Performance analysis of a novel tobacco-curing system with a solar-assisted heat pump

2021-10-21WuJianwenHuaYongmingLiBinFuLiliYanYongliangDuanLunbo

Wu Jianwen Hua Yongming Li Bin Fu Lili Yan Yongliang Duan Lunbo

(1Key Laboratory of Energy Thermal Conversion and Control of Ministry of Education, Southeast University, Nanjing 210096, China)(2Zhengzhou Tobacco Research Institute of CNTC, Zhengzhou 450001, China)(3School of Water, Energy and Environment, Cranfield University, Cranfield, Bedfordshire MK43 0AL, UK)

Abstract:A novel tobacco-curing system with a solar-assisted heat pump was proposed. The proposed system has various advantages, such as reducing energy consumption and pollutant emissions and enhancing the stability of system operation. The thermal characteristics of the system under different climate conditions were analyzed, and the economic and environmental benefits of different tobacco-curing technologies were compared. Results indicated that the dehydration rate, the mass flux of exhaust air, and the heat load of the novel tobacco-curing system in different months had similar changes with the baking time, and all reached the maximum in the later stage of color fixing. Compared with the power saving rate of a heat pump tobacco-curing system, that of the novel system reached 25.9%-35.1%. The dry leaf curing cost of the novel system was only 0.86-1.06 yuan/kg, which can reduce the cost by more than 60% compared with traditional coal-burning tobacco-curing systems in China. Compared with other parts of the tobacco leaf, the top leaf had the lowest dry leaf curing cost due to its highest mass of dry leaf. The payback period and the annual CO2 emission reduction of the novel system were 3.0-3.7 a and 15 586 kg, respectively.

Key words:tobacco-curing; solar energy; heat pump; thermal storage; CO2 reduction

Tobacco is a special agricultural product, and China’s tobacco planting area and output rank first in the world[1-2]. Baking is an important part of the tobacco production process, involving complex heat and mass transfer, which is also a high energy consumption process[3]. China’s drying field emits 260 million tons of CO2and 7.8 million tons of SO2each year from coal burning, resulting in serious environmental pollution[4]. Given the rich coal resources in China, coal-burning tobacco-curing systems are widely used with low efficiency of heat utilization[5]. The annual increase in coal prices also leads to an increase in tobacco-curing costs.

The importance of tobacco-curing systems not only lies in its great influence on product quality but also on energy consumption and the environment[6]. Heat pump technology has been widely used in many fields due to its advantages of energy saving, high efficiency, reliable operation, and environment friendliness[7]. In recent years, the application of air source heat pumps for tobacco curing has developed rapidly[8-10]. Lü et al.[9]reported that heat pump tobacco-curing systems could save 0.85 yuan compared with coal-burning tobacco-curing systems when producing per kg dry leaf. However, the decrease in ambient temperature reduces the coefficient of performance (COP) of air source heat pumps[11]. In addition, heat pump tobacco-curing systems often need auxiliary electric heating to meet the high heat load of tobacco-curing, thus increasing the energy consumption of the system[12].

The utilization of solar energy provides a solution for energy conservation and CO2emission reduction in industrial and commercial thermal energy production[13]. At present, solar energy has a widespread application in the drying of agricultural and marine products, such as coffee, peas, tea, medicinal herbs, and fish[14-15]. However, open sun drying requires a long drying cycle, and the product is easily contaminated[16-17]. In addition, solar energy is highly dependent on climatic conditions and has large randomness and fluctuation[18-19].

Solar-assisted heat pump tobacco-curing systems can relieve the burden of independent heat supply by the heat pump and reduce energy consumption[20]. In addition, the flexibility and stability of the system can be enhanced. Peng et al.[21]found that solar-assisted heat pump tobacco-curing systems could save energy consumption by 24.3% compared with heat pump tobacco-curing systems. Xu et al.[22]also found that the cost of energy consumption of solar-assisted heat pump barns is the lowest compared with other tobacco-curing barns. Nevertheless, the solar baking mode of these systems cannot operate at night or in rainy weather. Moreover, the COP of the heat pump is still highly affected by environmental conditions.

Here, a novel tobacco-curing system with a solar-assisted heat pump was proposed and investigated. The system can switch to different operation modes according to environmental conditions. It is also equipped with a heat storage water tank for continuous operation in rainy weather or at night to achieve the maximum utilization of solar energy. The thermal characteristics and the economic and environmental benefits of the system were analyzed, thereby providing an important reference for engineering applications.

1 Methodology

1.1 Tobacco-curing process

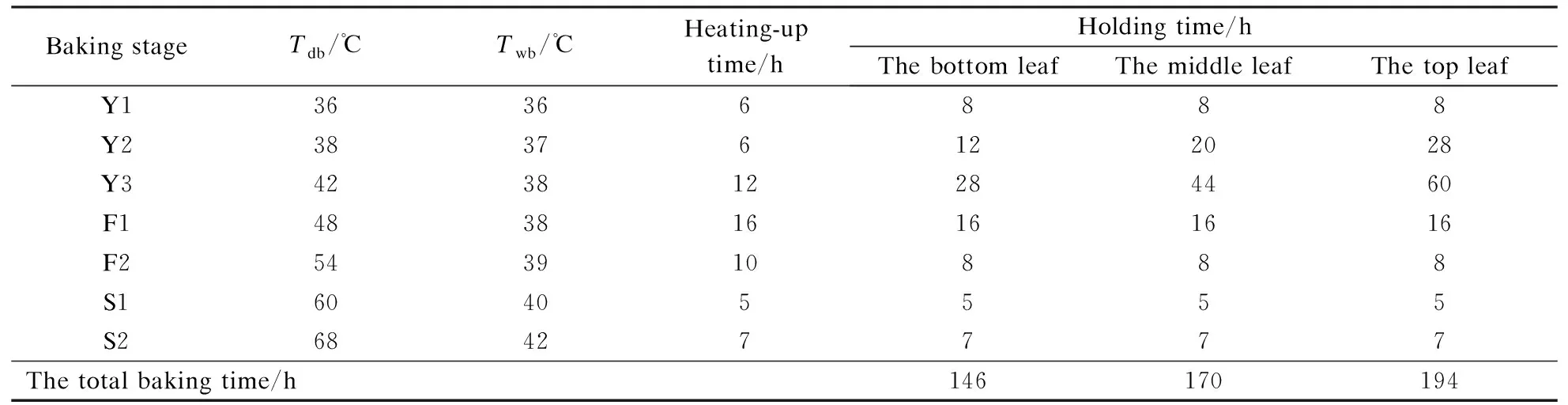

To ensure the quality of tobacco leaves, a three-stage tobacco-curing process with low temperature and slow yellowing as the core is generally adopted (i.e., yellowing stage, color fixing stage, and stem drying stage)[23]. This three-stage tobacco-curing process can be further subdivided into seven stages, namely, forced draught (Y1), the middle stage of yellowing (Y2), later stage of yellowing (Y3), early stage of color fixing (F1), later stage of color fixing (F2), early stage of stem drying (S1), and later stage of stem drying (S2), as shown in Tab.1. The total baking time is equal to the sum of the heating-up time and holding time.

The meteorological parameters of different tobacco-curing months in Kunming, Yunnan were selected as the basis for the system design calculation[24]. Yunyan 97 was chosen for calculation, and the mass of fresh leaf before baking is 3 000 kg. The initial water content of the top, middle, and bottom leaves are 82%, 84%, and 86%, respectively, and the final water content is 6.5%.

Tab.1 Operating conditions of tobacco baking

1.2 System description

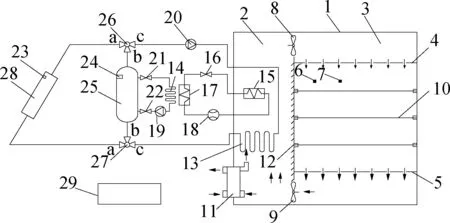

The novel tobacco-curing system is composed of a solar heating system, a heat pump system, a heat storage system, a defrosting system, and a control system, as shown in Fig.1. The system uses solar energy and a heat pump as dual heat sources. In addition, a heat storage water tank serves as an auxiliary heat source for solar heat collection to realize tobacco-curing under different climate conditions and to ensure the quality of the tobacco. To improve the efficiency of heat utilization, an energy recovery ventilator is installed at the exit of the barn to recover heat from the exhaust and reduce heat loss. The hot and humid air after the heat exchange is discharged to the evaporator, which also helps improve the COP of the heat pump.

1—Barn; 2—Heating chamber; 3—Baking chamber; 4, 5—Air distributor; 6, 7—Temperature and humidity sensor; 8, 9—Frequency conversion fan; 10—Grill; 11—Energy recovery ventilator; 12—Partition; 13—First heat exchanger; 14—Second heat exchanger; 15—Condenser; 16—Expansion valve; 17—Evaporator; 18—Inverter compressor; 19—First circulating pump; 20—Second circulating pump; 21—First electromagnetic valve; 22—Second electromagnetic valve; 23, 24—Temperature sensor; 25—Heat storage water tank; 26—First three-way valve; 27—Second three-way valve; 28—Solar collector; 29—ControllerFig.1 Schematic of the novel tobacco-curing system with a solar-assisted heat pump

The heat storage system has two functions. On the one hand, it can adjust solar heat input at different times to enhance the flexibility of system operation. On the other hand, the heat storage water tank can defrost the evaporator through the second heat exchanger under the condition of low ambient temperature. This setup broadens the operating conditions of the air source heat pump and maintains a high COP. The heat pump system uses R134a as the refrigerant due to its high critical temperature and low boiling point.

A schematic of the novel tobacco-curing system with a solar-assisted heat pump is shown in Fig.2. Sunlight and (or) electricity are the energy input of the system. The control system can switch between different operating modes according to the difference in solar radiation and water temperature.

Fig.2 Schematic of the novel tobacco-curing system with a solar-assisted heat pump

The system can realize three operating modes, namely, solar baking mode (SD), solar-assisted heat pump baking mode (SHPD), and heat pump baking mode (HPD), as shown in Tab.2. For nighttime and rainy days, solar radiation is small, and the novel tobacco-curing system operates at HPD. When the surface temperature of the evaporator is less than 5 ℃, the defrosting system is turned on. At this point, the first and second electromagnetic valves are opened. Driven by the first circulating pump, the hot water in the heat storage water tank flows into the second heat exchanger to realize the hot water-air heat exchange, thereby heating the cold air around the evaporator. The heated air then exchanges heat with the surface of the evaporator to defrost. The defrosting method is simple and does not affect the normal operation of the heat pump, thus ensuring the good quality of the tobacco.

Tab.2 Operation mode of the novel tobacco-curing system

1.3 Thermal calculation method

The operating parameters of the system were calculated in accordance with the energy balance and mass balance. Furthermore, to ensure the pressure balance of the system, the mass flux of exhaust air is equal to the mass flux of fresh air, and the exhaust air temperature is assumed to be equal to the baking temperature. The mass flux of exhaust air is expressed as

(1)

wherecis the dehydration rate, kg/h;d1andd2are the humidity ratio of preheated fresh air and exhaust air, respectively, kg/kg(a).

The required sensible heat during the curing process is given by[25]

Qe=mtct(Tf-Ti)

(2)

wheremtis the total mass of the tobacco leaf, kg;ctis the specific heat of the tobacco leaf, kJ/(kg·K);TiandTfare the initial and the final temperature of the tobacco leaf, respectively, ℃.

The required latent heat of vaporization during the curing process is given by[26]

Qa=mwγ

(3)

wheremwis the lost water mass, kg;γis the average required heat to vaporize per kg of water, 2 500 kJ/kg for the yellowing stage, 2 600 kJ/kg for the color fixing stage, and 2 800 kJ/kg for the stem drying stage[10].

Heat loss during the curing process is given by[27]

Ql=(Qe+Qa)s

(4)

wheresis the heat loss rate, %. To simplify the calculation,sis set as 10%[4].

The total required heat during the curing process is expressed as

Qt=Qe+Qa+Ql

(5)

The solar heat collection of the solar collector (The heat storage of the water tank is also part of the heat collection of the solar collector. To simplify the calculation, the heat storage is no longer considered separately.) is given by[4]

Qs=IsAcηwηc

(6)

whereAcis the solar collector area, taking 40 m2;ηcis the collector efficiency, taking 50%;ηwis the heating efficiency of hot water, taking 65%.

The heat provided by the heat pump is given by[28]

(7)

The minimum radiation required for independent solar baking is expressed as

(8)

whereQHEis the heat recovered by the energy recovery ventilator, kJ.

The minimum radiation required for the combined operation of the solar and heat pumps (i.e., the minimum irradiation required for the circulating water to achieve a certain temperature rise) is expressed as

(9)

1.4 Economic analysis of the system

The initial investment of the tobacco-curing system is expressed as

M=Me+Mi+Mb+Mp

(10)

whereMe,Mi,Mb, andMpare original equipment cost, equipment installation cost, building material cost, and power distribution and control cost, respectively, yuan.

The COP of the heat pump is expressed as

(11)

whereTkis the condensation temperature, K;T0is the evaporation temperature, K;ηe,ηcom,ηex, andηsysare the motor efficiency, compressor efficiency, heat exchanger efficiency, and system efficiency, respectively, %.

The power consumption of the novel tobacco-curing system is expressed as

(12)

wheretcis the running time of one baking cycle, s;PF,PP, andPHPare the power of the fan, water pump, and heat pump, respectively, kW.

The total curing cost of the tobacco-curing system is expressed as

R=Rc+Rp+Rl

(13)

whereRc,Rp, andRlare the cost of coal consumption, operating equipment, and labor, respectively, yuan.

The payback period of the tobacco-curing system compared with the coal-burning tobacco-curing system is given by[29]

(14)

1.5 Environmental benefit analysis

The CO2, SO2, and dust emission reduction of the tobacco-curing system compared with the coal-burning tobacco-curing system are defined by[29]

Ser=iSj

(15)

whereSjis the standard coal saving of the system, kg. For CO2, SO2, and dust,iis 2.493, 0.22, and 0.01, respectively.

2 Results and Discussion

2.1 Tobacco-curing characteristic analysis

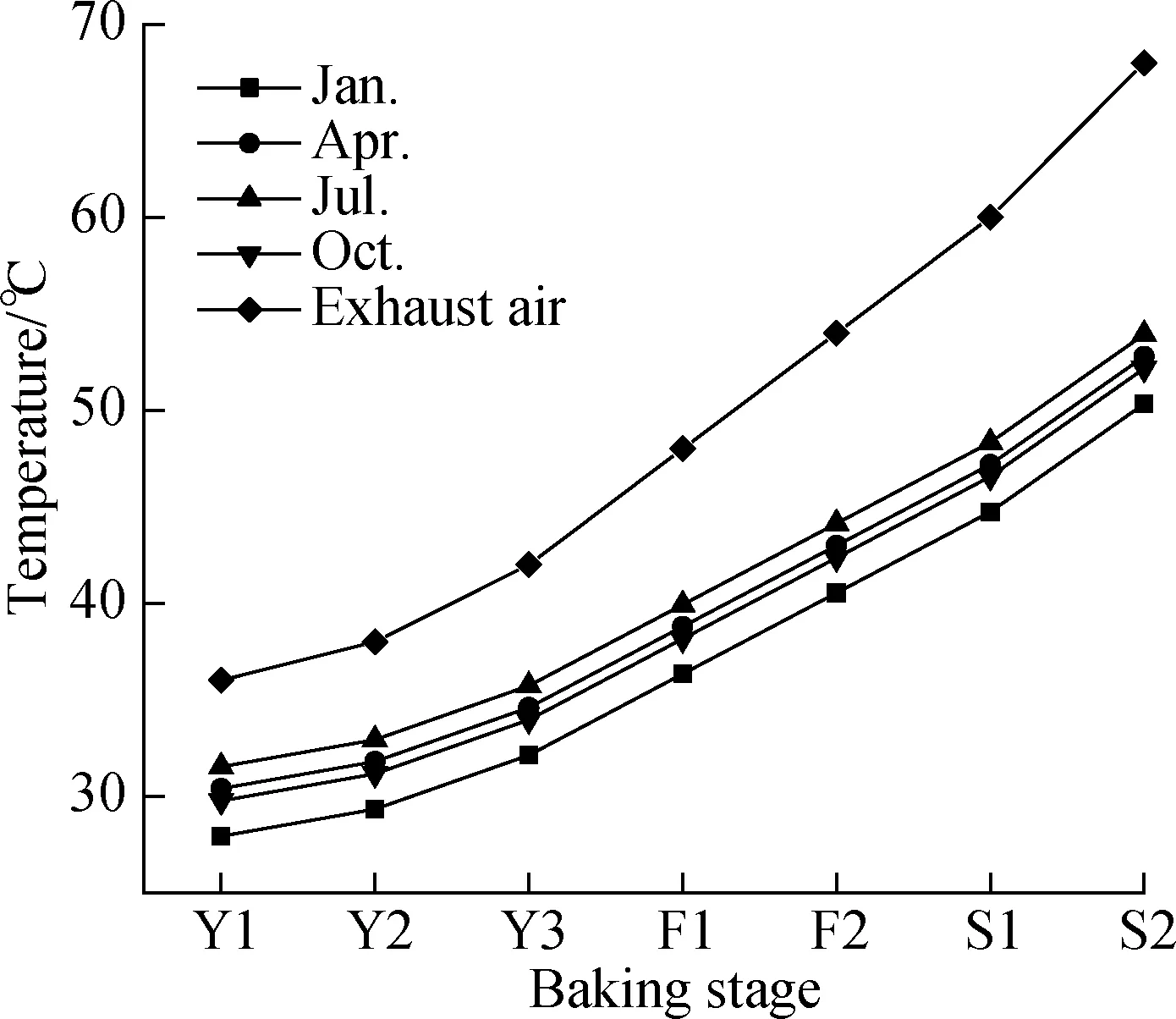

Fig.3 shows the temperature of preheated fresh air and exhaust air in the tobacco-curing barn in different baking stages. The fresh air and the exhaust air exchange heat through the energy recovery ventilator, thereby increasing the temperature of preheated fresh air. With the increase in exhaust air temperature, the temperature of preheated fresh air in different months all showed an upward trend.

Fig.3 Temperature of preheated fresh air in different months and the temperature of exhaust air

In addition, the temperature of preheated fresh air in each stage was the highest in July because the mean ambient temperature in July was the highest in Kunming, Yunnan; the heat recovery of the exhaust air and the temperature of preheated fresh air were also correspondingly higher. This result indicates that ambient temperature is the main factor that affects the temperature of preheated fresh air under the same heat recovery rate and exhaust air temperature.

Fig.4 shows the thermal characteristics in different baking stages, taking the curing process of the top leaf as an example. Data of each stage in the figure show averages. The dehydration rate, the mass flux of exhaust air, and the heat load have similar changes with the baking time. Similar results have been found by Lü et al.[10]and Yao[6]. These three parameters all reach their maximum values in F2 but decrease significantly in S1. The water evaporation rate of the tobacco leaf has a decisive effect on the changes of these three parameters. The water content of tobacco leaf in the early baking stage is high, and the water vapor pressure on the surface of the tobacco leaf is greater than that in the baking chamber; thus, the free water on the surface of the tobacco leaf evaporates quickly. With the increase in baking time, the water vapor pressure on the surface of the tobacco leaf decreases, the vaporized surface layer gradually moves inward, and the water transfer resistance increases, resulting in a significant reduction in dehydration rate in the stem drying stage[30]. In addition, the average mass flux of exhaust air in each baking stage in July is more than that in other months. The capacity of the system to dehumidify may

decline due to the hot and humid weather, thereby increasing the mass flux of the exhaust air of the system[31]. As shown in Fig.4(c), the heat loss rate under different environmental conditions is assumed to be 10%; thus, the heat load of the system in different months has minimal difference and mainly depends on the latent heat of vaporization required by tobacco-curing. Moreover, the maximum average heat load is approximately 30 kW.

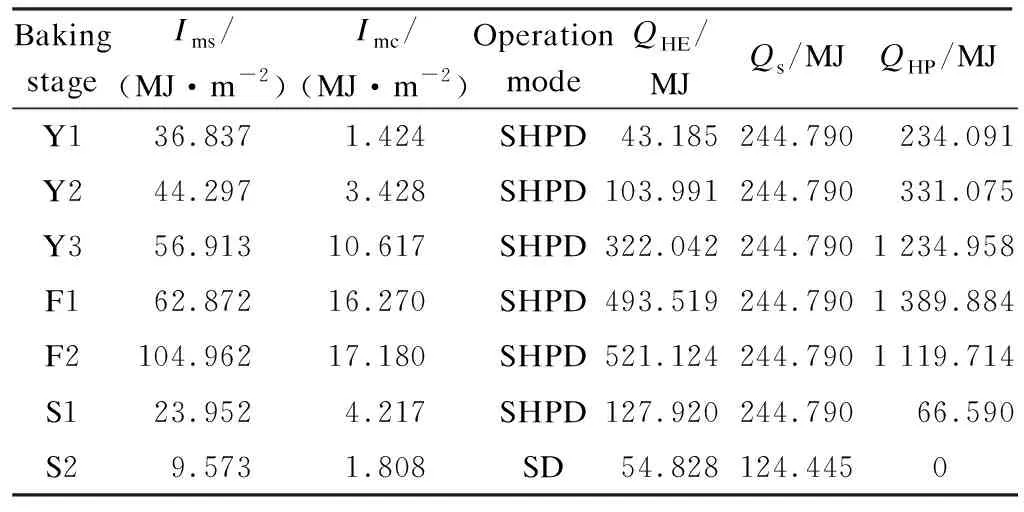

The bottom leaf is used as an example to analyze the operating mode of the novel system and the heat supply of each heating equipment in April, as shown in Tab.3. Given the great average daily solar radiation in April, the utilization rate of the solar energy of the system is significantly high. In addition, given a large amount of total required heat, solar collectors hardly achieve separate operations. Therefore, the entire tobacco-curing process relies more on the heat pump, and solar energy can relieve the burden of the independent heat supply by the heat pump and reduce energy consumption.

Tab.3 Operation mode of the novel tobacco-curing system in April (Is=18.830 MJ/m2)

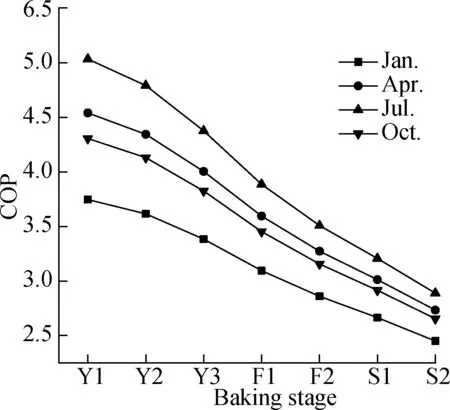

Fig.5 shows the COP of the heat pump at different baking stages. Under certain environmental conditions, the required heat pump condensing temperature continues to increase, whereas the COP of the system gradually decreases when the baking temperature increases. In addition, in the same baking stage, the COP of the system in July was higher than that of other months, indicating that the increase in ambient temperature helps increase the COP of the system. This result is obtained because the increase in ambient temperature helps improve the evaporation temperature of the evaporator. According to Carnot’s theorem and Eq.(11), the increase in evaporation temperature helps improve the COP of the heat pump.

Fig.5 COP of the heat pump in different baking stages

2.2 Comparison with other tobacco-curing techniques

Fig.6 shows the comparison of power consumption between the novel tobacco-curing system and heat pump tobacco-curing system (no heat recovery and solar heat collection). When baking the same part of the tobacco leaf under the same environmental conditions, the power consumption in the novel tobacco-curing system is significantly lower than that of the heat pump tobacco-curing system. According to calculations, the power saving rate of the novel tobacco-curing system is 25.9%-35.1% compared with the heat pump tobacco-curing system. In addition, the curing process of different parts of a tobacco leaf reached the minimum power consumption in April in the novel tobacco-curing system. The average daily solar radiation was the highest, and the humidity ratio of the air was low in April for Yunnan. Thus, the curing condition was superior, and the power consumption of the system reached the minimum value. In Yunnan, July is the rainy season, air humidity is high, and the average daily solar radiation is lower than that in April; thus, the power consumption of the novel tobacco-curing system in July is higher than that in April[32]. However, in the heat pump tobacco-curing system, ambient temperature is the main factor affecting system power consumption; thus, the system power consumption reached the lowest in July. Moreover, the novel tobacco-curing system and the heat pump tobacco-curing system reached the maximum power consumption in January; thus, tobacco-curing is not suitable in January. In the two kinds of tobacco-curing systems, the order of the power consumption of different parts of the tobacco leaf is as follows: top leaf > middle leaf > bottom leaf. The longest baking time of the top leaf leads to the maximum power consumption of the system, whereas the shortest baking time of the bottom leaf leads to the minimum power consumption.

Fig.6 Comparison of power consumption between the novel tobacco-curing system and heat pump tobacco-curing system

In accordance with the thermal calculation results, equipment selection and cost evaluation of the novel tobacco-curing system were conducted. Tab.4 shows the initial investment of three kinds of tobacco-curing systems. The cost of building materials for the novel tobacco-curing system and heat pump tobacco-curing system consists of the cost of color steel plates and polyurethane insulation. Equipment installation costs are calculated at 13.5% of equipment and building materials costs. Through a comprehensive consideration of various costs, the initial investment of the novel tobacco-curing system increased by 30 989 yuan, and the heat pump tobacco-curing system increased by 18 390 yuan compared with the coal-burning tobacco-curing system. Although the initial investment of the novel tobacco-curing system is relatively high, the tobacco company subsidizes the new energy and heat pump tobacco-curing technology in a large proportion and thus can reduce its investment cost[33].

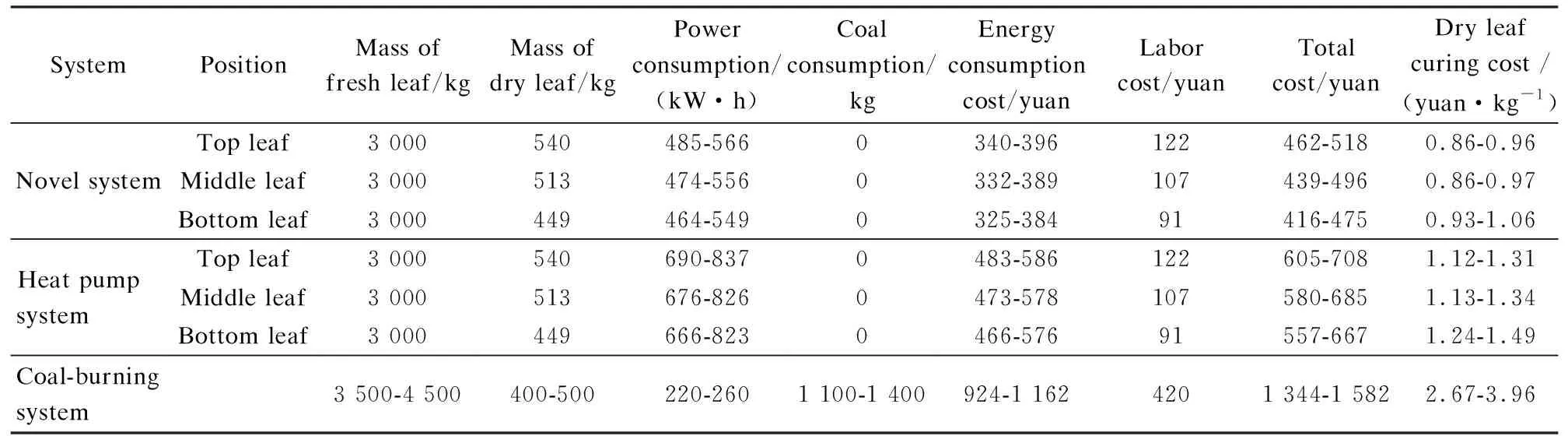

Tab.4 Comparison of initial investment costs of the three tobacco-curing systems Yuan

Tab.5 compares the curing costs, which mainly include energy-consumption cost and labor cost, of the three tobacco-curing systems. Compared with the coal-burning tobacco-curing system, the novel tobacco-curing system and the heat pump tobacco-curing system have a higher degree of automation and avoid the manual coal-feeding process; thus, they can effectively reduce the labor cost by more than 70%. Furthermore, the dry leaf curing cost of the coal-burning tobacco-curing system is 2.67-3.96 yuan/kg, and that of the novel tobacco-curing system is only 0.86-1.06 yuan/kg, which saves more than 60% of the curing cost. Therefore, the cost reduction effect of the novel tobacco-curing system is evident. In addition, the order of the dry leaf curing costs of different parts is as follows: bottom leaf > middle leaf > top leaf, which is exactly the opposite of the order of total curing costs. The top leaf has the lowest initial water content and the highest mass of dry leaf; thus, the dry leaf curing cost is the lowest.

Tab.5 Comparison of operation costs of three tobacco-curing systems

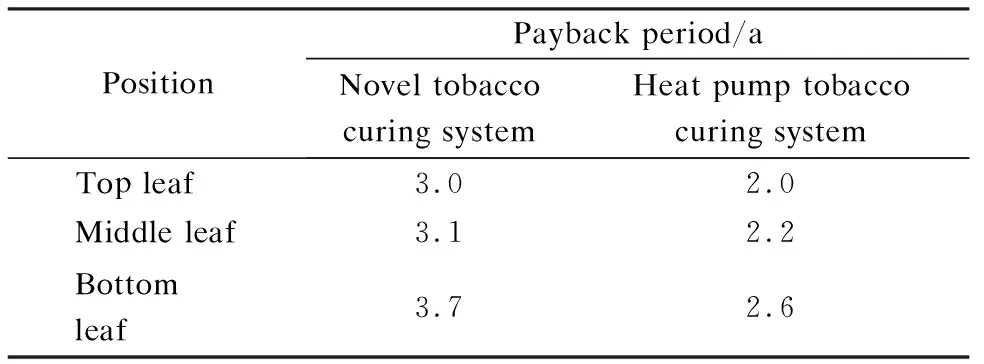

July to September is the main season of tobacco leaf picking and baking in Yunnan.Assume that the tobacco leaf is baked eight times in a year (3 000 kg tobacco leaf per kang), and the curing cost is averaged for economic analysis. As shown in Tab.6, the payback period of the heat pump tobacco-curing system is 2.0-2.6 a, whereas that of the novel tobacco-curing system is 3.0-3.7 a, which is slightly higher than that of the heat pump tobacco-curing system; nevertheless, the novel tobacco-curing system is relatively economical and feasible. The high initial investment of the novel tobacco-curing system increases the system’s payback period. Thus, further research is needed to reduce its initial investment.

Tab.6 Payback period of two different tobacco-curing systems

The energy consumption of the three tobacco-curing systems was converted into standard coal for calculation. The conversion coefficient of power was 0.404 kg/(kW·h), and the conversion coefficient of raw coal was 0.714 3 kg/kg. The emission reduction of different parts of tobacco leaf during the curing process was calculated, and the average value was taken, as shown in Tab.7. The novel tobacco-curing system has a significant reduction in pollution reduction, reducing 15 586 kg CO2annually. This result indicates that the novel tobacco-curing system has considerable environmental benefits.

Tab.7 Emission reduction of two different tobacco-curing systems

3 Conclusions

1) The thermal calculation indicated that dehydration rate was a key parameter during the tobacco-curing process. The mass flux of exhaust air and the heat load had similar changes to the dehydration rate, and both reached the maximum in the late color fixing.

2) Economic analysis indicated that the dry leaf curing cost of the novel tobacco-curing system was only 0.86-1.06 yuan/kg. In addition, the annual CO2, SO2, and dust emission reduction of the novel system could reach 15 586, 1 375, and 63 kg, respectively.

3) Compared with the heat pump tobacco-curing system, the novel system has important economic and environmental benefits, but the payback period is slightly longer. Future research should focus on reducing the initial investment of the novel tobacco-curing system to reduce its payback period.

杂志排行

Journal of Southeast University(English Edition)的其它文章

- Sustainability of health information exchange platform based on information cooperation

- TOD typology: A review of research achievements

- Concept and evaluation method of equipment system of systems contribution rate

- Comparative study of low NOx combustion optimization of a coal-fired utility boiler based on OBLPSO and GOBLPSO

- Clay mineral expansion of black cotton soil based on interlayer cation hydration

- Crossed products for Hopf group-algebras