Adaptive Control for Space Greenhouse Light Assembly

2021-09-25BerkovichBuryakOchkovPerevedentsevSmolyanina

Y. Berkovich,A. Buryak,O. Ochkov,O. Perevedentsev,S. Smolyanina

(State Science Center - Institute for Biomedical Problems Russian Academy of Sciences,Moscow 123007,Russia)

Abstract:To date, Light Emitting Diodes-based (LED) illuminators are widely used for plants lighting in greenhouses in addition to natural light, as well as in plant factories without natural light. Optimization of artificial lighting parameters, such as the daily light integral and the ratios of different spectral components, can significantly reduce the cost of crop production in light culture including Space Greenhouses (SG) in Biological Life Support Systems (BLSS). However, the optimization of LED lighting systems is so far limited by the lack of information about the physiological effects caused by narrow-band radiation, as well as the complexity of the mathematical description of plant crops reactions to the changes of LED lighting parameters. In conditions of artificial illumination, crop producers usually strive to establish an optimal light regime that is constant throughout the whole growing season.However, there is experimental data on changes in the requirements for the illumination regime of crops with increasing age of plants. A promising approach to improving the parameters of crops LED lighting is the adaptive method of search engine optimization using biological feedback. The Adaptive Lighting System (ALS) is described on the basis of illuminator with red and white LEDs built at the Institute for Biomedical Problems (Moscow, Russia) for Chinese cabbage cultivation. The adaptive control procedure implements a continuous automatic search for current lighting parameters that provide optimal plant growth characteristics in real time. ALS includes a closed growth chamber with Light Assembly (LA) based on red and white LEDs, equipped with a Gas CO2 Analyzer (GA). The Photosynthetic Photon Flux Density (PPFD) from each type of LEDs can be controlled independently from each other according to the program in the MicroProcessor (MP). Periodically, infrared GA measures the decrease in CO2 concentration inside the growth chamber caused by Visible Photosynthesis (VF) of the crop. MP receives a signal from the GA output and calculates the photosynthesis rate of the crop, as well as the value of the lighting quality functional at the current time.Then the program compares the obtained values of the optimization criterion at the current moment and at the previous step and calculates the direction of the gradient according to picked algorithm and the new values of the LED supply currents, leading to a change in the value of the optimization criterion in the right direction. Further, the power supply unit realizes the currents of LED chains of each type and LA changes the plant lighting mode. As a criterion for the lighting quality in SG we used the minimum specific value of the Equivalent System Mass (ESM), which depends on the plants lighting regime. The cost coefficients of the unit of SG planting area equivalent mass and the unit of electric power consumed by SG significantly depend both on the spacecraft design and on the space expedition scenario. According to the literature, the equivalent system mass estimates depending on the light flux density and the crop light efficiency have been calculated in a spacecraft for the space expedition scenario at a long-term use lunar base with a crew of 4. To search for the current optimal lighting parameters during the plant growth, gradient and simplex algorithms were used. As optimization factors, the integral PPFD incident on the crop at the shoot tips level and the ratio of red and white light flux densities (factors X1 and X2, respectively) were used. Factor X1 was regulated in the range from 200 μmol/(m2·s) to 700 μmol/(m2·s), and factor X2 was from 0 to 1.5. The effectiveness of ALS was evaluated by comparing ESM when using ALS or the best constant LED lighting from comparison experiment. Adaptive optimization of Chinese cabbage crop lighting from the 14th to 24th day of vegetation according to the minimum ESM criterion (1) for the lunar base expedition led to a 14.9% saving in the SG equivalent mass. Similar systems with other optimization criterion can be use for terrestrial plant factories.

Keywords:space greenhouse;adaptive optimization;crop productivity;visible photosynthesis;light-emitting diodes;light spectral composition

Introduction

Currently, the concept of human Life Support Systems (LSS) designed to accomplish the immediate task of the astronautics - exploration of the Moon and flights to the Mars is being actively developed. According to some experts, it will be expedient to include a Space Greenhouse(SG) for on board fresh vitamin greens growing, which can provide more adequate habitat for astronauts. The objective of the SG is to produce fresh vitamin greens as an additive to the main diet, as well as to ensure the psychological comfort of the crew[1-4]. By growing vegetables in long space missions, it is possible to solve the problem of supplying the crew with well-digestible vitamins with a short shelf life, primarily vitamin C(ascorbic acid) and vitamin A (retinol)[2,5]. Currently,intensive work is underway to create greenhouse facilities for growing plants on board manned spacecraft and planetary bases. The crops lighting regime optimization is an urgent task in the design of modern life support systems for lunar orbital and surface stations, for the Martian passenger ship and other space objects. For example,according to modern estimates, with fully artificial LED lighting, the LA energy consumption can reach 50% of the total energy consumption in vegetable space greenhouses[4],and the energy consumption for LED lighting for SG crops in the Lunar module with a crew of 6 members can amount to more 100 kW[6].

In contrast to ground-based vegetation facility, an important requirement for SGs is to minimize the consumption of the main onboard resources: volume, mass of equipment and consumables, energy consumption,cooling costs, as well as unit labor costs per unit of biomass grown due to severe restrictions on these resources and their high cost[7].To compare the effectiveness of various structures and assemblies in the space LSS composition, including SGs, the term “Equivalent System Mass (ESM)” is widely used[8-9]. The smaller is ESM of some assembly, the cheaper is its delivery and operation on the spacecraft board. Initially, the equivalent mass included the mass of the greenhouse equipment itself with reserves of consumables, materials and spare elements for a certain time of operation, the mass of the energy source with auxiliary equipment, the mass of the thermal and moisture control system. Subsequently, other resources reduced to mass units through empirical or calculated coefficients depending on the structure and level of technical implementation of the LSS units, as well as on the duration and scenario of the space expedition, for example, labor costs for servicing the greenhouse and the reliable operation duration, began to be included in the ESM[9]. One of the important directions of the plants growing efficiency increasing and reducing the consumption of on-board resources in SG is the optimal control of environmental parameters in the growing chamber. In addition, a significant modification of the techniques for plants growing worked out on Earth should be elaborated, especially for microgravity conditions.

Methods of precision agriculture, which are currently being actively developed, in particular, functionalstructural models of growth and development of plant crops are used in terrestrial farming to optimize the crop growth due to the selection of the optimal environment,and in particular, the crops lighting parameters[10]. From plant physiology is known that plant metabolism, as well as their photosynthesis and morphogenesis, substantially depend on a number of indicators: plant age, phase of their development, and environmental factors. The complex structure and multivariate functioning of the plants photosynthetic apparatus during plant growth do not yet allow the mathematical modeling suitable for accurate calculation and prediction of phytocenosis photosynthesis rate depending on parameters of the lighting regime such as the radiation spectrum and photon flux density at different stages of ontogenesis[11]. The relationship of photosynthesis with the crop production processes (for example with the rate of biomass accumulation in organs)is also rather complex and ambiguous depending on the stages of their development. On the one hand, the current plant productivity is regulated by genetically determined processes of growth, morphogenesis, generative development and aging, but on the other hand, photosynthesis is the only source of light energy transformation and primary carbohydrate synthesis. At the same time, the relationship between photosynthesis and the synthesized substances accumulation (the so-called donor-acceptor relations) is regulated both by the influence of environmental factors (lighting regime, meteorological indicators,mineral nutrition regime, etc.) and endogenous regulation mechanisms, for example, through transport hormonal regulation and distribution of assimilates, secondary metabolism in chloroplasts, leaf and in the plant storage organs[12]. If it were possible to build a model of a certain efficiency index of crop growing in SG dependence on these factors, then the calculation of the optimal combination of such indicators could be carried out using conventional mathematical programming methods.

Known mathematical models of the crop production process, like CERES[13], Hortisim[14], “GreenLab”[15-16], are based on the calculations of growth processes in plant organs using current and predicted information on environmental parameters and with subsequent integration over the growing period. The main disadvantage of such models is that they require an extensive database of preliminary experimental information on the crop characteristics in different environmental conditions to identify many empirical model coefficients. For example,the model for the current assessment and prediction of wheat crop productivity from[17]contained 119 parameters.

One approach for refining the model of the crop production is the parallel use of a model as “GreenLab”[10,18-19]and a model based on measured current data on environmental parameters (for example, air temperature and humidity, photon flux density and light spectrum,etc.). This approach is called “a Knowledge and Data driven modeling”, KDDM. In real time, a number of physiological indicators are calculated (for example, the intensity of photosynthesis and respiration of plants, the rate of transpiration, etc.). Then, according to the empirical model, for which, for example, the radial basis function of a neural network can be utilized, using current data, a number of intermediate (hidden) variables are estimated,which are then used to more accurately identify the calculated current indicators of sowing productivity in the“GreenLab” model[10]. This procedure allows reduce of model identification errors and makes it possible to more accurately predict crop productivity as the neural model is trained according to experimental data. In practice, in terrestrial crop production, wide experimental databases are still found only for the most common industrial crops,so technological programs for each plant species are determined on the basis of numerous and laborious preliminary experiments, weather forecast and intuition of plant growers, and the degree of approximation of the received programs to the optimal ones usually remains unknown. There are no such databases for space greenhouses, and the described optimization methods are not yet available here.

Another approach to determine the optimal lighting and environmental parameters for plant crop is the construction of mathematical models based on approximation of the multivariate experiments results(regression models)[11,20]. For example, in the works[20-21]a fractional 3-factor experiment to select the optimal lighting parameters for leaf cabbage is described. The found regime ensured the maximum yield of edible biomass at a fixed cost of on-board resources in the currently designed SG “Vitacycle-T” for Russian segment of International Space station. In this experiment, two types of LEDs were used in the light assembly - with white and red radiation.This approach allowed, on the one hand, to avoid disturbances in plant morphogenesis and ontogenesis,which appear in the narrow-band LED lighting spectrum in some cases[22], and, on the other hand, to reduce the search space dimension for optimal parameters of the lighting. As a result of more than 60 growing experiments,the regression dependences of the leaf cabbage biomass on 3 parameters of LED lighting: 1 - photosynthetic photon flux density, PPFD, 2 - the ratio of PPFD from red and white LEDs and 3 - the distribution of radiation over time(pulsed or continuous) were determined. It should be noted that in the described work, as well as in the most of other similar works on optimizing artificial lighting of crops, the recommendations obtained are intended only for the case when the lighting parameters remain unchanged throughout the whole vegetation period.

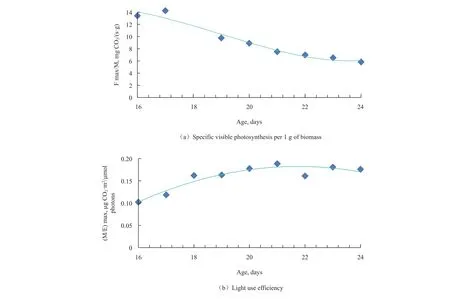

However, it is known from experiments that the characteristics of the plant growth and development substantially depend on their age, i.e. cannot be considered as stationary. For example, even with stabilized cultivation conditions, significant changes in photosynthetic rate are observed in crops with increasing age of plants due to an increase of the leaf area, changes in the structure and activity of the photosynthetic apparatus, as well as due to changes in the vegetation cover optical density and light distribution inside it[12]. For the cabbage (Brassica pekinensis (Lour) Rupr, cultivar Khibinskaya), it was experimentally established that the maximums of productivity and the light energy use efficiency corresponded to different values of the Photon Flux Density (PPFD) and the light period per day with the plant age increasing[4]. Figure 1 shows obtained drift characteristics of the Chinese cabbage crop in our plant growing chamber with a light assembly based on red and white LEDs. These data indicate that any lighting regime that is constant during the growing period can be further improved by the lighting fine-tuning with the age of the plants, and that the optimal lighting conditions for crops should have variable parameters during cultivation.

Fig. 1 Age drift of Chinese cabbage crop characteristics

Earlier in the works[23-24]for unsteady objects with a priori unknown parameters, automatic optimization systems with adaptation, or adaptive optimization systems,were proposed. The aim of this work is to estimate the feasibility and usefulness of such systems for the dynamic optimization of the crops LED lighting in relation to SG.In this case of Adaptive Lighting System (ALS), crop is considered as a “black box” with minimal information about the properties of the function of the indicator of the cultivation effectiveness on lighting parameters, like continuity and smoothness at any time. The radiation parameters from the LED-lighting assembly are controlled using search algorithms that optimize the selected quality cultivation indicator using a biological feedback signal, for example, visible, or apparent, photosynthesis of the crop.

ALS includes a closed growth chamber (phytotron)with Light Assembly (LA) based on red and white LEDs,equipped with a Gas CO2Analyzer (GA). The PPFD from each type of LEDs can be controlled independently from each other according to the program in the MicroProcessor(MP).

1 Methods

According to the theory of mathematical programming[25], the solution to any optimization problem is possible in the presence of the following clearly formulated characteristics: optimization criterion (goal);optimization parameters (optimization tools); areas of acceptable values of optimization parameters and optimization algorithm. The adaptive control of the LED lighting regime is carried out by continuous automatic search for the crop lighting current parameters, which provide optimal value of the optimization criterion using real time information about the current state of the object,in our case, the current visible photosynthesis of the crop.The computer program compares the obtained values of the optimization criterion at the current moment and at the previous measurement step and calculates the direction of the gradient according to a certain algorithm, and from it the value of the supply currents, leading to a change in the value of the optimization criterion in the right direction. If we denote by Q (X, t) the dependence of the optimality criterion indicator on the vector of the parameters of the lighting X and the plants age by t, then the formulation of the LED lighting parameters in SG adaptive optimization problem can be written as follows: find such a trajectory X* (t) so that for any t the condition is satisfied

Here X1 – the integral photon flux density from the LEDs LA;X2 – the ratio of the photon flux density from the LEDs with red and white radiation at the shoot tips level, respectively; D1 – the range of the PPFD values from the LED LA; D2 – the range of possible PPFD ratios from red and white LEDs in the LA.

The functional diagram of the ALS is shown in Figure 2. The system operates as follows. The plants are grown in an airtight growth chamber with a device for supplying a nutrient solution to the plant roots and an LED LA located above planting area and containing several chains of LEDs with radiation in different ranges of Photosynthetic Active Radiation (PAR). The basic parameters of the plant habitat in the growth chamber are stabilized in an adequate level by the appropriate regulators. There are either PPFD meters for each type of LEDs irradiation or for their supply currents meters corresponding to the photon fluxes emitted by them in the ALS. The growth chamber is also equipped with a gas analyzer for measuring the current carbon dioxide absorption rate by the crop. As is known, the crop apparent photosynthesis is proportional to the rate of decrease in CO2concentration in the air of a closed chamber with plants[26].

At some point in time ti, corresponding to a certain age of the crop, the gas analyzer gives a signal of the crop apparent photosynthesis value to the microcontroller,which is used to calculate the current value of the crop optimization criterion. Then the program compares the obtained values of the optimization criterion at the current moment and at the previous measurement step and calculates the direction of the gradient according to the given algorithm. Then LED power controllers establish the value of the LEDs supply currents for each type LED chains, which leads to a change in the value of the optimization criterion in the right direction. Further, the LA changes the crop lighting regime. Then the whole procedure is repeated for the next search step at time ti+1.The resolution of the search steps in our ALS was 15 minutes. To search for the current optimal lighting parameters during plant growth, gradient and simplex algorithms were used[27].

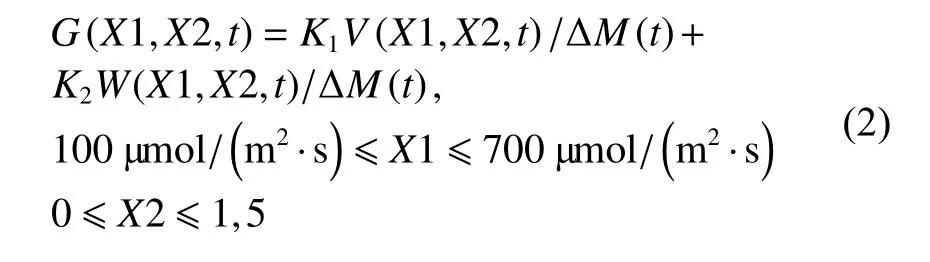

For the technical implementation of the ALS, it is required that optimization criterion and optimization parameters can be measured non-invasively during plant cultivation. As the current optimization criterion for SG,we used an integral specific value of the ESM for 3 main onboard resources calculated on the production of 1 kg of plant biomass: the volume occupied by the crop, the power consumed by the LED illuminator and the power used to cool the vegetation chamber. Every from the values is depending from lighting mode. The optimization criterion can be written as following.

where X1, X2, t – have the same meaning as in equality(1); V – the volume of the SG vegetation chamber,necessary for growing the crop; W – the radiation power of the LED illuminator, necessary for the crop cultivation; K1and K2are the cost of volume unit occupied by the greenhouse and the cost of power unit consumed by the greenhouse’s electricity on board a space object,respectively, in units of reduced mass, ΔM(t) is the current value of the biomass increase obtained from a unit of the SG landing volume (or area).

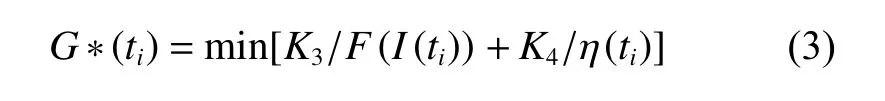

In our previous work[4], it was shown that the planting area of the same types of vegetation devices, at least for salad crops, can be considered proportional to their volume, and ΔM(t) is approximately proportional to the crop visible photosynthesis F. We introduce the notation:η = ΔM/E(I, t), where E is the light energy and I is the average PPFD supplied for the crop during the period of ΔМ synthesis, correspondingly. It can be shown that η characterizes the efficiency of the light use for the crop biomass synthesis. For the current elementary time interval(ti+1- ti) estimates we can assume that η = n•F/I, where n is a constant. Taking into account the above relations, the optimal value of criterion (2) at time tican be rewritten in the form

here K3and K4are the cost coefficients of the equivalent mass unit and the unit of electric power consumed by LED illuminator in SG intended for the production of 1 kg of crop, in kg/m2and kg/kW,respectively. K1and K2in expression (2) and accordingly K3and K4in expression (3) significantly depends both on the design of the spacecraft in which the greenhouse is installed, and on the space expedition features it performs– duration, work program, number of crew members, etc.In this paper we used the onboard resources cost estimates in mass units for some specific space missions from the works[28-30]. When assessing the total power of electricity consumed by SG, we took into account both the energy consumption of all subsystems of SG and the power consumed by the cooling system, which grows approximately in proportion to the power consumption of the subsystems of lighting, ventilation, mineral nutrition,etc. As a result of this, we approximately believed that the coefficient of the consumed in a SG electric energy unit cost (K2) is the sum of the equivalent masses of the SG energy consumption itself and the energy consumption for its cooling.

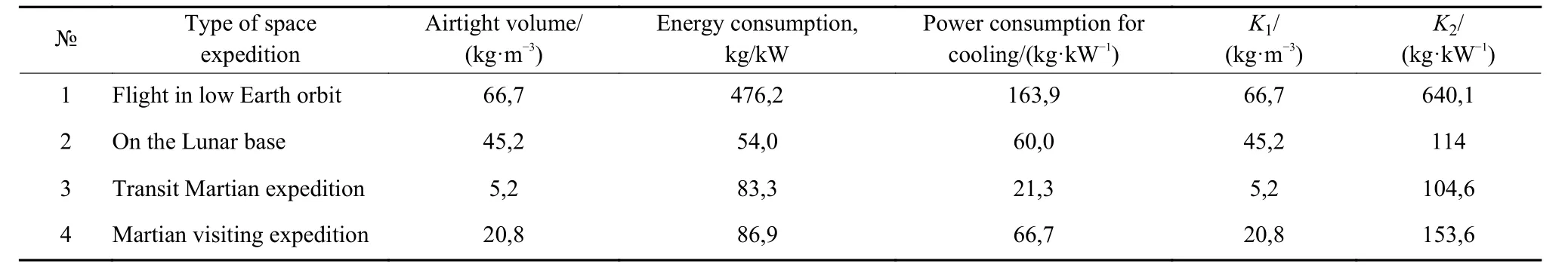

Table 1 gives the equivalent mass estimates of the main onboard resources and the cost coefficients K1 and K2 calculated for 4 scenarios of the space expeditions from the papers[28-30].Flight of the ISS in low Earth orbit with a duration of more than 10 years, a crew of 6 people(on average) with crewmembers rotation every 90 days and with 2 sessions of extra-space activity per month.

Table 1 The cost of the main onboard resources in the space greenhouse in the equivalent mass units for 4 scenarios of space expeditions[28-30]

Expedition to the lunar base of long-term use at a gas pressure of 1 standard atmosphere indoors at a temperature of about 20 °C, using external protection of the inhabited compartment from the regolith layer, using sunlight to illuminate plants during a lunar day at a PPFD level of about 500 μmol/(m2s) and crop lighting from artificial light sources with lower PPFD at night.

A transit Martian manned expedition lasting about a year using solar electric batteries as an energy power source.

A Martian visiting expedition lasting about 20 months with a stay on the planet’s surface, using a 100 kW nuclear energy source along with the establishment of sunlight to illuminate plants.

Since the cost of onboard resources in the Table 1 has a certain dimension, when calculatingK3andK4for equation (3), conversion factors were used for the light flux density and photosynthesis measurement units. To convertI(t) to kW units according to the method described in our previous work[31], we used the averaged coefficient(5 × 103μmol/(m2s))/(kW/m2), taking into account that in the LED illuminator radiation spectrum recommended in the work[22], the part of photons in the red region of the spectrum is about 73%. To convert crop visible photosynthesis integral from mgCO2to the biomass growth units (kg) in accordance with the photosynthesis equation for carbohydrate crops, a conversion factor of 8,5 kg of raw biomass per 1 kg of carbon dioxide absorbed by the crop was obtained. The average dry matter content in the biomass of cabbage was taken equal to 8%,according to experimental data.

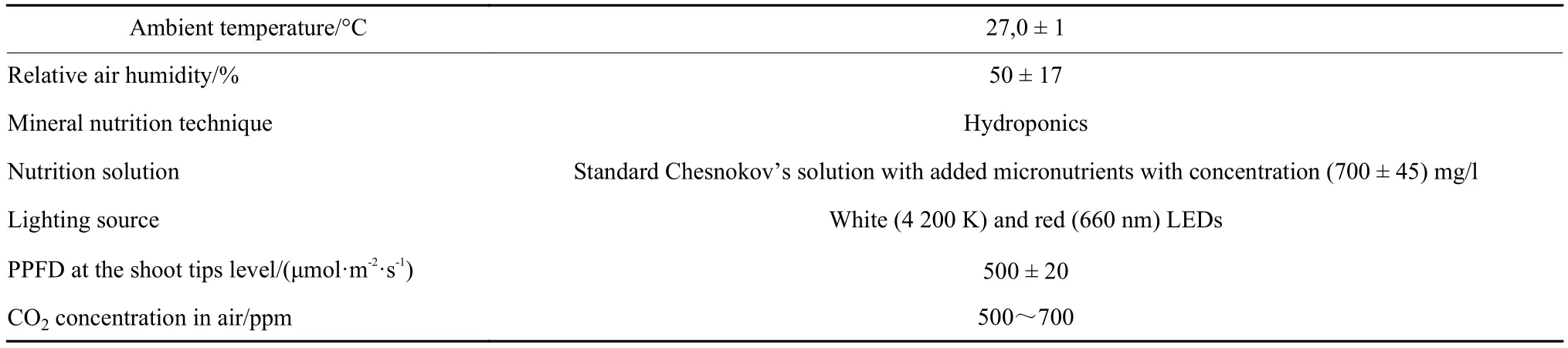

The object of the study was Chinese cabbage Brassica chinensis L., cv.Vesnyanka (selected by VNIISSOK Co.,Russia) aged from 14 to 25 days. Plants were grown in Root Modules (RM), simulating RM for the developed onboard “Vitacycle-T” greenhouse. Each RM was a roll of fibrous soil substitute “BIONA-V3”TM50 cm long and dry weight (25 ± 3) g. A roll of soil substitute was coiled round horizontally arranged tube of finely porous titanium with outer diameter of 16 mm. 20 seeds of Chinese cabbage were planted in a longitudinal slot in the roll at equal distances from each other. The porous tube was connected to the reservoir in the form of a Mariotte vessel,filled with a standard Chesnokov’s nutrient solution. The Mariotte vessel provided a stabilized water potential in the root zone in the range from (–1.0) kPa to (–1.5) kPa. Two identical crops were grown in a growth chamber from seed planting until the 13th day of vegetation. The growth chamber was placed in a thermostatically controlled room under illuminator with red and white LEDs with a PPFD ratio of red and white LEDs equal to 1.5 and a total PPFD value of 500 μmol/(m2s). Lighting regime was noctidial.On the 14th day from planting, RMs with experimental plants was moved for 10 days to the measuring stand with ALS, described in detail in the previous work[32]. The second synchronous crop was kept in the same growth chamber as a control. The growing conditions are presented in Table 2. Figure 3 shows a general view of the experimental stand with the Chinese cabbage crop.

Table 2 Chinese cabbage growth conditions

Fig. 3 Growth chamber with the Chinese cabbage crop in the experimental stand: 1 - LED illuminator, 2, 3 - blower of the growth chamber ventilation system, 4 -fans for air mixing, 5 - root module with the crop, 6 - weight platform with load cells, 7 - platform for regulating the distance between the crop and illuminator, 8, 9 -tubes for the nutrient solution supply

The advantage of the experimental lighting compared with the control one was evaluated by the decrease in the specific ESM in the crop grown with an ALS on compared to the control crop during the growing period. The measure of “saving” the equivalent mass was the value

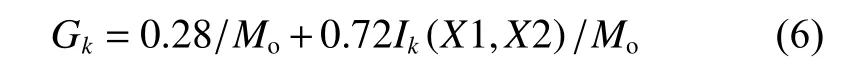

Here, G and Goare the estimates of the specific ESM for the adaptive search of the lighting and in the control with the best lighting, constant during the growing period,respectively. Since δ from expression (4) is ratio of the ESMs, to simplify the calculations G according to equation (2) we normalized the coefficients K1and K2by the sum (K1+ K2) from Table 1. After that, G was calculated as follows

where Mois the mass (kg) of the harvest from m2of the sowing, obtained in the control experiment for 24 days of vegetation. In the expressions (5) and (6), the light flux was expressed in kW/m2.

2 Results and discussion

The data in Table 1 indicate that the contribution of the power unit consumed by the LED illuminator to the SG ESM (taking into account the energy for cooling also)for every considered space expedition scenario from Table 1 is significantly greater than of the unit volume (or sown area unit). For example, for a scenario with a lunar base,ESM of power consumed for the production of a crop unit mass gives 72% of the contribution to the value of the optimality criterion (3). For the transit Martian expedition,one can almost neglect the optimization of the crop specific productivity, minimizing the light energy expended in SG for the production of a crop biomass unit,i.e. the reciprocal of the light use efficiency. As a result,for such an expedition it would be advantageous to maximize η(ti) from expression (3) during the growing time and grow crop at relatively low value of total light flux density. However, it should be noted that estimates of onboard cost coefficients, according to previous work[33],can change significantly as the space missions’ scenarios and the structures of life support systems are clarified in upcoming space expeditions. As a result, the trajectories of changes in the operating regimes in the ALS that we obtained can serve to illustrate the capabilities of such systems only and cannot be considered as actual recommendations for existing SGs.

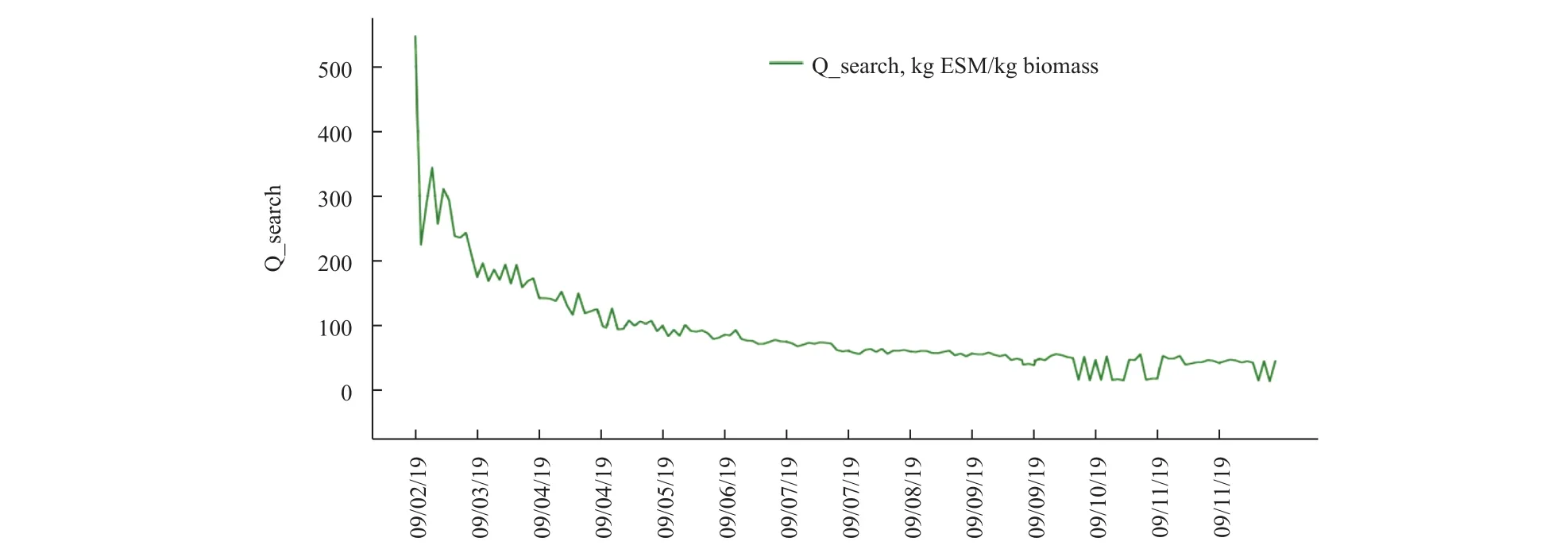

Figure 4 shows the drift trajectory of the specific ESM of the Chinese cabbage crop that are optimal according to criterion (3) during the growing time in relation to the Lunar base scenario from Table 1.

Fig. 4 Age drift of optimal specific ESM for Chinese cabbage vegetation in the space greenhouse for Lunar base

As a result of the lighting optimization for Chinese cabbage crop from the 14th to 24th days of vegetation according to the criterion of the current minimum ESM,the saving of the SG equivalent mass for the production of 1 kg of fresh biomass was 14.9%.

Table 3 represents data on the obtained biomass productivity and composition in the experimental and control Chinese cabbage crops. As follows from the above data, in the experiment the yield, calculated on the plants dry weight, decreased by about 27%. The reason for this was mainly the fact that the search algorithm in our ALS during the growing season lowered the integral PPFD to about 260 μmol/(m2s), i.e. almost twice as compared to the control. The PPFD is closer to the value corresponding to the maximum light use efficiency of the crop. As was shown in our previous work[4], for example, the more PPFD, the higher crop productivity. It also follows from the table 3 that the plants of the control and experimental variants did not have significant differences in the biomass nitrate content, while in both variants the nitrate content was below the maximum permissible norms established by both Russians (3 000 mg/kg) and Europeans (2 500 mg/kg).A slight difference between the values of the leaf specific surface density, as well as the chlorophylls and carotenoids content in the biomass in the experiment and the control crops indicates that the use of ALS did not cause significant changes in the morphogenesis and the photosynthetic apparatus in the plant leaves. At the same time, the experimental plants were significantly inferior to the control plants in the content of ascorbic acid in the leaves, which can significantly reduce the worth of the obtained plant biomass for the astronauts’ diet. The high lability of the selected Chinese cabbage cultivar ascorbic acid content in the biomass depending on the LED illumination characteristics was noted earlier, for example,in (22).

Table 3 Characteristics of the control and experimental Chinese cabbage crops at age of 24 days

In general, the data in table 3 indicate that adaptive optimization of the LED plant lighting according to criterion (3) should be accompanied by a control of the crop biochemical characteristics, because of possible contradiction between the requirement to lower the ESM of the greenhouse and to raise the content of vitamin C in the grown biomass. For the successful application of the adaptive optimization system for plant lighting in vitamin SG, additional studies are needed to clarify different optimization criteria and the limits of the LED lighting variations for specific space missions.

Nevertheless, our experimental results show that adaptive control could be practicable and profitable for optimizing of space greenhouse light assemblies. Similar systems with other optimization criteria can be used for terrestrial plant factories.

3 Conclusions

1) Adaptive LED lighting system allows saving onboard resources (energy, volume etc.) in a space greenhouse without analyzing of big experimental data received from labor-consuming and time-taking growing experiments.

2) In the case of using the equivalent mass minimum as a criterion for the lighting system optimization in the space greenhouse for given estimates of the cost of power consumption and airtight volume, in the Moon base compartment, the adaptive LED lighting system allowed to reduce the system equivalent mass by about 15%.

3) When the adaptive LED lighting system is operating in the space greenhouse under various optimization criteria, it is necessary to control the quality of the grown biomass: the content of nitrates, vitamins,and other biologically active components.

This work was carried out within the framework of topic No. 65.4 of Fundamental Scientific Research Program of the Russian Academy of Sciences.