Flexible transparent wood enabled by epoxy resin and ethylene glycol diglycidyl ether

2021-07-15HangchuanCaiZhiqiWangDiXiePanpanZhaoJianpingSunDaoyuQinFangchaoCheng

Hangchuan Cai·Zhiqi Wang·Di Xie·Panpan Zhao·Jianping Sun·Daoyu Qin·Fangchao Cheng

Abstract Transparent wood has potential application in intelligent building,solar cell,electronics,and other advanced materials,while its single functionability hinders its further development.Flexible transparent wood (FTW)was prepared by alkaline pretreatment and bleaching treatment of paulownia wood followed by impregnation of epoxy resin and ethylene glycol diglycidyl ether (EDGE).The effect of delignification degree on the optical and mechanical properties of FTW was studied,and the influence of the epoxy/EDGE ratio on the flexibility and mechanical properties of FTW was also investigated.The results showed that higher delignification degree resulted in higher transmittance of FTW.More EDGE addition led to better flexibility of FTW,while overmuch addition of EDGE will reduce the mechanical properties.The optimal FTW sample resulted in a high transmittance of 89% and an ultrahigh haze value of 97% with outstanding flexibility and excellent mechanical properties.The investigation of FTW broadens the research field of transparent wood,and provides great possibility for its application in flexible wearable devices and flexible materials.

Keywords Transparent wood·Epoxy resin·Ethylene glycol diglycidyl ether·Flexibility

Introduction

As a natural and sustainable material,wood plays an extremely important role in the field of materials due to its low price,tractability,environmental friendliness,sustainability and other advantages (Xiao et al.2019).In recent years,transparent wood,as a new type of wood-based material,has attracted much attention of the society,because it exhibits a combination of high transmittance and haze,outstanding toughness,low thermal conductivity,low density,anisotropic optical and mechanical performance (Montanari et al.2019).Transparent wood can be used to produce building materials (Brischke et al.2012;Li et al.2016a;Yaddanapudi et al.2017),solar cells (Jia et al.2017) and magnetic materials (Gan et al.2017a).In particular,due to its promising transmittance,haze and thermal insulation,transparent wood shows great application potential in intelligent buildings (Yu et al.2017).The directional channels derived from the natural porous structure of wood endow the transparent wood with unique light guiding effects (Li et al.2016a).Consequently,transparent wood can be used as the alternate building materials for roofs and windows to provide a bright and private space (Yaddanapudi et al.2017).

To prepare transparent wood,it is usually needed to remove lignin to increase transparency (Li et al.2018).There are many delignification processes including oxidation,chemical modification and enzymatic hydrolysis.Among them,most of the oxidation method usually employ hypochlorous acid (Gan et al.2017b) or sodium chlorite(Yaddanapudi et al.2017) as the oxidant.During the oxidation treatment,the benzoquinone structure and the conjugate double bond of side chain in lignin are oxidized,and lignin is eventually dissolved in water (Tong et al.2000).Qin et al.(2018) delignified balsa wood and basswood with NaClO2(1%) at 80 °C followed by the treatment with H2O2(5 mol L−1) at 90 °C.The as-prepared laminated transparent wood with structures showed high transmittance of 90% and excellent mechanical properties.In the chemical purification method,wood is mainly treated by alkaline sodium sulfite and the mechanism is introducing a sulfonic acid group into the side chain of the benzene ring to make lignin soluble in water,which can lead to highly transparent wood (Bi et al.2018).Zhu et al.(2016) remove the lignin of basswood with 2.5 mol L−1NaOH and 0.4 mol L−1Na2SO3at 100 °C for 12 h,and bleached the delignified wood with 2.5 mol L−1H2O2.The transparent wood was then prepared by combining chemically modified basswood with polymethyl methacrylate (PMMA),leading to a high transmittance of more than 90%.The enzymatic hydrolysis,as an environmentally friendly method,can used for the de-colorization of wood(Cullis and Mansfield 2010),and the transparent wood preparation with the enzymatic strategy still remain to be explored.The general procedures of lignin removal during the transparent wood preparation process involves the utilization of strong oxidants,thus it is necessary to optimize the delignification process and shorten it as much as possible.

Another key issue in the preparation of transparent wood is the selection of resin.In order to prevent the refraction and scattering of light at the interface of different media,the impregnated resin should have high transparency,and its refractive index should match with that of wood (Zhu et al.2016).Most of the transparent wood was prepared by impregnating wood with PMMA (Bi et al.2018) and epoxy resin (Qin et al.2018).Gan et al.(2017b) produced luminous transparent wood by removing lignin with sodium chlorite and immersing the delignified wood in the mixture of PMMA and 2,2′-azo(2-)methylpropanitrile for prepolymerization.Li et al.(2016a) prepared transparent wood as an energy efficient building material using chemical purified basswood and epoxy resin,resulting in high optical transparency (> 85%),broadband optical haze (> 95%),and excellent thermal insulation with a thermal conductivity of about 0.32 m W−1K−1along the growth direction of wood.Epoxy resin and PMMA have played great roles in the preparation of transparent wood,while their disadvantages,e.g.high viscosity and many curing requirements,restrict the functionality of transparent wood,which is of great importance to broaden the application field of transparent wood.Therefore,transparent wood needs to be endowed with more functions in the preparation process,such as flexibility(Subba Rao et al.2019).

Ethylene glycol diglycidyl ether (EDGE),as an important fine chemical intermediate,contains two highly active epoxy groups at the ends of the molecular chain,which can react with hydroxyl,amino and other groups (Wang et al.2002).EDGE has been mainly used for active diluting of epoxy resin,fabric finishing,resin modification,and cross-linking of natural polymers (Wizeman and Kof inas 2001;Zhang et al.2009;Tanabe et al.2004).In view of the above problems,EDGE was introduced into the epoxy resin system to prepare flexible transparent wood (FTW).Through regulating the treatment intensity and the ratio of epoxy resin to EDGE,the optimal FTW showed excellent mechanical properties,high flexibility,promising transmittance,and effective absorption of ultraviolet light.During the preparation process,hemicellulose and lignin were effectively separated by KOH and NaClO2treatment respectively,the pores in wood were filled with epoxy resin and EDGE,and the transparent wood was endowed with flexibility to form a solid transparent light transmission medium.The numerous advantages of FTW in this study make it an important material to apply in architecture,furniture,solar cells and wearable electronics.

Materials and methods

Materials

The paulownia wood (Paulownia fortune(Seem.) Hemsl.)with the density of 0.32 g cm−3were purchased from Dingkai Forestry Co.LTD,Guangxi Province,China,and cut into samples with dimensions of 150 mm × 50 mm × 20 mm.The chemicals (sodium chlorite,potassium hydroxide,ethanol,glacial acetic acid,sodium hydroxide,and 98% sulfuric acid) were purchased from Shanghai Aladdin Biochemical Technology Co.,LTD,China.Bisphenol A epoxy resin was provided by Yichun Xingda Chemical Factory;curing agent D230 was purchased from Changzhou Runxiang Chemical Co.,Ltd.;EDGE was received from Saan Chemical Technology (Shanghai) Co.,Ltd.

FTW preparation

Alkali pretreatment

The dried wood samples were submerged in 2.5 M KOH solution (100 mL) at 90 °C for 8 h.The treated sample was washed with distilled water until neutral and stored in distilled water.

Delignification treatment

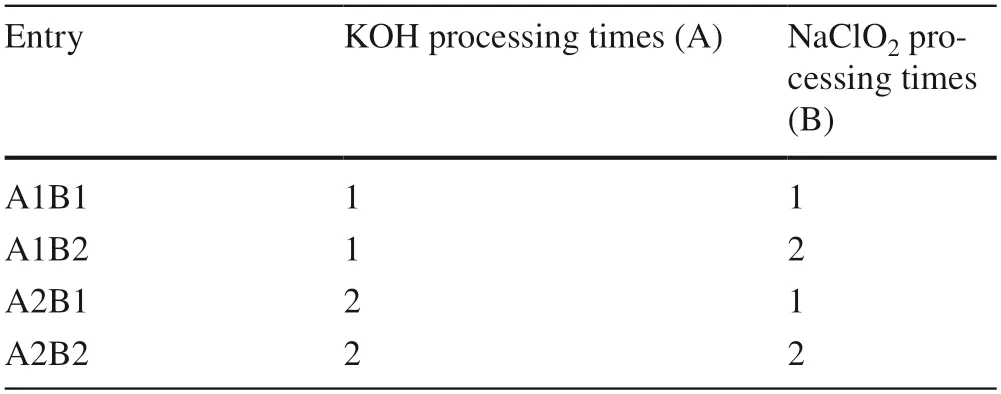

The sample after alkaline pretreatment was bleached by sodium chlorite (130 mL solution containing 1.4 g sodium chlorite and 1 mL glacial acetic acid) at 75 °C for 8 h.During this period,1.4 g sodium chlorite and 1 mL glacial acetic acid were added every 1 h,and then,the treated samples were washed with distilled water until neutral and stored in anhydrous ethanol.In this study,different treatment conditions of delignification processes were selected to achieve different delignification degree,as shown in Table 1.

Table 1 Different treatment conditions of delignification processes

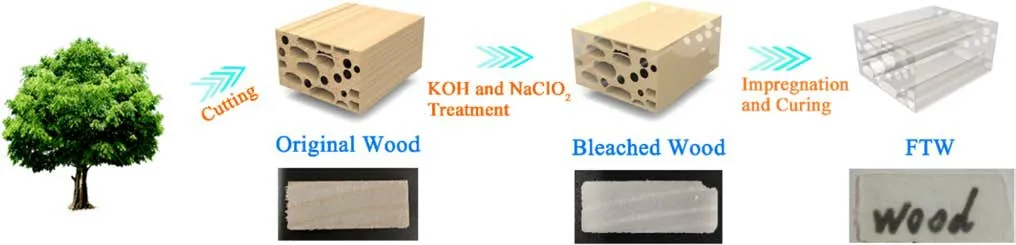

Impregnation process

Bleached wood sample was filtrated under vacuum for 2 min to remove the ethanol in it,and then put into different proportions of impregnation solution (epoxy resin,curing agent,and EDGE) at −0.08 MPa for 30 min.The ratio of epoxy resin to curing agent was fixed at 3:1 and the ratio of epoxy resin to EGDE was varied.The above procedure was repeated three times,and the samples was taken out and flipped each time to achieve uniform resin impregnation.The sample was then taken out,wrapped with aluminum foil.After clamping with two glass plates,the sample was placed horizontally at room temperature and cured for 24 h.The preparation processes for FTW is summarized in Fig.1.

Fig.1 Schematic diagram of the preparation processes of FTW

Characterizations

Lignin content analysis

The previous method was used to determine the lignin content (Cheng et al.2019).Brief ly,0.1 g of dried wood sample was treated with 2 mL 72% H2SO4for 2 h.The solution was refluxed for 4 h after diluted to 3%.The acid insoluble lignin was weighed after drying,and the acid soluble lignin was then determined by UV spectrum at 205 nm.

Fourier transform infrared (FT-IR) analysis

The chemical structures of original wood,bleached wood and FTW were characterized using a Nicolet iS.50 V FT-IR spectrometer (Waltham,Massachusetts,USA) with the attenuated total reflection (ATR) technique.The FT-IR spectra were collected through 16 scans at a resolution of 4 cm−1over the range from 400 to 4000 cm−1.

Scanning electron microscopy (SEM)

The morphologies of original wood,bleached wood and FTW were analyzed using a Hitachi S-3400N SEM (Tokyo,Japan).SEM images were recorded with an accelerating voltage of 5–20 kV.All samples were coated with gold before SEM measurements.

Ultraviolet–visible (UV/Vis) spectroscopy analysis

The transmittance of all samples was measured using a PerkinElmer Lambda 950 spectrophotometer (Shelton,Connecticut,USA) with a wavelength ranging from 250 to 800 nm.

Haze determination

The haze value of the FTW sample in the visible region was determined using a Suga HZ-V3 haze meter (Takahagi,Japan) with the double beam method.

Mechanical properties

The tensile test of t he FT W samples(50 mm × 20 mm+2 mm) was performed at a SUNS CMT5504 universal mechanical testing machine (Shenzhen,China) at 25 °C with a loading speed of 2 mm min−1.

Results and discussion

Lignin content and transparency of bleached wood

In this study,paulownia wood was employed as raw materials,because of its high cellulose content,light color,fast growth and low bulk density.In order to investigate the effect of treatment intensity on the delignification efficiency,the lignin content of the bleached wood samples were compared.It is found that increased treatment intensity led to decreased lignin content (Fig.2 a).The A1B1 condition resulted in a lignin content of 9%,and further treatment can give a lignin content of about 6%.The A2B2 condition led to the lowest lignin content.The digital photographs of bleached wood samples indicated that both alkali treatment and bleaching treatment can increase the transparency(Fig.2 b).The transparency of A2B1 sample was better than that of A1B2 sample,which revealed that NaClO2treatment of wood was superior to KOH treatment in lignin removal(Fig.2 b).KOH treatment can remove a certain amount of lignin,while NaClO2treatment can effectively promote ringopening reaction and make most of lignin dissolved in the water (Tang et al.2018).

Fig.2 Results of bleached wood under different treatment conditions:a lignin content and b digital photographs

Effect of treatment intensity on the optical and mechanical properties of FTW

After removing hemicellulose and lignin and impregnating epoxy resin and EDGE,the as-prepared FTW samples presented varied color and transparency (Fig.3 a).It is obvious that the treatment intensity greatly influenced the apparent color and transparency,and higher intensity led to lighter color and higher transparency.The phenomenon should be mainly attributed to the removal of lignin and hemicellulose during the treatment (Wang et al.2019).High-intensity treatment can remove most of lignin and hemicellulose,thus decolorizing the sample and providing plenty of pores for resin permeability.

UV/Vis spectra of FTW prepared with different treatment intensities also confirmed the influence of treatment intensity on the transmittance (Fig.3 b),and the transmittance of FTW samples increased with the increase of treatment intensity.Both of the transmittance of the A2B2 and A1B2 samples can reach 89% at 600 nm,which was equivalent to the reported transmittance of transparent wood (Li et al.2018;Wu et al.2019).FTW presented a very low transmittance in UV region,revealing the ability of FTW to absorb UV light.Excellent transparency makes transparent wood have great application potential in solar cell,green sustainable lighting,electronic display screen and other fields (Li et al.2018).The FTW samples prepared with different treatment conditions exhibited ultrahigh haze values of more than 94%,and the treatment condition showed limited influence on the haze of FTW (Fig.3 c).A2B2 sample gave a highest haze value of 95.4% in the visible region,which was comparable to that of the reported transparent wood prepared with basswood and epoxy resin (Li et al.2016a).

The tensile strength across the grain were determined to investigate the effect of treatment intensity on the mechanical properties of FTW (Fig.3 d).The original paulownia wood had a tensile strength of 2.98 MPa,and the tensile strengths of FTW samples were greater than that of the original wood except the A2B1 sample.The A2B2 sample prepared with the highest treatment intensity showed the highest tensile strength among all samples (3.74 MPa).After the KOH and delignification treatment,the well-developed porosity of wood cell wall enhanced the resin permeation(Gan et al.2017b).The mechanical properties of wood are anisotropic,and it shows a poor tensile strength across the grain,which is much lower than that of the cured epoxy resin(Cao et al.2003).Consequently,the effective permeation of epoxy resin can lead to a higher tensile strength of FTW thanthat of the original wood.The tensile strength of the A2B1 sample was lower than that of the original wood,which may be caused by the incomplete resin filling under this condition.By comparing the tensile strength of the A1B2 and A2B1 samples (Fig.3 d),it can be found that the influence of alkali treatment on the mechanical properties was larger than that of the bleaching treatment.

Fig.3 Results of FTW samples with different treatment conditions:a the digital photographs,b UV/Vis spectra,c Haze results,and d tensile strength results

Effect of EGDE content on the transparency,flexibility,and mechanical properties of FTW

For the preparation of transparent wood,the impregnated resin should have a high transparency,and its refractive index should match that of the wood matrix in order to prevent the refraction and scattering of light at the interface of different media (Zhu et al.2016).It is worth noting that the refractive index of epoxy resin is 1.50,and that of EGDE is 1.46,which is similar to that of cellulose 1.53.Besides,both of them are colorless and transparent,thus it is suitable to use epoxy resin and EGDE system to prepare FTW.In this study,EGDE was used as the reactive diluent of epoxy resin to regulate the flexibility of transparent wood.

The digital photographs of FTW samples with different epoxy/EDGE ratios indicated that the color of the sample gradually turned yellow and the transparency decreased with the adding amount of EGDE increased (Fig.4 a).In addition,the EDGE content played an important role on the flexibility of FTW samples (Fig.4 b).FTW prepared with pure EDGE exhibited a light yellow color,which led to low transparency of FTW.As the EDGE content decreased,both of the transparency and flexibility were improved.FTW samples prepared with the epoxy/EDGE ratios of 4:1 and 5:1 showed high transparency and excellent flexibility.The ultimate bending angle of FTW sample increased as the EDGE content decreased (Fig.4 b).FTW prepared with an epoxy/EDGE ratio of 5:1 exhibited an ultimate bending angle can reach nearly 180°.Similar results have been reported that appropriate addition of active diluent (usually 5–10% in weight) can improve the toughness of epoxy resin (Varley 2004),while excessive addition may lead to decreased performance.The reason should be that appropriate EDGE addition can introduce flexible molecular chains to the epoxy network and increase the flexibility of the resin system,while further addition of EDGE may result in more number of flexible chain networks,which in turn yielded negative influence on the cross-linking density and mechanical properties of the epoxy resin (Sinha et al.2018).

Fig.4 Results of FTW samples prepared with different epoxy/EDGE ratios:a digital photographs,b a comparison of flexibility,c UV/Vis spectra;d haze results;e comparisons of the optical properties of the reported and present sample:basswood/epoxy (Li et al.2017),balsa/epoxy (Qin et al.2018),and poplar/polyvinyl alcohol (PVA)/ propylene glycol (PG) (Subba Rao et al.2019);ftensile strength results

The UV/Vis spectra of FTW prepared with different epoxy/EDGE ratios confirmed the influence of EDGE addition on the transmittance of FTW (Fig.4 c).FTW prepared with pure EDGE exhibited a relatively low transmittance around 65% in the visible region,and the transmittance of FTW increased to more than 85% as the epoxy/EDGE ratio decreased,which indicated the negative influence of EDGE on the transparency of FTW.However,EDGE addition showed limited influence on the haze value of FTW(Fig.4 d),and various FTW samples gave ultrahigh haze values (up to 97%).The ultrahigh haze value of FTW was mainly attributed to the directional porous structure of wood(Zhu et al.2016),and the transparent matrix played a limited role on the haze.The optical properties of FTW were also compared with those of the reported transparent wood (Li et al.2016a;Qin et al.2018;Subba Rao et al.2019).The transmittance and haze of the present FTW were comparable to those of the reported transparent wood prepared with epoxy and various species of wood (Fig.4 e),and the present FTW showed slightly better optical properties than those of the reported FTW prepared with PVA and PG,which should be mainly due to the different matrix resins.

FTW samples were prepared based on the A2B2 bleached wood with various ratios of epoxy resin to EGDE to investigate the effect of EGDE content on the mechanical properties of FTW.The results of tensile test across the grain showed that the increase of EDGE addition can decrease the mechanical properties of the FTW sample,and an appropriate epoxy/EDGE ratio ranging from 5:1 to 3:1 can lead to better tensile strength than that of the original wood(Fig.4 f).The sample prepared with the epoxy/EDGE ratio of 4:1 gave the highest tensile strength of 3.74 MPa.The tensile strength decreased with the increase of EGDE content,and FTW prepared with the pure EGDE had the lowest tensile strength of 2.03 MPa.It is found that the present FTW exhibited a lower tensile strength than that of the reported transparent wood (6.0 MPa) prepared with balsa wood and epoxy resin (Qin et al.2018).This should be mainly because the addition of EDGE led to the strength reduction of the epoxy resin.At the same time,the purified wood sample was stored in ethanol,and the residual ethanol in wood may affect the crosslinking density during the curing process of the epoxy resin.

EDGE endowed transparent wood with flexibility,but it cannot provide sufficient strength to transparent wood.Epoxy resin shows high rigidity after curing,which can enhance the mechanical properties of transparent wood(Qin et al.2018).Therefore,appropriate epoxy/EDGE ratio should be selected to achieve a balance between flexibility and mechanical properties.For example,the epoxy/EDGE ratios of 4:1 and 5:1 resulted in high transparency,promising flexibility and excellent strength,and resulted in FTW samples with balanced properties.

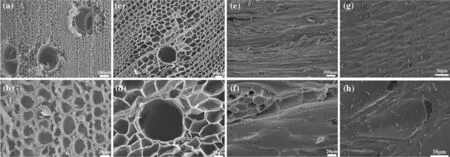

Morphology analysis

The morphology analysis of the original and bleached wood and FTW was carried out through the SEM observation (Fig.5).Compared with the original wood,the cell wall of bleached wood became thinner,and the cell lumen became larger after the delignification process (Fig.5 a–d).The changes were mainly attributed to the effective removal of hemicellulose and lignin.The removal of hemicellulose and lignin can increase the porosity of the wood and enhance the resin impregnation.The SEM images of the longitudinal section and cross section of FTW indicated that the epoxy resin had been completely impregnated into the wood cell lumens and closely bound to the cell wall (Fig.5 e–h),leading to much thicker cell wall structures of FTW than those of the bleached wood.Wood is mainly composed of cellulose,hemicellulose and lignin.Both cellulose and hemicellulose are polysaccharides,and lignin is a 3-dimensional amorphous polyphenol macromolecule (Schwanninger et al.2004).Lignin is mainly located on the surface of the cellulosic microfibril,thus the cell wall will become thinner after removal of lignin (Li et al.2016b;Song et al.2017).The generated pores after removal of lignin and hemicellulose allowed the resin to impregnate into the wood cells and connect with the cellulose skeleton.

Fig.5 SEM images of different samples:a,b paulownia wood sample,c,d bleached wood,e,flongitudinal section of FTW,g,h cross section of FTW

FT-IR analysis

The chemical structure of original wood,bleached wood and FTW were compared through FT-IR analysis (Fig.6).In the spectra,the peak at 3340 cm−1was attributed to the O–H stretching vibration and hydrogen bonding,and the peak at 2900 cm−1was attributed to the C–H symmetrical stretching,both of which were the characteristic absorption peak of cellulose (Schwanninger et al.2004).The band at 1732 cm−1was attributed to the acetyl group in hemicellulose,the benzene ring skeleton vibration bands at 1592 cm−1and 1506 cm−1were the characteristic absorption peaks of lignin (Tjeerdsma and Militz 2005),and the bands at 1244,921,and 827 cm−1in the fingerprint region were attributed to the epoxy group (Meure et al.2010).Compared with the original wood spectrum,the characteristic peaks at 3340 and 2900 cm−1for the bleached wood showed no significant change in the intensity,and it indicated that the cellulose structure and the original wood structure of the bleached wood was preserved after the treatment,which was in accordance with the SEM results.Different from the original and bleached wood,the O–H stretching band in the spectrum of FTW shifted to 3400 cm−1with an increased intensity,which indicated the change of hydrogen bonding network during the preparation process of FTW.Additionally,the characteristic peaks for hemicellulose and lignin at 1732,1592 and 1506 cm−1almost disappeared after the KOH and delignification process,which confirmed the effective removal of hemicellulose and lignin.

Fig.6 FT-IR spectra of original wood (OW),bleached wood (BW)and FTW

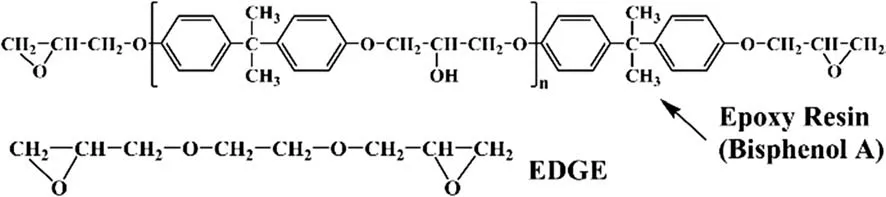

The chemical formulas of epoxy and EDGE presented their main functional groups,such as the epoxy group(Fig.7).The characteristic peak of the epoxy group at 1244,921,and 827 cm−1in the spectrum of FTW indicated that epoxy resin was impregnated into the pores of the transparent wood.The bands at 1005,1035 and 1180 cm−1were attributed to C–O stretching vibration in epoxy and EDGE (Jawad et al.2019;Abdulhameed et al.2019),which can produce different displacement according to different degrees of coupling.All these result indicated that the original chemical structure wood was partially preserved during the preparation of FTW,and epoxy and EDGE were successfully combined with the wood components in FTW.

Fig.7 Chemical formulas of epoxy resin and EGDE

Conclusion

The preparation process of FTW was optimized by regulating the delignification degree and the epoxy/EDGE ratio.Both the delignification level and the addition amount of EDGE greatly influenced the flexibility as well as the optical and mechanical properties of FTW.The optimal FTW showed high tensile strength of up to 3.74 MPa and outstanding flexibility,which can be easily bent into“U”shape.It also exhibited a high transmittance of up to 89%,an ultrahigh haze of up to 97%,and effective ability on UV light absorption.The balance of transparency,flexibility and mechanical properties of FTW was finally realized through regulating the EDGE addition amount,which provided an effective way to prepare functional transparent wood.Considering the numerous advantages of the as prepared FTW,it shows great potential in the applications of architecture,furniture,solar cell and wearable electronics.

杂志排行

Journal of Forestry Research的其它文章

- A new species of Exoristobia (Hymenoptera:Encyrtidae)from China

- Diversity and surge in abundance of native parasitoid communities prior to the onset of Torymus sinensis on the Asian chestnut gall wasp (Dryocosmus kuriphilus) in Slovenia,Croatia and Hungary

- Ozone disrupts the communication between plants and insects in urban and suburban areas:an updated insight on plant volatiles

- Testing visible ozone injury within aLight Exposed Sampling Site as aproxy for ozone risk assessment for European forests

- Logging and topographic effects on tree community structure and habitat associations in a tropical upland evergreen forest,Ghana

- Spatial pattern dynamics among co-dominant populations in early secondary forests in Southwest China