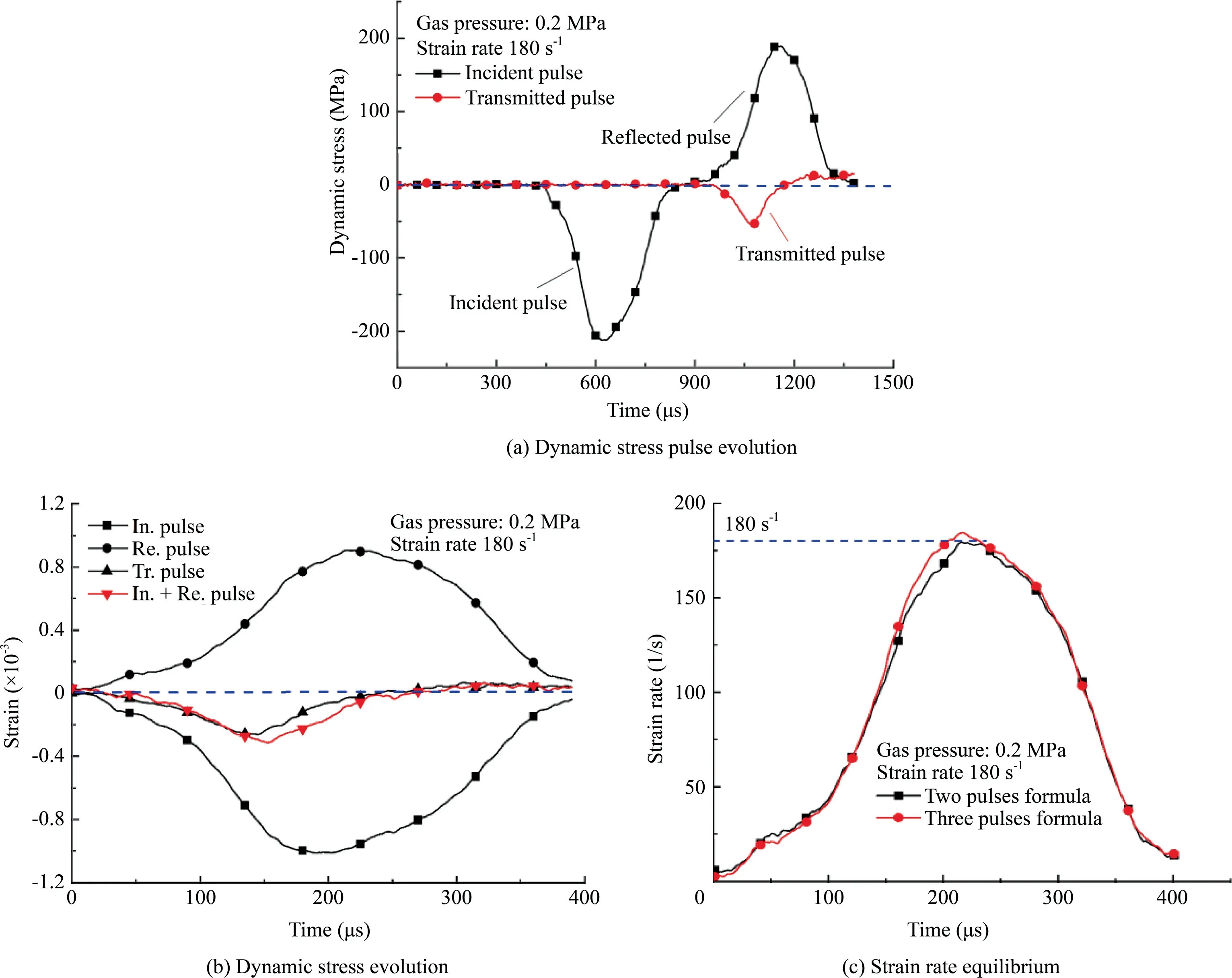

Fig.5 shows the typical dynamic stress pulses of a concrete specimen recorded at an impact strain rate of 180 s-1under the unconfined condition.In Fig.5a,the half-sine incident pulse shows that dynamic stress smoothly increases under impact loading.The transmitted pulse presents similar forms,comprising a combination of incident and reflected pulses before the specimen is damaged,as shown in Fig.5b.This means that the stress equilibrium of specimens has well arrived under impact loads in the experimental process,and the results of testing are credible.The dynamic stress,dynamic strain,and strain rate are calculated by Eqs.(7)–(9) under the unconfined condition.The average strain rate of the specimen is the peak value of its equilibrium section,as shown in Fig.5c.

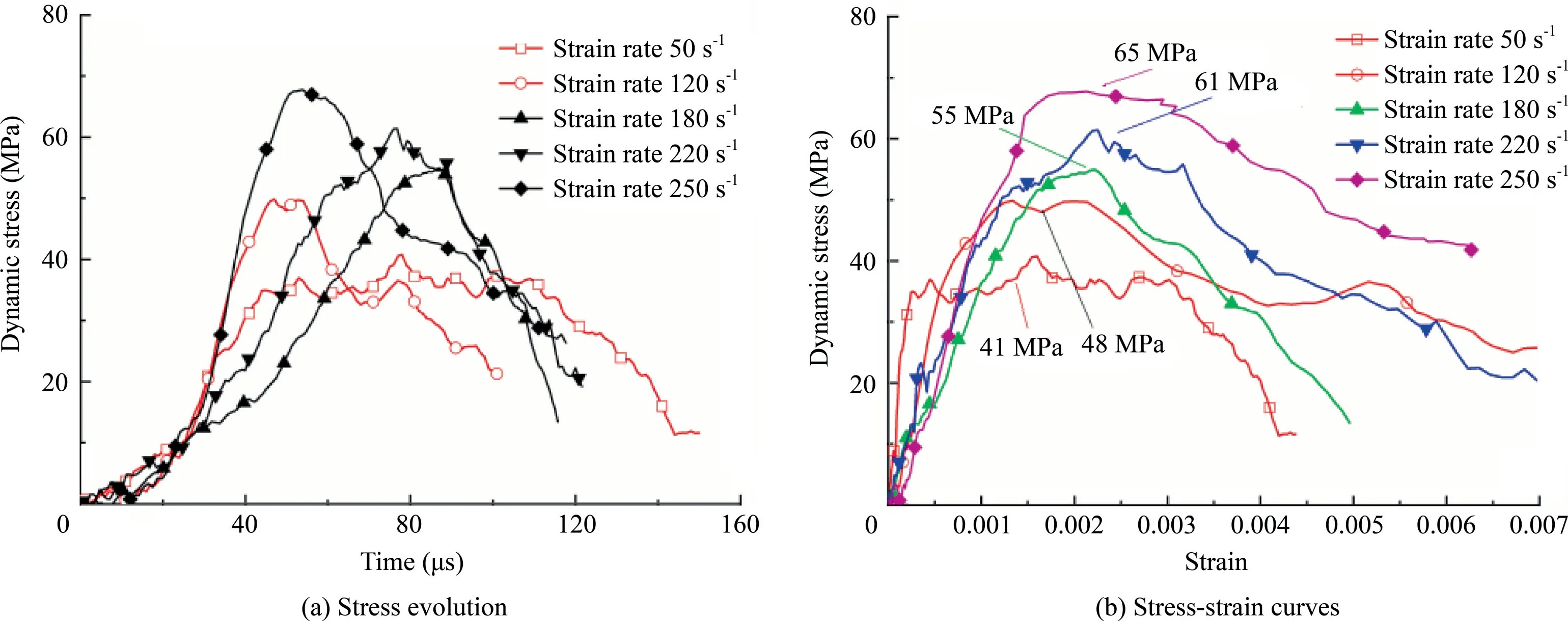

Fig.6 shows the dynamic stress-loading curves and stress–strain curves of concrete.The loading duration of the dynamic peak stress decreases with increasing strain rate while dynamic compressive strength increases from 41 to 65 MPa,corresponding to the fact that the DIF increases from 1.08 to 1.84 as the strain rate increases from 50 to 250 s-1.This result proves that concrete has a strong strain rate effect,or concrete is strain rate-sensitive material.Moreover,Fig.6b shows that the deformation modulus (it is the ratio of peak stress to corresponding strain) of concrete presents a slightly increasing tendency as the strain rate increases from 50 to 250 s-1.Similar conclusions have also been reported in previous works [57,58].

It should be noted that the pulse shaping technique is not used in the experiment when the impact velocity of the striker is in a relatively low state (≤120 s-1),as plotted in red in Fig.6.In other words,the pulse shaping technique is applied at high strain rate conditions(>120 s-1).This technique is used to modify the incident pulse and to revise the initial portion of the dynamic stress–strain curve of brittle materials under high strain rate conditions [59].The initial stage of dynamic stress increases more quickly when the pulse shaping is not applied.The experimental result proves that the action of pulse shaping is effective under impact loads at high strain rate conditions (e.g.180,220,and 250 s-1).

3.2.Confined experimental results

Fig.5.Stress pulse evolution of concrete under the unconfined condition.Note that “In.pulse”,“Re.pulse”,and “Tr.pulse” represent incident pulse,reflected pulse,and transmitted pulse,respectively.

Fig.6.Experimental results under the unconfined condition at different strain rates.

Fig.7.Experimental results of concrete under confined condition.

To comparatively investigate the dynamic response of concrete at a similar strain rate under unconfined conditions,a total of seven strain rates(75–225 s-1)under confined conditions are presented.Fig.7 presents typical experimental records of concrete under multiaxial impact loads(strain rate of 75 s-1).Fig.7a shows that the incident and lateral pulses start from zero.The incident pulse is then transformed as a compressive negative pulse,and the dynamic lateral response pulse starts about 708 μs due to Poisson’s effect of concrete.Part of the incident pulse is reflected from the end of the incident bar as a tension(unloading)pulse,and the resting pulse transmits into the transmitted bar through the barspecimen interface.Those pulses are collected through the gauges attached to the metal bars (Fig.4).Fig.7b verifies the dynamic stress equilibrium is well reached,and the dynamic testing results are credible.The dynamic stress,strain rate,and dynamic strain of concrete at the loading direction are defined by Eqs.(7)–(9).Fig.7c shows that the dynamic lateral stress increases synchronously with increasing dynamic axial stress,and the dynamic peak lateral stress is registered at 192 μs.

The dynamic axial stress evolution of concrete under confined condition is shown in Fig.8.Compared with the unconfined condition,the dynamic axial stress under confined condition takes more time to reach the peak value.For example,the dynamic stress takes 45 μs to reach the peak stress value under the unconfined condition(65 MPa at a strain rate of 250 s-1),while it is 220 μs to attain the peak stress value under the confined condition (319 MPa at a strain rate of 225 s-1).Fig.8 shows that the dynamic axial stress rapidly increases before the loading time approaches 145 μs at high strain rates (e.g.160,190,and 225 s-1).Then,the dynamic axial stress slowly increases until reaching the peak value.This phenomenon may be due to the frictional sliding of coarse aggregate or sand particles inside the concrete.After that,the deterioration is sufficient to trigger the microfracture inside under dynamic loads,while the bearing capacity of concrete increases until the dynamic peak stress is attained under the confined condition.These results prove that the confining effect not only greatly improves the dynamic peak axial stress but also extends the dynamic stress loading duration and weakens the brittleness of concrete under dynamic loads.

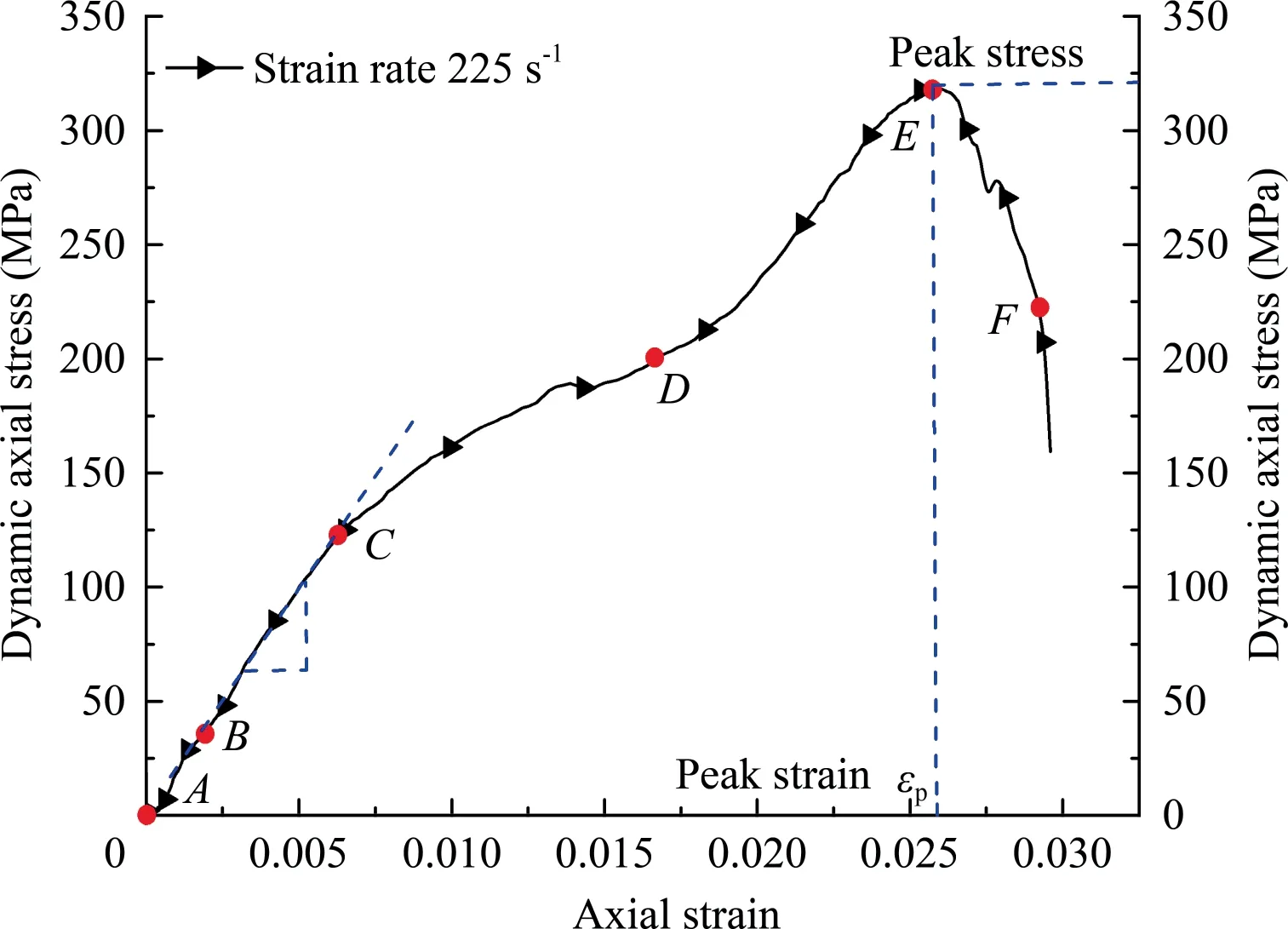

Fig.9 shows a typical experimental result of a specimen under a confined condition.It can be seen that the dynamic axial stress–strain curve of concrete consists of five sections.In the first stage,which is the section fromAtoB,a convex characteristic in the stress–strain response of the concrete occurs.Different from the quasi-static compression condition of the concrete,there is no obvious compression stage under a high strain rate impact,and the duration of impact loads is insufficient to achieve the compaction of pores and micro-cracks under dynamic compression conditions [60].In the second stage,which is the segment fromBtoC,the increase of dynamic stress is nearly linear,which is similar to the quasi-elastic deformation behavior of concrete.In the third stage,which is the section fromCtoD,the increasing tendency of the stress–strain curve slows down due to the sliding of coarse aggregates/sand particles.In the fourth stage,which is the segment fromDtoE,the stress–strain response concaves downward before its peak value under the confined condition.In the fifth stage,which is the section fromEtoF,the concrete exhibits a strain-softening behavior,in which the dynamic axial stress suddenly decreases due to the fracture of concrete.

Fig.8.Dynamic axial stress evolution of concrete with confinement.

Fig.9.Typical dynamic axial stress–strain curve with confinement.

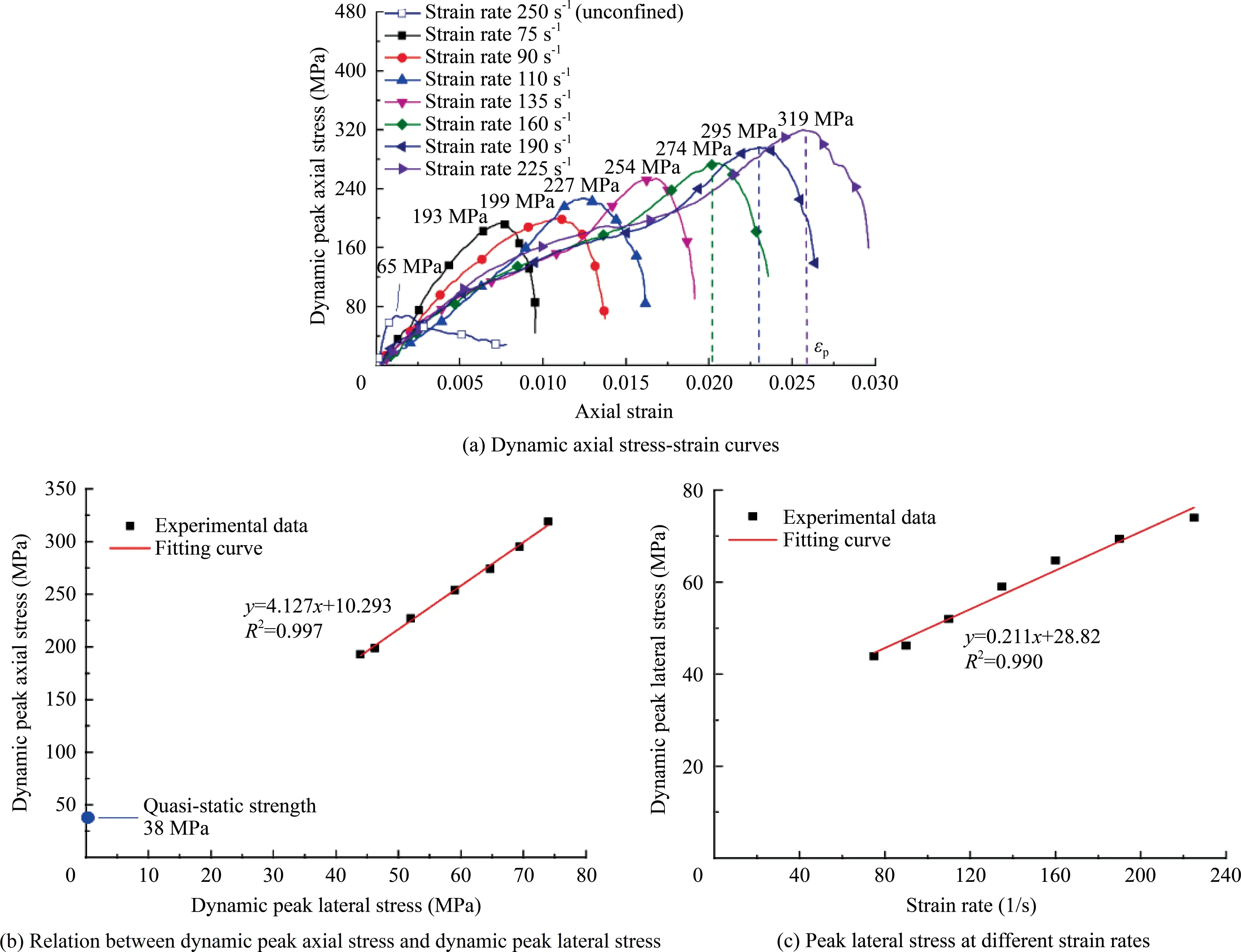

Fig.10 shows the dynamic behaviors of concrete at different strain rates in the confined state where the dynamic peak axial stress and dynamic peak axial strain (εp) both increase with increasing strain rates.Specifically,the dynamic peak axial stress increases from 193 to 319 MPa as the average strain rate increases from 75 to 225 s-1,and the dynamic peak lateral stress increases from 43.9 to 74.0 MPa under the confined condition.In comparison,the dynamic peak stress of concrete is 65 MPa in the unconfined state (250 s-1).Additionally,the dynamic peak strain of concrete is 0.0027 at a strain rate of 250 s-1in the unconfined state,while it is 0.0257 at a strain rate of 225 s-1under the confined condition.In Fig.10a,the deformation modulus under unconfined conditions is greater than that under confined conditions.The confinement limits the deformation and improves the energy dissipation efficiency of concrete under compression,which can enhance the deformability of concrete.In other words,the confinement can effectively strengthen the bearing capacity and ductility of concrete under dynamic loads.In an unconfined state,the stress–strain curve presents obvious strain-softening behaviors when the strain exceeds the peak value,while dynamic axial stress of concrete abruptly drops without the obvious strain-softening trends under dynamic confining loading conditions.

Based on the experimental results in a confined state,a fitting curve of the dynamic peak lateral stress is established against the dynamic peak axial stress in Fig.10b.Fig.10c shows that the dynamic lateral stress increases with increasing strain rate.It proves that dynamic compressive strength and dynamic loading capacity of concrete possess strong sensitivity to strain rate.Furthermore,a linear relationship between the strain rate and dynamic peak axial stress (peak lateral stress) is summarized.

3.3.Failure patterns

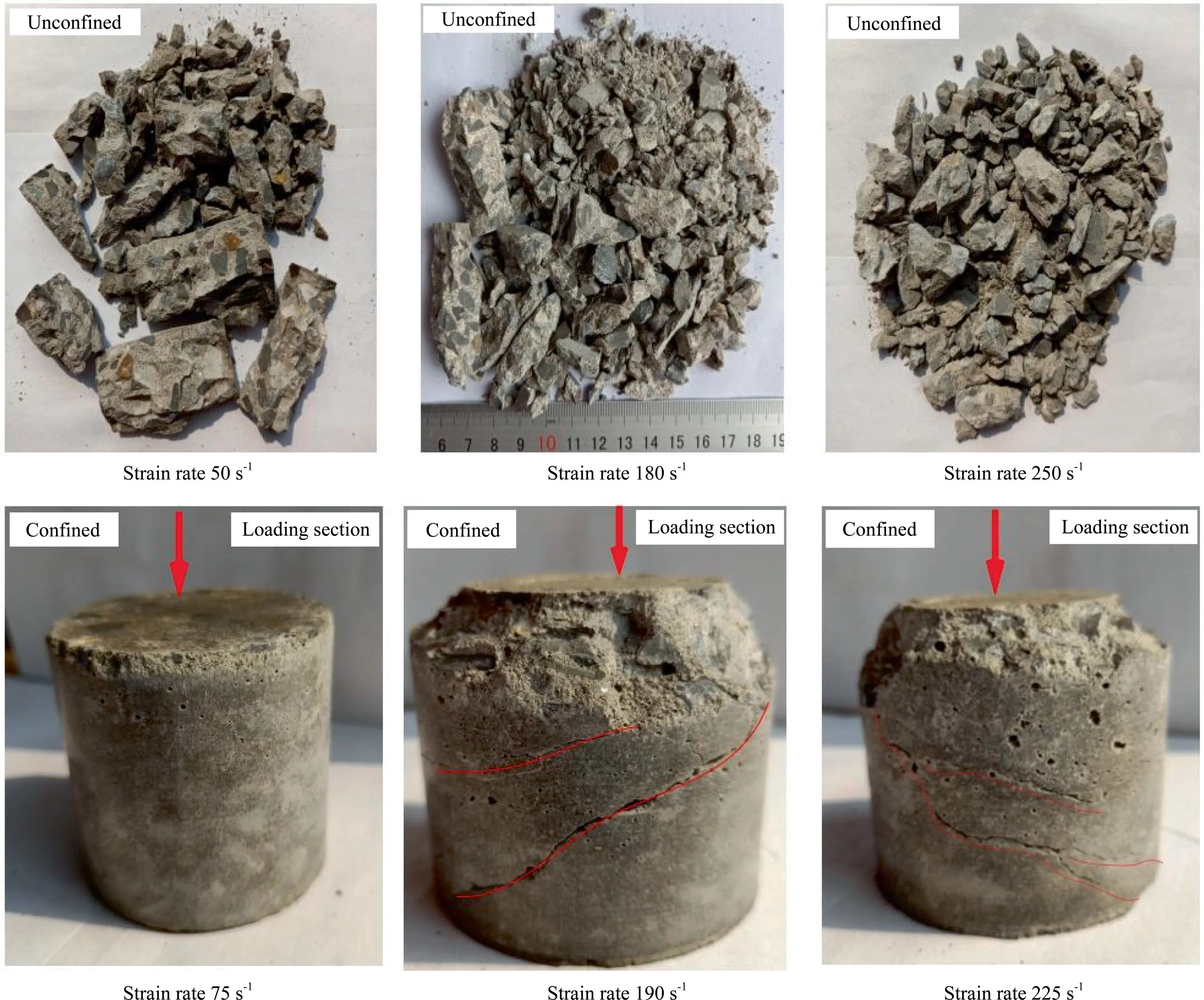

Fig.11 presents the failure behavior of specimens under unconfined and confined conditions.The strain rate condition has obvious effects on fracture patterns of concrete under unconfined conditions.The specimens are fragmented into distinct blocks at the strain rate of 50 s-1,and smashed into irregular small pieces at the strain rate of 250 s-1under the unconfined condition.Compared with confined conditions,specimens keep intact at the average strain rate of 75 s-1,while local damage on the loading surface and shear cracks of concrete are observed at a high strain rate of 225 s-1.

Concrete contains many micro-cracks,closed pores,and other micro-defects.The initiation,growth,and coalescence of those micro-defects would cause fracture and damage of concrete due to dynamic loads.Under the confined condition,the application of confining pressure can suppress the initiation and propagation of micro-cracks of concrete,which leads to an increase of dynamic load-carrying capacity.It has also been suggested that the large confining pressure can activate plastic flow or quasi-brittle behavior of brittle materials [61].The typical fracture observations,shown in Fig.11,prove that a high strain rate dynamic loading can generate aggregate rearrangement and leads to a shear fracture inside the concrete under a confined condition.It is worth noting that failure patterns are related to the length-diameter ratio of the testing specimen,which is advised from 0.5 to 1.0 in SHPB experiments [62,63].

Fig.10.Dynamic behaviors of concrete under confined condition.

4.Mechanism of rate-dependence under confining pressure

Many works on the mechanism of concrete strain rate effects have been conducted,both experimental and theoretical [64–68].However,the mechanism of the strain rate of concrete,particularly those considering confining pressure,has not reached a common ground.Three physical mechanisms can be summarized for describing strain rate-dependent behavior of concrete materials[62–64,67]:the thermo-activated mechanism,viscosity mechanism (Stefan effects),and the inertial mechanism,as described in Fig.12.The whole strain rate range is divided into several regions,including low strain rate (quasi-static),medium strain rate,high strain rate,and super-high strain rate regions.As the impact loading rate of concrete is under the medium strain rate stage,the thermo-activated mechanism and viscosity mechanism mainly control the dynamic strength performance.The inertial mechanism plays a dominant role at high/super high strain rates,which suggests that the main contribution to the dynamic stress property is owed to inertial action.

In this study,the testing strain rate ranges from 50 to 250 s-1,which is between the medium and the high strain rates (Fig.12).It can be found that the dynamic strength performance of concrete is controlled by three mechanisms:the thermo-activated mechanism,the viscosity mechanism,and the inertial mechanism.The thermo-activation is a kind of thermal vibration effect at the atomic scale,which causes the breakage of atomic bonds and the creation of micro-cracks in the concrete under dynamic loads.More cracks are formed as dynamic loads are stronger,and more energy is required for the propagation of these cracks.Then it results in the increasing strength of concrete.The viscosity mechanism is related to the moisture of the concrete.The inertial mechanism contains two parts:the radial inertia action and the vertical inertia effect.Radial inertia action is related to the friction between ends of bars and sections of the testing specimen,and the vertical inertia effect mainly depends on fragment acceleration of the specimen in the loading direction after dynamic loadings.

The thermal vibration intensity of atoms has a close relation to the generation of cracks of concrete under dynamic loads.Fracture of a specimen is the result of the generation and propagation of many micro-cracks inside the concrete.The dissipated energy required for a crack to generate is far greater than that required for a crack to propagate [69,70].Therefore,the dynamic strength of concrete slightly increases under a low strain rate condition(<100s-1)due to the fractures caused by a few cracks,which propagate along the path with the lowest dissipation energy.As the strain rate increases to medium or high-level conditions,the thermo-activation of concrete is greatly enhanced due to the dynamic loads with a high strain rate.Then,much more microcracks are needed inside concrete to dissipate the impact energy.In other words,the substantial increase of the dynamic strength of concrete is contributed to the increasing of dissipated energy.The number of cracks of concrete is an important indicator of the thermo-activated mechanism for representing the strain rate effect.In addition,two kinds of concrete specimens (confined and unconfined) are prepared,conducted,and cured under the same condition to reduce the difference caused by the viscosity mechanism.The effects of viscosity and inertial actions are negligible due to the lubricating grease attached around the specimen for reducing the friction,compared with the thermo-activated effects in the ranges of strain rate in this experimental study.

Fig.11.Typical fractures of concrete under unconfined and confined conditions.

From the above,the dynamic strength enhancement mechanism of concrete under impacts in this investigation mainly depends on the thermo-activated mechanism.At a certain strain rate,it is easier to create a larger number of cracks inside concrete under an unconfined condition.In other words,the concrete presents a stronger strain rate effect under an unconfined condition than under a confined condition.The failure characteristics of concrete are confirmed by the typical fracture specimen,as shown in Fig.11.Concrete is fractured with one or several through cracks under low strain rate impact loads.The number of cracks rapidly increases with increasing strain rate,causing breakage into small fragments (even powders) at a high strain rate under the unconfined condition.By contrast,concrete is fractured by a number of cracks under the confined condition due to high strain rate impact loads.

5.Discussion

Fig.13.Dynamic response of concrete under confined and unconfined conditions.

The relationship between the strain rate and dynamic mechanic performance of concrete under impact loads is illustrated in Fig.13.The strain rate of impact loads of concrete can strongly affect its dynamic peak axial stress and peak axial strain.Based on the experimental results,Fig.13a shows the semi-empirical formulas established between the dynamic peak (axial) stress and strain rate under unconfined and confined conditions.It can be seen that the fitting curve presents a higher slope in a confined state than that under unconfined conditions.It proves that dynamic peak stress in the confined state is greatly sensitive to both strain rate and confining pressure conditions.Peak strain is a key parameter to describe the deformability of concrete materials.Fig.13b presents the empirical formula between the peak strain and strain rate of concrete.The dynamic peak strain increases with increasing strain rate both under unconfined and confined conditions.A similar observation is also obtained by Malvern et al.[71]and Carrasquillo et al.[72].Compared with the peak strain(between 3000 and 3500 με)for a similar strength concretes under quasi-static compression,the dynamic peak axial strain increases by about 50%–60% under dynamic loads.Certainly,the dynamic peak strain of concrete under dynamic compression is easily affected by many factors such as surface flatness,cement type,aggregate features,the precision of equipment.

The DIF is the ratio of dynamic compression peak stress to quasi-static uniaxial compression peak stress in an unconfined state,which is one of the key parameters in the dynamic mechanic research of concrete.Referring to the definition of DIF,DIFc is defined as the ratio of dynamic compression peak axial stress to quasi-static compression strength under confined conditions.However,the static compressive strength of the specimen under the confined condition in this study is absent due to the high confining pressure requirements of experiments.Therefore,the compression strength of concrete under the confined condition is calculated by an empirical formula[73],in which the static triaxial compression strength of concrete can be predicted by the uniaxial compression strength [74,75].

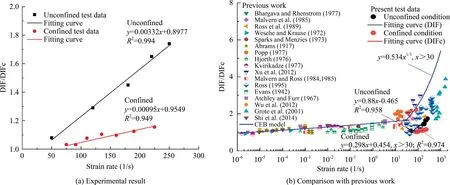

Fig.14 shows the linear fitting curves of DIF and DIFc against strain rate.It is found that DIF and DIFc are both sensitive to strain rate;the value of DIF is larger than that of DIFc at a similar strain rate(>30 s-1).The fitting expression also reveals that DIF increases faster than DIFc with increasing strain rate.This means that the dynamic compressive strength of concrete in the unconfined state presents more sensitive strain rate effects than that under the confined condition.As mentioned previously,the number of microcracks (tensile cracks) depends on the strain rate condition,and the dynamic stress waves generate fractures inside as well as induce the volumetric expansion of brittle materials[76].The tensile microcrack initiation and volumetric expansion of concrete easily develop to completion in an unconfined state under dynamic loads,which presents a stronger strain rate effect.However,the application of confining pressure can restrain the activation,propagation,and volumetric expansion of tensile microcracks.Therefore,compared to concrete under an unconfined condition,it presents a weak sensitivity to strain rate under the confined condition at a similar strain rate.

In engineering practice,the deformation modulus is a valid index to evaluate the deformation performance of concrete.The mean dynamic deformation modulus (the first point is zero and the second point is the peak value) of stress–strain curves under confined and unconfined conditions are summarized in Table 1.Three dynamic compression experiments are repeated under the unconfined condition and two calibration tests are conducted under confined conditions (limit to the metal sleeve).The testing results show that the dynamic deformation modulus of concrete seems to increase with increasing strain rate under unconfined conditions,while it decreases with increasing strain rate in the confined state.The strain rate effect of the deformation modulus is not a common conclusion,with some works showing the relation to be a positive or negative correlation,and other works showing that the deformation modulus is a constant parameter of the material [77,78].The dissipation of energy of concrete is realized by the deformation under unconfined conditions,while it needs to overcome the confining pressure limit for energy consumption when undergoing deformation dissipation under the confined condition.Therefore,the existence of confining pressure enhances the deformability of concrete and reduces the deformation modulus.

Table 1Deformation modulus of concrete under dynamic loads.

The dynamic multiaxial loading response of concrete is a noteworthy topic,which has an important consequence for concrete protection engineering structures.The dynamic behaviors of concrete have presented at a high strain rate under conventional triaxial (σ1>σ2=σ3) compression conditions.It should be noted that this laboratory study does not fully consider the diversity requirement of engineering practices.Due to the limitation of this experimental method,the dynamic lateral response stress of concrete specimens depends on the impact velocity of the striker.Therefore,it hard to realize the dynamic loading experiments with different impact strain rates but with the same confining stress.As a result,more novel approaches are needed to develop to explore the dynamic mechanical properties of concrete material under complex initial static stress conditions (e.g.σ1>σ2>σ3as well as σ1=σ2>σ3).Many factors,such as axial pre-stress,constant confining,hydrostatic pressure,cyclic loading history,and true triaxial pre-stress confining,should be considered for the experimental study of concrete under impact loads.Furthermore,the dynamic mechanical mechanism of confining pressure of concrete-like materials such as rock,ceramic,and hybrid composite materials,also needs to be studied under high strain rate conditions.

Fig.14.Relationship between DIF/DIFc and strain rate of concrete.

6.Conclusions

Dynamic compressive experiments of concrete are conducted using a modified 50-mm-diameter SHPB system,in which the strain rate ranges from 50 to 250 s-1under confined and unconfined conditions.Based on the dynamic experimental results,the dynamic stress evolution,dynamic peak axial stress,strain rate effects,peak axial strain,DIF,DIFc,failure patterns,and mechanism of confining pressure effects of concrete are investigated.The main conclusions can be drawn as follows.

(1) The dynamic peak stress and peak strain of concrete increase with increasing strain rate under unconfined dynamic loads.The dynamic peak stress increases from 41 to 65 MPa,the peak strain increases from 0.00159 to 0.00265,and the corresponding DIF increases from 1.08 to 1.84 when the strain rate increases from 50 to 250 s-1.Furthermore,the dynamic stress–strain curves show strain-softening behaviors as the dynamic strain exceeds its peak value.

(2) Dynamic peak axial stress,dynamic peak lateral stress,and peak strain of concrete show strong sensitivity to strain rate.There exists a significant positive correlation of these dynamic mechanical properties with loading rate under confined conditions.The dynamic peak axial stress of concrete increases from 193 to 319 MPa,the peak axial strain increases from 0.0075 to 0.0257 and the corresponding DIFc increases from 1.03 to 1.15 as the strain rate increases from 75 to 225 s-1.

(3) The failure patterns of concrete under impact loads show strong relation with the strain rate and confining pressure condition.Fractures on the loading end and shear failure pattern of the specimen are found under the confined condition,while it was broken into irregular small pieces in the unconfined state under impact loads condition with a high strain rate.

(4) Concrete has stronger strain rate effects under an unconfined condition than that under a confined condition.This can contribute to the action of confining pressure,which is easier to generate more cracks without confining pressure rather than that with confinement under a similar strain rate condition.

(5) The empirical formulas between dynamic peak axial(lateral)stress and strain rate (ranging from 50 to 250 s-1) of concrete are established based on the dynamic experimental results as the confining effects are considered.The formulas confirm that the DIF is more sensitive to the strain rate than the DIFc because the crack activation of concrete is suppressed by confinement.

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Nos.52027814 and 51839009).

杂志排行

矿业科学技术学报的其它文章

- Super-absorbent swellable polymer as grouting material for treatment of karst water inrush

- Spatio-temporal variation and propagation direction of coal fire in Jharia Coalfield,India by satellite-based multi-temporal night-time land surface temperature imaging

- Location estimation of autonomous driving robot and 3D tunnel mapping in underground mines using pattern matched LiDAR sequential images

- Implications for rock instability precursors and principal stress direction from rock acoustic experiments

- Proposing a novel comprehensive evaluation model for the coal burst liability in underground coal mines considering uncertainty factors

- Machine learning-based constitutive models for cement-grouted coal specimens under shearing