某高强钢轻量化副车架的动刚度优化

2021-09-16韦友超周思伍马志

韦友超 周思 伍马志

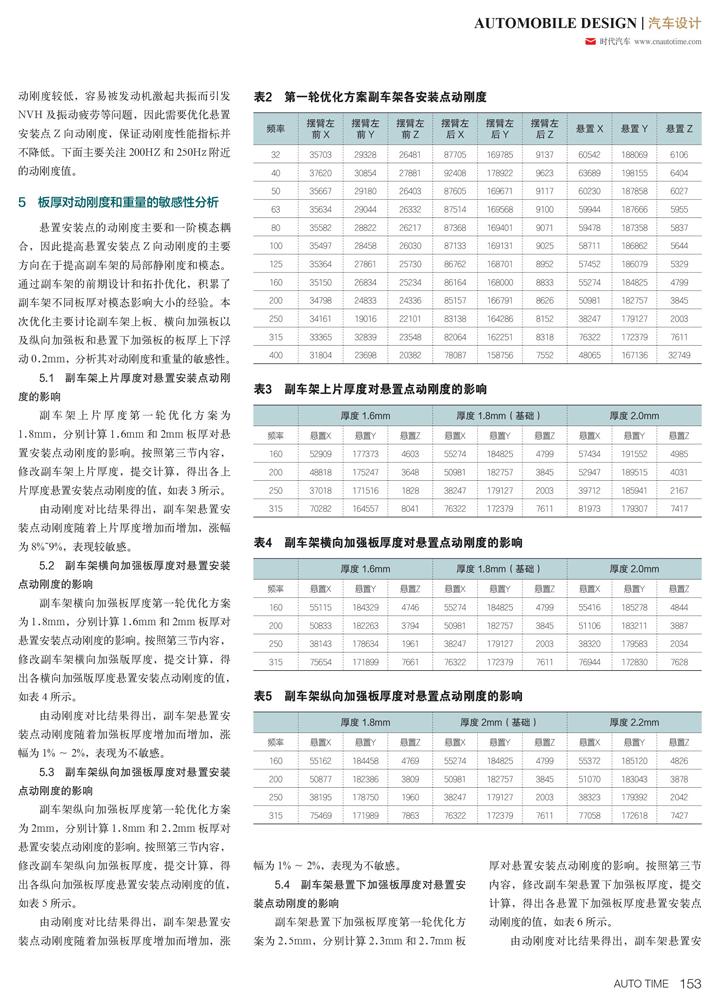

摘 要:由于前副車架通过发动机后悬置与发动机相连,为了避免结构共振和降低轰鸣声, 提升NVH性能,必须进行副车架的动态响应分析,其中动刚度是极为重要的指标。本文以某公司SUV的前副车架为例, 采用FB780高强钢减薄并结构优化得到第一轮轻量化模型,运用有限元软件Optistruct对轻量化模型进行动刚度分析, 并通过调整子级零件板材的厚度分析其对动刚度的敏感性,同时结合重量敏感性得出不同板材厚度的最优组合。最终得到最优的轻量化方案,比原量产副车架减重3.8KG,减重20%,而动刚度性能指标并不降低。为乘用车前副车架的设计和优化提供了动刚度分析依据。

关键词:副车架 动刚度 轻量化 敏感性 Optistruct

Dynamic Stiffness Optimization of a High-strength Steel Lightweight Subframe

Wei Youchao,Zhou Si,Wu Mazhi

Abstract:Since the front subframe is connected to the engine through the engine rear mount, to avoid structural resonance, reduce roar and improve NVH performance, the dynamic response of the subframe must be analyzed, among which dynamic stiffness is an extremely important indicator. This article takes the front sub-frame of a companys SUV as an example, uses FB780 high-strength steel to thin and optimize the structure to obtain the first round of lightweight model, use finite element software Optistruct to analyze the dynamic stiffness of the lightweight model, and adjust the sub-parts. The thickness of the plate analyzes its sensitivity to dynamic stiffness, and combines the weight sensitivity to obtain the optimal combination of different plate thicknesses. In the end, the optimal lightweight plan was obtained, which reduced the weight of 3.8KG and 20% compared with the original mass-produced sub-frame, while the dynamic stiffness performance index did not decrease. It provides a basis for dynamic stiffness analysis for the design and optimization of the passenger car's front subframe.

Key words:subframe, dynamic stiffness, lightweight, sensitivity, Optistruct