WC含量对TiB2基金属陶瓷微观组织与力学性能的影响

2021-09-07王帅汪建英娄嘉汪炯张翔杨海林

王帅,汪建英,娄嘉,汪炯,张翔,杨海林

WC含量对TiB2基金属陶瓷微观组织与力学性能的影响

王帅1,汪建英1,娄嘉2,汪炯1,张翔1,杨海林1

(1. 中南大学 粉末冶金国家重点实验室,长沙 410083;2. 湘潭大学 材料科学与工程学院,湘潭 411105)

采用粉末冶金法制备(WC)为0~20%的TiB2-WC-0.8Cr3C2-20(Co/Ni) (质量分数,%)金属陶瓷,研究WC含量对TiB2基金属陶瓷微观组织与力学性能的影响。结果表明,随WC含量增加,TiB2在黏结相中的溶解度降低,TiB2/黏结相界面减少,使得TiB2基金属陶瓷晶粒细化,晶粒尺寸更加均匀。此外,添加WC可显著改善TiB2基金属陶瓷的力学性能。当(WC)为15%时,金属陶瓷的性能最佳,硬度(HRA)、抗弯强度以及相对密度分别达到92.6±0.2、(1256±30) MPa和(99.65±0.20)%。但添加过量WC((WC)=20%)时部分WC相发生团聚并生成脱碳相W2C,使得TiB2基金属陶瓷的力学性能降低。

力学性能;微观组织;TiB2基金属陶瓷;WC添加;晶粒细化

二硼化钛(TiB2)具有高熔点、高硬度和高弹性模量,以及优良的导电导热性能、耐磨性能和耐腐蚀性能,是一种综合了各种优异性能的陶瓷材料[1],在刀具、耐磨件、高温结构材料、中子吸收剂和轻质抗冲击装甲材料等领域受到广泛的关注[2−4]。然而至今都难以获得高致密度的TiB2材料,导致该材料的热抗震性能抗弯强度和断裂韧性低,从而限制其更广泛的应用[5]。由于TiB2的熔点高、自扩散系数低,导致其烧结性能差,在无压烧结条件下,2 200 ℃烧结的TiB2单相材料相对密度不到95%[6−7]。此外,TiB2颗粒表面氧化物(B2O3和TiO2)的存在也会降低TiB2金属陶瓷的烧结密度[8]。因此,要获得近全致密的TiB2材料通常需要较高的烧结温度(>2 000 ℃)和压力。但高温高压烧结会导致TiB2晶粒异常长大,从而使材料的力学性能下降[9−10]。

为了提高TiB2基金属陶瓷的致密度,国内外对其烧结制备技术进行了大量研究,如:放电等离子烧结(spark plasma sintering,SPS)、热压(hot press,HP)和热等静压(hot isostatic pressing,HIP)等[11−14]。NGUYEN等[11]在1 500 ℃温度和40 MPa压力下进行SPS,获得相对密度约为97%的纯TiB2材料。YAN等[13]采用热压法制备单相TiB2陶瓷的相对密度为96%,加入15%(体积分数)的SiC颗粒可使陶瓷的相对密度进一步提高至98.2%。尽管采用这些先进的烧结技术可提高TiB2基陶瓷的致密度和力学性能,但由于成本和材料尺寸的限制,目前难以实现大规模工业化生产。许多研究者通过添加各种非金属烧结助剂如NbC、SiC、AlN、TiC、B4C、Al2O3、MoSi2等[15−21],以及金属烧结助剂如Fe、Ni、Co、Cr等[22−23],来改善TiB2基金属陶瓷的烧结性能,促进其烧结致密化。对于金属烧结助剂而言,与Ni、Fe和Cr相比,Co与碳化物结合表现出更好的性能[24]。此外,合适的黏结相对提高金属陶瓷的综合性能具有十分重要的作用[25−26],Ni作为一种重要的黏结剂,在TiB2基金属陶瓷中能与细小颗粒形成均匀的结构[27−28]。因此采用Co/Ni混合黏结相制备TiB2基金属陶瓷,有望提高材料力学性能。此外,抑制烧结过程中的晶粒长大也是提高金属陶瓷强度和韧性的有效途径。晶粒生长抑制剂主要有Cr3C2和VC[29−31]。Ti(C,N)基金属陶瓷中添加Cr3C2可使环形相中的Cr元素溶解,从而细化晶粒,并且环形相塑化,使界面强化,提高金属陶瓷的横向断裂强度[32]。近年来,WC对金属陶瓷微观组织和性能的影响也受到关注。HUANG等[33]研究了WC掺杂的NbC-Ni基金属陶瓷的核−壳结构随成分、烧结温度和保温时间的变化。为了进一步提高TiB2基金属陶瓷材料的力学性能,本文选择Co/Ni基混合黏结剂,添加Cr3C2作为晶粒长大抑制剂,制备WC含量(质量分数)为0~20%的TiB2基陶瓷,并研究WC含量对金属陶瓷的微观组织和力学性能的影响。

1 实验

1.1 原料

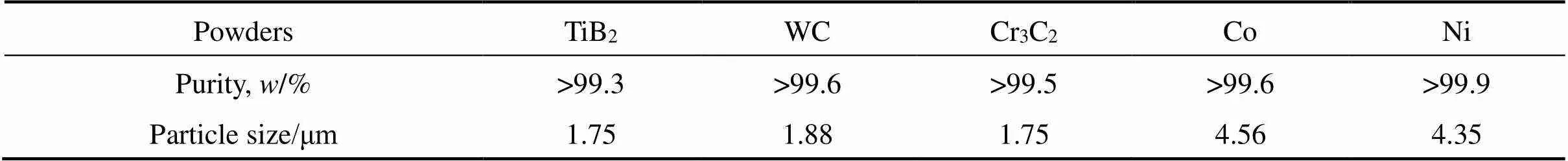

采用市售的TiB2、WC和Cr3C2粉末;Co粉和Ni粉均由湖南博云东方粉末冶金有限公司提供。原料粉末的性能参数列于表1。

1.2 TiB2基金属陶瓷的制备

实验设计5组不同WC质量分数的TiB2基金属陶瓷,表2所列为5组金属陶瓷的编号和原料配比。首先按照表2称量各种原料粉末和作为成形剂的石蜡,混合球磨30 h。球磨介质为无水乙醇,球磨转速为260 r/min,球料质量比为3:1。将球磨后的混合浆料在真空烘箱中70 ℃下干燥10 h,再过80目筛(筛孔直径为0.2 mm),尽可能地去除粉末团聚体。在100 MPa的单轴压力下压制成尺寸为25 mm×8 mm×5 mm的长条形样品,然后在气压烧结炉(型号:ZTQ-180-20)中500 ℃下脱蜡2 h,随后在6 MPa的Ar气压下1 490 ℃烧结1 h,随炉冷却,得到5组不同WC含量的TiB2基金属陶瓷。

表1 实验用粉末的性能参数

表2 TiB2基金属陶瓷的原料配比

1.3 组织与性能表征

将TiB2基金属陶瓷进行机械打磨,并用0.5~1 µm的金刚石磨盘抛光。采用三点弯曲法,用电子万能测试仪(Instron3369,美国)在14.5 mm的跨度下测定材料的抗弯强度,加载速度为2.0 mm/min。用500MRA洛氏硬度计测定材料的硬度(HRA),每个样品至少测5个点。每种材料至少取5个试样进行抗弯强度和硬度测定,计算平均值。

采用X射线衍射仪(XRD, Hitachi RAX-10 A-X, Japan)分析TiB2基金属陶瓷的物相组成。通过扫描电镜(SEM)观察材料抛光表面和弯曲断口形貌。为了进一步确定TiB2基金属陶瓷的显微组织,用Tecnai G2 F20透射电镜进行表征。为了制备TEM分析样品,从烧结样品上切下薄片,机械研磨至50 µm厚度,然后用Gatan精密离子抛光系统(PIPS)进行离子减薄,电压为5 kV,离子入射角设置为3°~7°。采用线截距法,用Image J软件基于材料表面放大10 000倍的SEM (BSE)图像,统计金属陶瓷的晶粒尺寸分布,晶粒数大于200个。

2 结果与讨论

2.1 微观组织

图1所示为TiB2-WC-0.8Cr3C2-20(Co/Ni)金属陶瓷的XRD谱。由图可知,(WC)为0的金属陶瓷中只检测到基体TiB2和Co/Ni相。所有含WC的金属陶瓷中均存在TiB2、WC和Co/Ni的特征峰。其中,(WC)为20%的金属陶瓷中有较弱的W2C相特征峰,这表明WC添加量过高时,WC相在烧结过程中可能发生脱碳反应而产生脱碳相W2C。

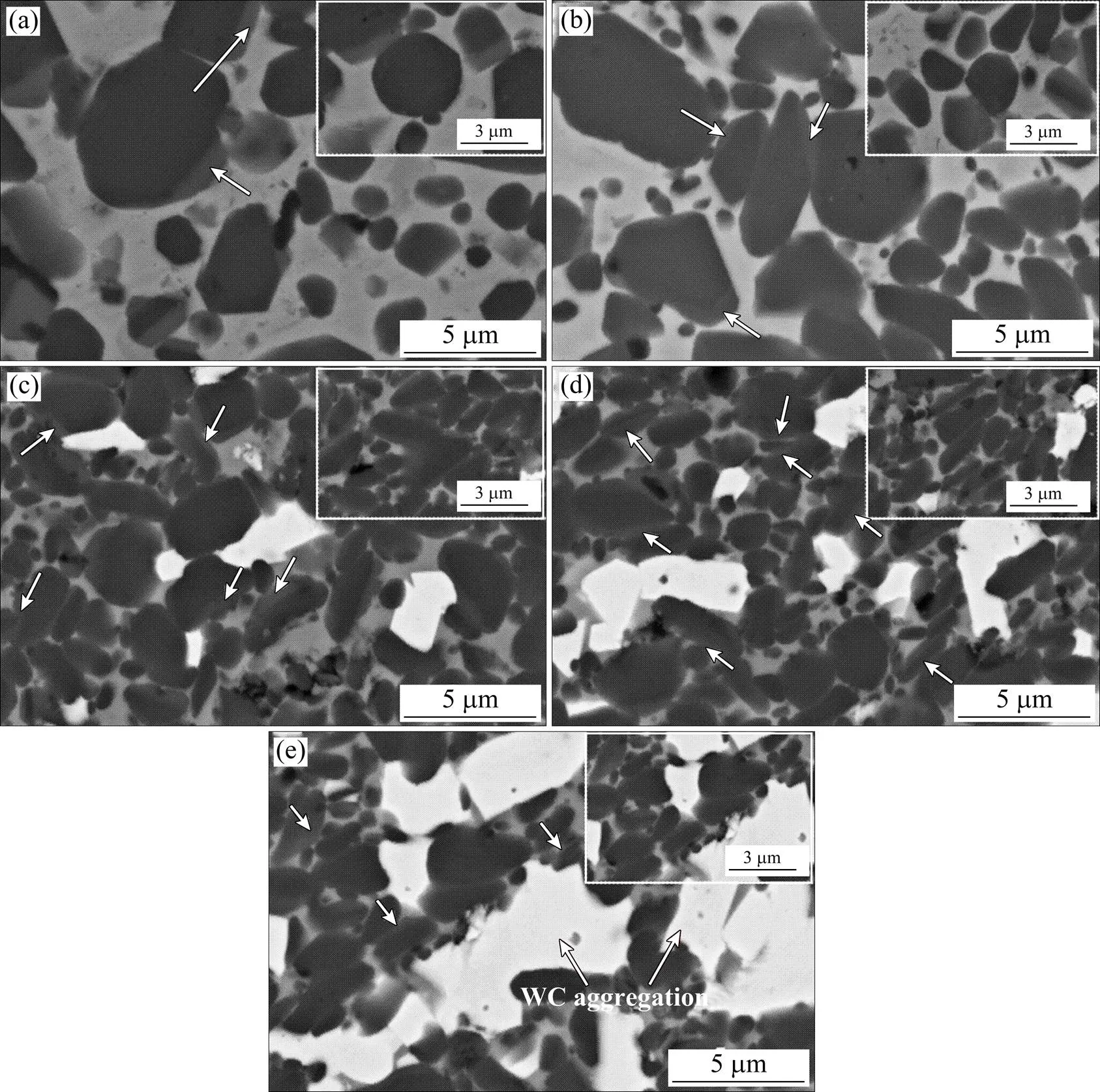

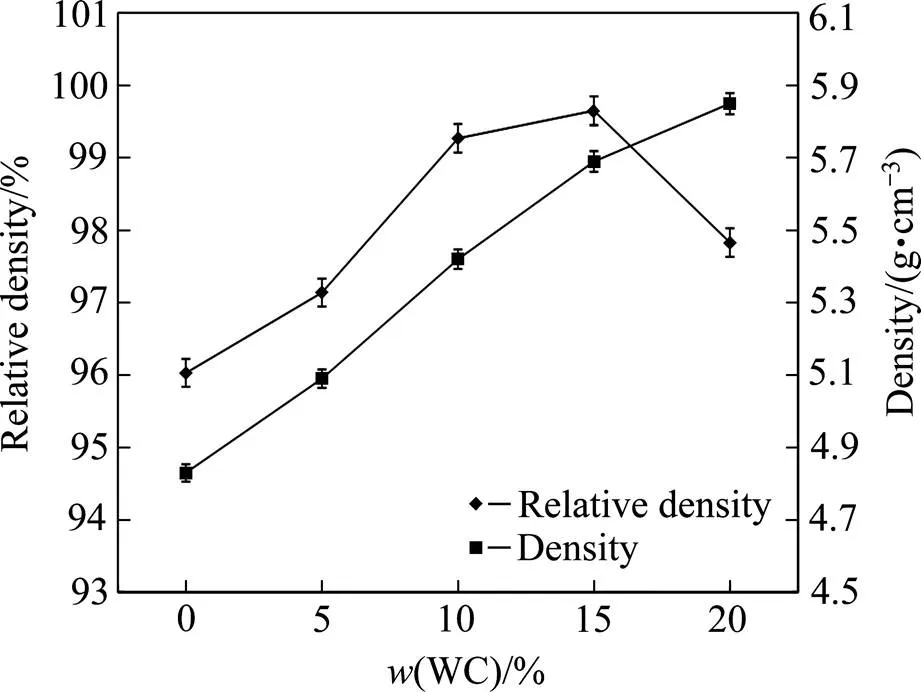

图2所示为TiB2-WC-0.8Cr3C2-20 (Co/Ni)金属陶瓷抛光表面的SEM形貌,右上角插图为高倍SEM图像。从图2看出,所有金属陶瓷中都没有明显缺陷(如较大的孔隙等)。在(WC)为0和5%的金属陶瓷中存在较明亮的Co/Ni黏结相和黑色TiB2硬质相;当(WC)增加到10%时出现白色WC相;(WC)达到15%的TiB2基金属陶瓷中,TiB2和WC晶粒分布均匀;然而当(WC)增加到20%时,WC相发生团聚(见图2(e))。从图2还看出,由于WC在Co/Ni黏结相中的溶解−析出,使得TiB2晶粒界面上包覆部分灰色相,形成金属陶瓷典型的核壳结构,如图中的白色箭头所示,该灰色相是一种固溶体相,其数量随(WC)增加而增加。图3所示为TiB2基金属陶瓷的密度和相对密度。由图可知,随(WC)从0增加到15%,金属陶瓷的相对密度迅速增大;当(WC)为15%时,相对密度为(99.65±0.20)%;而当(WC)超过15%时,TiB2基金属陶瓷的致密度显著降低,这表明添加过量WC会导致TiB2基金属陶瓷的致密度降低。

图1 TiB2-WC-0.8Cr3C2-20(Co/Ni)金属陶瓷的XRD谱

图2 TiB2-WC-0.8Cr3C2-20 (Co/Ni)金属陶瓷的SEM-BSE照片

(a)(WC)=0; (b)(WC)=5; (c)(WC)=10; (d)(WC)=15; (e)(WC)=20

图3 WC含量对TiB2基金属陶瓷密度和相对密度的影响

图4所示为TiB2晶粒的平均晶粒尺寸和晶粒尺寸分布。从图看出,随(WC)从0增加到15%,尺寸为0~1 µm的晶粒所占比例逐步增大到约43%左右,而TiB2平均晶粒尺寸从3.24 μm减小到1.31 μm;当(WC)增加至20%时,0~1 µm晶粒所占比例急剧减小至不足5%,平均晶粒尺寸增大到2.66 μm。综合以上分析,当(WC)<15%时,晶粒细化效果明显。这一结果与图2所示SEM分析结果一致。值得注意的是,含有WC的金属陶瓷中没有产生异常长大的TiB2晶粒,说明添加WC可消除TiB2晶粒异常长大的现象。WC抑制TiB2晶粒长大有以下2个方面的原因:1) TiB2在黏结相中的溶解度随WC含量增加而降低,从而使Ti和B在烧结过程中的扩散通量降低,进而延缓TiB2溶解−析出的生长过程[34]。 2) WC对基体TiB2晶粒产生强大的钉扎作用,导致烧结过程中晶界的运动迁移受到阻碍[35]。此外,还观察到随WC含量增加,TiB2晶粒形状趋于扁平化(如图(2)右上角所示),这可能是由于WC抑制TiB2晶粒的溶解−析出。从而改变TiB2晶粒的生长方向。

图4 不同WC含量的TiB2基金属陶瓷的TiB2晶粒尺寸分布

(a)(WC)=0; (b)(WC)=5%; (c)(WC)=10%; (d)(WC)=15%; (e)(WC)=20%

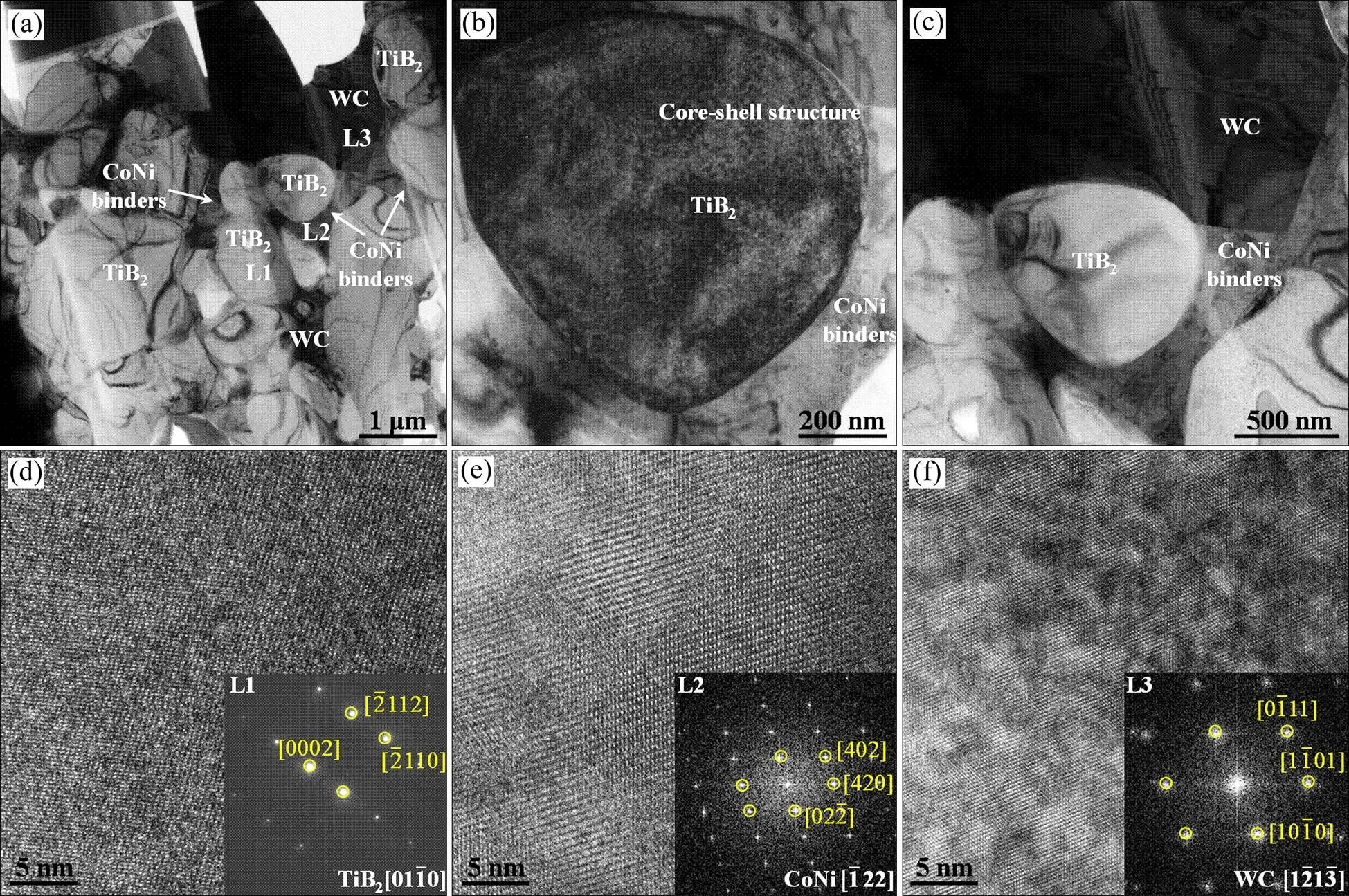

图5所示为TiB2基金属陶瓷的明场相图和选区电子衍射花样。从图5中发现L1、L2和L3等3种不同的相。选区电子衍射分析表明,L1为具有HCP结构的TiB2相,L2是FCC结构的Co/Ni粘结相,L3为HCP结构的WC相。图6所示为w(WC)为15%的 TiB2基金属陶瓷的高角环形暗场像−扫描透射电子图像。由图可见,基体相中富集Ti和B元素。而白色第二相主要含有W和C元素。此外,少量Ti、B、W和C元素溶解在黏结相中,由此清晰地观察到金属陶瓷微观组织中元素的固溶现象。

2.2 力学性能

图7所示为WC含量对TiB2基金属陶瓷硬度(HRA)和抗弯强度的影响。由图可见,TiB2基金属陶瓷的硬度随WC含量增加而增加,当(WC)为15%时达到最大硬度,HRA为92.6±0.2。当(WC)增加至20%时,硬度降低。这一方面是由于在溶解−析出过程中,不同相之间的元素相互固溶,产生明显的固溶硬化效果,从而提高材料的硬度[36]。另一方面,WC可抑制TiB2晶粒生长,随WC含量增加,晶粒细化效果明显,从而提高TiB2基金属陶瓷的硬度。然而当(WC)从15%增加到20%时,金属陶瓷硬度下降,这一方面是由于WC相的部分团聚降低其抑制TiB2晶粒生长的作用,TiB2晶粒变得粗大;另一方面是由于WC的硬度(~22 GPa)远低于TiB2的硬度(~30 GPa)[37],随WC含量增加,TiB2含量相应减少,在一定程度上导致TiB2基金属陶瓷的硬度降低。

图5 TiB2-15WC-0.8Cr3C2-20 (Co/Ni) 金属陶瓷的TEM图片

(a) Bright-filed TEM image implies the distribution of TiB2, WC and CoNi binders; (b), (c) Bright-field TEM image shows core-rim structure and distribution of WC, TiB2and CoNi binders at higher magnification; (d), (e), (f) High-resolution TEM images of L1(TiB2phase), L2 (CoNi phase) and L3(WC phase) in Fig.4(a), respectively

图6 TiB2-15WC-0.8Cr3C2-20 (Co/Ni)金属陶瓷的高角环形暗场像−扫描透射电子图像和元素面扫描图

(a) HAADF-STEM image; (b), (c), (d), (e), (f) Elemental scanning maps of Ti, B, W, C, Co and Ni , respectively

图7 WC含量对TiB2基金属陶瓷硬度和抗弯强度的影响

随WC含量增加,TiB2基金属陶瓷的抗弯强度与硬度有类似的变化。当(WC)为15%时,抗弯强度达到(1 256±30) MPa。金属陶瓷的断裂模式以及黏结剂与硬质相的结合强度对抗弯强度有很大影响。图8所示为TiB2基金属陶瓷弯曲断口形貌。由图可见金属陶瓷的主要断裂方式为穿晶断裂和沿晶断裂。沿晶断裂是一种耗能较低的脆性断裂,而穿晶断裂则耗能较高,当裂纹在陶瓷颗粒上扩展时必须克服高能势垒,这极大地阻碍了裂纹的扩展,故材料的抗弯强度高。从图8(a)看出,未添加WC的TiB2基金属陶瓷,其断裂模式主要为沿晶断裂,此外还观察到金属陶瓷的断面有明显的颗粒拔出现象,这表明未添加WC的TiB2基金属陶瓷中Co/Ni黏结相与基体TiB2陶瓷颗粒之间的结合相对较弱[38]。由此分析可知,不含WC的TiB2基金属陶瓷以沿晶断裂为主,伴随少量的晶粒拔出,因此其抗弯强度低于含有WC的TiB2基金属陶瓷。当(WC)从5%增加到15%时,晶粒拔出以及沿晶断裂减少,穿晶断裂增加,如图8(b)~(d)所示。(WC)为10%和15%的TiB2基金属陶瓷的抗弯强度较高,这是由于其主要的断裂方式均为穿晶断裂。另外,从图2可知添加一定量的WC能阻碍TiB2基体与Co/Ni黏结相发生反应,从而提高不同相之间的结合强度[36]。此外,加入WC使金属陶瓷的晶粒分布更加均匀,产生晶粒细化,从而提高金属陶瓷的抗弯强度。当(WC)增加到20%时,在TiB2基金属陶瓷中的晶间断裂和晶粒拔出再次占据主导地位(见图8(e))。这是由于部分WC发生团聚,金属陶瓷各组分间的结合力降低并生成脱碳相W2C,导致金属陶瓷的抗弯强度降低。

3 结论

1)采用气压烧结法制备TiB2-WC-0.8Cr3C2-20 (Co/Ni) (质量分数,%)金属陶瓷,随WC质量分数从0增加至20%,金属陶瓷的硬度(HRA)和抗弯强度先升高后降低。当(WC)为15%时,TiB2基金属陶瓷的综合性能最佳,抗弯强度为(1 256±30) MPa,HRA为92.6±0.20。

图8 TiB2-xWC-0.8Cr3C2-20 (Co/Ni)金属陶瓷的弯曲断口SEM形貌

(a)=0; (b)=5; (c)=10; (d)=15; (e)=20

2) WC的加入使TiB2晶粒分布更均匀,晶粒更细小,从而提高金属陶瓷的硬度和抗弯强度。但过量的WC会导致TiB2基金属陶瓷性能下降。

[1] 李苏, 李俊寿, 赵芳, 等. TiB2材料的研究现状[J]. 材料导报, 2013, 5(5): 34−38.

LI Su, LI Junshou, ZHAO Fang, et al. Research status of TiB2materials[J]. Materials Guide, 2013, 5(5): 34−38.

[2] BASU B, RAJU GB, SURI AK. Processing and properties of monolithic TiB2based materials[J]. International Materials Reviews, 2006, 51(6): 354−374.

[3] SUBRAMANIAN C, SURI AK. Development of boron based neutron absorber materials[J]. Met Mater Process, 2004, 16(1): 39–52.

[4] MURTHY T S R Ch, SONBER J K, SUBRAMANIAN C, et al. Densification and oxidation behavior of a novel TiB2-MoSi2-CrB2composite[J]. International Journal of Refractory Metals & Hard Materials, 2013, 36: 243−253.

[5] WU N, XUE F D, WANG J Y, et al. Effect of TiN addition on the microstructure and mechanical properties of TiB2-FeNi based cermets[J]. Materials Science and Engineering A, 2019, 743: 546−557.

[6] EINARSURD M A, HAGEN E, PETTERSE G, et al. Pressureless sintering of titanium diboride with nickel, nickel boride, and iron additives[J]. Journal of the American Ceramic Society, 2005, 80(12): 3013−3020.

[7] 安晶. TiB2基增韧补强型陶瓷刀具的制备工艺及性能研究[D].太原: 太原理工大学, 2018.

AN Jing. Study on preparation process and properties of TiB2-based toughening and reinforcing ceramic tool[D]. Taiyuan: Taiyuan University of Technology, 2018.

[8] BAIK S, BECHER P F. Effect of oxygen contamination on densification of TiB2[J]. Journal of the American Ceramic Societ, 2010, 70(8): 527–530.

[9] WANG W M, FU Z Y, WANG H, YUAN R Z. Influence of hot pressing sintering temperature and time on microstructure and mechanical properties of TiB2ceramics[J]. Journal of the European Ceramic Society, 2002, 22(7): 1045−1049.

[10] HEIDARI H, ALAMDARI H, DUBE D, et al. Interaction of molten aluminum with porous TiB2-based ceramics containing Ti-Fe additives[J]. Journal of the European Ceramic Society, 2012, 32(4): 937−945.

[11] NGUYEN V H, SHAHEDI A M, HAMIDZADEH M Z, et al. Role of co-addition of BN and SiC on microstructure of TiB2-based composites densified by SPS method[J]. Ceramics International, 2020, 46(16): 25341−25350.

[12] GHAFURI F, AHMADIAN M, EMADI R, et al. Effects of SPS parameters on the densification and mechanical properties of TiB2-SiC composite[J]. Ceramics International, 2019,45(8): 10550–10557.

[13] YAN S R, LYU Z, FOONG L K. Effects of SiC amount and morphology on the properties of TiB2-based composites sintered by hot-pressing[J]. Ceramics International, 2020,46(11): 18813– 18825.

[14] MA L, YU J C, GUO X, et al. Preparation and sintering of ultrafine TiB2powders[J]. Ceramics International, 2018, 44(4): 4491−4495.

[15] RAN S L, VAN der B O, VLEUGELS J. In situ platelet-toughened TiB2-SiC composites prepared by reactive pulsed electric current sintering[J]. Scripta Materialia, 2011, 64(12): 1145−1148.

[16] LI L H, KIM H E, SON K E. Sintering and mechanical properties of titanium diboride with aluminum nitride as a sintering aid[J]. Journal of the European Ceramic Society, 2002, 22(6): 973−977.

[17] 郭峰, 李历坚. TiB2基陶瓷材料的研发进展与展望[J]. 粉末冶金材料科学与工程, 2009, 14(5): 285−289.

GUO Feng, LI Lijian. Development and prospect of TiB2based ceramic materials[J]. Powder Metallurgy Materials Science and Engineering, 2009, 14(5): 285−289.

[18] SRIVATSAN T S, GURUPRASAD G, BLACK D, et al. Microstructural development and hardness of TiB2-B4C composite samples: Influence of consolidation temperature[J]. Journal of Alloys and Compounds, 2006, 413(1): 63−72.

[19] GU M L, HUANG C Z, XIAO S R, et al. Improvements in mechanical properties of TiB2ceramics tool materials by the dispersion of Al2O3particles[J]. Materials Science and Engineering A, 2007, 486(1): 167−170.

[20] MURTHY TAMMANA S R, BASU B, BALASUBRAMANIAM R, et al. Processing and properties of TiB2with MoSi2sinter-additive: A first report[J]. Journal of the American Ceramic Society, 2010, 89(1): 131−138.

[21] WANG S W, ZHENG Y, ZHANG G T, et al. Effect of NbC addition on the microstructure, mechanical properties and thermal shock resistance of Ti(C,N)-based cermets[J]. Materials Research Express, 2019,6(5): 056557.

[22] KANG S H, KIM D J, KANG E S, et al. Pressureless sintering and properties of titanium diboride ceramics containing chromium and iron[J]. Journal of the American Ceramic Society, 2010, 84(4): 893−895.

[23] 周书助, 汤郡, 尹绍峰, 等. TiB2基硬质材料的研究进展[J]. 硬质合金, 2016, 33(6): 428−436.

ZHOU Shuzhu, TANG Jun, YIN Shaofeng, et al. Research progress of TiB2based cemented carbide[J]. Cemented Carbide, 2016, 33(6): 428−436.

[24] WAN W C, XIONG J, GUO Z X, et al. Effects of Cr3C2addition on the corrosion behavior of Ti(C,N)-based cermets[J]. International Journal of Refractory Metals & Hard Materials, 2013, 39(6): 6019−6028.

[25] ZHAN B, LIU N, JIN Z B, et al. Effect of VC/Cr3C2on microstructure and mechanical properties of Ti(C,N)-based cermets[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(5): 1096−1105.

[26] PING Feng, HE Yuehui, et al. Effect of VC addition on sinterability and microstructure of ultrafine Ti(C,N)-based cermets in spark plasma sintering[J]. Journal of Alloys and Compounds, 2008, 460(1/2): 453−459.

[27] ZHENG Y, YOU M, XIONG W, et al. Effect of Cr3C2on valence-electron structure and plasticity of rim phase in Ti(C,N)-based cermets[J]. Journal of the American Ceramic Society, 2010, 87(3): 460−464.

[28] HUANG J H, HUANG S G, ZHOU P, et al. Microstructure and mechanical properties of WC or Mo2C modified NbC-Ni cermets[J]. International Journal of Refractory Metals and Hard Materials, 2020, 95(2): 105440.

[29] WALTER L, FABIO S. Ti(C,N)-based cermets: critical review of achievements and recent developments[J]. Solid State Phenom, 2018, 274: 53−100.

[30] WANG H, WANG B, LI S, et al. Toughening magnetron sputtered TiB2coatings by Ni addition[J]. Surface & Coatings Technology, 2013, 232: 767−774.

[31] ZHAO Y, HUANG C Z, ZOUB, et al. Effects of sintering processes on mechanical properties and microstructure of TiB2-TiC+8% nano-Ni composite ceramic cutting tool material[J]. Materials Science & Engineering A, 2012, 540: 235– 244.

[32] PENG Y, MIAO H, PENG Z. Development of TiCN-based cermets: Mechanical properties and wear mechanism[J]. International Journal of Refractory Metals & Hard Materials, 2013, 39(7): 78−89.

[33] ZENG W M, GAN X P, LI Z Y, et al. Effect of WC addition on the microstructure and mechanical properties of TiN-based cermets[J]. Ceramics International, 2017, 43(1): 167– 173.

[34] 史晓亮, 邵刚勤, 段兴龙, 等. 超细硬质合金晶粒生长抑制剂VC、Cr3C2作用机理的研究[J]. 硬质合金, 2006, 23(4): 193− 197.

SHI Xiaoliang, SHAO Gangqin, DUAN Xinglong, et al. Study on the mechanism of VC and Cr3C2in ultrafine cemented carbide[J]. Cemented Carbide, 2006, 23(4): 193−197.

[35] ABBAS S N, ZOHRE A, AZIZ B, et al. Microstructure and thermomechanical characteristics of spark plasma sintered TiC ceramics doped with nano-sized WC[J]. Ceramics International, 2019, 45(2): 2153−2160.

[36] SHANKAR E, BALASIVANANDHA PRABU S. Influence of WC and cobalt additions on the microstructural and mechanical properties of TiCN-Cr3C2-nano-TiB2cermets fabricated by spark plasma sintering[J]. International Journal of Refractory Metals and Hard Materials, 2017, 69: 110−118.

[37] JI W, ZHANG J, WANG W, et al. Fabrication and properties of TiB2-based cermets by spark plasma sintering with CoCrFeNiTiAl high-entropy alloy as sintering aid[J]. Journal of the European Ceramic Society, 2015, 35(3): 879−886.

[38] MUKHOPADHYAY A, VENKATESWARAN T, BASU B. Spark plasma sintering may lead to phase instability and inferior mechanical properties: A case study with TiB2[J]. Scripta Materialia, 2013, 69(2):159−164.

Effects of WC content on the microstructure and mechanical properties of TiB2-based cermets

WANG Shuai1, WANG Jianying1, LOU Jia2, WANG Jiong1, ZHANG Xiang1, YANG Hailin1

(1. State Key Laboratory of powder metallurgy, Central South University, Changsha 410083, China; 2. School of materials science and engineering, Xiangtan University, Xiangtan 411105, China)

The TiB2-WC-0.8Cr3C2-20(Co/Ni) (mass fraction, %) cermets ((WC) are 0−20%) with high-density were prepared by powder metallurgy (P/M) method. The effects of WC content on the microstructure and mechanical properties of TiB2-based cermets were investigated. The results indicate that with the increase of WC content, the solubility of TiB2in the bonded phase decreases, and the TiB2/ bonded phase interface decreases, which makes the grains of TiB2based cermets finer and more uniform. In addition, the addition of WC can significantly improve the mechanical properties of TiB2based cermets. When(WC) is 15%, the properties of cermets are the best, and the hardness (HRA), bending strength and relative density reach 92.6±0.2, (1 256±65) MPa and (99.65±0.20)%, respectively. However, the addition of excessive WC (20%) will lead to the partial agglomeration of WC phase and the formation of decarburized phase W2C, which will reduce the mechanical properties of TiB2based cermets.

mechanical properties; microstructure; TiB2-based cermet; WC addition; grain refinement

TG148

A

1673-0224(2021)04-298-08

2021−02−22;

2021−03−10

杨海林,副教授,博士。E-mail: y-hailin@csu.edu.cn

(编辑 汤金芝)