Study on Selection of Wheat Varieties for Noodle Production in Hebei Province and Factors Affecting the Processing Quality

2021-04-08GuocongZHANGZhanliangSHI

Guocong ZHANG, Zhanliang SHI

Shijiazhuang Academy of Agricultural and Forestry Sciences/Research Center of Wheat Engineering Technology of Hebei, Shijiazhuang 050041, China

Abstract [Objectives] To screen out the specific wheat varieties for noodle production in Hebei Province and analyze the factors affecting the processing quality of noodle. [Methods] The quality characteristics of grains, flour and noodle of major medium gluten wheat varieties in Hebei Province were detected and analyzed. [Results] The sensory score of noodle is significantly positively correlated with wet gluten content of medium gluten wheat flour, and extensile length, cohesiveness, resilience, elasticity, gumminess, chewiness and extensile distance of TPA of noodle, and is significantly negatively correlated with softening degree. TPA of noodle can indirectly reflect sensory quality of noodle. [Conclusions] Han 7086, Xingmai 4, Liangxing 66, Shiyou 17, Heng 5229 and Liangxing 99 are suitable for producing high-quality noodle, and they can be used as noodle-specific varieties for promoting in Hebei Province.

Key words Hebei, Noodle, Specific wheat variety, Screening, Processing quality, Affecting factor

1 Introduction

As a traditional staple food of the Chinese, noodle has a history of more than 4 000 years. Because of simple preparation and convenient eating, it is very popular in China, especially in the main wheat producing areas in the north. Noodle processing accounts for about 35% of wheat flour consumption, and the proportion shows an increasing trend. With the continuous improvement of people’s living standards, the demand for high-quality noodle has been increasing. Market demand not only raises requirements for the quality of noodle (appearance, texture,etc

.), and at the same time, more and more attention is paid to the quality of flour used in noodle processing. The quality of raw materials has a decisive effect on the quality of processing. To produce high-quality noodle, there must be special flour with stable quality, and the source of special flour is high-quality special wheat. Hebei Province is a major wheat producing province in China, and it is a key development area of high-quality special-purpose wheat. At present, there are numerous wheat varieties promoted in Hebei Province, and most of them are medium gluten varieties. The special varieties suitable for making high-quality noodle are still unclear, so screening out special varieties for noodle processing is imminent.The quality of noodles is affected by many factors including the quality of wheat flour. Different wheat flour quality characters exert effects on the appearance and texture of noodle in different directions and degrees. As early as the beginning of the last century, developed countries in the West were in the world’s leading position in the selection and breeding of high-quality wheat and the production of special flour, and special flour production accounted for 80% of flour output. However, China only started relevant research in the early 1980s. The research on noodle theory is seriously inconsistent with its status as the largest consumer of noodle, and urgently needs to be further strengthened.

Previous studies have found that most wheat varieties suitable for noodle processing are medium gluten wheat. But not all medium gluten wheat is suitable for making noodle. This study intends to select wheat varieties suitable for noodle processing from the major medium gluten wheat varieties in Hebei Province, and to study the factors affecting the processing quality of noodle, so as to provide theoretical and technical basis for the breeding of special wheat varieties, the selection of wheat flour for noodle processing and the government’s agricultural production planning of Hebei Province.

2 Materials and methods

2.1 Materials

A total of 19 medium gluten wheat varieties (grain subsidy) currently promoted in Hebei Province were selected. They were planted in experimental base in Zhao County, Hebei Province (37°50′065″ N, 114°45′715″ E). Field management was carried out as usual. After storing for 3 months, the wheat grains were ground into flour using MLU202 mill. The wheat flour obtained was stored for half a month. Australian Standard White (provided by Yihai Kerry Grain and Oil Co., Ltd.) was used as the control.2.2 Methods

2.2.1

Determination of wheat quality characters. Thousand-grain weight was measured according to GB/T 5519-2008. Bulk density was measured using a bulk density tester according to GB/T 5498-2013 (Changchun Tianhui Technology Co., Ltd.). Grain hardness was measured with near-infrared grain quality analyzer (9100, Perten Instruments Group, Sweden) according to GB/T 21304-2007. Wheat grains were ground into flour with experimental mill (MLU202, Wuxi Buhler Machinery Manufacturing Co., Ltd., China) according to NY/T1094-2006. Flour yield and ash content were measured using experimental mill (MLU202, Wuxi Buhler Machinery Manufacturing Co., Ltd., China) according to NY/T 1094.1-2006, NY/T 1094.2-2006, NY/T 1094.3-2006 and NY/T 1094.4-2006. Flour whiteness was measured with whiteness meter (C-100, KETT, Japan) in line with GB/T 12097-89. Flour color was measured with chromatic aberration meter (CS-80C, Beijing Kangguang Instrument Co., Ltd., China). Protein content was measured by near-infrared grain quality analyzer (9100, Perten Instruments Group, Sweden). Wet gluten content and gluten index were measured with gluten index meter (2200, Perten Instruments Group, Sweden) in accordance with GB/T 5506.2-2008. Farinographic properties were measured with farinograph (810110, Brabender, Germany) in accordance with GB/T 14614-2006. Extension parameters were measured with extensograph (8600.33.002, Brabender, Germany) according to GB/T 14615-2006. Sedimentation value was measured with sedimentation value tester (880508, Brabender, Germany) in line with GB/T 15685-1995. Falling number was measured by falling number meter (1900, Perten Instruments Group, Sweden) according to GB/T 10361-2008. Cohesive parameters were measured with RVA rapid visco analyzer (SUPER3, Newport, Australia) in line with LS/T 6101-2002.2.2.2

Noodle production and quality determination. Noodle was prepared referring to the noodle preparation method of the Grain Testing Center of the Ministry of Agriculture of China. A certain amount (200 g) of wheat flour was poured into a kneading machine (Shanghai Zaomiao Food Co., Ltd.). Within 30 s, the calculated amount of water was added evenly into the kneading machine (132 r/min) to maintain the moisture content of the flour (basic moisture content assigned as 14%) at (30±2)%. After continuing to stir for 30 s, the flour was stirred at a high speed (290 r/min) for 2 min and then stirred at a low speed for 2 min. The reconciled granular dough was poured into a humidor or a humidifying bag, and let standard at room temperature for 30 min. The rolling distance of the noodle press (Beijing Dongfang Fude Technology Development Center) was first set at 2 mm, straight-rolled one time, triple-folded two times and half-folded one time. Subsequently, the rolling distance was set at 3.5 mm, half-folded one time, and straight-rolled one time. Then, at the rolling distance of 3.0, 2.5, 2.0 and 1.5 mm, the dough was straight rolled once. Finally, the rolling distance was adjusted to make the noodle cut at a width of 2.0 mm and thickness of (1.25±0.02) mm. The noodle cut was 220 mm in length.A certain amount (10 strips) of the fresh-cut noodle was put into 1 500-mL boiling water. From the 4min on, the dough pieces were taken out every 30 s to observe whether the core of the noodle was still white. Till the core of the noodle just disappeared, the noodle was cooked well. According to the best cooking time, another 10 strips of noodle were boiled in 1 500-mL water, followed by rinsed in cold water and drained.

Using TA-X2i physical property tester (SMS company, UK), the hardness, viscosity, elasticity, cohesiveness, gumminess, chewiness, and resilience of the cooked noodle were measured with HDP/PFS rectangular probe. The measurement mode was as follows. Force measurement was performed under compressed condition. Before measurement, the moving speed of the probe was 2.0 mm/s; during measurement, the moving speed of the probe was 1.0 mm/s; and after measurement, the probe returned at a speed of 1.0 mm/s. The maximum moving distance of the probe was 75%. The extension force, extension area and extensile distance of the cooked noodle were measured using TA-X2i physical property tester installed with A/SPR aluminum probe. The measurement mode was as follows. Under extension condition, force was measured. Before measurement, the moving speed of the probe was 2.0 mm/s; during measurement, the moving speed of the probe was 3.0 mm/s; and after measurement, the probe returned at a speed of 10.0 mm/s. The maximum moving distance of the probe was 100.0 mm.

2.2.3

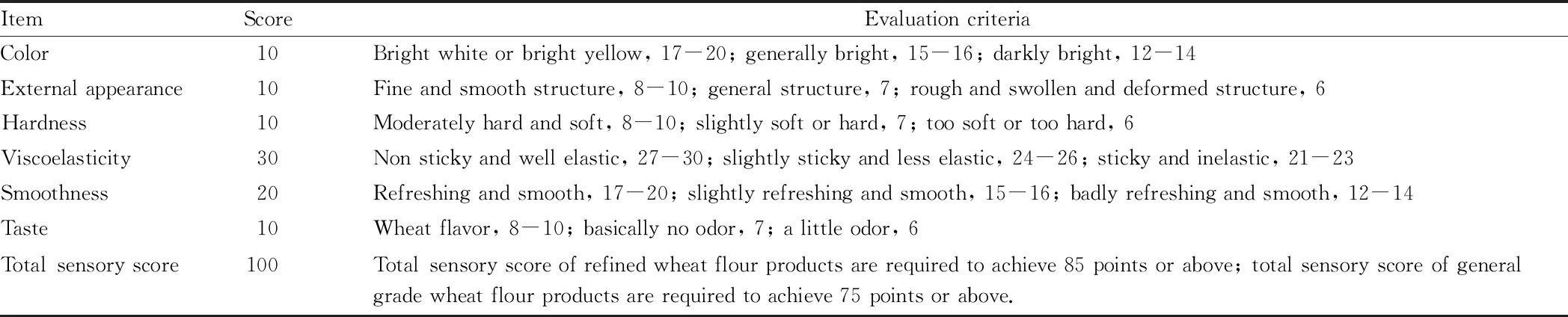

Sensory evaluation. A certain amount (100 g) of fresh-cut noodle was poured into 1 000-mL boiling water and cooked for 7 min. Subsequently, the noodle was taken out and soaked in cold water for 30 s. The noodle was scored by an evaluation panel composed of 6 experienced and trained personnel. The scoring standards referred to the method adopted by the Grain Testing Center of the Ministry of Agriculture of China (Table 1). Considering that the samples collected were all new wheat of the year, with good taste (based on 8 points), only the color, appearance, hardness, viscoelasticity, and smoothness of the noodle were scored.

Table 1 Criteria for sensory evaluation of noodle cooked

2.3 Data processing

The variance of the data was analyzed using SAS V8, and comparisons among treatments were completed using Duncan’s multiple range test.3 Results and analysis

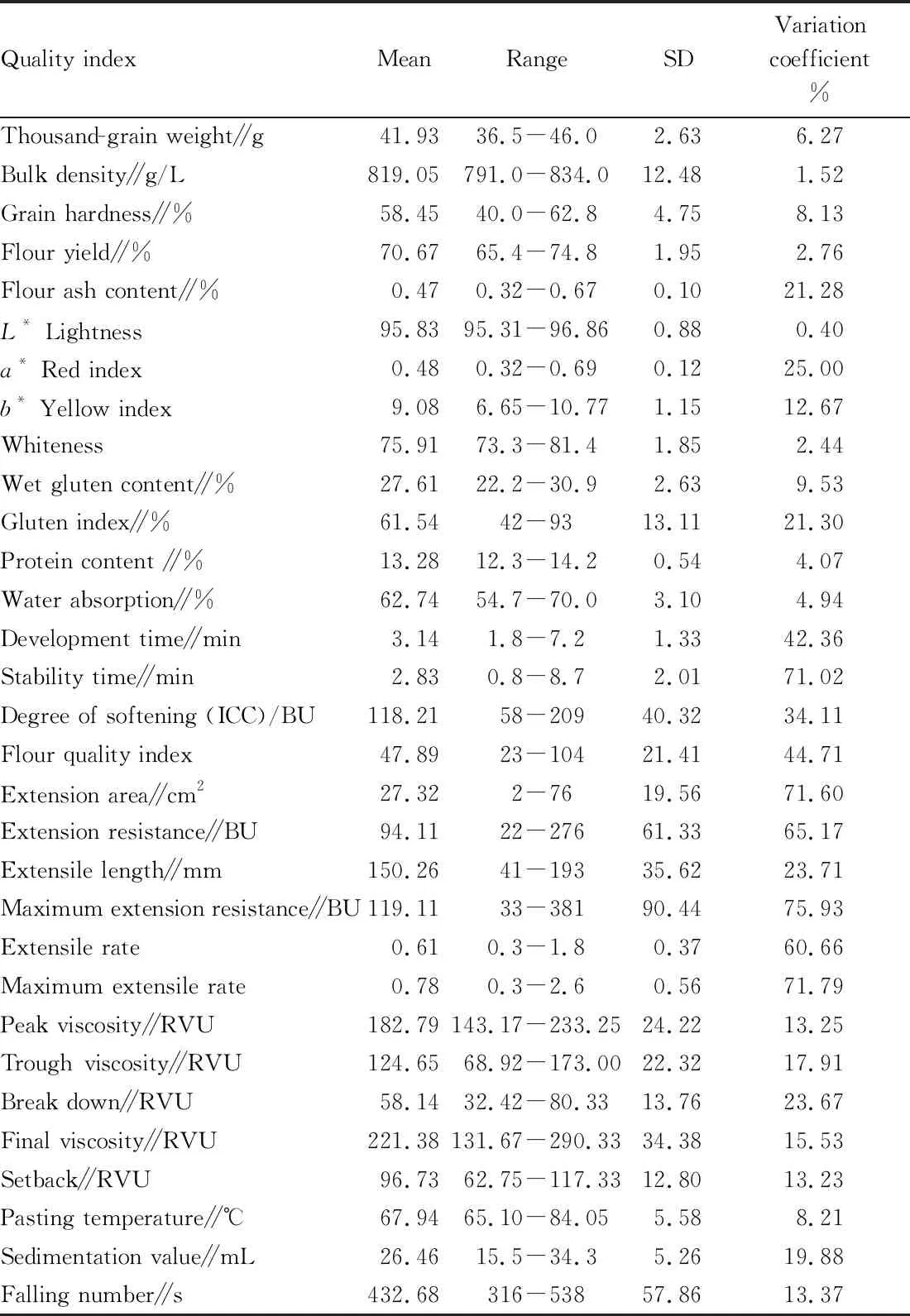

3.1 Quality of major medium gluten varieties in Hebei Province

The coefficients of variation of all the indices, except bulk density, thousand-grain weight, grain hardness, flour yield, flour color L, whiteness, wet gluten content, protein content, water absorption and pasting temperature, were greater than 10% (Table 2). Among them, the coefficients of variation of maximum extension resistance, maximum extensile rate, extension area, dough stability time, extension resistance and extensile rate were 75.93%, 71.79%, 71.60%, 71.02%, 65.17% and 60.66%, all greater than 50%, indicating that most of the quality characters of the medium gluten wheat varieties in Hebei Province are quite different and the genetic diversity is relatively rich.

Table 2 Quality characters of major medium gluten wheat varieties promoted in Hebei Province

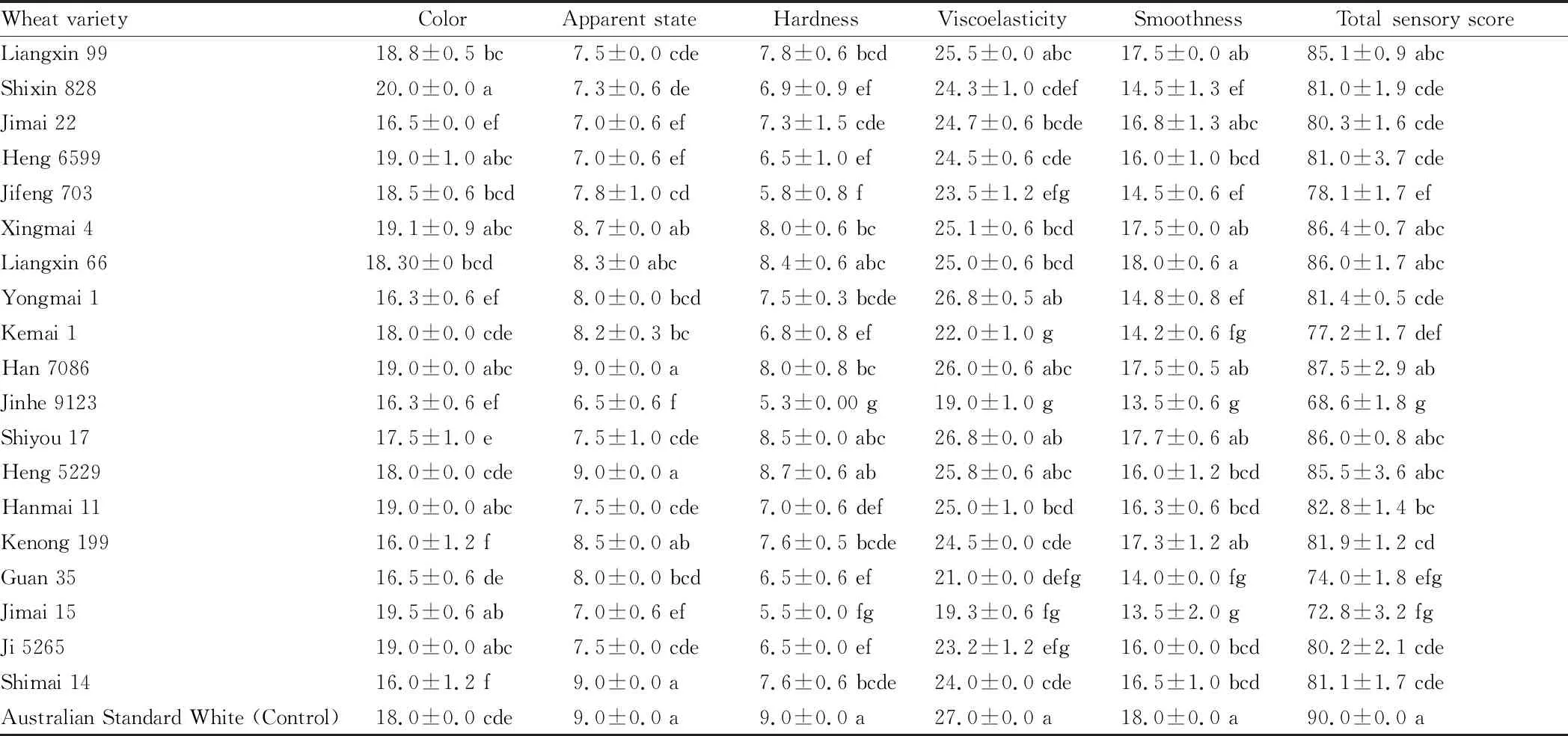

3.2 Sensory evaluation of noodle

The sensory evaluation results of the noodle prepared from the major medium gluten wheat varieties promoted in Hebei Province are shown in Table 3. The color of noodle made from Shixin 828, Shimai 15, Kenong 199 and Shimai 14 was significantly different from the control. Among them, the Shixin 828 and Shimai 15 were higher than the control, while Kenong 199 and Shimai 14 were lower than the control. The difference between other tested varieties and the control was not significant. The appearance of the noodle made from the test varieties, except Xingmai 4, Liangxing 66, Han 7086, Heng 5229, Kenong 199 and Shimai 14, showed a significant difference with the control, poorer than the control. The harness of the noodle made from the test varieties, except Liangxing 66, Shiyou 17 and Heng 5229, was significantly lower than the control. The noodle viscoelasticity of the tested varieties, except Liangxing 99, Yongmai 1, Han 7086, Shiyou 17 and Heng 5229 was significantly lower than the control. The noodle smoothness of the tested varieties, except Liangxing 99, Jimai 22, Xingmai 4, Liangxing 66, Han 7086, Shiyou 17 and Kenong 199 was significantly lower than the control. In terms of sensory score, all the tested varieties were lower than the control, except Liangxing 99, Xingmai 4, Han 7086, Liangxing 66, Shiyou 17 and Heng 5229.The major medium gluten wheat varieties promoted in Hebei Province, except Jinhe 9123, Guan 35 and Shimai 15, are all suitable for making noodle, accounting for 84.21% of the total. For high-quality noodle, the sensory score should be not less than 85 points, and all sensory indices should be qualified. Considering comprehensively, among the major medium gluten wheat varieties promoted in Hebei Province, Liangxing 99, Xingmai 4, Liangxing 66, Han 7086, Shiyou 17 and Heng 5229 are suitable for processing high-quality noodle.

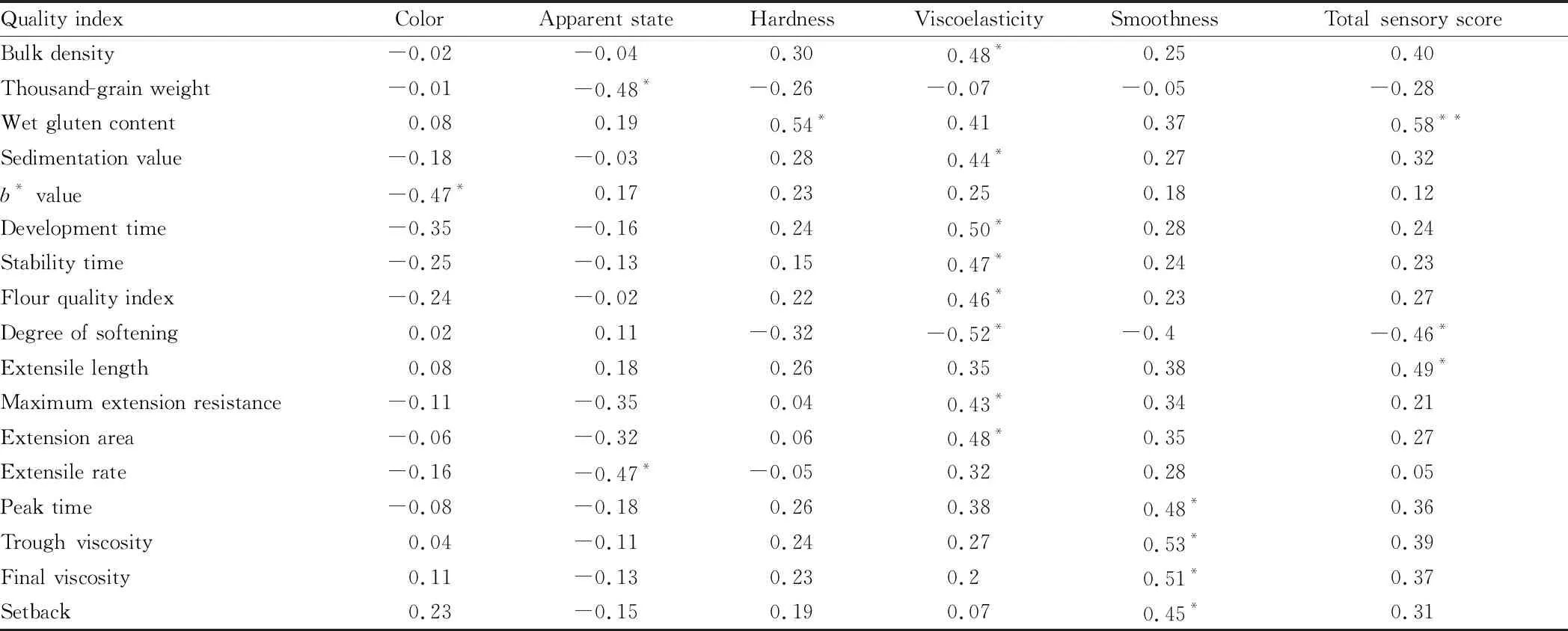

3.3 Correlation between sensory quality of noodle and quality characters of medium gluten wheat

Table 4 shows the color of noodle was significantly negatively correlated with theb

value of wheat flour (P

<0.05). The appearance of noodle was significantly negatively correlated with the thousand-grain weight and extensible rate (P

<0.05). There was a significant positive correlation between noodle hardness and wet gluten content (P

<0.05). The viscoelasticity of noodle was significantly positively correlated with the bulk density, sedimentation value, development time, stability time, quality index, extension force and maximum extension resistance of wheat flour (P

<0.05), and significantly negatively correlated with the softening degree of wheat flour (P

<0.05). The smoothness of noodle was significantly positively correlated with the trough viscosity, final viscosity, setback and peak time of wheat flour (P

<0.05). The sensory score of noodle was significantly positively correlated with the wet gluten content and extensile length (P

<0.05,P

<0.01), and significantly negatively correlated with the degree of softening of wheat flour (P

<0.05).3.4 Correlation between quality parameters and texture profile analysis (TPA)

The color of noodle was significantly negatively correlated with the extension area and extensile distance of the noodle TPA (P

<0.05). There were significant positive correlations between noodle hardness and cohesiveness, extensile distance, elasticity, chewiness, resilience, extension area of noodle TPA (P

<0.05,P

<0.01), between noodle viscoelasticity and hardness, elasticity, cohesiveness, gumminess, chewiness, extension force, extension area, extensile distance and resilience of noodle TPA (P

<0.05,P

<0.01), between noodle smoothness and gumminess, hardness, elasticity, cohesiveness, chewiness, extension force, extension area and extensile distance of noodle TPA (P

<0.05,P

<0.01), and between noodle sensory score and cohesiveness, resilience, elasticity, gumminess, chewiness and extensile distance of noodle TPA (P

<0.05,P

<0.01) (Table 5).

Table 3 Sensory evaluation of noodle made from major medium gluten wheat varieties promoted in Hebei Province

Table 4 Correlation between sensory quality of noodle and quality characters of medium gluten wheat

Table 5 Correlation between noodle quality characters and TPA parameters

Note: *P<0.05; **P<0.01.

4 Discussion

In this study, the medium gluten wheat varieties promoted in Hebei Province were used as the test materials, and through the noodle making trial and sensory evaluation, 6 wheat varieties suitable for making high-quality noodle were screened, providing technical support for the formation of an integrated industrial chain of high-quality wheat planting, production and processing in Hebei Province. This study further verified that medium gluten wheat is the main raw material for noodle flour and most of the quality characters of medium gluten wheat varieties in Hebei Province are significantly different, showing that the genetic diversity of medium gluten wheat in Hebei Province is relatively rich, which can provide rich breeding resources for wheat quality improvement in Hebei Province.

Noodle quality is the result of the comprehensive effect of multiple wheat quality characters. Miskellyet

al

.believed that strong flour can provide Chinese noodles with better hardness and elasticity, and it is more suitable for making Chinese noodle than weak powder. Yang Jinet

al

.believed that the wheat used to make Chinese high-quality noodle requires hard texture, white color, low ash content, high gluten content, high dough strength and good extensibility. Research by Liu Jianjunet

al

.showed that wheat varieties with medium grain hardness, high flour whiteness, high gluten strength, and good starch properties are suitable for making high-quality noodle. Li Bishuoet

al

.found that high-quality noodle require that the protein content, gluten content and dough extensibility of wheat flour should be controlled within appropriate ranges. In this study, the total sensory score of noodle was significantly positively correlated with wet gluten content and extensile length, and significantly negatively correlated with the degree of weakening, showing that the wheat with high gluten content, good extensibility and low weakening degree is suitable for making high-quality noodle. Color accounts for a large proportion in the sensory evaluation of noodle. Color of dough can be predicted through the color of flour, and theb

value of wheat flour has a greater impact on the color of its processed products, consistent with the results of this study. The protein and starch quality of wheat flour affect the quality of noodle. Liu Jianjunet

al

.believed that protein quality mainly affects the texture of noodle, and gelatinization property of starch affect the texture and appearance of noodle. Research by Zhang Xiaoyanet

al

.showed that the dry gluten content affects the hardness of noodle. Ohet

al

.found that gluten protein affects the strength and hardness of Asian noodle, and wet gluten content affects the smoothness and color of Asian noodle. This study found that the content of wet gluten is positively correlated with the hardness of noodle, and the gelatinization property of starch affects the smoothness of noodle, incompletely consistent with the results of previous studies. Li Wupinget

al

.studied the correlation between noodle score and some rheological properties of dough. It is believed that noodle score is significantly related to water absorption rate, stability time, and evaluation score of dough, inconsistent with the results of this study. The results of this study are inconsistent with those of some similar research. This may be related to the differences in the range of the test materials’ strength and the sensory evaluation criteria.The quality of noodle is mainly judged by sensory evaluation, and if instrumental methods are used to replace part of the sensory evaluation, human error will be reduced. Lei Jiet

al

.found that TPA hardness and gumminess can characterize the appearance and toughness of noodle, and elasticity and resilience of TPA can characterize the viscosity and smoothness of noodle. In this study, most of the TPA parameters showed a good correlation with the hardness, viscoelasticity and smoothness of noodle; and the sensory score of noodle was significantly correlated with the cohesiveness, resilience, elasticity, gumminess, chewiness and extensile distance of noodle TPA. The results of this study can provide a theoretical basis for replacing part of sensory evaluation with instrumental methods in the evaluation of noodle quality, thereby reducing human error.杂志排行

Asian Agricultural Research的其它文章

- Construction and Exploration of Ideological and Political Education in Crop Breeding Course

- Research and Practice on the Training Mode of Innovative and Entrepreneurial Talents in Colleges and Universities: A Case Study of Academic Association of "Federation of Life Science Research and Innovation"

- Key Points of Simple Cultivation Technique for Whole-plant Silage Maize in Guangxi

- Breeding of Yuetang 08776, a New Sugarcane Variety Suitable for Mechanized Production

- Effects of Nine Kinds of Household Vase Solutions on Fresh-keeping Effect of Lilium Cut Flowers

- Effects of Straw and Biochar Returned to the Soil on Soil Physical Properties and pH Value in Cold Rice Region