Changes in the thermodynamic properties of alkaline granite after cyclic quenching following high temperature action

2021-10-26JinjunHuHepingXieQingSunCunboLiGuikngLiu

Jinjun Hu,Heping Xie,Qing Sun,Cunbo Li,Guikng Liu

a College of Water Resource and Hydropower,Sichuan University,Chengdu 610065,China

b Guangdong Provincial Key Laboratory of Deep Earth Sciences and Geothermal Energy Exploitation and Utilization,Institute of Deep Earth Sciences and Green Energy,College of Civil and Transportation Engineering,Shenzhen University,Shenzhen 518060,China

c Shenzhen Key Laboratory of Deep Underground Engineering Sciences and Green Energy,Shenzhen University,Shenzhen 518060,China

d Geological Research Institute for Coal Green Mining,Xi’an University of Science and Technology,Xi’an 710054,China

Keywords:Alkaline granite Quenching cycle Thermal conductivity P-wave velocity High-temperature Deep rock

ABSTRACT During the development of hot dry rock,the research on thermal fatigue damage caused by thermal shock of cold and heat cycles is the basis that ensures the long-term utilization of geothermal resources,but there are not enough relevant studies at present.Based on this,the thermal damage tests of granite at different temperatures (250,350,450 °C) and quenching cycles (1,5,10,15 cycles) were carried out.Preliminary reveals the damage mechanism and heat transfer law of the quenching cycle effect on hot dry rock.The results show that with the increase of temperature and cycles,the uneven thermal expansion of minerals and the thermal shock caused by quenching promote the crack development of granite,resulting in the decrease of P-wave velocity,thermal conductivity and uniaxial compressive strength of granite.Meanwhile,the COMSOL was used to simulate the heat transfer of hot dry rock under different heat treatment conditions.It concluded that the increase in the number of quenching cycles reduced the heat transfer capacity of the granite,especially more than 10 quenching cycles,which also reflects that the thermal fatigue damage leads to a longer time for the temperature recovery of the hot dry rock mass.In addition,the three-dimensional nonlinear fitting relationship among thermal conductivity,temperature and cycle number was established for the first time,which can better reveal the change rule of thermal conductivity after quenching thermal fatigue effect of hot dry rock.The research results provide theoretical support for hot dry rock reservoir reconstruction and production efficiency evaluation.

1.Introduction

With the development of underground space and the exploitation of deep energy,the study of physical and mechanical properties of rock has never been interrupted [1–4].The thermophysical properties of rock under high temperatures have become an important research topic for various technological applications in rock engineering,such as protection and restoration of important buildings after the fire,nuclear waste burial,and geothermic exploitations [5–12].Granite,an important building material,has been widely studied by many scholars [13–20].For example,Cho et al.measured the thermal conductivity of granite under different water and porosity conditions[21].Ozebo et al.discussed the thermal conductivity of granite based on its availability and usage in building and construction [22].Du et al.tested 25 granite specimens before and after exposure to different high temperatures and observed that the wave velocities of granite were reduced by varying degrees [23].Gautam et al.found that the Jalore granite damage factor calculated from the mass loss rate,P-wave velocity loss rate and thermal conductivity loss rate has a similar exponential growth trend with increasing temperature [24].Zhang et al.used acoustic emission-integrated devices to study the evolution of P-wave velocity and acoustic emission of granite under uniaxial compression[25].It is clear that the influence of high temperature on the physical and mechanical properties of granite is very significant.In addition,the failure mode of granite will change at different temperatures.For example,Jalore granite after heat treatment at 300–600 °C showed a transition from brittle to ductile failure[26].Many similar experiments have examined thermal damages to granite,which provides an important theoretical support for the safety development of deep engineering.

As a clean and sustainable geothermal energy,hot dry rock(HDR) is considered to be one of the alternatives to traditional fossil energy [27–30].In the process of HDR development,cold water is injected into the water injection well,and then hot water and steam are extracted from the water outlet well for energy supply after the cold water is fully contacted with the HDR[29,30].The temperature of HDR is 150–300°C,or even higher.And the thermal damage caused by the process of HDR contact with cold water is very different from the previous research.There are two main characteristics of thermal damage of HDR:(1) quenching effect of high temperature rock mass in cold water (also known as thermal shock);(2) quenching process repeated,which produces thermal fatigue effect on hot dry rock.Some scholars have carried out a series of studies on thermal shock damage of hot dry rock.Fan et al.found that the thermal shock damage caused by rapid cooling of high temperature granite in water is greater than that caused by slow cooling [31].Yu et al.used DIC and acoustic emission techniques to explore the damage evolution of granite during loading after cyclic thermal shock [32].In addition,there are many researches on the physical and mechanical properties of granite after thermal shock damage,mainly focusing on wave velocity,porosity,elastic modulus,Poisson’s ratio,tensile strength and compressive strength [33–39].The above research results are of great help to understand the physical and mechanical properties of hot dry rock after thermal shock.However,there are few studies on thermal shock damage and heat transfer law of alkaline granite after cyclic quenching following high temperature.In particular,the change laws of granite thermal parameters,temperature and cycles need to be further studied.It is of great significance to explore the heat transfer law of HDR after multiple quenching fatigue damage for evaluating the development efficiency and value of geothermal energy.

In this paper,the influence of the numbers of quenching cycle on the surface cracks,P-wave velocity,thermal conductivity,and uniaxial compression of alkaline granite after different temperature treatment has been investigated.The damage mechanism of granite under the dual effects of quenching and thermal fatigue is analyzed.Meanwhile,combined with the experimental data,the influence of the number of cycles on the heat transfer of granite at different temperatures was explored by numerical simulation.The relationship among temperature,number of cycles and thermal conductivity is established for the first time,and law of heat transmission after quenching cycle effect of HDR is revealed.This study provides a theoretical support for efficient exploitation and utilization of HDR.

2.Materials and methods

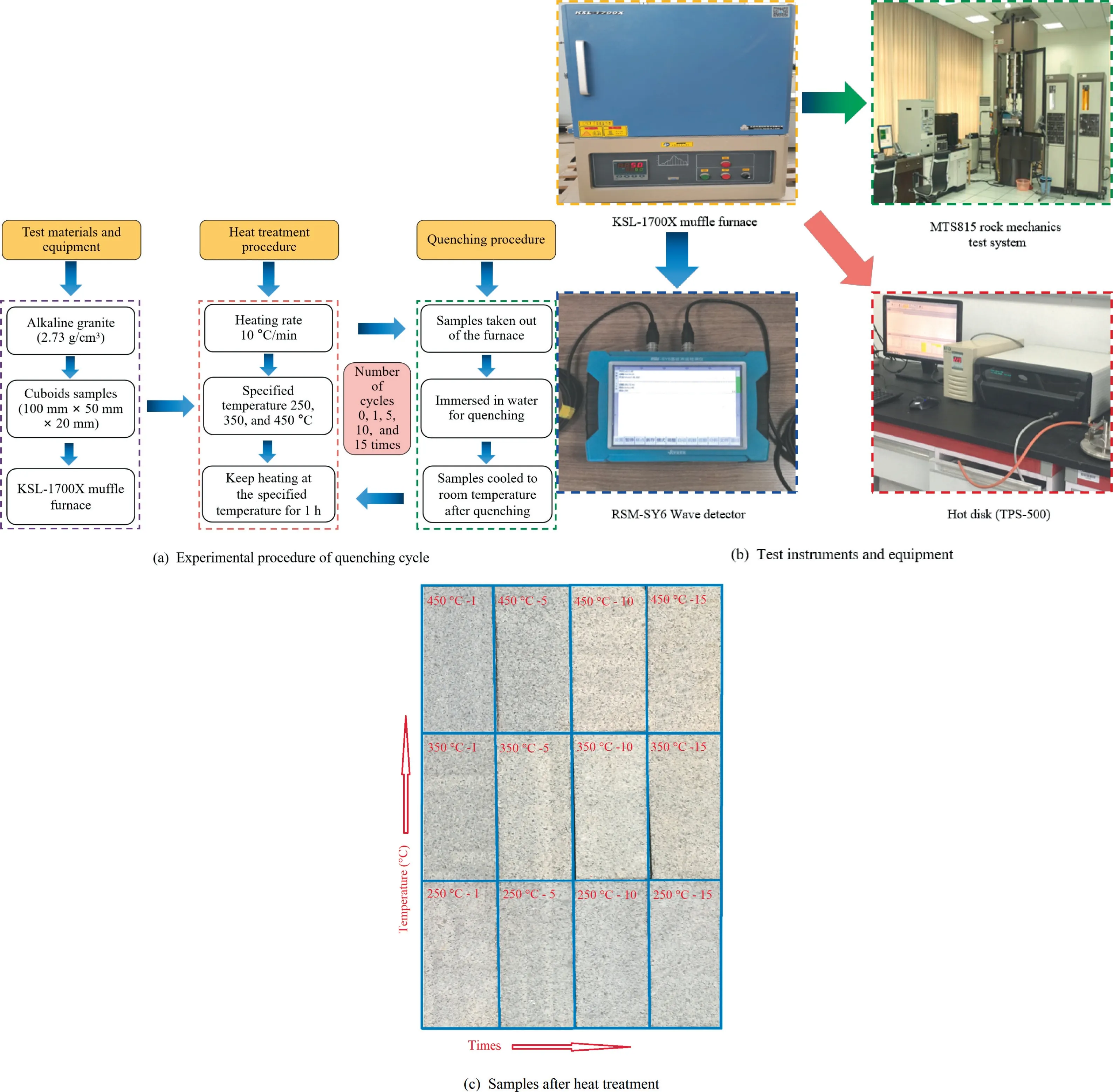

The alkaline granite samples were collected from surface outcrops in Xinjiang,China,with an average bulk density of 2.73 g/cm3.The main minerals and contents of the granite samples were measured by XRD (Table 1). Cuboids samples(100 mm× 50 mm× 20 mm) were made and were heated to 250,350,and 450 °C,respectively.The experimental procedure of samples heating and quenching cycle is shown in Fig.1a.The samples were heated to a specific temperature using the KSL-1700X muffle furnace at 10 °C/min.The constant temperature accuracy of the muffle furnace is ± 1 °C.Next,the samples were maintained at the designated temperature for about 1 h.The samples were then removed from the furnace,immersed in water,and allowed to cool to room temperature,after which they were returned to the furnace to rise to the next specified temperature.In order to compare the effects of unquenched and different quenching cycles on granite,the samples were quenched 0,1,5,10,and 15 cycles at each temperature.

Table 1Main mineral composition and content of alkaline granite.

The heat treatment instrument and physical and mechanical parameters test equipment are shown in Fig.1b.The thermal conductivities of the samples at high temperatures were tested using hot disk (TPS-500).The range of thermal conductivity measured of the hot disk(TPS-500)is 0.03–100 W/mK,and the test accuracy is within 0.2%.The longitudinal wave velocity of the samples is measured by the RSM-SY6 wave detector,and the sound amplitude accuracy and sound time accuracy of the instrument are within 3%and 0.5%,respectively.The sampling interval is between 0.1 and 200 μs.In order to reduce the test error,applying a proper amount of petroleum jelly between the probe and the sample is to make full contact.MTS815 rock mechanics test system is used in uniaxial compression test,and the loading rate is 0.04 mm/min.Samples after the high-temperature treatments are shown in Fig.1c.The mineral composition of rock samples will change to a certain extent after temperature [12,24,26].The mineral composition of alkaline granite under different temperatures is shown in Fig.2.

3.Results

3.1.Changes in surface cracks and the P-wave velocity

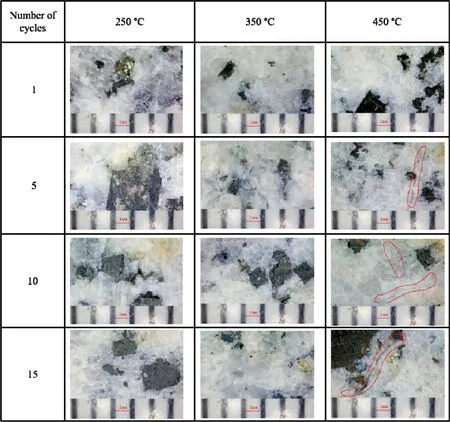

The surface of alkaline granite was observed by B700 typeSuper-Eyeequipment,which can magnify the surface of the samples up to 500 times.In order to observe the development of cracks on the sample surface after different heat treatments more accurately,50 test points are evenly divided on the surface of each sample,as shown in Fig.3.By comparing the images of multiple test points,the typical images of each sample are screened out,as shown in Fig.4.When the heat treatment temperatures were 250 and 350 °C,there were no obvious cracks on the surface of the sample with the increase in the number of cycles.However,when the temperature reached 450 °C,obvious cracks were observed on the surface of the sample.Moreover,the crack width increased with an increase in the number of cycles.Thus,the number of cycles and temperature have a significant influence on the surface cracks of alkaline granite.

Fig.4. Super-Eye images of specimens with different temperatures and the number of cycles.

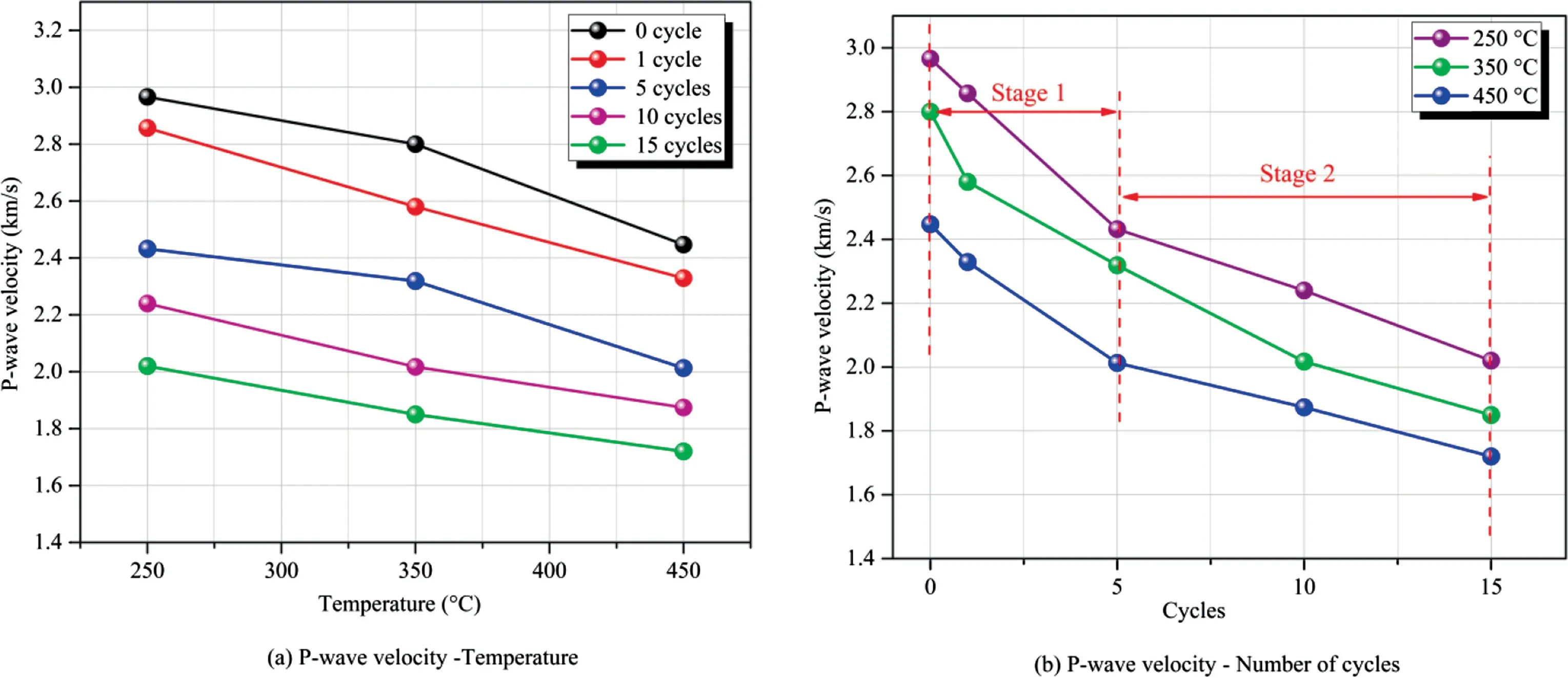

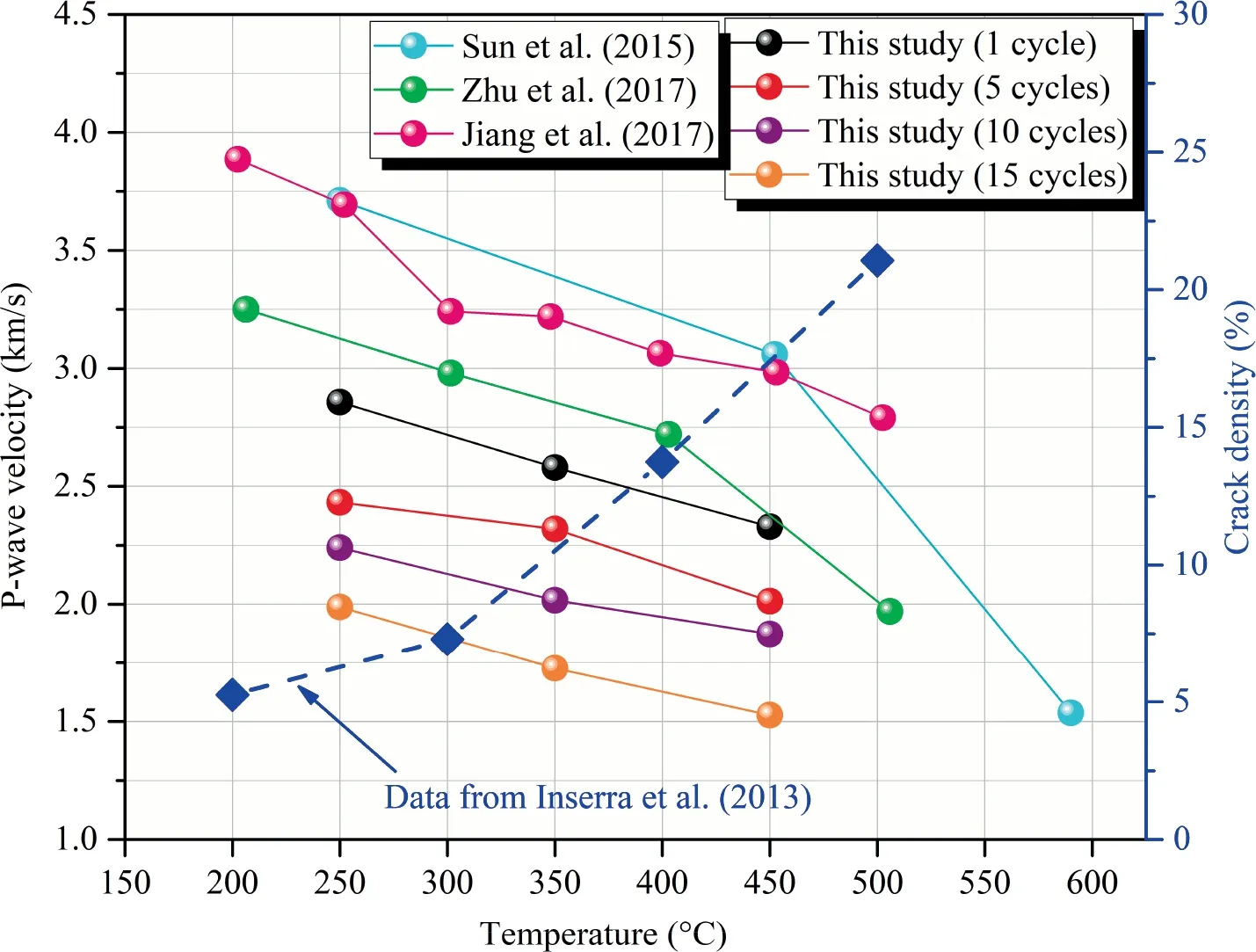

The longitudinal wave velocity of alkaline granite at room temperature is 3.114 km/s.Fig.5 shows the variation characteristics of P-wave velocity of granite after quenching and thermal fatigue treatment.Under different quenching cycles,the P-wave velocity of granite has similar temperature effect,which decreases with the increase of temperature,as shown in Fig.5a.When the temperature rises from 250 to 450°C,the P-wave velocity change rates at Nos.0,1,5,10 and 15 of cycles are 17.5%,18.48%,17.22%,16.33%and 14.85%,respectively.In addition,at a particular quenching temperature,the P-wave velocity of alkaline granite decreased with the increase in the cycles.It should be noted that zero cycle represents only heat treatment without quenching in water.When the cycle numbers ranged from 0 to 15,the P-wave velocity of granite decreased from 2.966 to 2.02 km/s at 250 °C;the change rate of P-wave velocity was about 31.9%.The P-wave velocity decreased from 2.8 to 1.85 km/s under 350 °C when the number of cycles ranged from 0 to 15;the change rate of P-wave velocity was about 33.93%.The P-wave velocity decreased from 2.447 to1.72 km/s under 450 °C when the number of cycles ranged from 0 to 15;and the change rate of P-wave velocity was about 30.93%.When the number of cycles reaches 15 cycles,the P-wave velocity of granite decreases by more than 30%at the three heat treatment temperatures.It can be inferred that the higher the number of cycles was,the smaller the P-wave velocity would be.Moreover,the influence of the number of cycles on P-wave velocity could be divided into two stages,as shown in Fig.5b.The 0–5 cycles were the first stage,in which the wave velocity of granite dropped rapidly with the increase in cycles.And the P-wave velocity changes at 250,350 and 450°C are 18%,17.17%and 17.74%,respectively.The 5–15 cycles were the second stage.Compared with the first stage,the P-wave velocity decreased slowly with the increase of cycles.And the P-wave velocity changed at 250,350 and 450°C are 16.4%,16.17% and 14.55%,respectively.We could observe that the change of P-wave velocity was more obvious when the granite was quenched 5 cycles.

Fig.1.Experimental procedures,equipment and alkaline granite samples.

Fig.2.Variation of mineral composition of alkaline granite with temperature.

Fig.3.Schematic diagram of test points division on the surface of sample after heat treatment.

Fig.5.Variations in the P-wave velocity of alkaline granite based on the temperature and number of quenching cycles.

3.2.Variations in the thermal conductivity

Fig.6.Variations in thermal conductivity of granite based on temperature and the number of quenching cycles.

The initial thermal conductivity of unheated alkaline granite is 2.523 W/(mK).The thermal conductivity,as influenced by the quenching cycle temperature treatment,is shown in Fig.6.When the number of cycles remained constant,the samples’thermal conductivity decreased gradually as the temperature increased.In the range from 250 to 450 °C,the thermal conductivity change rates for 1,5,10,and 15 cycles were 22.45%,28.95%,36.94%,and 40.43%,respectively.When the temperature was held to be constant,the samples’ thermal conductivity also decreased gradually as the number of cycles increased,as shown in Fig.6.When the number of cycles ranged from 1 to 15,the thermal conductivity of granite decreased from 2.352 to 1.484 W/(mK) under 250 °C;the change rate of thermal conductivity was about 36.9%.When the number of cycles ranged from 1 to 15,the thermal conductivity of granite decreased from 2.028 to 1.286 W/(mK)under 350°C;the change rate of thermal conductivity was about 36.58%.However,when the number of cycles ranged from 1 to 15,the thermal conductivity of granite decreased from 1.824 to 0.884 W/(mK) under 450 °C;the change rate of thermal conductivity was about 51.53%.In addition,the range of different cycles also affected the rate of decrease of thermal conductivity.It can be observed from Fig.6 that the decrease rate of thermal conductivity at 1–5 and 10–15 cycles was higher than that at 5–10 cycles.

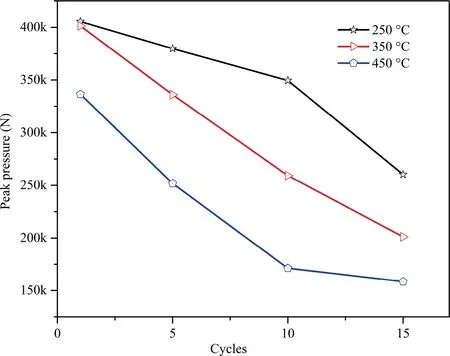

3.3.Variations in uniaxial compression

Fig.7.Uniaxial compression displacement curve of alkaline granite for 5 cycles.

Fig.8.Peak pressure curve at different number of quenching cycles.

The results of uniaxial compression tests of samples are shown in Figs.7 and 8.From Fig.7,it can be observed that with the increase of the loading displacement,the pressure increased until the granite failure pressure dropped rapidly.The degree of thermal damage of granite at different temperatures and cycles of quenching was different.Before being crushed,the heat-treated sample at a lower temperature required more pressure to achieve the same displacement,as shown in Fig.7a.In addition,the higher the number of cycles at that particular temperature,the greater the pressure needed to achieve the same loading displacement,as shown in Fig.7b.Fig.8 shows that the temperature and the quenching cycles have a significant impact on the size of the peak pressure during the failure of granite.When the temperature of the heat treatment was constant,the peak pressure decreased with the increase in the cycles,especially from 1 to 10 cycles.Moreover,the higher the heat treatment temperature was,the smaller the peak pressure was when the alkaline granite was destroyed.

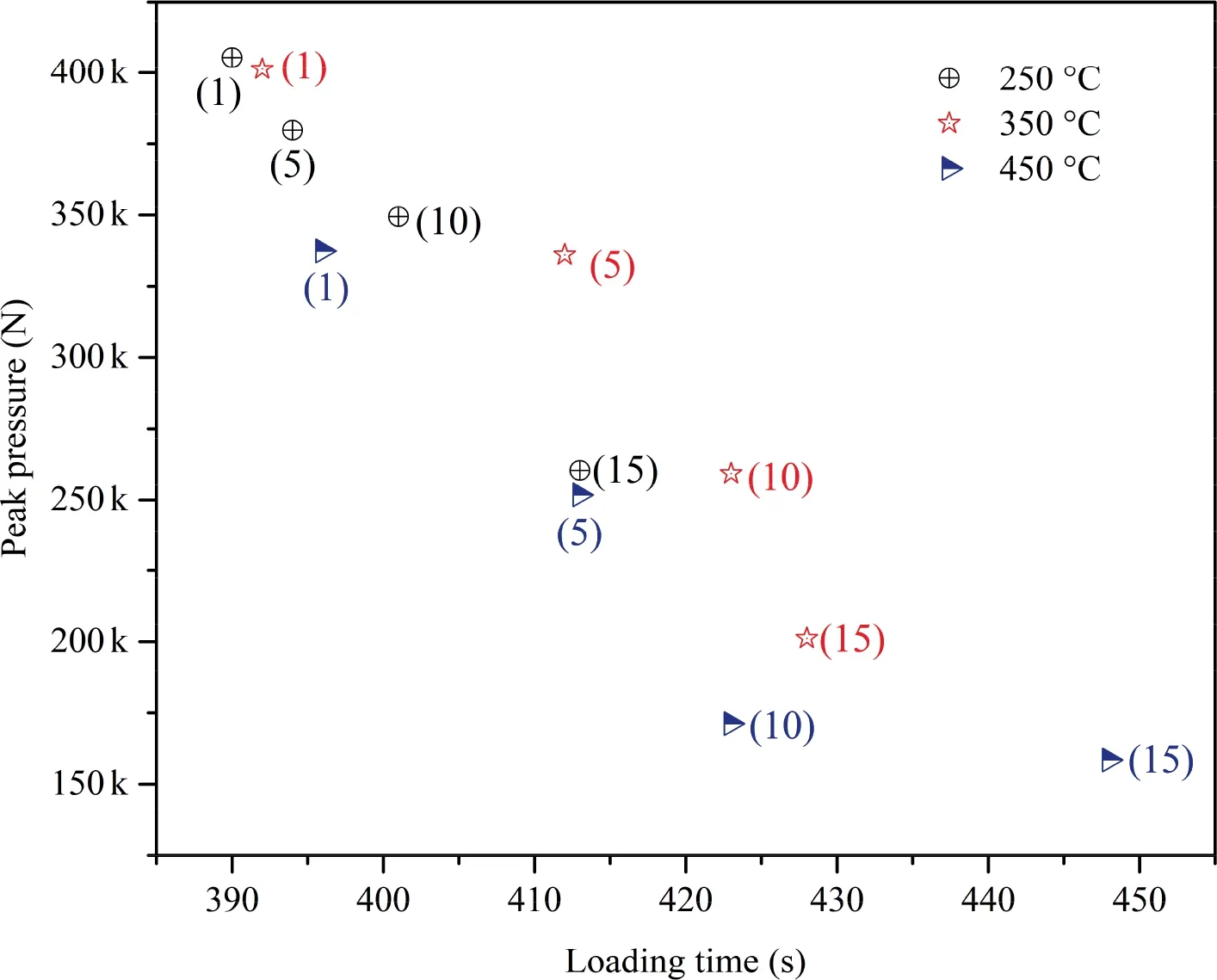

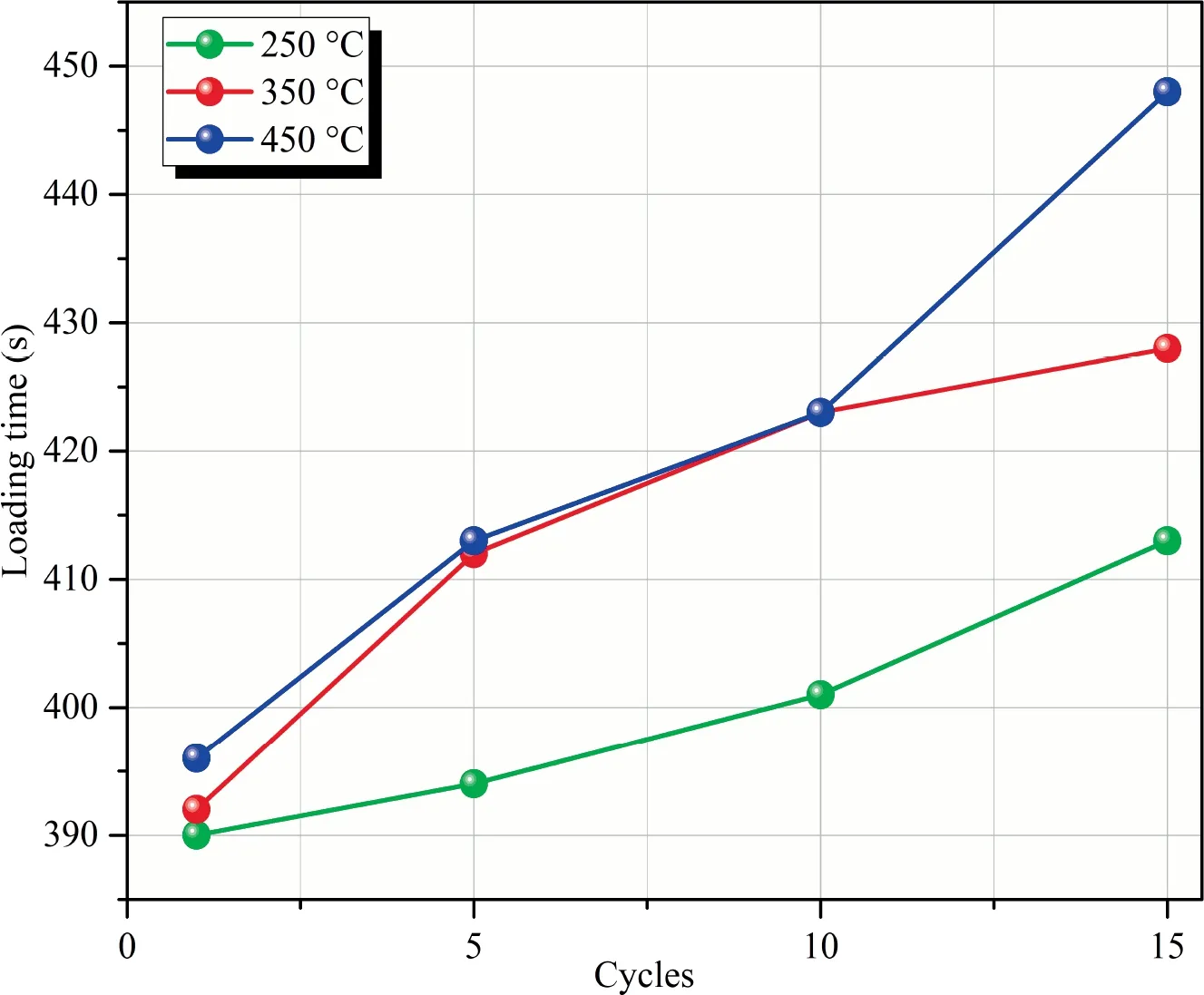

Figs.9 and 10 show the relationship between the peak stress and the required loading time of the samples after the quenching cycles.As can be observed from Figs.9 and 10,when the number of cycles was constant,the higher the temperature is,the longer the loading time of the peak stress is.In addition,when the temperature is constant,the more quenching cycles is,the longer the loading time of the peak stress is.Due to the increase of temperature and the number of quenching cycles,the toughness of alkaline granite and the time required for damage increased.It can be concluded that the change of temperature and the number of cycles will change the mechanical properties of alkaline granite.

3.4.Numerical simulation of the heat transfer in alkaline granite at different temperatures and number of quenching cycles

Fig.9.Relationship between peak stress and loading time.

Fig.10.Relationship between the loading time of peak stress and the numbers of quenching cycles.

After the heat treatment,the thermal conductivity of alkaline granite has an obvious change that significantly influences the heat-transfer of the rock mass.Along with the experimental data,we used COMSOL software to simulate the heat transfer of alkaline granite with heating time at different temperatures and the number of cycles.Setting the shape of the rock sample as a cylinder with a dimension of Φ50 mm× 100 mm,the initial internal temperature as 25 °C,the external ambient temperature as 250,350,and 450 °C,respectively,and the heating time as 1 h.The sample density and thermal parameters were set as to be obtained in the experiment as the initial material conditions for the numerical simulation.

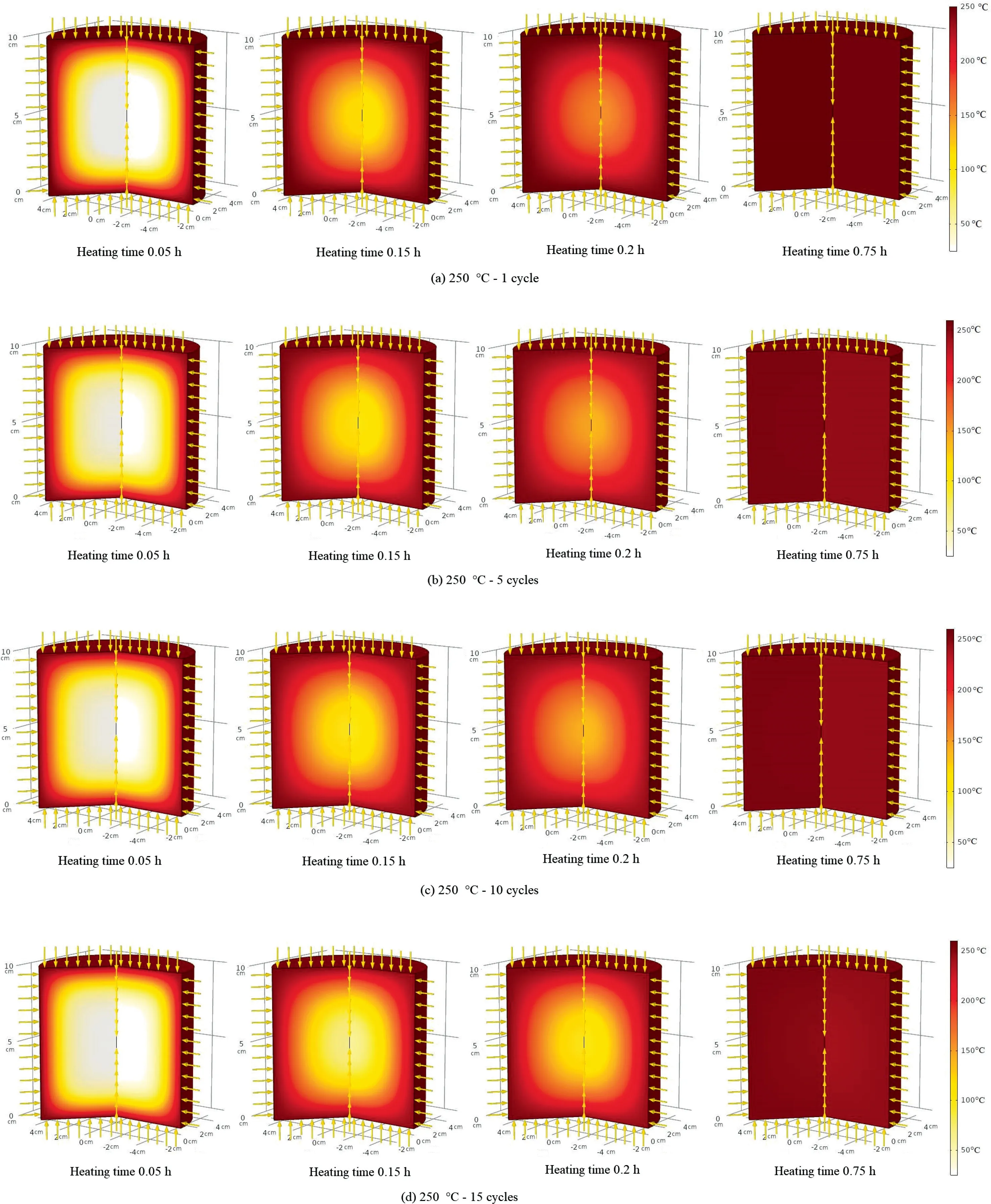

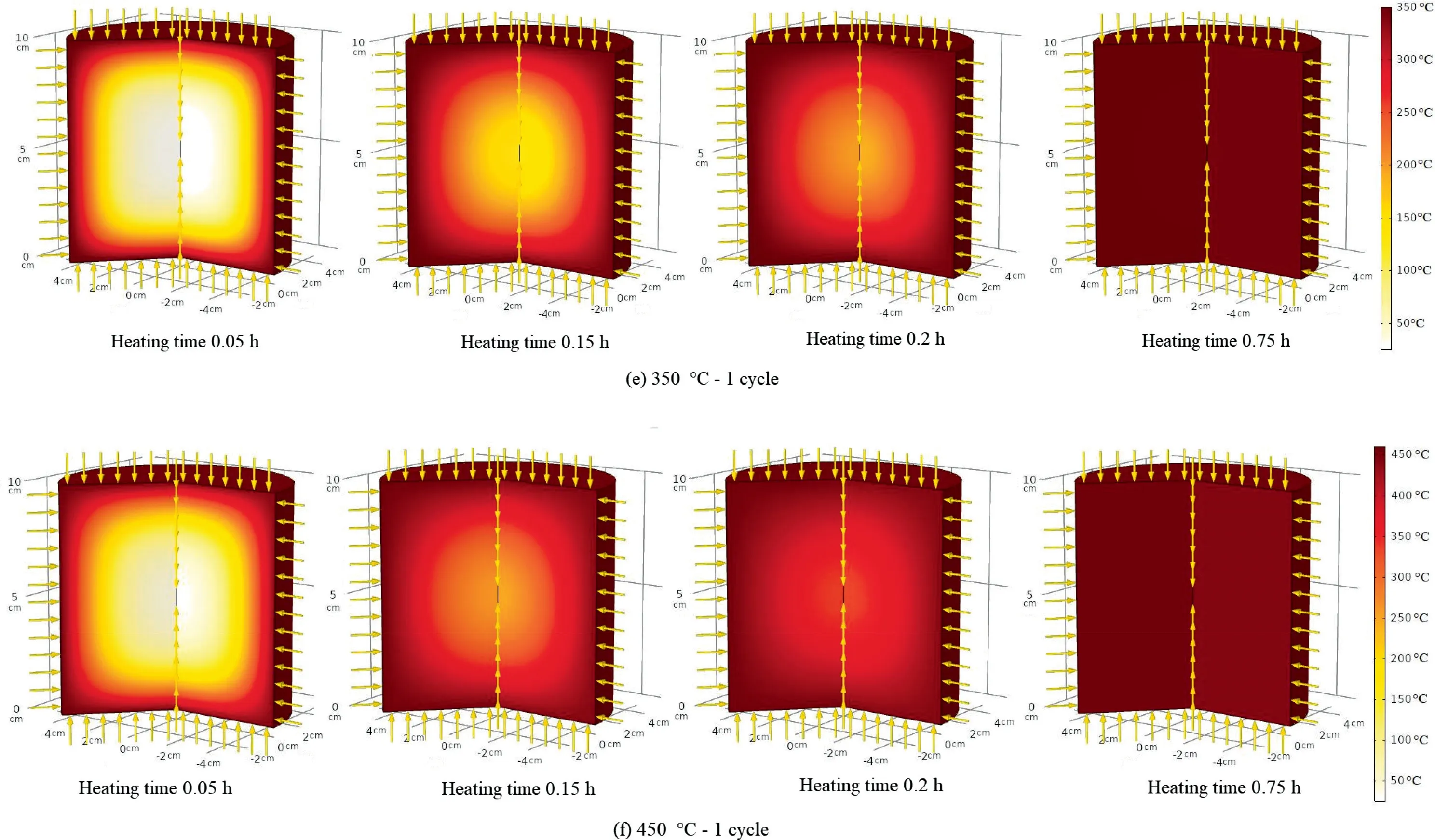

Fig.11 shows the change of heat transfer with time under different heat treatment conditions.At the same temperature and cycles,the temperature inside the material increased with time (Fig.11a).For example,when the sample was heated for 0.05,0.15,0.2,and 0.75 h at 250 °C and cycled once,the temperatures on the sample axis were 28.94,121.18,163.92,and 250.00 °C,respectively.Comparing Fig.11a,11b,11c,and 11d,when the treatment temperature and time are constant,the internal temperature of samples with different cycles had significant differences.For example,at 250 °C and 0.15 h,the temperature of the inner axis of the sample was 121.18,101.69,97.44,and 63.10 °C,respectively,when the cycle numbers were 1,5,10,and 15.There were similar changes at 350 and 450 °C.In addition,comparing Fig.11a,11e,and 11f,it can be observed that the temperature also had an influence on the heat transfer of alkaline granite.For example,when the alkaline granite was heated for 0.15 h and cycled once,the temperatures of the internal axis of the material were 121.18,132.92,and 257.42 °C,respectively at the external ambient temperature of 250,350,and 450 °C.Therefore,the higher the external temperature,the faster the internal heat transfers.

Fig.11.Heat transfer characteristics of alkaline granite at different temperatures and numbers of cycles.

Fig.11 (continued)

4.Discussion

4.1.Influence of mineral expansion and crack on physical properties of granite

Mineral expansion is one of the main causes of cracks in granite[26],which affects the thermal conductivity and wave velocity.Quartz and feldspar are the main minerals of granite.Fig.12 shows the thermal dilatation of quartz and feldspar as temperature increases (dated from Winkler) [40].Thermal dilatation of quartz and feldspar increases with the increase in temperature,especially for quartz,as shown in Fig.12.At high temperatures,the differences in thermal expansion of the same mineral in different directions and the differences in thermal expansion of different minerals are the two main causes of granite damage.

Fig.12.Thermal expansion of quartz and feldspar as a function of temperature[40].

In addition,quenching effect can cause secondary temperature stress,as shown in Eq.(1) [41].where σijis secondary temperature stress;αijthe thermal expansion coefficients of rock inijarea;Eijthe elastic modulus of rock inijarea;vijthe Poisson’s ratio of the rock inijarea;εijthe strain of the rock inijarea;and ΔTijthe temperature gradient of rock inijarea and adjacent area.The temperature stress caused by the non-uniform expansion deformation between minerals will cause cracks in the sample.The secondary temperature stress caused by quenching effect further leads to the stress concentration at the crack tip,which is conducive to the expansion of pores and cracks and leads to more serious damage in the rock[41].However,in this experiment,the physical and mechanical properties of granite after multiple quenching are not linear,which shows that the thermal stress of each cycle is different.Therefore,the secondary stress caused by quenching effect may be related to the number of cyclesN,as shown Eq.(2),which needs to be further verified in future research.

Different temperatures and quenching cycles make great influence on the crack density and connectivity of granite.The decrease of P-wave velocity reflects the increase of crack density.Fig.13 shows the various characteristics of P-wave velocity and crack density of granite with temperature.Obviously,with the increase of temperature,the longitudinal wave velocity of different experiments shows a downward trend [42–44],and the crack density is increasing[45].Although the experiments differ,the P-wave velocity variation rules are similar.

In addition,the influence of the number of cycles on the P-wave velocity presents two stages of rapid decline and slow decline,which are controlled by the development of cracks in the quenching cycle.When the quenching cycle is 0–5 cycles,the crack propagates rapidly and the P-wave velocity decreases rapidly.However,when the quenching cycle is more than 5 cycles,a relatively stable structure is formed between the mineral grains,and the cracks increase slowly,resulting in a slow decline of the P-wave velocity[46].

Fig.13.Variations in the P-wave velocity and crack density of granite based on temperatures from different tests.

The variation of microstructure is the direct reason for the evolution of thermal conductivity [47].The different thermal expansion of mineral particles is amplified at high temperature and leads to thermal cracks(Fig.12).The increase of quenching cycles makes the crack density and connectivity further develop,which may enhance the thermal resistance between mineral particles and lead to the decrease of thermal conductivity.In fact,many scholars have conducted experiments to examine the changes in granite’s thermal conductivity due to temperature[48–50].We collected experimental data that applied temperatures between 200 and 550°C to compare the results of this study (Fig.14).Different experiments had similar rules,and the thermal conductivity decreased as the temperature increased.However,the value of the change in thermal conductivity was different.The reasons might be the different granite samples,experimental equipment,numbers of cycles,and temperature,as given in Table 2 [47–49].It can be inferred that influence of the quenching cycles on granite’s thermal conductivity is readily apparent.

4.2.Nonlinear relationship between the peak pressure and P-wave velocity

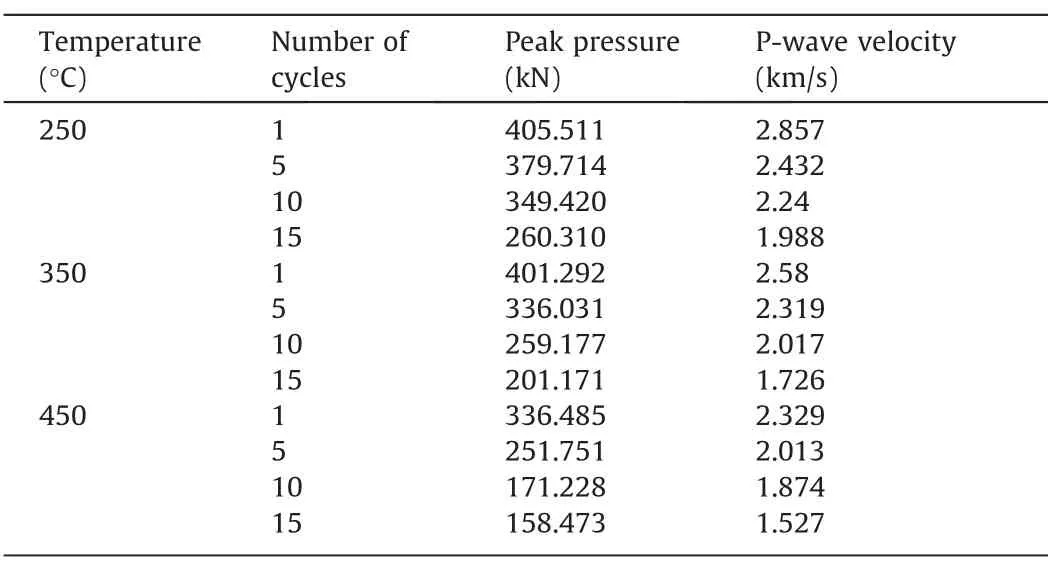

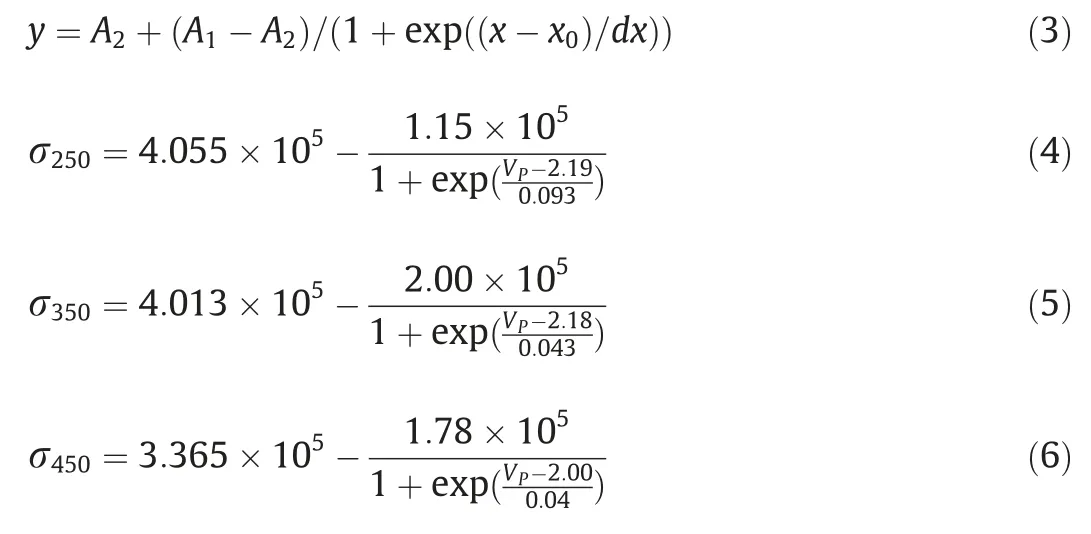

In general,the P-wave velocity will change after the thermal damage of the rock.In order to explore the relationship between P-wave velocity and uniaxial compression after quenching cycle heat treatment,the related data are shown in Table 3.The Boltzmann model(as shown in Eq.(3))is used to fit the P-wave velocity and peak pressure under different temperature conditions.The fitting function and correlation coefficient are shown in Eqs.(4)–(6):

Table 2Comparison of different heat treatment experiments of granite.

Table 3Average value of peak pressure and P-wave velocity of granite after quenching cycle heat treatment.

Fig.14.Variations in thermal conductivity of granite based on temperatures from different tests.

where σ250,σ350and σ450are the peak pressures at 250,350 and 450°C,respectively;andVPthe P-wave velocity,km/s.At 250,350 and 450 °C,the correlation coefficientsR2were 0.9628,0.9544 and 0.9973,respectively,suggesting that the dates fitted very well.The fitting curves are shown in Fig.15.It can be concluded that the peak pressure and the P-wave velocity have a similar change rule at 250–450 °C temperatures under the different numbers of cycles.Therefore,the wave velocity could be well used to evaluate the uniaxial compression of the granite after the quenching cycle.

4.3.Three dimensional nonlinear fitting of the P-wave velocity and the thermal conductivity with temperature and cycles

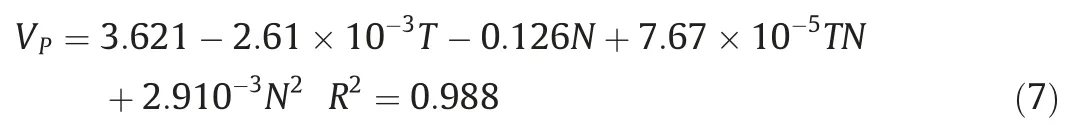

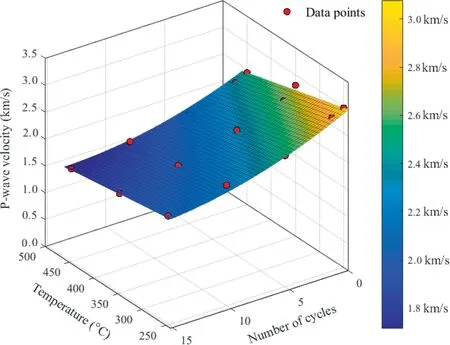

It can be seen from Sections 3.1 and 3.2 that temperature and the number of cycles had a great influence on the P-wave velocity and thermal conductivity.However,the relationship between the P-wave velocity (or thermal conductivity),temperature,and cycle numbers was not clear.Therefore,the relationship was established by a three-dimensional nonlinear fitting method,as shown in Eqs.(7) and (8).

whereVPis the P-wave velocity,km/s;Tthe temperature,T=250,350,450 °C;andNthe number of cycles,andN=1,5,10,and 15.R2is 0.988,which indicates that there is a strong correlation between the P-wave velocity,temperature,and numbers of cycle.It can also be observed from Fig.16 that more data points are distributed on the three-dimensional surface.Using the threedimensional nonlinear fitting relationship,we can use any two parameters to evaluate the change trend of the third parameter.

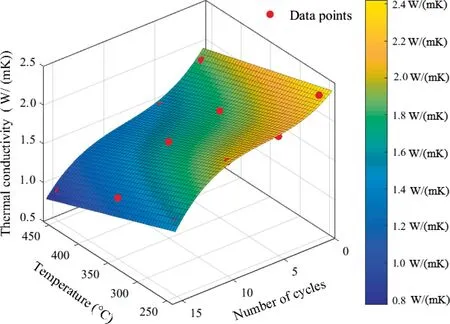

Similar to the P-wave velocity,thermal conductivity had a strong correlation with temperature and number of cycles,as shown in Eq.(8) and Fig.17.

whereKis the thermal conductivity,W/mK;Tthe temperature,T=250,350,450 °C;Nthe number of cycle,N=1,5,10 and 15;andR2is 0.982.It can be observed from Eq.(5) and Fig.17 that it is feasible to use polynomial to fit the relationship among thermal conductivity,temperature,and the number of cycles.The thermal conductivity of rock is an important physical parameter to explore deep engineering [28],such as the development of hot dry rock.In order to obtain heat energy of hot dry rock,cold water needs to be injected many cycles to exchange heat,which affects the thermal conductivity of the rock mass.This relationship can provide theoretical support for the development of hot dry rock to evaluate the change trend of thermal conductivity of rock through temperature and number of cycles.

Fig.15.Peak pressure vs.longitudinal wave velocity curve.

Fig.16.Three-dimensional nonlinear fitting relationship among the P-wave velocity,temperature,and numbers of cycle.

Fig.17.Three dimensional nonlinear fitting relationship among thermal conductivity,temperature,and the number of cycles.

5.Conclusions

In order to deeply understand the change of physical and mechanical properties and heat transfer performance of HDR after thermal damage during geothermal energy development,we examined the characteristics of the P-wave velocity,thermal conductivity,uniaxial compression,and in alkaline granite samples that were heat-treated and exposed to different numbers of cycles.The main conclusions are as follows:

(1) It is observed that the P-wave velocity of alkaline granite decreased with the increase of temperature and the number of quenching cycles,which is caused by the increasing crack density of alkaline granite due to quenching thermal fatigue.Moreover,after 5 quenching cycles,the crack growth rate gradually slowed down,resulting in a gradual slowdown in the P-wave velocity decline.

(2) The thermal conductivity decreased with an increase in the number of cycles and temperature.In the range from 250 to 450 °C,the thermal conductivity change rates for 1,5,10,and 15 cycles were 22.45%,28.95%,36.94%,and 40.43%,respectively.Furthermore,the effect of quenching cycles on thermal conductivity is not linear.The decrease of thermal conductivity at 0–5 cycles and 10–15 cycles is faster than that at 5–10 cycles.

(3) With the increase of temperature and the number of quenching cycles,the uneven expansion of minerals and the secondary stress caused by thermal shock effect aggravated the damage of granite,resulting in the gradual decrease of the peak pressure of granite.At the same time,the Boltzmann model was used to establish the nonlinear relationship between the peak pressure of rock failure and the P-wave velocity,and the correlation coefficient was as high as 0.9973,which also shows the feasibility of utilizing the wave velocity to evaluate the uniaxial strength of granite.

(4) Through numerical simulation,it is observed that the increase in the number of cycles results in the decrease of heat transfer energy of alkaline granite.It can be inferred that the crack connectivity in granite increases and the temperature recovery ability weakens after multiple quenching cycles.In addition,when the numbers of cycle and heat treatment time were fixed,the higher the external environment was,the faster the internal temperature rose.

(5) Under the dual effects of quenching and thermal fatigue,the heat conduction law of granite is affected by temperature and cycles.The thermal conductivity (or P-wave velocity)had a strong nonlinear relationship with temperature and number of cycles,and theR2was more than 0.98.The variation trend of thermal conductivity(or P-wave velocity)during the development of HDR can be evaluated by the threedimensional nonlinear relationship.

Acknowledgements

This research was supported by the Department of Science &Technology of Guangdong Province(No.2019ZT08G315),the open foundation of Key Laboratory of Deep Earth Science and Engineering (Sichuan University),Ministry of Education(No.DESE202102),National Natural Science Foundation of China (Nos.41972288,51804203,and 51827901),Applied Basic Research Programs of Sichuan Province (No.2021YJ0411) and Shenzhen City Clean Energy Research Institute.

杂志排行

矿业科学技术学报的其它文章

- Super-absorbent swellable polymer as grouting material for treatment of karst water inrush

- Spatio-temporal variation and propagation direction of coal fire in Jharia Coalfield,India by satellite-based multi-temporal night-time land surface temperature imaging

- Location estimation of autonomous driving robot and 3D tunnel mapping in underground mines using pattern matched LiDAR sequential images

- Implications for rock instability precursors and principal stress direction from rock acoustic experiments

- Proposing a novel comprehensive evaluation model for the coal burst liability in underground coal mines considering uncertainty factors

- Machine learning-based constitutive models for cement-grouted coal specimens under shearing