基于X-ray μCT技术的玉米籽粒结构特征的粒位效应分析

2021-06-30银学波侯俊峰王克如李少昆谢瑞芝

银学波,明 博,侯俊峰,王克如,李少昆,谢瑞芝

基于X-rayCT技术的玉米籽粒结构特征的粒位效应分析

银学波1,明 博1,侯俊峰2,王克如1,李少昆1,谢瑞芝1※

(1. 中国农业科学院作物科学研究所/农业农村部作物生理生态重点实验室,北京 100081;2. 浙江省农业科学院/玉米与特色旱粮研究所,东阳 322100)

玉米籽粒因其在果穗上着生位置不同存在较大差异,明确籽粒结构特征的粒位效应为玉米的消费、加工和播种质量等玉米产量和品质性状的评价提供参考。该研究以3个不同籽粒类型的玉米品种登海618(DH618)、KX3564和先玉335(XY335)为材料,利用X射线计算机断层(X-ray micro-computed tomography,X-rayCT)技术扫描测试样本,通过图像滤波、阈值分割等图像分析方法重建籽粒3维结构,获取玉米果穗不同粒位籽粒的胚、胚乳、皮下空腔、胚空腔、硬质胚乳、粉质胚乳、胚乳空腔等结构参数。数据分析表明,籽粒不同结构指标在果穗上呈现不同的变化规律,从基部到顶部(不考虑果穗两端的极端籽粒),胚、胚乳及硬质胚乳体积线性下降,各指标在果穗上的变化范围分别为15.82~33.36、180.15~296.50及87.13~166.00 mm3;胚乳空腔>皮下空腔>胚空腔,果穗中部籽粒的空腔较小且稳定,3个品种表现一致;胚与胚乳的比值在粒位间基本稳定,粉质胚乳体积、硬质胚乳与粉质胚乳的比值从基部至顶部逐渐减小,但不同指标的变化斜率存在差异。3个供试品种的籽粒结构参数不同:DH618果穗不同部位籽粒胚与胚乳的比值大于KX3564和XY335,XY335籽粒硬质胚乳与粉质胚乳的比值大于DH618和KX3564。在籽粒空腔方面,KX3564皮下空腔的比例较高,而XY335胚乳空腔的比例较高。3个品种胚、胚乳、皮下空腔体积在玉米籽粒中的比例平均分别为9.27%、89.87%、0.86%。X-rayCT扫描技术为玉米籽粒性状的研究提供新的方法与思路,明确果穗籽粒结构的粒位效应有利于全面地掌握玉米果穗上籽粒的性状特征,为玉米的生产、加工及品种改良等提供借鉴。

作物;玉米;粒位效应;籽粒结构;X-rayCT

0 引 言

籽粒内部结构影响玉米的农艺性状、商品性状、加工品质以及其他应用价值[1-2]。玉米是中国播种面积、总产量最高(国家统计局),玉米籽粒结构的研究在种子生产、收获、饲用及其他工业用途中具有广泛的应用空间。

玉米籽粒主要由种皮、胚、胚乳3部分结构组成,不同的结构在籽粒中发挥着不同的作用。种皮约占籽粒质量的6%~8%,主要由纤维素组成,保护籽粒免受非生物和生物胁迫,减少籽粒破损与虫霉率[3]。胚占籽粒总质量的10%~15%,由胚芽、胚轴、胚根、子叶(盾片)所组成,是种子萌发所必需的组织,且含有籽粒中的大部分脂肪[4]。胚乳位于胚的周围,含有丰富的营养物质,一般较胚发育早,供胚发育时所需要的养料。根据其中蛋白质和淀粉紧实程度,胚乳又分为硬质胚乳和粉质胚乳,其组织结构及理化特性的诸多差异影响籽粒的质地,对玉米机械粒收收获质量和饲用玉米淀粉的消化率等有重要的影响[5-6]。在籽粒结构测定方面,传统方法是将籽粒浸泡20~36 h,刀片分割出籽粒胚、硬质胚乳、粉质胚乳等结构,烘干称干质量,人工手动分割不准确且测量特征少[7]。后期应用的机器视觉技术虽然解决了人为因素干扰,但均是在获取籽粒2维图像信息的基础上分割胚部与非胚部的边界[8-9]。X-rayCT扫描技术可在不改变籽粒形态的和内部结构的情况下,提取籽粒胚、胚乳、空腔、孔隙度、籽粒饱满度等更精细特征的籽粒结构信息[10]。本团队前期工作就发现,籽粒密度和皮下空腔体积等对玉米机械收获时籽粒耐破碎性有显著影响[11]。

因在果穗上的着生位置不同玉米籽粒大小和粒形存在较大差异[12]。相对果穗中下部,果穗上部籽粒灌浆充实度差,籽粒质量偏低[13]。张丽等[14]研究发现,不同粒位玉米籽粒容重也表现为下部籽粒>上部籽粒>中部籽粒。王晓燕等[15]发现,果穗不同粒位胚乳细胞数表现为中部>下部>上部。禾谷类作物籽粒在果穗不同部位存在差异的现象称之为粒位效应,并且在大穗型作物中尤为突出[16-18]。目前,关于粒位效应的研究主要集中在籽粒表型和籽粒生理生化特征等方面,未见在玉米果穗不同部位籽粒内部结构上的关注。因此,本研究以不同籽粒类型的玉米品种为研究对象,利用X-rayCT扫描这一新兴的技术手段,分析玉米果穗不同部位籽粒结构的变化规律,旨在探明果穗不同部位、不同类型籽粒内部结构的差异,为玉米果穗不同粒位籽粒发育、不同功用品种筛选以及玉米籽粒加工、贮藏等相关性状评价提供帮助。

1 材料与方法

1.1 供试样品

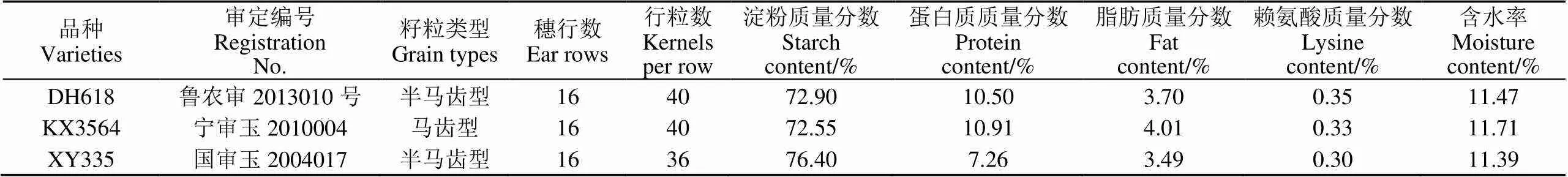

本研究以登海618(DH618)、KX3564、先玉335(XY335)3个不同籽粒类型的玉米品种为试验材料(表1)。2018年于新疆奇台(89°46′01″E,43°50′41″N)种植,种植密度和水肥管理均参照当地大田生产。每个品种选取生长正常均匀一致的3个果穗,每个果穗选取一行,从果穗基部到顶部每隔3粒选取一个籽粒(图1a),由于果穗近基部和顶籽粒变异较大,在果穗两端增加取样量,每个果穗平均12个籽粒,3个品种共计104个样本,用于X-rayCT扫描。玉米果穗手工脱粒,85℃烘干至恒定质量,根据籽粒鲜质量和干质量计算籽粒含水率:籽粒含水率=(鲜质量−干质量)/鲜质量×100%。籽粒含水率经国标130 ℃烘干方法校正[19]。

表1 玉米品种来源和特征特性

注:籽粒品质参数来自中国玉米品种系谱数据库。

Note: The grain quality parameters were obtained from database of Chinese maize variety genealogy.

1.2 X-ray μCT扫描技术

X-rayCT扫描仪型号为SkyScan 1172(Bruker公司生产)(图1b)。X-rayCT扫描后每个籽粒可获取900多张不同灰度的籽粒2维扫描图像(---),其与籽粒物理分割的籽粒结构相对应,X-rayCT扫描精度较高(图2),X-rayCT扫描技术原理及具体操作见文献[10-11]。

注:从果穗基部至顶部每隔3粒选取一个试验样本,果穗两端增加取样量。方框内籽粒为X-rayCT扫描样本,数字为籽粒在果穗上所在粒位。

Note: A test sample is taken from the base to the top of the ear every 3 grains, increased the sample amount at both ends of ear. The grains in the box are the scanned samples by X-rayCT, and the numbers on the grains are their kernel positions on the ear.

图1 试验样本与X-rayCT扫描系统

Fig.1 Test samples and X-ray computed tomography system

1.皮下空腔 2.胚空腔 3.胚 4.硬质胚乳 5.粉质胚乳 6.胚乳空腔

1.Subcutaneous cavity 2.Embryo cavity 3.Embryo 4.Hard endosperm 5.Soft endosperm 6.Endosperm cavity

注:籽粒发育过程中由于种皮的程序性死亡,种皮与胚乳难以分割,本研究中胚乳是胚乳和种皮的总和。

Note: The endosperm is the sum of the endosperm and the seed coat, which are difficult to separate due to the programmed death of the seed coat during graindevelopment.

图2 籽粒物理切片和X-rayCT扫描图像

Fig.2 Physical slice and the image of X-rayCT scan

由于籽粒内部结构密度和成分存在差异,表现对X射线的吸收率不同,因而可实现籽粒内部结构参数的获取。根据籽粒的结构组成,将籽粒分为胚、胚乳、皮下空腔3大主要结构。根据籽粒内孔隙的分布位置,将籽粒内空腔定义为3类:存在于胚内的为胚空腔,存在于胚乳内的为胚乳空腔,皮下空腔是存在于胚乳外种皮内的一种孔隙。

1.3 图像处理与数据分析

图像预处理步骤包括滤波或平滑和光束硬化校正,使用交互式阈值分割算法将样品信息、背景信息、样品内部不同特征区域划分出来,每一张2维切片由不同的体素数组成(灰度值0~256)。然后通过图像处理软件(CT-Analyser和CT Scan NRecon)对籽粒大量的2维图像重构、分割与渲染(图3),不同内部结构渲成不同的颜色,把籽粒内部结构剥离出来,从而实现籽粒内部结构的可视化,并重建三维籽粒和内部空腔等结构(图4)。

采用Microsoft Excel 2010进行数据整理;SPSS 19.0进行方差分析;GraphPad Prism 5作图。由于果穗两端籽粒结构变异较大,线性拟合时果穗两端籽粒未计算在内。

注:编号所指结构与图2一致。

Note: The structure referred to by the number is the same as Fig. 2.

图3 籽粒内部结构的分割

Fig.3 Segmentation of the internal structure of the grain

注:编号所指结构与图2一致。

Note: The structure referred to by the number is the same as Fig. 2.

图4 籽粒三维重建

Fig.4 Three-dimensional reconstruction of grain

2 结果与分析

2.1 胚与胚空腔体积

玉米果穗两端粒位籽粒变异较大,若不考虑果穗两端1~5个籽粒(下同),从果穗基部至顶部,随着粒位的增加,胚体积逐渐减小,果穗顶端籽粒胚体积最小,3个品种规律一致。3个品种果穗不同粒位籽粒胚体积范围为15.82~33.36 mm3,其中,DH618籽粒胚体积较大,果穗不同部位籽粒胚体积均大于其他2个品种,平均较KX3564和XY335分别大23.40%、25.13%(图5a)。从图5b可以看出,胚中胚空腔的比例较小且稳定,比较不同类型玉米的均值,胚空腔的比例在品种间存在差异,由大到小依次为KX3564、XY335和DH618,3个品种平均胚空腔在胚中的比例分别为6.49%、5.52%、4.07%。

2.2 胚乳与胚乳空腔体积

从果穗基部到顶部,胚乳、硬质胚乳体积逐渐减小(图6a, 6b),3个品种表现一致。在不考虑果穗两端的极端籽粒时,不同品种果穗中部胚乳体积的变化范围为180.15~296.50 mm3,其中DH618果穗不同部位胚乳体积均大于其他2个品种。不同品种果穗不同部位籽粒硬质胚乳体积差异较小,硬质胚乳胚乳体积的变化范围为87.13~166.00 mm3。粉质胚乳体积在3个品种的果穗基部差异较小(图6c),随着粒位的增加,品种间差异增大,粉质胚乳体积范围为80.64~130.50 mm3,且不同品种硬质胚乳大于粉质胚乳体积。胚乳中胚乳空腔的比例在果穗中部较小且不同粒位间较稳定(图6d),但品种间存在明显的差异,XY335胚乳空腔的比例较大,平均为2.87%,DH618和KX3564胚乳空腔的比例无差异,均为1.89%。

注:胚乳体积为硬质胚乳和粉质胚乳体积总和。

Note: Endosperm volume is the sum of hard endosperm and soft endosperm volume.

图6 玉米果穗不同粒位籽粒胚乳、硬质胚乳、粉质胚乳体积和胚乳空腔在胚乳中的比例

Fig.6 The endosperm volume, hard endosperm volume and soft endosperm volume and the proportion of endosperm cavities in the endosperm in different positions of ear

2.3 籽粒的皮下空腔体积与皮下空腔在籽粒中的比例

玉米基部籽粒皮下空腔较大(图7a),3个品种存在较大差异。KX3564基部籽粒皮下空腔体积最大值可达6.97 mm3,顶部最小值也为2.28 mm3。不考虑果穗两端籽粒,KX3564皮下空腔体积变化范围为2.28~4.52 mm3,而XY335、DH618的籽粒中皮下空腔范围分别是0.89~2.06、0.69~1.80 mm3。约从果穗基部第10粒开始,皮下空腔体积基本保持稳定,KX3564皮下空腔体积平均为2.92 mm3,相比于DH618和XY335分别大66.58%、52.08%。而从籽粒中皮下空腔的比例看(图7b),果穗两端籽粒中皮下空腔的比例大于果穗中部籽粒。KX3564籽粒中皮下空腔的比例在3个品种中最大。

2.4 品种间结构差异比较

不同玉米品种胚、胚乳及皮下空腔在籽粒中体积占比存在一定的差异(图8)。DH618、KX3564和XY3353个品种果穗不同部位胚在籽粒中的比例分别为9.11%~11.39%、8.01%~9.37%、8.12%~9.83%,胚乳占比分别为88.16%~90.19%、88.54%~90.50%、89.41%~91.32%,皮下空腔占比分别为0.22%~0.96%、0.87%~2.82%、0.38%~1.46%。3个品种平均胚、胚乳、皮下空腔在籽粒中的比例分别为9.27%、89.87%、0.86%。其中,DH618籽粒中胚的比例显著大于KX3564和XY335(<0.05),约占籽粒体积的10.42%,而其胚乳在籽粒中的比例在3个品种中最小。从图9a可以看出,DH618籽粒胚与胚乳比值在果穗不同部位大于KX3564和XY335,不同粒位籽粒胚与胚乳的比值平均为0.12,而KX3564和XY335的比值基本相同,约为0.10。同时胚与胚乳的比值在果穗基部与顶部籽粒中差异较小,基本不受粒位的影响。籽粒硬质胚乳和粉质胚乳的比值在果穗不同部位和品种间均存在明显差异(图9b),靠近果穗基部不同品种籽粒硬质胚乳与粉质胚乳的比值差异较小,随着粒位的增加,品种间差异增大;比较不同品种籽粒硬质与粉质胚乳的比值的均值,XY335平均为1.34,大于DH618和KX3564。

注:不同字母表示同一结构指标品种间在<0.05水平差异显著。

Note: Different letters represent significant differences among varieties of the same structural indicators at<0.05 level.

图8 果穗不同粒位胚、胚乳、皮下空腔在籽粒中的比例

Fig.8 Proportion of embryo, endosperm and subcutaneous cavity of grain in different positions of ear

3 讨 论

相较于以往手工测量、机器视觉等籽粒结构特征参数的常规获取方式,本试验利用X-rayCT技术,高分辨率且无损状态下扫描玉米果穗不同部位的籽粒,具有可视化并定量分析的特点,获取了籽粒胚、胚乳、皮下空腔、胚空腔、硬质胚乳、粉质胚乳、胚乳空腔等结构指标,特别是籽粒空腔结构,解决了传统方法无法对籽粒内部结构精确测定的问题。

本研究结果表明,果穗不同部位籽粒结构存在差异:在不考虑果穗两端的极端籽粒时,籽粒各结构指标在果穗上均呈一定的规律性变化:胚、胚乳及硬质胚乳体积线性下降;皮下空腔、胚空腔及胚乳空腔在果穗中部保持稳定,且明显低于果穗两端籽粒,3个品种表现一致;粉质胚乳体积、胚与胚乳比值、硬质胚乳与粉质胚乳比值在果穗上的变化规律存在品种间差异。前人对果穗粒位间差异的研究主要集中在籽粒表型与理化指标等方面[12-14],发现果穗基部与顶部的籽粒往往表现出籽粒质量、形态、体积、密度、内部淀粉粒体积分布的差异[20],但胚、胚乳、空腔等籽粒结构特征在果穗上的分布规律未见报道。关于粒位间差异的原因,前人认为可能是由于籽粒在果穗上位置不同,导致不同籽粒发育顺序、物质积累量及同化物运输差异[21]:玉米雌穗小花受精完成后,果穗中下部籽粒最先发育,光合产物转化量多,籽粒灌浆更充实,而顶部籽粒发育较晚[18],因而,果穗中下部籽粒的胚、胚乳体积较大,空腔体积较小。赵波等[22]研究表明,相较于果穗顶端,果穗基部籽粒更耐机械损伤。籽粒结构在一定程度上反映了籽粒的灌浆充实状况,玉米果穗不同部位籽粒结构差异为果穗发育研究、科学试验中的合理取样及玉米的生产应用奠定基础。

本试验中,XY335和DH618均为半马齿型籽粒,KX3564为马齿型籽粒。本研究结果表明,DH618胚与胚乳的比值在3个品种中最大,XY335硬质胚乳与粉质胚乳的比值显著大于DH618和KX3564。可能是由于不同品种遗传物质的差异,籽粒发育过程中各结构参数的相关基因表达活性不同[23]。玉米籽粒的形成过程分为胚胎发生、物质积累和成熟脱水3个阶段,胚和胚乳中储存物质的积累主要发生在籽粒灌浆期[24]。因淀粉体与蛋白体的发育与充实状况不同,不同品种角质胚乳与粉质胚乳比例存在差异。一般来说,半马齿型籽粒角质胚乳较多,马齿型籽粒的中央和顶部均为粉质淀粉,且该比例随着蛋白含量的不同而有较大差异[25]。分析不同品种的品质成分,DH618和XY335籽粒蛋白质含量较高,KX3564籽粒淀粉含量较高(表1)。籽粒结构影响籽粒质地,Guelpa等[26]研究表明,籽粒硬质胚乳与粉质胚乳的细胞结构和淀粉颗粒不同,从而导致籽粒不同的硬度,硬质胚乳与粉质胚乳的比值可作为评价品种硬度的指标。Wang等[27]研究表明,玉米籽粒硬质胚乳较粉质胚乳具有显著的力学强度优势,硬质胚乳比例高的玉米品种更耐破碎。

由于籽粒内孔隙空间测量难度大,有关籽粒空腔的研究非常有限。本研究表明,胚空腔在果穗不同部位籽粒中的分布及形态变化较小;胚乳空腔主要分布在胚的外围和籽粒顶端,集中在粉质胚乳中;皮下空腔主要分布在籽粒尖端,少量分布在籽粒四周。果穗不同粒位籽粒总空腔约占籽粒体积的3.72%,其中,胚乳空腔>皮下空腔>胚空腔。KX3564皮下空腔体积明显高于其他两个品种,而皮下空腔体积与籽粒破碎率有显著的关系[11],与张万旭等[28]划分KX3564为易破碎品种,DH618和XY335为耐破碎性品种结果一致。XY335胚乳空腔体积较大,多位学者研究表明,XY335籽粒脱水速率较快,含水率稳定时其籽粒含水率较低[29-30],后续可进一步探究胚乳空腔与籽粒脱水之间的关系。

4 结 论

果穗上着生位置不同,籽粒内部结构存在较大差异,不同结构指标在果穗上的变化规律不同。

果穗两端结构变异较大,不考虑果穗两端极端籽粒,从果穗基部至顶部,胚体积、胚乳体积及硬质胚乳体积线性减小,各指标变化范围分别为15.82~33.36mm3、180.15~296.50 mm3、87.13~166.00 mm3;胚乳空腔>皮下空腔>胚空腔,果穗中部籽粒的空腔较小且稳定;胚与胚乳比值粒位间基本稳定,粉质胚乳体积、硬质胚乳与粉质胚乳比值从基部至顶部逐渐减小,随着粒位的增加,品种间差异增大。品种间籽粒结构存在较大差异:DH618不同粒位胚与胚乳的比值较大,XY335胚乳空腔体积及硬质胚乳与粉质胚乳的比值较大,KX3564皮下空腔体积较大。

[1] 黄熊娟,梁和,吴子恺. 高油玉米含油率、籽粒结构与氮钾施用量的通径分析[J]. 中国农学通报,2006,22(8):268-271.

Huang Xiongjuan, Liang He, Wu Zikai. Correlation and path analysis among grain oil rate and grain structure anddifferent levels of nitrogen and potassium of high oil corn. Chinese Agricultural Science Bulletin, 2006, 22(8): 268-271. (in Chinese with English abstract)

[2] 马秀凤,郭强,蔺崇明,等. 不同胚乳类型玉米籽粒超微结构及其营养品质的动态变化[J]. 西北农林科技大学学报:自然科学版,2016,44(1):53-60.

Ma Xiufeng, Guo Qiang, Lin Chongming, et al. Dynamiac changes of ultra-structure and nutritional quality in maize kernels with different endosperm types[J]. Journal of Northwest A&F University: Nat. Sci. Ed., 2016, 44(1): 53-60. (in Chinese with English abstract)

[3] Jaime H, Calderini D F. Pericarp growth dynamics associate with final grain weight in wheat under contrasting plant densities and increased night temperature[J]. Annals of Botany. 2020, 126(6): 1063-1076.

[4] 孙源泽. 玉米种胚不同发育时期生理生化指标及甲基化水平的变化[D]. 长春:吉林农业大学,2016.

Sun Zeyuan. Changes of Maize Germ Physiological and Biochemical Indexes and Methylation Levels During Developmental Stages[D]. Changchun: Jilin Agricultural University, 2016. (in Chinese with English abstract)

[5] Waelti H. Physical Properties and Morphological Characteristics of Maize and Their Influence on Threshing Injury of Kernels[D]. Iowa, America: PhD Dissertation of Iowa State University, 1967.

[6] 杜双奎. 玉米品种籽粒品质与挤压膨化特性研究[D]. 杨凌:西北农林科技大学,2006.

Du Shuangkui. Kernel Quality Properties and Extrusion Characteristics of Maize Varieties[D]. Yangling: Northwest A&F University, 2006. (in Chinese with English abstract)

[7] 郭祯祥,赵仁勇. 玉米硬度测定方法研究[J]. 粮食与饲料工业,2002(12):44-46.

Guo Zhenxiang, Zhao Renyong. Corn hardness determination[J]. Cereal&Feed Industry, 2002(12): 44-46. (in Chinese with English abstract)

[8] 韩仲志,赵友刚,杨锦忠. 基于籽粒RGB图像独立分量的玉米胚部特征检测[J]. 农业工程学报,2010,26(3):222-226.

Han Zhongzhi, Zhao Yougang, Yang Jinzhong. Detection of embryo based on independent components for kernel RGB images in maize[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2010, 26(3): 222-226. (in Chinese with English abstract)

[9] 宁纪锋,何东健,杨蜀秦. 玉米籽粒的尖端和胚部的计算机视觉识别[J]. 农业工程学报,2004,20(3):117-119.

Ning Jifeng, He Dongjian, Yang Shuqin. Identification of tip cap and germ surface of corn kernel using com putervision[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2004, 20(3):117-119. (in Chinese with English abstract)

[10] Schoeman L, Williams P, Plessis A D, et al. X-ray micro-computed tomography (CT) for non-destructive characterisation of food microstructure[J]. Trends in Food Science & Technology, 2016, 47: 10-24.

[11] Hou J F, Zhang Y, Jin X L, et al. Structural parameters for X-ray micro-computed tomography (CT) and their relationship with the breakage rate of maize varieties[J]. Plant Methods, 2019, 15(1): 915-920.

[12] Yin X B, Hou J F, Ming B. Kernel position effects of grain morphological characteristics by X-ray micro-computed tomography (CT)[J]. International Journal of Agricultural and Biological Engineering, 2021, 14(2):159-166.

[13] 徐云姬,顾道健,秦昊,等. 玉米灌浆期果穗不同部位籽粒碳水化合物积累与淀粉合成相关酶活性变化[J]. 作物学报,2015,41(2):297-307.

Xu Yunji, Gu Daojian, Qing Hao, et al. Changes in carbohydrate accumulation and activities of enzymes involved in starch synthesis in maize kernels at different positions on an ear during grain filling[J]. Acta Agoronmica Sinica, 2015, 41(2): 297-307. (in Chinese with English abstract)

[14] 张丽,张吉旺,周伟,等. 玉米不同粒位子粒容重与子粒物理性状的相关分析[J]. 玉米科学,2015,23(2):64-68.

Zhang Li, Zhang Jiwang, Zhou Wei, et al. Correlation analysis on test weight of maize grains at different grain positions with grain physical characters[J]. Journal of Maize Sciences, 2015, 23(2): 64-68. (in Chinese with English abstract)

[15] 王晓燕,董树亭,高荣岐,等. 不同类型玉米胚乳细胞增殖动态及其与粒重的关系[J]. 华北农学报,2006(2):23-26.

Wang Xiaoyan, Dong Shuting, Gao Rongqi, et al. Endosperm cell proliferating and its relation to grain weight indifferent types of maize[J]. Acta Agriculturae Boreali-Sinica, 2006(2): 23-26. (in Chinese with English abstract)

[16] 杨建昌. 水稻弱势粒灌浆机理与调控途径[J]. 作物学报,2010,36(12):2011-2019.

Yang Jianchang. Mechanism and regulation in the filling of inferior spikelets of rice[J]. Acta Agoronmica Sinica, 2010, 36(12): 2011-2019. (in Chinese with English abstract)

[17] Nagato K. Differences in grain weight of spikelets located at different positions within a rice panicle[J]. Japanese Journal of Crop Science, 1941, 13: 154-169. (In Japanese)

[18] 杨同文,李潮海. 玉米籽粒发育的粒位效应机理研究[J].种子,2012,31(3):54-58.

Yang Tongwen, Li Chaohai. Study on mechanisms of kernel position effects in maize kernel developing[J]. Seed, 2012, 31(3): 54-58. (in Chinese with English abstract)

[19] Gao S, Ming B, Li L L, et al. Maize grain moisture content correction: From nonstandard to standard system[J]. Biosystems Engineering, 2021, 204(5): 212-222.

[20] Zhao F C, Jing L Q, Wang D C, et al. Grain and starchgranule morphology in superior and inferior kernels of maizein response to nitrogen[J]. Scientific Reports, 2018, 8(1): 6343.

[21] 徐云姬. 3种禾谷类作物强、弱势粒灌浆差异机理及其调控技术[D]. 扬州:扬州大学,2016.

Xu Yunji. Mechanism in the Filling Difference Between Superior and Inferior Caryopses of Three Cereal Crops and Its Regulation Techniques[D]. Yangzhou: Agricultural College Yangzhou University, 2016. (in Chinese with English abstract)

[22] 赵波,吴雅薇,李小龙,等. 玉米强弱势粒间机械脱粒破碎率的差异[J]. 中国生态农业学报,2020,28(6):843-851.

Zhao Bo, Wu Yawei, Li Xiaolong, et al. Differences in mechanical threshing broken rate between superior and inferior maize grains[J]. Chinese Journal of Eco-Agriculture, 2020, 28(6): 843-851. (in Chinese with English abstract)

[23] 于涛,李耕,刘鹏,等. 玉米早期发育阶段粒位效应的蛋白质组学分析[J]. 中国农业科学,2016,49(1):54-68.

Yu Tao, Li Geng, Liu Peng, et al. Proteomics analysis of rain position effects during early developmental stages of maize[J]. Scientia Agricultura Sinica, 2016, 49(1): 54-68. (in Chinese with English abstract)

[24] Sreenivasulu N, Wobus U. Seed-development programs: A systems biology-based comparison between dicots and monocots[J]. Annual Review of Plant Biology. 2013, 64: 189-217.

[25] Eckhoff S R, Watson S A. Corn and Sorghum Starches: Production. In: BeMiller J, Whistler R. Starch: Chemistry and Technology (3rded.)[M]. Burlington, MA, USA: Academic Press, 2009: 373-440.

[26] Guelpa A, Plessis A D, Kidd M, et al. Non-destructive estimation of maize (L.) kernel hardness by means of an X-ray micro-computed tomography (CT) density calibration[J]. Food and Bioprocess Technology, 2015, 8: 1419-1429.

[27] Wang B, Wang J. Mechanical properties of maize kernel horny endosperm, floury endosperm and germ[J]. International Journal of Food Properties, 2019, 22(1): 863-877.

[28] 张万旭,王克如,谢瑞芝,等.玉米机械收获子粒破碎率与含水率关系的品种间差异[J]. 玉米科学,2018,26(4):74-78.

Zhang Wanxu, Wang Keru, Xie Ruizhi, et al. Relationship between maize grain broken rate and moisture content as well as the differences among cultivars[J]. Journal of Maize Sciences, 2018, 26(4): 74-78. (in Chinese with English abstract)

[29] 李璐璐,谢瑞芝,范盼盼,等. 郑单958与先玉335子粒脱水特征研究[J]. 玉米科学,2016,24(2):57-61,71.

Li Lulu, Xie Ruizhi, Fan Panpan, et al. Study on dehydration in kernel between zhengdan958 and xianyu335[J]. Journal of Maize Sciences, 2016, 24(2): 57-61, 71. (in Chinese with English abstract)

[30] 朱亚利,王晨光,杨梅,等. 不同熟期玉米不同粒位籽粒灌浆和脱水特性对密度的响应[J]. 作物学报,2021,47(3):507-519.

Zhu Yali, Wang Chenguang, Yang Mei, Response of grain filling and dehydration characteristics of kernels located in different ear positions in the different maturity maize hybrids to plant density[J]. ActaAgoronmicaSinica, 2021, 47(3): 507-519. (in Chinese with English abstract)

Effects of various grain positions of ear on the internal structural parameters of maize grain using X-rayCT

Yin Xuebo1,Ming Bo1, HouJunfeng2, Wang Keru1, Li Shaokun1, XieRuizhi1※

(1/,,100081,; 2322100,)

Grain structure is an important characteristic of maize varieties, particularly in representing the grain filling and texture in some cases. But the effect of kernel positions on grain structures in maize still remained unclear. Clarifying the kernel position effects of grain structure is beneficial to comprehensively grasp the grain characteristics of maize ears, and provides a reference for the production, processing and variety improvement of maize. In this study, three grain types of maize cultivars were taken to clarify the kernel position effects, including Denghai 618 (DH618), KX3564, and Xianyu 335 (XY335), from Qitai, Xinjiang of Western China in 2018. Samples were selected at regular kernel intervals, where each ear was in an average of 12 grains. A total of 104 samples were scanned from the three varieties. The grain three-dimensional structures were reconstructed by imaging processing, such as segmentation, thresholding, and reconstruction, where more than 900 2D images were obtained in the different sections (--, and-) of grains using an X-ray micro-computed tomography (X-rayCT). In addition to visualization, the grain structural parameters were also extracted, including the embryo, endosperm, subcutaneous cavity, embryo cavity, hard endosperm, soft endosperm, and endosperm cavity. The internal structure of grain was more accurately determined, especially on the cavity structure of grain, compared with the traditional manual and machine vision. The results showed thatthe effect of kernel position grain structure indicators on ear was different. Specifically, the volume of embryo, endosperm, and hard endosperm showed a linear downward trend from the base to the top of the ear, without considering the extreme grains at both sides of the ear. The range of each indicator on ear was 15.82-33.36, 180.15-296.50 and 87.13-166.00 mm3, respectively. The cavity volume of subcutaneous, embryo, and endosperm remained stable in the middle of the ear, significantly lower than those in the upper and lower parts, in the sequence endosperm cavity> subcutaneous cavity> the embryo cavity. The ratio of embryo to endosperm was basically stable among grains. The volume of soft endosperm and the ratio of hard endosperm to soft endosperm decreased gradually from the base to the top, but the slope was different. There was the same tendency of parameters at different kernel positions in three varieties, but there were differences in absolute value:the ratio of grain embryo to endosperm at different positions of the ear in DH618 was significantly higher than those in KX3564 and XY335. The ratio of hard to soft endosperm in XY335 was significantly larger than those in DH618 and KX3564. In terms of grain cavities, KX3564 had a higher proportion of subcutaneous cavities and XY335 had a higher proportion of endosperm cavities. The volume proportion of embryo, endosperm and subcutaneous cavity in maize grains of the three varieties was 9.27%, 89.87% and 0.86%, respectively. X-rayCT technology provides a new method and idea for the study of maize grain characters. Kernel position has also played a significant role in the grain structure among different positions of the maize ear. The findings suggest that the sampling position should be considered when conducting kernel research, due mainly to the differences of grain structure in positions of the maize ear.

crops; maize; kernel position effects; grain structure; X-rayCT

2020-09-03

2021-02-26

国家重点研发计划项目(2018YFD0300405);国家玉米产业技术体系项目(CARS-02-25);国家自然科学基金(31971849);中国农业科学院科技创新工程项目

银学波,研究方向为玉米籽粒机械收获。Email:3023937790@qq.com

谢瑞芝,博士,研究员,研究方向为玉米生理与生态学。Email:xieruizhi@caas.cn

10.11975/j.issn.1002-6819.2021.07.002

S513.210.70

A

1002-6819(2021)-07-0008-07

银学波,明博,侯俊峰,等. 基于X-rayCT技术的玉米籽粒结构特征的粒位效应分析[J]. 农业工程学报,2021,37(7):8-14. doi:10.11975/j.issn.1002-6819.2021.07.002 http://www.tcsae.org

Yin Xuebo, Ming Bo, Hou Junfeng, et al. Effects of various grain positions of ear on the internal structural parameters of maize grain using X-rayCT[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(7): 8-14. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2021.07.002 http://www.tcsae.org