Novel heating technologies to improve fermentation efficiency and quality in wheat products:A short review

2021-06-24ZhenWangJihongHuangSenMaXiaoxiWangBinghuaSunFengchengWangLiLiQingdanBao

Zhen Wang,Jihong Huang,Sen Ma,Xiaoxi Wang,Binghua Sun,Fengcheng Wang,Li Li,Qingdan Bao

College of Food Science and Engineering,Henan University of Technology,Zhengzhou 450001,China

ABSTRACT Identifying novel processing methods is an important research direction in the field of food engineering.Fermented flour products have been popular all over the world for a long time because of their unique flavor and texture.Whether for yeast or sourdough,the accurate temperature control is essential for the fermentation process.Some novel heating methods have shown potential in the processing of fermented flour products.Microwave heating(MWH),radiofrequency heating(RFH),and ohmic heating(OH)are undoubtedly the most promising heating methods.MWH affects the fermentation time of the dough by affecting the water molecules in the dough,and may also improve the fermentation quality of wholewheat flour products.RFH contributes to the control of harmful substances in the fermentation process and has shown potential for the production of sourdough bread.OH has superiority in accurately controlling the temperature,enzymes,microorganisms,etc.in the fermentation process,and it is beneficial to shortening the fermentation time.Researchers have applied these heating methods with different properties to different uses.This article summarized the application and potential of these three novel heating methods in the production of fermented flour products.The application scenarios and parameter settings of novel heating technologies in dough fermentation process need further research.It is reasonable to believe that novel heating methods can become an important tool to improve the efficiency of dough fermentation and the quality of fermented dough in the future.

Keywords:Microwave heating Radiofrequency heating Ohmic heating Novel heating technology of fermentation

1.Introduction

Fermentation is not only one of the most commonly used methods in the production of flour products,but also a key step in determining the final texture and quality of flour products[1].Both Eastern steamed bread and Western baked bread are made from dough with a water content of 50%-60%after being fermented by various fermentation methods,including pure yeast fermentation(about 2 h)and sourdough fermentation(up to a few days)[1-3].The basis of fermentation is that the yeast uses glucose,fructose,etc.for respiration and releases carbon dioxide to make gas cells appear in the dough.Compared with dry yeast,sourdough increases the process of decomposition of a part of macromolecular substances(protein,starch,etc.)in the dough due to the diversity of bacteria.In addition,different from yeast,sourdough can be divided into four types(I,II,III and IV)according to the fermentation process and technological process:(i)the type I sourdough includes yeast and lactic acid bacteria(LAB),which are formed spontaneously under suitable conditions;(ii)the type II sourdough is obtained by inoculating different concentrations of bacteria into the dough;(iii)the type III sourdough is obtained simply by dehydrating the type II sourdough;(iv)the type IV sourdough is a mixture of type I and type II sourdoughs,which is usually made into liquid during cultivation[2].At the same time,high moisture and long fermentation time increase the chance of introducing harmful microorganisms and microbial toxins during the fermentation process.Therefore,the biggest challenge in the fermentation process is to shorten the fermentation time as much as possible to control the amount of harmful substances while ensuring the quality of the fermentation.For fermentated products,consumers expect high quality and long shelf life.

Traditional heating treatments have been used to reduce the quantity of microbes in fermented foods and deactivate enzymes,as many quality changes occurring during the distribution and storage of these foods are due to harmful microorganisms and enzyme-catalyzed reactions involving Escherichia coli,Staphylococcus aureus,peroxidase,polyphenol oxidase,pectin methyl esterase,etc.[4,5].However,thermal processing also changes the textural and nutritional quality attributes of the dough and products.When using traditional heating methods during the fermentation process,some undesirable changes related to the conversion of thermolabile compounds into other products may occur.Therefore,current fermentation technologies usually adopt constant temperature control systems to minimize products'quality loss.With advancements in technology and higher expectations for high-quality fermented products,novel physical technologies have the potential to completely or partially replace traditional heating processes and have attracted increasing attention of researchers in terms of industrial applications[4].

Physical technology also shows great potential in terms of greenness,safety and sustainability[6].Novel thermal processing technologies based on physical technologies may meet the needs of consumers.Some heating technologies may improve the quality of processed food,shorten fermentation time,and extend the shelf life without using additives.As part of the electromagnetic spectrum,microwaves(300-300,000 MHz)and radiofrequency waves(0.003-300 MHz)could generate heat in food(dough is a dielectric material)through dipole rotation and/or ion polarization[7].Ohmic heating(OH)is another novel technology that has shown many advantages compared with traditional heating methods.Since heating occurs within the product itself and does not rely on conventional heat transfer based on conduction,convection,or radiation,the heat is distributed in a very fast and uniform manner[8,9].Extensive research has been carried out on various heating technologies,with studies involving their use in sterilization,baking,drying,rapid extraction,enhanced reaction kinetics,selective heating,insect removal,etc.[10-12].Normally,these technologies are used for hightemperature and short-term food processing.However,as alternatives to conventional heating treatment,these novel technologies are being continuously explored to provide opportunities to improve the quality of fermented products.The purpose of this short review is to understand the potential of novel heating technologies in food fermentation,and the findings are expected to be very helpful for subsequent research.

2.Effects of novel heating technologies on fermentation processes and products

2.1.Microwave heating

Microwave heating(MWH)is a technique based on electromagnetic radiation with frequencies ranging from 300 to 300,000 MHz.Many researchers have explored the feasibility of several potential microwave applications related to fermentation processes,such as the production of hydrolases,the generation of biohydrogen,the shortening of fermentation time,the reduction of accumulative gas production,and the preservation of fermentation products[7].MWH has a direct effect on macromolecules in terms of ion conduction and dipole rotation[7].When MWH is applied,the absorption of energy in the dough(especially polar macromolecules,such as water)facilitates the fermentation process.Therefore,MWH is usually used for the fermentation of liquid fermentation products,such as juice,yogurt,etc.[13].At the same time,there is a lack of information on the commercial viability of MWH in the fermentation process of flour products.Limited studies have shown that microwaves can improve fermentation-related processes.For example,Kapcsándi et al.[14]evaluated the impact of using MWH technology on fermentation time,and found that the fermentation time was reduced by 40% when compared to the control sample when the test sample was pretreated with microwaves under optimal conditions.Another study assessed the effect of microwave pretreatment on enzymes during solid-state fermentation;the results showed that MWH could increase the yield of hydrolase,and compared with the untreated samples,the activity of glucose amylase and protease after microwave pretreatment(30 s)was significantly increased[15].Macromolecular hydrolase activity is critical to the successful operation of grain-based biological fermentation,which is conducive to the conversion of macromolecular substances in the dough,such as starch,protein,and fat,into fermentable sugars and free amino acids.There is an evidence that MWH treatment can improve the indexes of fermented batter(bulk density,rehydration ratio,color difference,and overall acceptability scores)[16].In addition,MWH can use lignin,cellulose,and other biomass in wheat bran to have effects on fermentable sugar production[17,18].At the same time,MWH can increase the content of soluble dietary fiber components in the system,such as arabinoxylan[19,20].This suggests that MWH may contribute to the production and quality control of whole-wheat fermentation products.Refer to Fig.1 for the fermentation process using MWH.

Fig.1.Model of microwave heating fermentation process.

It should be noted that some conditions may limit the use of MWH in dough fermentation.Firstly,microwaves have high heating energy,and poorly controlled microwave heating conditions can lead to the inactivity of beneficial bacteria in the fermentation process[13].Secondly,microwave heating equipment for the industrial production of fermented dough needed to be redesigned and remanufactured.Therefore,specialized operators are required for their use and maintenance.

2.2.Radiofrequency heating

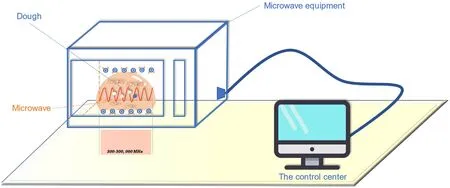

Conventional heat treatment of foo d products relies on the transfer of heat through conduction and convection.However,wheat flour/dough is a poor conductor of heat,so it is difficult to uniformly heat them with traditional heating methods.Radiofrequency heating(RFH)is an effective alternative method to conventional heating.The wavelength frequency of RFH(0.003-300 MHz)is exactly complementary to that of WMH(300-300,000 MHz).The electromagnetic energy of RFH is transferred directly to the material being heated,and the longer wavelength of RFH penetrates deeper into the material,resulting in more uniform heating[21].Under normal circumstances,RFH is not only used for bulk products,but also for processing packaged food ingredients.In other words,RFH equipment can be used to process packaged products and prepared foods[4].It is also possible to pretreat wheat flour with RFH before fermentation to inactivate harmful bacteria,such as E.coli,S.enteritidis PT 30,and E.faecium[22,23].RFH technology allows for a more uniform temperature distribution than conventional heating,and the heat transfer process does not require direct contact with the food,thus effectively avoiding contaminants in the final food[24].In addition,since the radiofrequency method creates heat faster than conventional methods,it is more effective[24].RFH equipment can stabilize the fermentation environment at about 35°C through the heat generated by the coil,so as to keep the environment similar to that of a traditional fermentation tank.The temperature of the center and surface of dough processed by RFH equipment is constant.In contrast,the traditional fermentation box usually realize heat transfer from the outer layer of the dough into the center,which cannot guarantee the same temperature between the center and surface of the dough.Therefore,RFH has more advantages in terms of fermentation efficiency and control of fermentation conditions.RFH is very suitable for fermented dough due to its high-water content[25].In addition to heating efficiency,research has also been focused on shelf life,color,and sensory quality.Compared with MWH,RFH results in less damage to bread texture and nutrients[26].At the same time,RFH is conducive to the crust color that most consumer expect(that is,the Maillard reaction and caramelization)[24].Due to the milder heating behavior of RFH,there are still partially active LAB existing in fermentation products after the heat treatment,but the shelf life of the products is prolonged due to the reduced content of LAB and complete inactivation of the fungi[27].Obviously,RFH treatment is more beneficial to the sourdough fermentation process.However,another study revealed the disadvantages of RFH treatment.RFH treatment kills harmful microorganisms while also killing a considerable amount of yeast[28].This may affect the speed of fermentation and the gas cell volume of the fermented dough.On the other hand,the post-acidification process is prone to changes during the storage period of sour bread and yogurt[29].The reduction in LAB content may help to reduce the degree of post-acidification of the food for the same storage time.Therefore,RFH treatment is more conducive to maintaining the quality of sour bread during the storage period.

As mentioned earlier,the type IV sourdough is mainly a product of fermentation broth.Controlling and clearly grasping the number of microorganisms in the fermentation broth are important tasks[2].Many years ago,the dielectric constant of microbial suspension under radiofrequency was reported as a new method for real-time estimation of microbial biomass[30].The described method proves the possibility of the real-time control and tracking of microbial growth during the fermentation process.The originality of the method of estimating biomass is related to the noninterference of noncellular particles.Therefore,RFH could be used to achieve the goal of cultivating the desired amount of bacteria in the fermentation broth.Refer to Fig.2 for the fermentation process using RFH.

Fig.2.Radiofrequency heating fermentation process model.

2.3.Ohmic heating

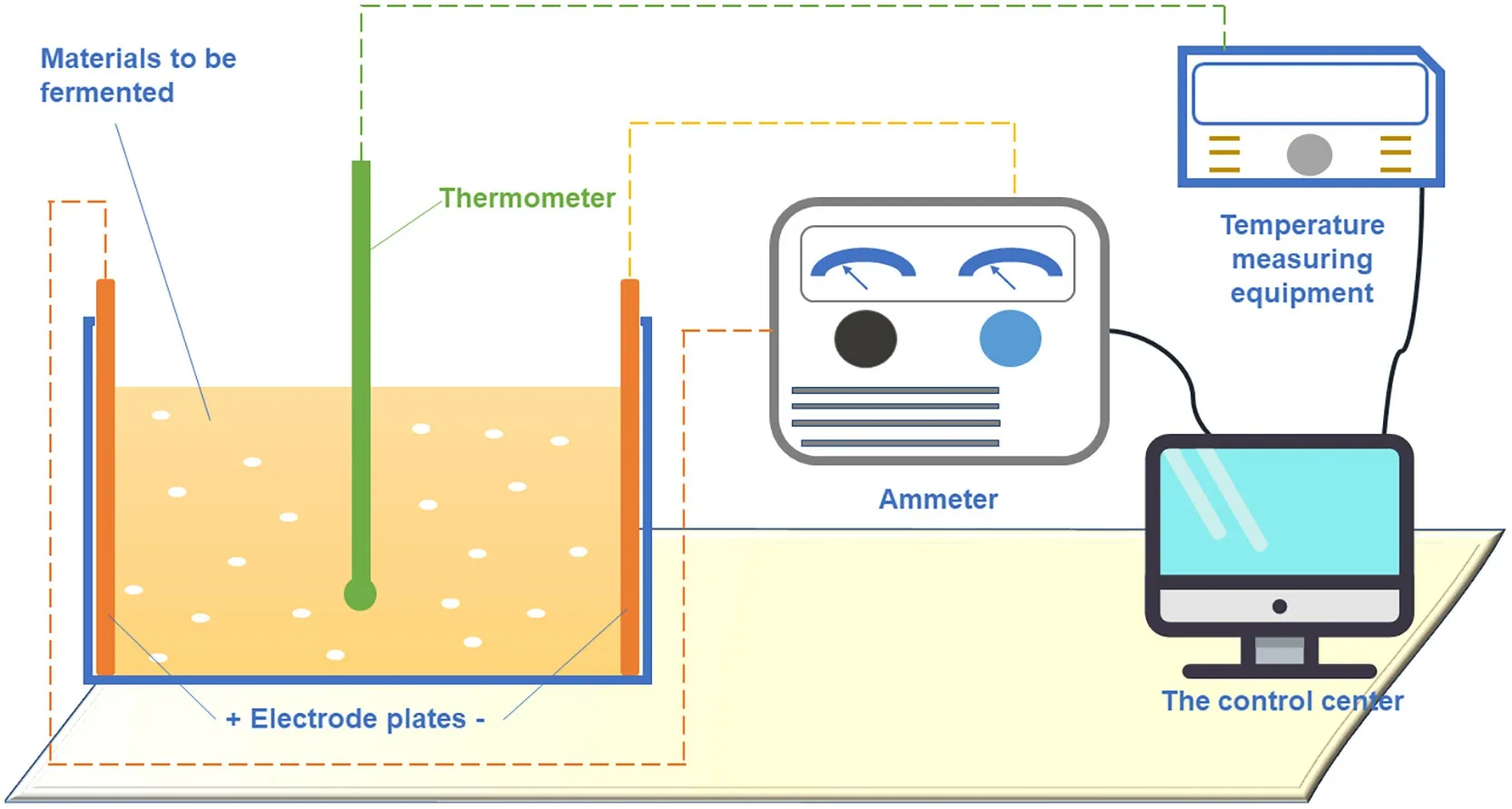

OH treatment is the process of heat ing the dough via electric current passing through the dough.In OH,energy is directly dissipated into the dough to avoid destroying internal solid particles[31].OH has been reported for various food processing applications,including blanching,evaporation,dehydration,fermentation,extraction,sterilization,and pasteurization[32-35].Compared to MWH and RFH,OH seems to be more suitable for the process of bread fermentation.Specifically,OH and an electric field of suitable intensity can assist the fermentation process through thermal and non-thermal effects.Electricity can reduce the lag phase of fermentation of L.acidophilus,S.thermophilus and S.cerevisiae,electricity can change the type and concentration of fermentation products,the main mechanism is to quickly adjust the temperature,the release of micronutrients from the substrate and the enhancement of cell permeability[36].In addition,the fermentation process produces gas cells,the conductivity of the bread dough decreases linearly with porosity,and the electrode is mainly responsible for the temperature gradient in the product,which provides good results for the simple numerical model of OH for bread dough[37].In terms of the influence on the enzymes in the dough,the presence of an electric field does not increase the inactivation of alkaline phosphatase,pectinase,or β-galactosidase,but significantly affects the kinetics of lipoxygenase and polyphenol oxidase,thereby reducing the time required for inactivation[38].

One of the important advantages of OH is that it is an environmentally friendly technology and can retain better sensory and nutritional properties of products than traditional methods.Another advantage of this technology is the lack of heat transfer surfaces due to its continuous operability.Therefore,the system can be easily implemented into existing production lines.In addition,compared to conventional heating,the overheating effect and undesirable surface skinning of products are reduced during OH processing,and the energy lost during the heating of the food is minimized(there is no residual heat transfer after the electric current is turned off).During the fermentation process,proofing the dough with OH can make the yeast quickly reach its optimal temperature activity.Using a higher heating rate than conventional proofing can shorten the proofing time by reducing the lag phase[39].The use of OH can lead to lower energy consumption and may therefore be of interest to the baking industry.Proofing by OH results in a lower temperature gradient,which means that the quality of the dough may be improved.In the case of low-temperature yeast dough,OH technology may be of interest[39].Moreover,OH treatment is a promising solution to tackle the quality problems associated with gluten-free bread[40].Gluten-free bread produced by OH achieves the best balance between quality,sensory properties,carbon dioxide release time,and porosity[41].

Applying an electric field under OH may involve electroporation of cell membranes,which limits its use in the commercial development of certain products[4].However,this feature has great advantages when conducting targeted electroporation of the cell membrane.After being applied at the lethal temperature of microorganisms,the electroporation effect caused by OH has shown promise in terms of the use of L.acidophilus in the fermentation process[42].However,despite the potential benefits of this technology,there is a lack of information about its use in fermentation-related processes.In a study comparing fermentation processes using traditional heating(water bath)and conventional heating with OH at a constant voltage value,with fermentation carried out at different temperatures(30-40°C),it was observed that the application of an electric field caused electroporation of the cell membrane and delayed the fermentation period of the product[43].This behavior may be explained by the efficiency of nutrient transport within the cell.Refer to Fig.3 for the fermentation process using OH.

Fig.3.Ohmic heating fermentation process model.

However,the disadvantages of OH also need to be considered.Firstly,in contrast to MWH and RFH,the characteristics of OH dictate that it must have at least two planes that need to contact the material.For the fermented dough,the irregular surfaces may have different contact areas after being squeezed separately by two electrode plates.In other words,the shape and volume of the dough need to be controlled in order to achieve the best heating effect of the OH.Secondly,after the dough has been fermented,some of the sticky proteins may inevitably stick to the contact surface.In addition,the moisture content of the dough seems to be another important factor,since the moisture content and distribution determines the electrical conductivity of the material.This will create additional work for the next batch of dough for fermentation and equipment maintenance.

3.Conclusions and prospects

Through these analysis,it can be seen that these three new thermal technologies have the potential to be widely used in fermentation-related applications(pretreatment,improving the shelf life of fermented food,and enhancing fermentation function).MWH treatment may shorten the fermentation process time,but this requires more supporting evidence.However,MWH may be important as a pretreatment tool in the fermentation process to improve the texture and nutritional value of whole-wheat products because it facilitates the production of valuable compounds.Compared with traditional heat treatments,RFH may improve the shelf life of fermented flour products,as well as their sensory and nutritional properties.It is most promising to use RFH coordination during sourdough fermentation.In addition,OH is a commonly used heating method that has the advantages of accurate temperature control and wide application conditions.OH may be more suitable for gluten-free dough fermentation.

Although the potential use of novel heating technologies seems obvious in the fermentation process,their use is still limited due to the lack of necessary theoretical and databased support.Therefore,further exploration of the combined effect of different setting parameters of MWH,RFH and OH on the fermented dough should be carried out to determine the optimal heating parameter conditions.At the same time,the effect of the novel heating technologies on the fermented dough prepared with different leavening agents(yeast,sourdough,etc.)should also be taken into account.Overall,it is an interesting and challenging task to investigate the application of novel heating technologies in fermented flour products.

Author Contributions

Zhen Wang:Conceptualization,software,writing-original draft preparation;Jihong Huang:Funding acquisition,writing-reviewing and editing;Sen Ma:Supervision,writing-reviewing and editing,project administration;Xiaoxi Wang:Funding acquisition,supervision;Fengcheng Wang:Writing-reviewing and editing;Binghua Sun:Software,investigation;Li Li:Visualization,investigation;Qingdan Bao:Writing-reviewing and editing.

Conflicts of Interest

The authors declare that there are no conflicts of interest.

Acknowledgements

This work was supported by the Key scientific and technological project of Henan Province(No.202102110143),State Scholarship Fund of China Scholarship Council(No.202008410106),Talent Projects from Henan University of Technology(No.2018RCJH08),and Zhongyuan Scholars in Henan Province(No.192101510004).

杂志排行

Grain & Oil Science and Technology的其它文章

- Effect of the degree of milling on the physicochemical properties,pasting properties and in vitro digestibility of Simiao rice

- Vanillin and its derivatives,potential promising antifungal agents,inhibit Aspergillus flavus spores via destroying the integrity of cell membrane rather than cell wall

- Study on crystallization behavior of Tibet butter

- Production of a novel non-toxic γ-PGA/casein composite hydrogel using MTG and optimization by response surface methodology

- Congratulations

- Grain & Oil Science and Technology