Comparison of the Pore Structure of Ultralow-Permeability Reservoirs Between the East and West Subsags of the Lishui Sag Using Constant-Rate Mercury Injection

2021-03-05WANGJinkaiZHANGJinliangSHENWenlongandLIUHengyi

WANG Jinkai, ZHANG Jinliang, SHEN Wenlong, and LIU Hengyi

Comparison of the Pore Structure of Ultralow-Permeability Reservoirs Between the East and West Subsags of the Lishui Sag Using Constant-Rate Mercury Injection

WANG Jinkai1), 2), 4), ZHANG Jinliang1), *, SHEN Wenlong3), and LIU Hengyi1), 2)

1),,100875,2),,266590,3),,200335,4),,266237,

In this study, the differences in reservoir parameters, such as pore radius, throat radius, and pore-throat ratio, between the east and west subsags of the Lishui Sag are analyzed by using data obtained from a constant-rate mercury injection experiment. Furthermore, the quality of the reservoirs in the two subsags is systematically evaluated. Results show that the throat radius of the Lishui west subsag is larger than that of the east subsag, and this parameter has a positive correlation with reservoir quality. However, the pore-throat ratio of the east subsag is larger than that of the west subsag, which has an inverse relationship with reservoir quality. The main reasons for this reservoir difference can be attributed to sedimentation and diagenesis. The sedimentary facies types of the Lishui east subsag are the fan delta, shore lake, shallow lake, and shore shallow lake; their sandstone composition maturity is low; the clay mineral content is high; and the rock has undergone strong diagenesis. Therefore, the physical conditions of the reservoir are poor. However, the sandstones in the Lishui west subsag have weak cementation and compaction, mainly with an intergranular pore structure type, which leads to good connectivity between pores. Therefore, the storage performance and seepage capacity of the Lishui west subsag are better than those of the east subsag; the west subsag is the main area of oil and gas accumulation, as confirmed in the process of exploration and development.

Lishui Sag; constant-rate mercury injection; sedimentary facies; diagenesis; rock pore structure

1 Introduction

1.1 Research Status of Ultralow-Permeability Sandstone Reservoir Development

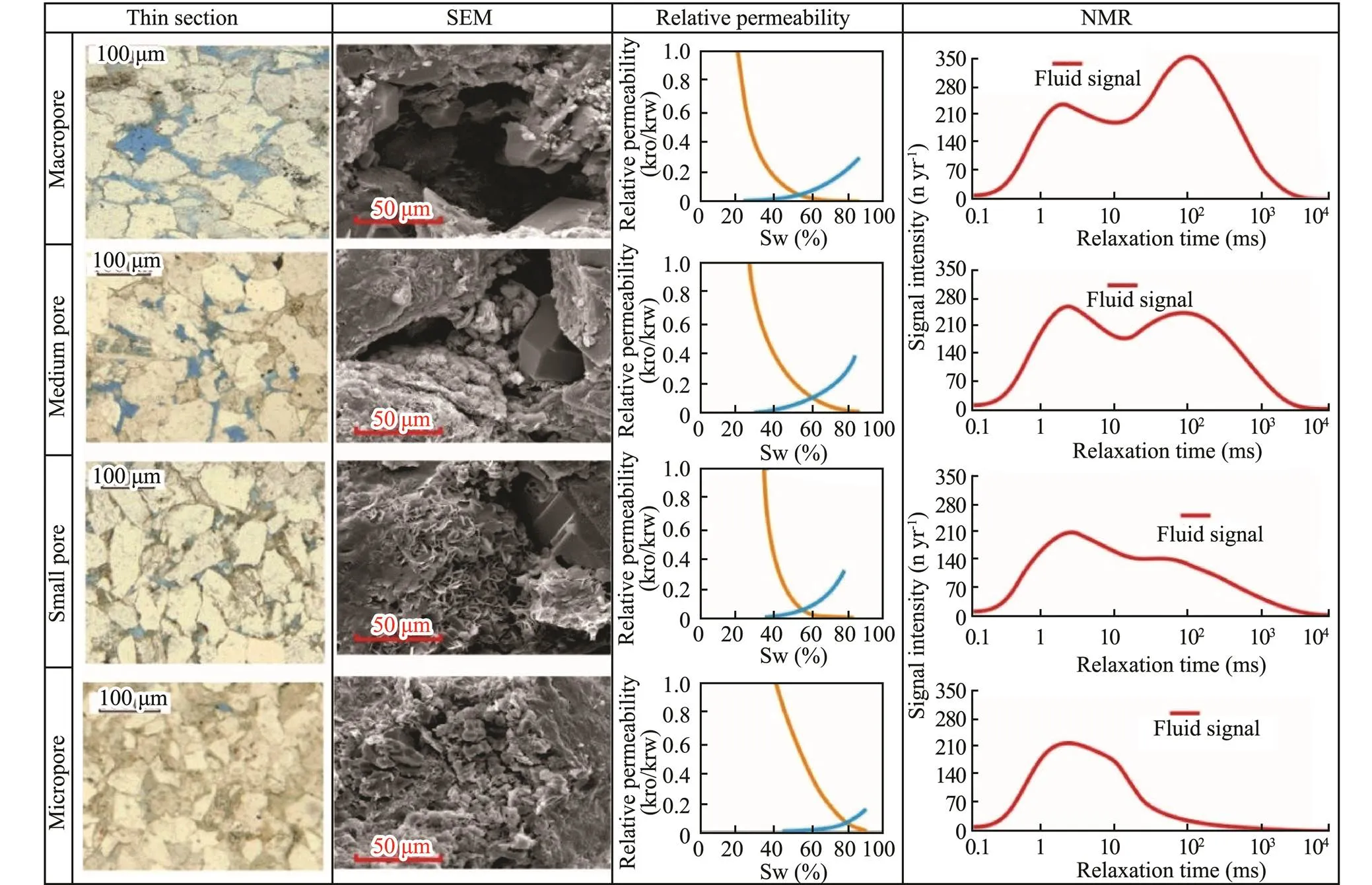

For general sandstone reservoirs, the pore structure of the reservoir changes greatly with the decrease in rock per- meability. These changes are mainly reflected in the following aspects:

1) When permeability decreases, the pore type of rock gradually changes from macropore to micropore, and the filling materials (clay minerals, carbonate minerals, siliceous minerals, iron minerals,.) in the pore gradually increase, thus greatly reducing the pore size and connectivity, this is the dominant factor of rock compaction (Zhang and Zheng, 2009; He., 2011).

2) When permeability decreases, the seepage law of rock changes greatly. The fluid flow in reservoirs with conventional pores and throats is mainly linear Darcy seepage; however, the seepage law of low-permeability res-ervoirs no longer obeys Darcy’s law, and a non-Darcy ef- fect becomes evident, leading to low reservoir recovery efficiency (Chen., 2018).

3) The proportion of movable fluids in low-permea- bility reservoirs is considerably lower than that of bound fluids due to the high content of clay minerals, irregular microstructure, and rough particle surface.

An ultralow-permeability reservoir is an important type of low-permeability reservoir; its pore structure is com- plex, and it has many types of diagenesis. Compared with conventional medium or high-permeability reservoirs, the relationship between the pore skeleton and the fluid percolation law has changed greatly; these changes cause the fluid flow in such reservoirs to be strongly affected by the interface effect, which is not conducive to oil recovery. Therefore, high oil recovery is difficult to achieve by using conventional technology to develop such reservoirs (Fig.1).

The purpose of micro pore structure evaluation is to characterize the size, shape, connectivity, and distribution of rock pores accurately through various experiments; on this basis, the correlation between these micro and macro parameters (porosity, permeability), which are an important link of reservoir quality evaluation in the process of oil and gas field exploration and development, is evaluated (Lai., 2018). In addition, the research results of sedimentary facies and diagenesis should be combined in the evaluation of micro parameters because the decisive factors of reservoir physical parameters are often the source and formation process of rocks. At present, researchers have two main methods, including a physical experiment method and a numerical simulation method, to characterize the pore structure of low-permeability reservoir rocks (Desbois., 2011). Physical experiment methods: a se- ries of data reflecting reservoir properties (pore radius, throat radius, particle size, ratio of movable fluid,.) is obtained through scanning electron microscope observation, cathode luminescence analysis, C–O isotope analysis, casting thin section observation, conventional mercury in- jection experiment, constant-rate mercury injection experiment, and a nuclear magnetic resonance experiment; then, data are analyzed by mathematical statistics to find some rules for the quantitative study of the spatial structure, wettability, and fluid distribution of low-permeability reservoirs (Mai, 2013; Deglint., 2017; Liang., 2017). On this basis, the limits and criteria of reservoir classification evaluation are established, and the storage performance and percolation capacity of low-permeability reservoirs are evaluated and comprehensively combined with diagenesis and physical property evolution analysis (Zhang., 2007; Xi., 2015), thereby providing a basis for the rational development of reservoirs (Yang.,2006). Numerical simulation method: it simulates the pore structure and fluid seepage process of rocks by establishing two- or three-dimensional spatial models and reproduces the internal structure and seepage law of low-per- meability reservoirs in the computer (Shu., 2016; Zhang., 2018). Using advanced X-ray CT monitoring equipment is also one of the numerical simulation research methods that use image segmentation and three- dimensional image reconstruction technology to evaluate quantitatively the distribution characteristics of bound water in two-dimensional slices and in three-dimensional pore spaces, thus characterizing its microoccurrence state (Gu., 2018). Furthermore, the application of fractal theory makes the characterization of reservoir micro pore structure more refined and realizes the quantitative characterization of different scale spaces (Lai., 2016). In recent years, with the continuous development of oil and gas exploration and development technology, unconventional reservoirs have become a trending research topic, and the research methods and technical means, which can characterize the micropore structure characteristics of reservoirs from different angles, are constantly being updated. Particularly, the constant-rate mercury injection experiment can describe the distribution of the micro pore structure more completely, thereby making the research results more intuitive and convincing (Dai., 2012).

Fig.1 Pore structure and seepage characteristics of reservoirs with different permeability levels.

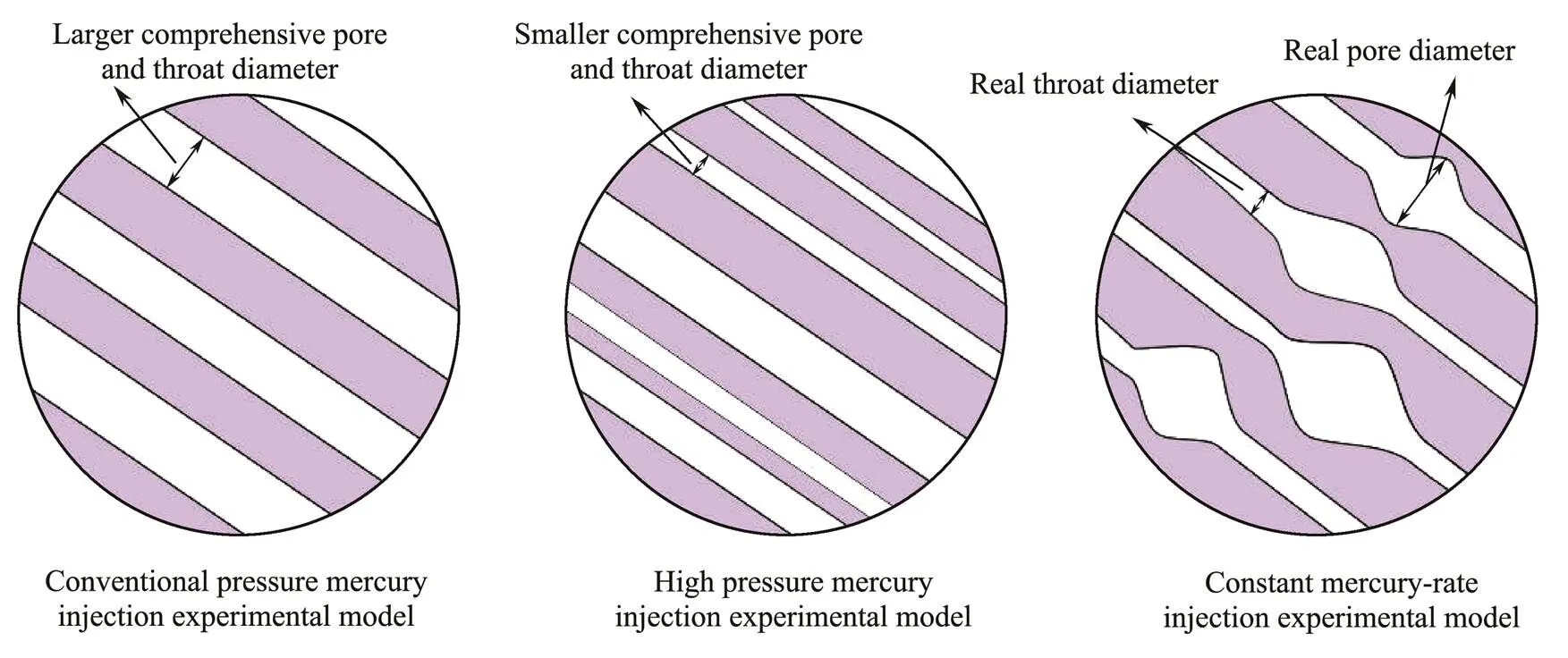

1.2 General Situation of Mercury Injection Technology

At present, two kinds of mercury injection experiments, namely, conventional and constant-rate mercury injection methods, are commonly used in the field of oil and gas development; both can obtain pore structure parameters of reservoir rocks, thus providing an objective evaluation of the reservoir properties. The conventional mercury in- jection experiment contains two different types: high-pre- ssure and conventional-pressure mercury injection, which have a wide range of application, mature technology, fast testing speed, and certain advantages (Lai and Wang, 2015). These two types of conventional mercury injection expe- riments have the same principle; however, high-pressure mercury injection experiments can measure the pore-throat space with a smaller scale than the conventional method due to its higher mercury injection pressure, which is more suitable for the study of micro pore structure characteristics of tight reservoir. In addition, conventional mercury injection experiments obtain parameters that reflect the pore size and seepage capacity, thus determining the lowerlimit of physical properties but not accurately distinguishing between pore and throat grades. The constant-rate mer- cury injection technology can freely control the pressure rise and fall in the experimental process to obtain the number distribution of pore throats; moreover, it can provide the capillary curves of the pore throats. It can also quantitatively evaluate the size and quantity of the reservoir pore and throat and has wide applicability (Fig.2).

In 1921, a mercury injection experiment was first used to determine the pore size and distribution of rocks. With continuous development and improvement, this technology has gradually developed into one of the most important methods in the field of reservoir pore structure characterization (Pitman, 1996; Tsakirogloua and Payatakesa, 1998). The constant-rate mercury injection method is one of the most advanced techniques for testing low-per-meability and thus has advantages over the traditional mercury injection method. It can provide more detailed mea- surement parameters and is more suitable for ultralow- permeability sandstone reservoirs with variable pore-throatproperties. The constant-rate mercury injection experiment can characterize the micro pore-throat system of the sand- stone reservoir. It can separate the pore and throat to obtain their parameters and quantitatively evaluate their cha- racteristics.

In addition, the capillary pressure curve of the reservoir can be obtained by a constant-rate mercury injection experiment, and parameters, such as the pore-throatsize, sortability, connectivity, and percolation capacity, canbe quantitatively determined by period analysis (Wang., 2003; Zhu., 2015). However, the constant-rate mercury injection experiment is time consuming and has some limitations in its application; therefore, it is not suitable for all pore structure research processes. By contrast, conventional mercury injection has great advantages in experimental efficiency and adaptability. Thus, in the actual research process, the two experimental methods can be reasonably fused to maximize their respective advantages so that the comprehensive evaluation of low- permeability reservoirs can be efficiently completed (Dou., 2016; Wang., 2018). In summary, the research methods of the micro pore structure are becoming more advanced, and the description methods are more diversified and refined to form qualitative and semiquantitative to quantitative characterization gradually. In this respect, constant-rate mercury injection technology has played an important role in promoting the deepening and accuracy of reservoir pore structure research.

Fig.2 Comparison of different types of mercury injection experiments.

2 Geological Settings

The Lishui Sag is structurally located southwest of the East China Sea Shelf Basin, adjacent to the Jiaojiang Sag in the north, the Yandang uplift in the east, and the Minjian uplift in the west and south. It developed on the basis of Mesozoic residual basins. At the end of the late Cretaceous, the Lishui Sag began to rift and was divided into the east and west subsags by the Lingfeng uplift. At the deposition stage of the Mingyuefeng formation in the late Paleocene, the Lingfeng uplift was gradually covered by sediments. The Lishui Sag is distributed in the NE–SW direction, and the distribution area of sedimentary rocks is approximately 15000km2(Chen., 2017). It is divided into five tectonic units by the NNE-trending fault system: Lishui west subsag, Lishui east subsag, the Lingfeng uplift, the Lishui south subsag, and the Lishui south uplift; the east and west subsags are the main oil and gas-bearing areas. The area of the east subsag is from 4300km2to 5100km2, and the maximum sedimentary thickness is from5000m to 8000m. The area of the west subsag is from 7800km2to 10000km2, and the thickest part of the deposit is from 10000m to 14000m (Fig.3).

Fig.3 Structural location map of the Lishui Sag.

3 Research Ideas and Methods

The east and west subsags adjacent to each other of the Lishui Sag have many differences due to their different forming process and filling mode. The most evident difference is the type of sedimentary microfacies; the beach bar facies far away from the source area dominates the west subsag, whereas the fan delta near the source area occupies the main part of the east subsag. The difference of sedimentary environment and facies results in the difference of reservoir rock type, pore structure, and filling material; these differences, especially the pore and throat characteristics of ultralow-permeability sandstone, which can only be described in detail with the help of accurate quantitative characterization experiments, are difficult to characterize from the macroscopic view. In view of this, the constant-rate mercury injection experimental method is used for the comparative study on the pore structure cha-racteristics of ultralow-permeability sandstone in the two subsags of the Lishui Sag to determine the differences be-tween them and provide guidance for the exploration and development of the gas field.

Firstly, in accordance with the division of structural units in the Lishui Sag, two main oil and gas-bearing areas are selected to compare the reservoir properties, and 21 samples of low-permeability rocks from seven coring wells in the Lishui east and west subsags (Table 1) were tested one by one. The quantitative values of the pore and throat parameters of rocks were obtained, and the expe- rimental data were analyzed statistically. Then, by using the parameters of porosity, permeability, pore radius, throatradius, pore-throat ratio, and displacement pressure, the re- servoir properties and fluid properties of the two subsags were systematically evaluated, and the controlling factors of the reservoir quality were defined. Lastly, in combination with data from casting thin section analysis, scanning electron microscopy (SEM), and physical property ana- lysis, the differences in the pore structure between the east and west subsags were compared, and the main reasons for the great differences between the two subsags were dis- covered (Fig.4).

Table 1 Classification of the permeability of the experimental samples

Fig.4 Research process of this study.

The sandstone in the two subsags of the Lishui Sag belongs to ultralow-permeability level and has poor physical properties, low porosity, and permeability. However, the analysis of rock samples from different wells in the study area shows that the sandstone petrological characteristics of different sampling locations are different; moreover, the components, structures, and grain sizes of the sandstone are also different, indicating that evaluating the reservoir in accordance with a single standard is not accurate. Therefore, dividing different levels according to their permeability and comparing their differences under the same level are reasonable to make the target of comparison clear and draw a practical conclusion.

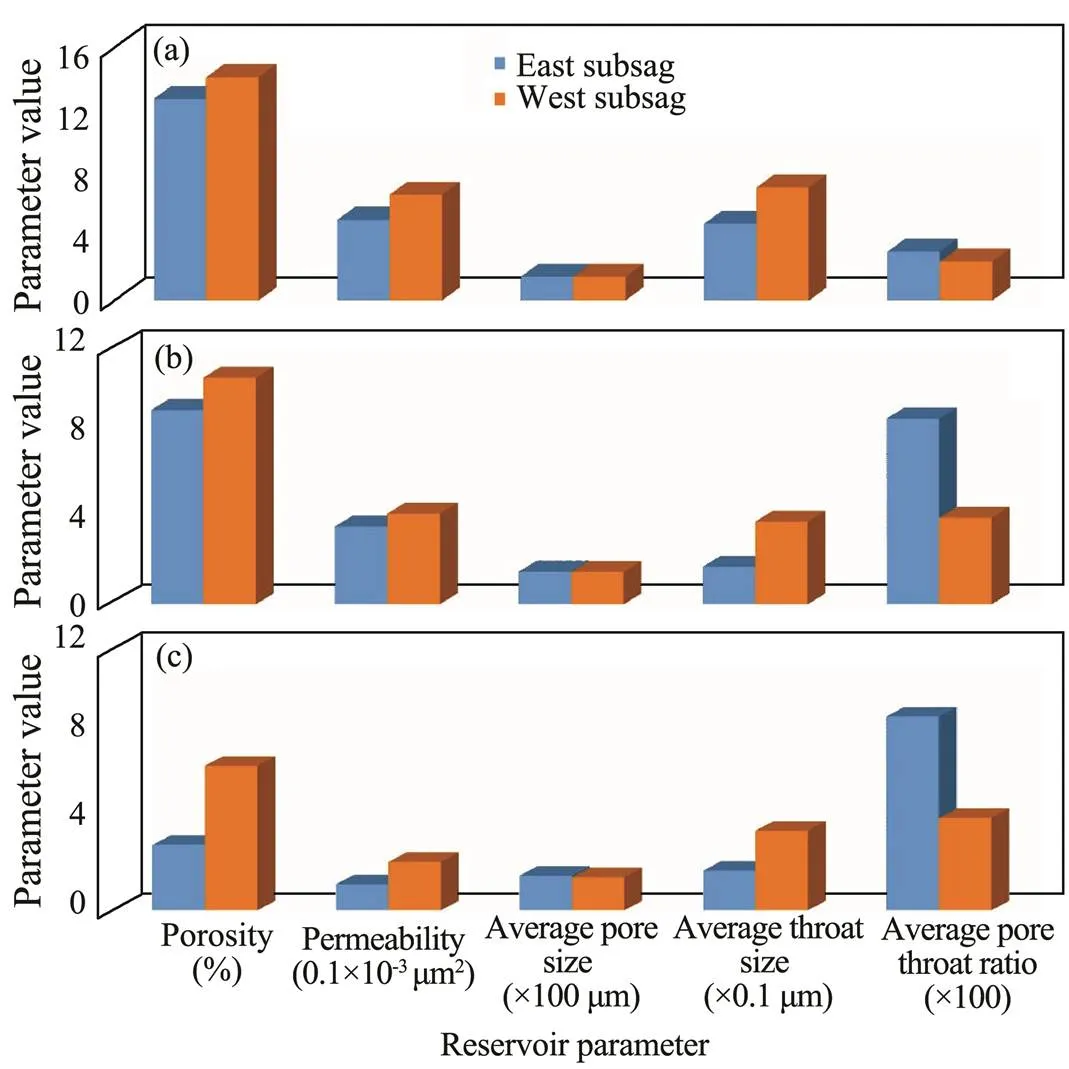

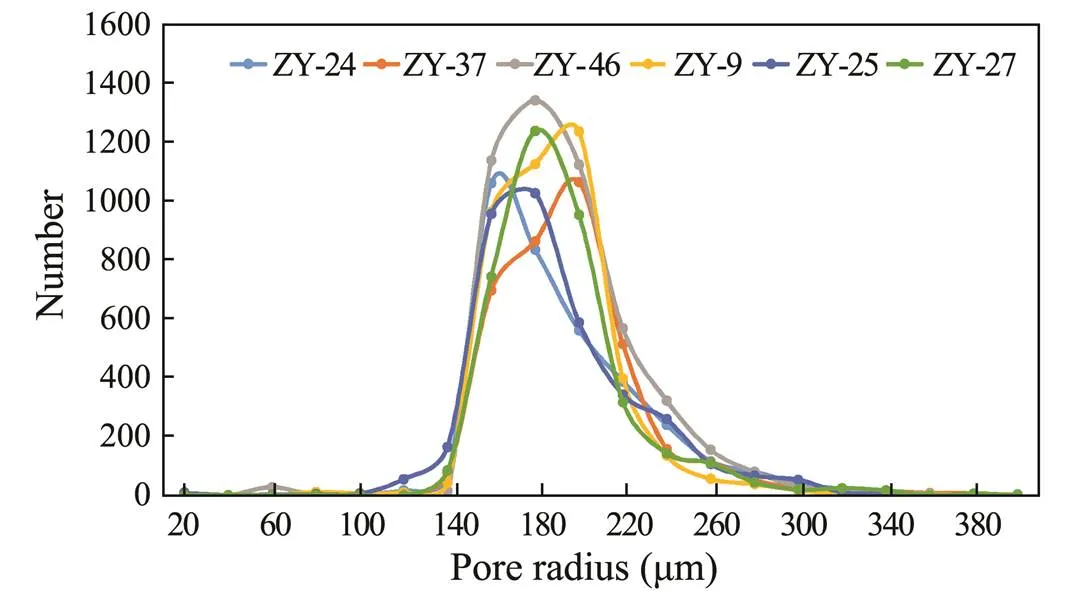

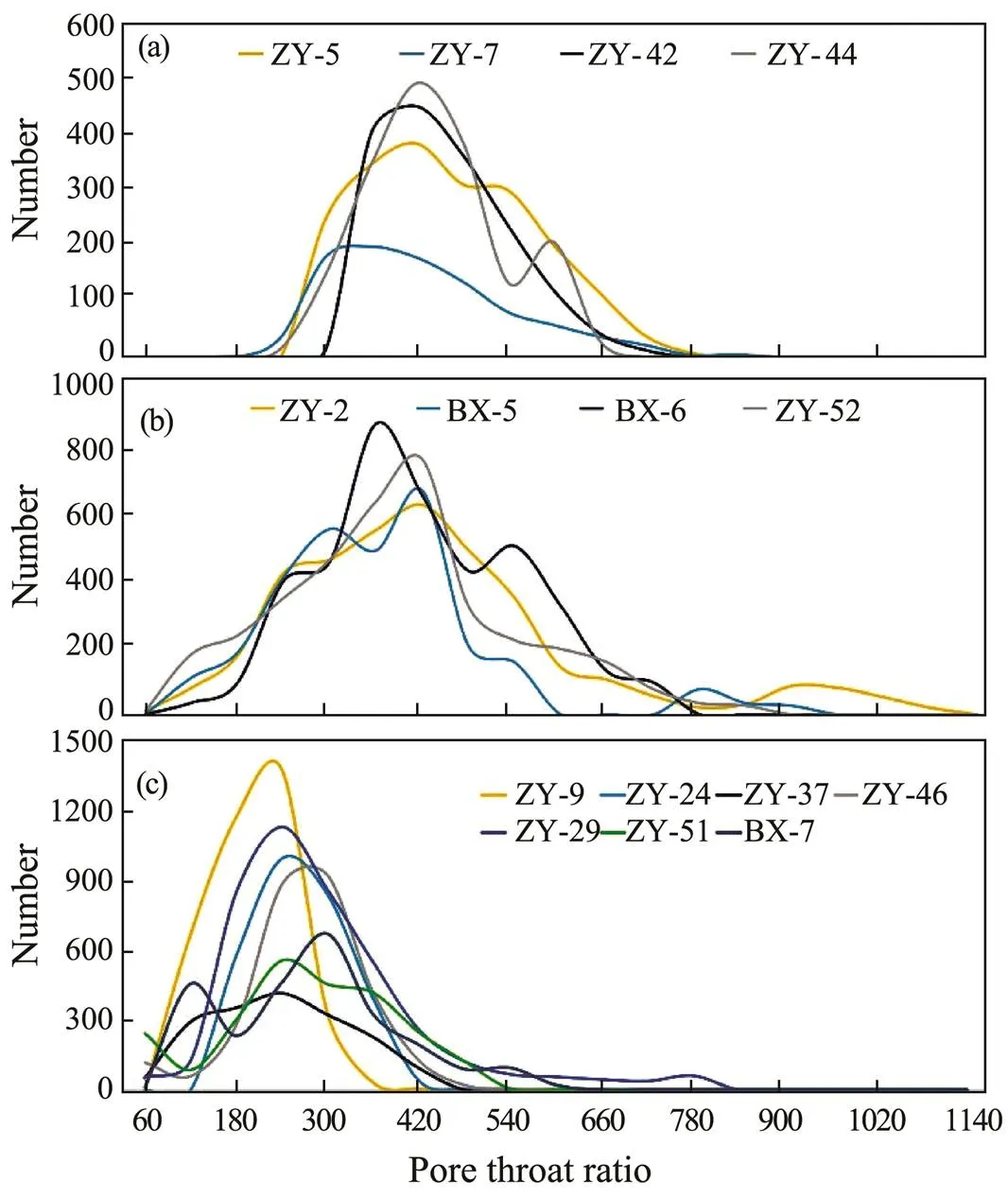

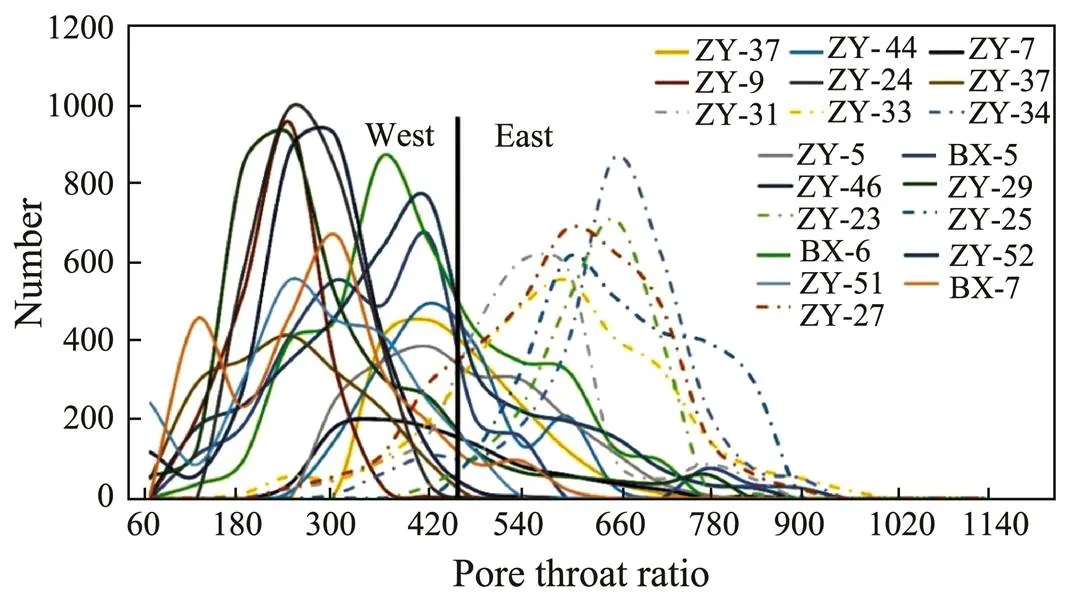

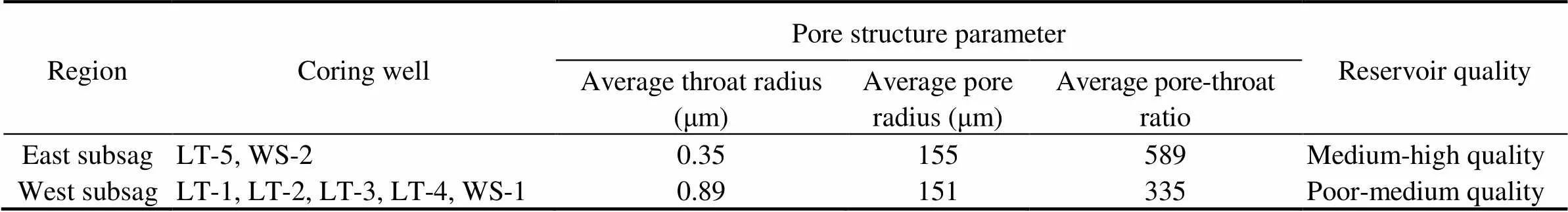

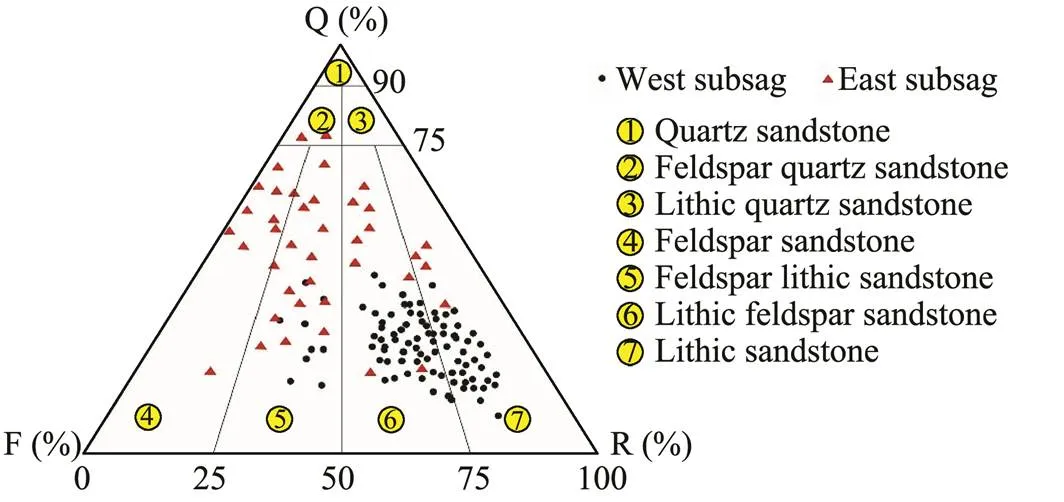

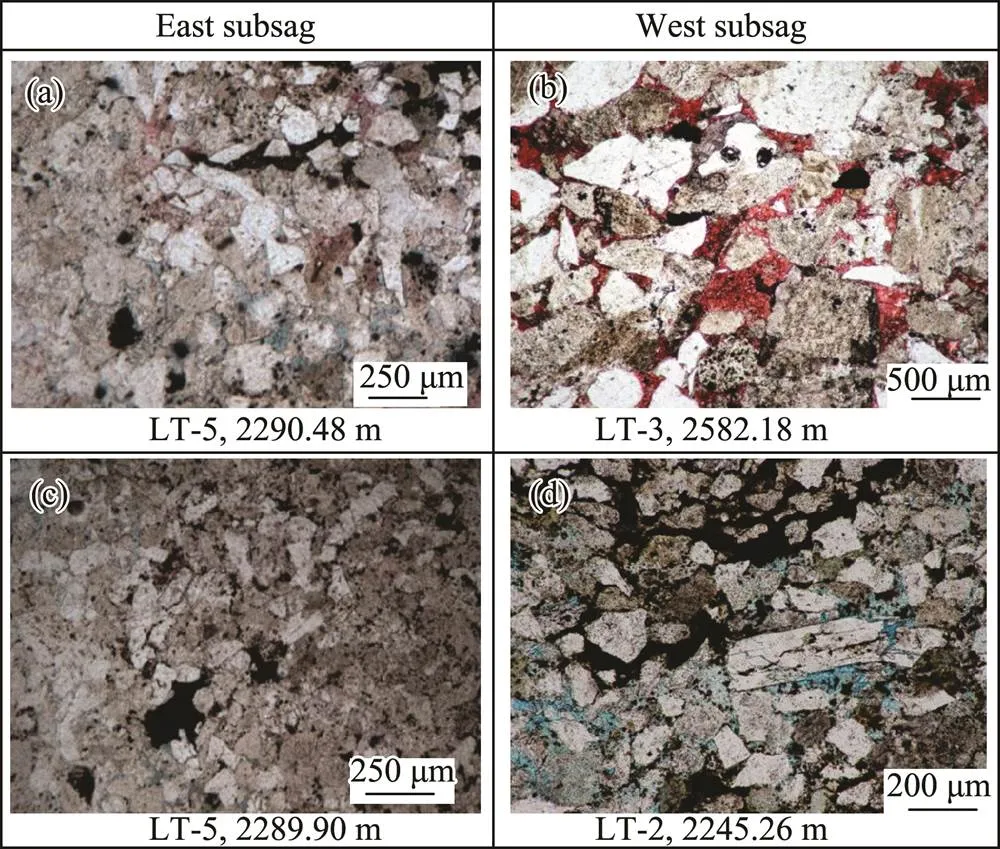

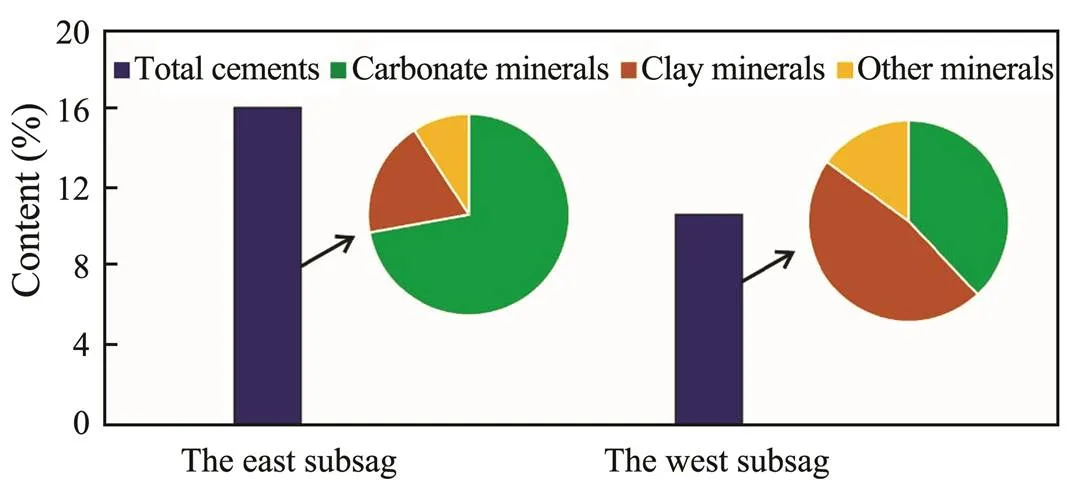

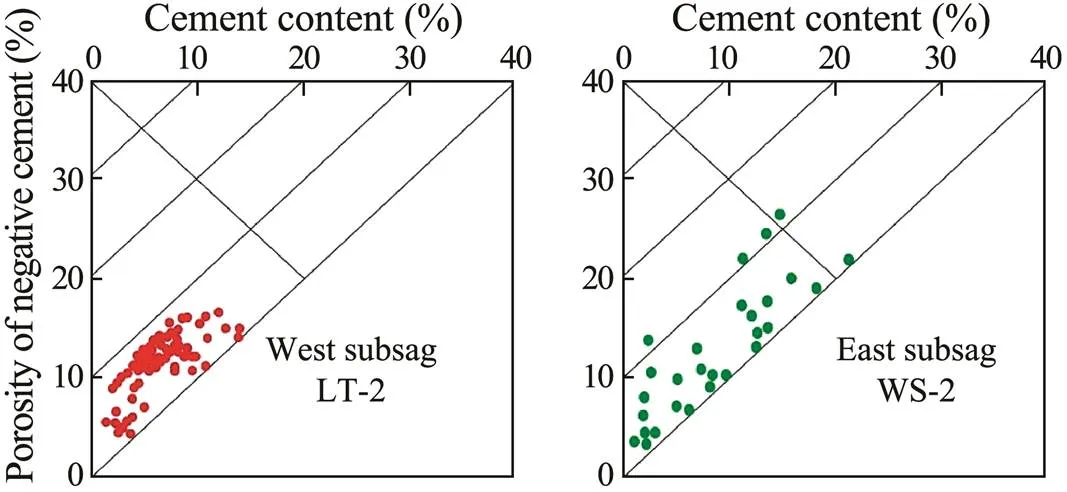

According to the reservoir physical parameters that were obtained from various experiments, the ultralow-perme- ability reservoirs in the Lishui Sag were divided into three different grades: Grade I (0.5mD In this study, the evaluation criteria of reservoir differentiation are mainly based on parameters, such as the pore radius, throat radius, and pore-throat ratio, and the difference in the pore structure of the reservoir can be distinguished by comparing the size of these parameters. The pore-throat parameters are the main evaluation parameters of the sandstone reservoir physical properties, which represent its storage performance and seepage capacity. Generally, the larger the absolute size of the pore and throat radius, especially the larger the throat radius, the better the physical properties of the reservoir. The size and shape of the throat control the permeability of the re- servoir (Jozefaciuk, 2009; Gao and Zhang, 2011). The small- er the difference of the pore-throat of the reservoir rocks, the more similar the pore radius and throat radius and the closer the radius of the capillary in the porous media net- work. Therefore, the additional seepage resistance of these reservoirs is weak, the fluid flows easily, and the reservoir recovery is high (Table 2). Fig.5 is a comparative columnar chart of the characteristic parameters of the different grade samples in the east and west subsags of the Lishui Sag. The graph shows that the porosity and permeability parameters of the reservoirs in the two subsags have good correspondence. The reservoir porosity and permeability of the west subsags are higher than those in the east subsags; the reservoir average throat diameter of the west subsags is higher than that in the east subsags, but the difference in the pore radius between the two subconcaves is small; therefore, the pore- throat ratio of the east subsag are higher than that of the west subsag. The difference of these parameters indicates that the source of the two subsags is different. The source of the west subsag is single, the maturity of the debris composition and structure is relatively high, and the quality of the sandstone is relatively pure. However, the sandstone type of the east subsag is complex, and the detritus are from different source regions whose sorting is poor; thus, its reservoir property is poor. In addition, the types and intensities of diagenesis that are experienced by the two subsags are different, especially with regard to later cementation and dissolution, resulting in the cementation strength of the west subsag being lower than that of the east subsag. The throat is a narrow passage that corresponds to the pore structure. The throat radius is an important parameter in constant velocity mercury injection experiments. When seepage occurs, the fluid enters the connected pore through the throat; when the pore space is filled, the fluid flows out into another pore through the next throat again. Its size directly controls the seepage ability and capacity of the reservoir, thus corresponding well to the physical and heterogeneous characteristics of the reservoir. 1) Comparison of the reservoir throat with different permeability levels Fig.6 shows the distribution curve of the sample throat radius with different permeability levels. The peak value of the curve of grade III samples is mostly distributed be- tween 0.23 and 0.55 microns, and the distribution of these curves is concentrated; moreover, the frequency distribution area is small, indicating that the throat is small, but its sortability is good (Fig.6a). The distribution range of the curve of the grade II samples was enlarged, the peak value distribution of the curve began to diverge, and the total value was between 0.31 and 1.2 microns. The distri- bution of the sample points began to appear in the range of 2 microns, indicating that the throat radius of the sample had gradually increased (Fig.6b). The curve distribution of grade I samples was wider and began to extend to the numerical range of 5 microns or even to more than 10 microns (Fig.6c). Although the peak value was not much different from grade II, the distribution of the large throat diameter increased remarkably, and the trend of the curve change was much gentler than before. Table 2 Basic parameter information of constant velocity mercury injection experiment Fig.5 Contrast of the low-permeability reservoir parameters of different grades. Fig.6 Distribution of the pore-throat curve of the sample with different permeability levels. Based on the curves, the radius of the throat shows a general increasing trend with the increase in permeability. Its curve distribution pattern tends to be smooth, its distribution range increases and gradually transits to a multi- peak state, and the number of roaring paths increases con- siderably. A comprehensive analysis shows that the throat radius has a great influence on the reservoir quality, and the absolute size of the throat radius is proportional to the reservoir permeability. 2) Throat radius comparison between the east and west subsags Fig.7 shows the distribution of the throat radius of all samples of the east and west subsags. The figure shows great differences in the shape of the throat radius curves of the two subsags; their distribution intervals and peak values are also different, and they can be easily divided into two parts according to these characteristics. In the east subsag, the frequency distribution area of the throat radius is small, the curve fluctuation is large, the distribution range of the laryngeal duct is small, and the peak value is small. The radius range of the laryngeal duct is 0.19–0.55µm (average is 0.35µm). However, the frequency distribution of the throat radius in the west subsag is large, the peak value becomes larger, and multipeaks are present; however, the curve fluctuation is small, and the average laryngeal radius is 0.89µm. Comprehensive analysis shows that the throat radius of the west subsag is generally larger than that of the east subsag reservoir, and the number of large throat distributions in the west subsag reservoir is considerably larger than that in the east subsag. Fig.7 Radius comparison of the concave throat between the east and west subsags. The pore is the main location where fluids are stored in the rocks. Fluids flow into the pore through the throat and is stored in the pore. Therefore, the pore size determines the reservoir storage capacity. 1) Comparison of the pore radius with different permeability levels Fig.8 shows the samples’ pore radius curves with different permeability levels. The figure shows that the pore radius curves of samples with different permeability levels have minimal difference, and the distribution range is similar. However, with the increase in permeability, the dis- tribution range of the pore radius shifts slightly from 100–200µm to 160–240µm. The analysis shows that the size and distribution of the pore radius have minimal effect on reservoir permeability and that they have less effect on the reservoir permeability than on the throat radius. The pore radius mainly affects the storage capacity of the reservoir; thus, judging the quality of the reservoir only by the parameters of the pore radius is difficult, and other evaluation parameters must be used simultaneously. 2) Comparison of the pore radius between the east and west subsags Fig.9 shows the pore radius distribution curves of all the samples in the east and west subconcaves. The figure shows that the pore radius distribution curves of the east and west subconcaves are similar in shape and have mi- nimal difference. Their distribution ranges are relatively concentrated, mainly between 150 and 220 microns. There- fore, as far as the parameters of the pore radius are concerned, the east and west subsags have minimal difference. Fig.8 Pore size distribution curves with different permeability levels. a, grade I samples; b, grade II samples; c, grade III samples. Fig.9 Comparison of the pore radius between the east and west subsags. The pore-throat ratio is one of the most important parameters in a constant-rate mercury injection experiment; it refers to the ratio of the pore radius to the throat radius. The pore-throat ratio reflects the relative difference between the pore and the throat, as well as the heterogeneity of the reservoir. The larger the pore-throat ratio, the greater the difference between the pore and the throat, and the stronger the heterogeneity of the reservoir. The smaller the pore-throat ratio, the smaller the difference between the pore and throat, the closer the radius of capillary in porous media network, and the stronger the permeability (Zou., 2015). 1) Comparison of the pore-throat ratio with different permeability levels Fig.10 shows the pore-throat ratio curves of samples with different permeability levels. As shown in the figure, the pore-throat ratio decreases continuously with the increase in reservoir permeability. The pore-throat ratio distribution range of the grade III samples is mainly 240–660µm (Fig.10a), that of the grade II samples is mainly 180–480µm (Fig.10b), and that of the grade I samples is mainly 120–360µm (Fig.10c). A comprehensive analysis shows that a close relationship exists between the reservoir permeability and pore-throat ratio; this relationship changes inversely. The larger the pore-throat ratio, the greater the pore-throat difference, the stronger the reservoir heterogeneity, and the lower the reservoir quality. Fig.10 Pore-throat ratio distribution curves with different permeability levels. 2) Comparison of the pore-throat ratio between the east and west subsags Fig.11 shows the sample pore-throat ratio distribution curve of the east and west subsags. The figure shows that the pore-throat ratio of the east subsag samples is larger than that of the west subsag samples; the main distribution range of the pore-throat ratio of the east subsag sample is 360–700 (average: 549), whereas that of the west subsag sample is 160–440 (average: 275). The difference between the pore and throat in the east subsag is strong, the overall heterogeneity of the reservoir is strong, and the additional seepage resistance is strong; therefore, reservoir development is difficult. However, the pore-throat ratio of the west subsag is relatively small, the difference between the pore and throat is small, the reservoir heterogeneity is weak, the seepage capacity of a single pore is controlled by a large throat, the oil and gas seepage re- sistance is weak, and the development effect is better than that of the east subsag. Fig.11 Comparison of pore-throat ratios between the east and west subsags. In accordance with the parameters of pore, throat, and total mercury saturation obtained from experiments, the capillary pressure curves of samples can be calculated and analyzed. The distribution law and relationship of the pore and throat in the reservoir can be clarified, and the basic law of fluid seepage in the reservoir can be clarified; thus, the reservoir properties can be reasonably distingui- shed. The mercury intrusion curves of samples with different permeability levels show that in the early stage of constant pressure mercury intrusion, the curve is mainly controlled by pore pressure; however, with the advancement of the experimental process, the pore space is gradually filled, and the pressure curve becomes mainly controlled by the throat. Overall, the mercury pressure of the first, second, and third permeability samples decreases gradually during the mercury injection process; that is, the mercury pressure increases with the decrease in permeability (Fig.12a). The capillary pressure curves of the east and west subsags show that under the same mercury injection pressure, the mercury saturation of the east subsag is lower than that of the west subsag, the pressure curve of the east subsag is not as smooth as that of the west subsag, and the reservoir sorting and reservoir quality are lower than that of the west subsag (Fig.12b). The pore radius of the east and west subsags is similar; however, according to the parameter analysis results of the constant-rate mercury injection experiments, the throat radius of the west subsag is larger than that of the east subsag, and the pore-throat ratio is smaller than that of the east subsag. Therefore, the difference between the pore and the throat is small, its heterogeneity is weak, and its seepage ability is strong; the reservoir quality is remarkably better than that of the east subsag. Comprehensive ana- lysis shows that the main reasons for this difference are sedimentation and diagenesis (Table 3). Fig.12 Characteristic sample capillary pressure curves. Table 3 Comparison of the pore structure of the east and west subsags 1) Petrological characteristic differences The reservoir properties of the east and west subsags in the Lishui Sag are different. The sandstone types in the west subsag are relatively single, and its main lithology is feldspar lithic sandstone and lithic sandstone; by contrast, the sandstone types in the east subsag are relatively complex, including nearly all the sandstone types. The compo- sitional maturity and structural maturity of reservoir sand- stones in the Lishui Sag appear to be relatively low, where- as that of the east subsag is more serious (Fig.13). Fig.13 Sandstone classification triangle of the east and west subsags. The sandstone grain size in the east and west subsags is different; the east subsag is coarser than that of the west one. The main sandstone of the west subsag is mainly fine sandstone and medium sandstone, whose grain size cumulative curves are the three-stage type (Figs.14a, b, c); the main sandstone of the east subsag is mainly medium sandstone and coarse sandstone, whose grain size cumulative curves are the two-stage type (Figs.14d, e, f). The statistical results of the grain size data show that the mineral size of the rock samples in the east subsag is larger than that in the west subsag; however, its sorting is poor, the pore retention is poor, and the rock is compact, thus indirectly reflecting that the reservoir permeability in the west subsag is higher than that in the east subsag (Table 4). 2) Sedimentological characteristic differences Fig.15 is the plane distribution map of the facies of the Mingyuefeng formation in the Lishui Sag. The map shows that the main facies type of the west subsag is a beach bar, its sandstone type is single, and the sandstone distribution area is large with good continuity and good physical condition. However, the sedimentary scale of the east subsag is relatively small, and the main facies type is fan delta, which is close to the provenance. The sand body types are diverse, and the physical conditions are poor. Overall, the reservoir physical properties of the west subsag in the Li- shui Sag are better than those of the east subsag. For example, the coring wells LT-6 (west subsag), LT-5, and WS-2 (east subsag) and their sampling depths are all in the lower part of the Mingyuefeng formation; LT-6 of the west sub- sag is located in sand sheet microfacies with a large thick- ness and good continuous distribution, whereas LT-5 and WS-2 of the east subsag are located in the shallow lake anddeep lake microfacies; and the sediments are mainly mudstone. Thus, there are obvious differences in the types and distribution law of sandstone in the east and western subsag. SEM experimental data and casting slice detection data based on image analysis technology are the main methods for obtaining core pore structure characteristics; such data can be used to find the size and distribution of the micro pore and throat of the reservoir and evaluate the reservoir differences (Xiao., 2016; Zhang., 2017). In this study, we use these data to validate the conclusions of the constant velocity mercury injection experiment and cla- rify the influence degree of reservoir diagenesis on the dif- ferences in the reservoir pore structure between the two subsags, thereby facilitating a comprehensive evaluation of the reservoirs. Fig.14 Sandstone grain size cumulative probability curves of the Lishui Sag. a, LT-2, 2246.35m; b, LT-4, 2758.21m; c, LT-2, 2258.36m; d, WS-2, 2275.48m; e, WS-2, 2305.16m; f, LT-5, 23359.62m. Table 4 Mineral particle size of the east and west subsags Fig.15 Sedimentary microfacies plan of the Mingyuefeng formation in the Lishui Sag. 1) Compaction The porosity that is lost by compaction cannot be re- covered, and with the increase in burial depth, the contact relationship between the particles becomes increasingly closer. They gradually transit from separation to point con- tact and then to concave-convex contact. At the same time, the pores of the rocks also decrease sharply. Close contact between particles leads to the pressure dissolution of quartz and feldspar, which form secondary enlarged edges of clastic particles. These changes have an important effect on reservoir porosity and permeability (Wang., 2018). The primary pore of the two subsags in the Lishui Sag almost disappeared due to the strong overlying strata compression, and the shrinking intergranular pore is the main pore. The number of pores is small, the pore radii are small, and the average porosity is less than 12%. All the pores belong to low-porosity reservoirs. However, com- pared with the two subsags, the porosity of the east subsag is worse than that of the west subsag, the sandstones are more compact, the filling material content in the pore is large and the types, which are dominated by the mechanical sedimentary particles, are complex (Figs.16a, b). The number of pores in the west subsag is relatively large, the original appearance of some intergranular pores is preserved, and the connectivity between the pores is relatively good (Figs.16c, d). 2) Cementation Cementation plays an important role in the transformation of sediments into sedimentary rocks, and it can occur in all stages of diagenesis. Cementation is also one of the main reasons for the decrease in the porosity and permeability of rocks; it belongs to destructive diagenesis. A data analysis shows that rocks in the Lishui Sag that have experienced cementation mainly include carbonate mineral, quartz, feldspar, and clay mineral cementation, where- as the main types of cementation are clay cementation and carbonate rock cementation (Zhang., 2017). Carbonate cementation is an important cementation process in the sandstones of the Lishui Depression, which mainly includes calcite and dolomite; carbon cementation is one of the main factors that destroy reservoir conditions (Fig.17a). Siliceous cementation is quartz secondary enlargement and authigenic quartz (Zhang., 2018), the new authi- genic quartz often coexists with illite (Fig.17b), and the authigenic feldspar also can be found (Fig.17c). The clay minerals, such as kaolinite (Fig.17d), illite (Fig.17e), chlo- rite (Fig.17f), and illite-montmorillonite mixed layer, in the pore are also important. Fig.16 Sandstone compaction characteristics in the Lishui Sag. Fig.17 Sandstone diagenetic minerals in the two subsags of the Lishui Sag. a, WS-1, 2894.42m; b, LT-5, 2354.18m; c, WS-1, 2776.52m; d, LT-2, 2891.35m; e, LT-4, 2738.55m; f, LT-1, 2296.15m. Fig.18 shows a statistical map of the difference in the cement contents and types between the east and west subsags of the Lishui Sag. The map shows that the cement types of the two subsags are different. The cement contents of the east subsag is considerably higher than that of the west subsag, and the carbonate cement content in the east subsag is higher than that in the west subsag, whereas the west subsag is dominated by the mechanical clay mineral cements, indicating that the diagenetic type of rocks in the east subsag is strong. Fig.19 shows a cross plot of the cement contents and the porosity of negative cements in the Lishui Sag sandstone. The figure shows that the data points in the source area of the east subsag are dispersed, and some samples have a high porosity of negative cements, indicating that the rocks have a high content and various types of cements, leading to complex and changeable controlling factors of the reservoir storage space. These characteristics are all related to the near provenance fan delta in the east subsag (Zhang., 2007). However, the sedimentary environment of the west subsag is relatively stable, and it is far from the provenance area, which has high composition and structural maturity of clastic particles. The types of rock cements are simple and are mainly clay minerals. Thedistribution of the data points on the map is relatively con-centrated, and the porosity of negative rock cements is low. Fig.18 Contents and types of cements in the east and west subsags. Fig.19 Cross plot of cement content and the porosity of negative cement of the two subsags. 3) Dissolution Given the continuous exchange of fluids in the rock pores, the dissolution of rock particles and interstitial ma- terials occur in different degrees in the process of dia- genesis, resulting in numerous secondary pores. Dissolution, which contains three main forms in the study area, is a kind of constructive diagenesis that can improve the physical properties of a reservoir. The most common is feldspar particle dissolution, which can be dissolved along the edges to form intergranular dissolution pores or completely dissolved to form mold pore (Figs.20a, b). Feldspar dissolution mainly occurs in the east subsag because of its high-proportion in the sandstone. The rock debris dissolution is also relatively large and mainly occurs in the west subsag (Fig.20c). In addition, cement dissolution (mainly carbonate dissolution with low dissolution degree, Fig.20d) is common in the study area, and its contribution to secondary pores is small. Fig.20 Dissolution of the sandstone in the Lishui Sag. a, dissolution of feldspar particles, Well WS-2, 2299.15m, single polarized light; b, dissolution of feldspar particles, with hair-like illite attached to the crystals, Well WS-2,2297.27m, SEM; c, dissolution of rock calcite cement, Well LT-3, 2162.35m, single polarized light; d, slight dissolution of calcite cement in pores, Well LT-7, 2197.85m, SEM. In accordance with the formation sequence and distribution law of authigenic minerals in sandstone pores, the following are determined as early diagenetic stage B and middle diagenetic stage A: the homogenization temperature of oil-gas inclusions, the combination and mutual transformation of clay minerals, composition and structural characteristics, pore structure and type, maturity of organic matter, burial history and paleogeotherm, and diagenetic evolution stages. The main diagenetic sequences of the sandstones in the Lishui Sag are primary rapid compaction, early quartz cementation, dissolution, clay mineral cementation, and other mineral cementation, which make these sandstones have a high degree of consolidation, low degree of retention of primary pores, and strong effect of transformation (Li., 2016). The sandstone primary porosity of the two subsags is estimated to be close to 40%; however, after sedimentation and diagenesis, the physical properties of rocks begin to undergo some sequential differentiation changes, thus resulting in the formation of rocks with different pore structures in the later stage (Fig.21). 1) Compaction is the main destructive factor that causes a reduction in primary porosity. The reduction degree of the east subsag is higher than that of the west subsag because its sediment types are complex. The reservoir poro- sity of the west subsag decreases by approximately 60%, whereas that in the east subsag decreases by 75%. 2) The early quartz secondary enlargement and the calcite cementation also reduce the primary porosity, but their influence is less than compaction. Among them, quartz secondary enlargement has minimal effect on the rocks of the two subsags; however, the effect of carbonate mineral cementation is different. The carbonate mineral content in the east subsag is higher, and the degree of cementation, which is the main process of pore reduction, is stronger than that of the west subsag, which is less affected by the cementation of carbonate minerals. Influenced by cementation, the degree of decrease in the west subsag is approximately 20%, whereas that in the east subsag is approximately 30% (Liu, 2015). 3) Subsequently, some minerals (feldspar, debris, and calcite) were dissolved, thus increasing the porosity of rocks. This dissolution was the main diagenesis that resulted in the formation of secondary pore zones. The disso- lution increased the porosity of the two subsags by 30%–40%. 4) The late cementation of clay minerals caused some damage to the pores, and different minerals had different effects on the pores. The content of clay minerals in the west subsag was high, and the degree of pore reduction was higher than that in the east subsag, which was approximately 20%. 5) Lastly, the appearance of some iron dolomite and pyrite also affected the pore size, although the effect was small. Fig.21 Controlling degrees of the various factors. 1) On the basis of a comparison of the parameters of the constant-rate mercury injection experiment, the throat radius of the west subsag is found to be larger than that of the east subsag in the Lishui Sag and has a positive correlation with the reservoir quality. The pore radius of the two subsags is similar, but the pore-throat ratio of the east subsag is larger, which indicates that the sandstone phy- sical condition in the west subsag is better than that in the east subsag. 2) The main reasons for the reservoir differences between the two subsags can be attributed to sedimentation and diagenesis. The original source of the sediment and the sedimentary environment determine the basic structure of rock physical properties. Later, diagenesis causes the filling or cementation of the pore interior and changes the pore structure. The microfacies types of the west subsag are sand mat and sand bar, which are widely distributed and have good physical conditions; by contrast, the microfacies types of the east subsag are complex (shore lake, shallow lake, shore shallow lake,.), the shale con- tent of the reservoir is high, and the physical conditions are poor. 3) Comprehensive analysis shows that the reservoirs in the west subsag are considerably better than those in the east subsag in terms of thickness, distribution range, pore structure, porosity, and permeability, which are the key areas for oil and gas exploration and development. This work was supported by the National Natural Science Foundation of China (Nos. 51504143 and 51674156), the SDUST Research Fund (No. 2015DJH101), and the Major National R&D Projects of China (No. 2016ZX0 5027-001-006). We are grateful to CNOOC for supplyingthe research data and permitting the publication of this research. Chen, C. F., Zhong, K., Zhu, W., Xu, D. H., Wang, J., and Zhang, B. C., 2017. Provenance of sediments and its effects on re- servoir physical properties in Lishui Sag, East China Sea Shelf Basin., 38 (5): 963-972. Chen, M., Li, M., Zhao, J. Z., and Kuang, Y., 2018. Irreducible water distribution from nuclear magnetic resonance and constant-rate mercury injection methods in tight oil reservoirs., 17 (4): 443. Dai, J. X., Ni, Y. Y., and Wu, X. Q., 2012. Tight gas in China and its significance in exploration and exploitation., 39 (3): 277-284. Deglint, H. J., Clarkson, C. R., Debuhr, C., and Ghanizadeh, A., 2017. Live imaging of micro-wettability experiments perform- ed for low-permeability oil reservoirs., 7 (1): 4347. Desbois, G., Urai, J. L., Kukla, P. A., Konstanty, J., and Baerle, C., 2011. High-resolution 3D fabric and porosity model in a tight gas sandstone reservoir: A new approach to investigate microstructures from mm- to nm-scale combining argon beam cross-sectioning and SEM imaging., 78 (2): 243-257. Dou, W. C., Liu, L. F., Wu, K. J., and Xu, Z. J., 2016. Pore structure characteristics and its effect on permeability by mercury injection measurement: An example from Triassic Chang-7 reservoir, southwest Ordos Basin., 62 (2): 503-511. Gao, Y., and Zhang, Z. G., 2011. Valuation on difference of pore throat structure of low permeability sandstone by constsp mer- cury penetration technique., 30 (4): 73-76. Gu, X. Y., Pu, C. S., Huang, H., Khan, N., Liu, J., He, Y. L., Jing, C., Huang, F. F., Qi, A. J., and Kong, X. Z., 2018. The visual and quantitative study of the microoccurrence of irreducible water at the pore and throat system in a low-permeability sandstone reservoir by using microcomputerized tomography., 2018: 1-14, https://doi.org/10.1155/2018/6062475. He, S. L., Jiao, C. Y., Wang, J. G., Luo, F. P., and Zou, L., 2011. Discussion on the differences between constant-speed mercury injection and conventional mercury injection techniques., 18 (2): 235-237. Jozefaciuk, G., 2009. Effect of the size of aggregates on pore characteristics of minerals measured by mercury intrusion and water-vapor desorption techniques., 57 (5): 586-601. Lai, J., and Wang, G. W., 2015. Fractal analysis of tight gas sand-stones using high-pressure mercury intrusion techniques., 24: 185-196. Lai, J., Wang, G. W., Fan, Z. Y., Chen, J., Wang, S. C., Zhou, Z. L., and Fan, X. Q., 2016. Insight into the pore structure of tightsandstones using NMR and HPMI measurements., 30 (12): 10200-10214. Lai, J., Wang, G. W., Wang, Z. Y., Chen, J., Pang, X. J., Wang, S. C., Zhou, Z. L., He, Z. B., Qin, Z. Q., and Fan, X. Q., 2018. A review on pore structure characterization in tight sandstones., 177: 436-457. Li, D. Y., Jiang, X. D., Xu, F., Liu, J. S., and Hou, G. W., 2016. Geochemistry of the Paleocene clastic rocks in Lishui Sag, East China Sea Shelf Basin: Implications for tectonic background and provenance.–, 90 (1): 166-181. Liang, C., Wu, J., Jiang, Z. X., Cao, Y. C., and Song, G. Q., 2017. Sedimentary environmental controls on petrology and organic matter accumulation in the upper fourth member of the Shahejie formation (Paleogene, Dongying Depression, Bohai Bay Basin, China)., 186: 1- 13. Liu, J. S., 2015. Fine description of structure research of Lishui Sag, East China Sea Basin., 8 (7): 4433-4441. Mai, B., 2013. Diagenesis and quartz cement distribution of low- permeability upper Triassic–middle Jurassic reservoir sandstones, Longyearbyen CO2lab well site in Svalbard, Norway, 97 (4): 577-596. Pittman, E. D., 1996. Relationship of porosity and permeability to various parameters derived from mercury injection-capil- lary pressure curves for sandstone., 76 (2): 191- 198. Shu, Q. L., Guo, Y. C., Sun, Z. G., Cong, G. L., and Xu, Y., 2016. Research and application of percolation mechanism in extra- low permeability oil reservoir., 23 (5): 58-64. Tsakirogloua, C. D., and Payatakesa, A. C., 1998. Mercury intrusion and retraction in model porous media., 75: 215-253. Wang, J. K., Liu, H. Y., Zhang, J. L., and Xie, J., 2018. Lost gas mechanism and quantitative characterization during injection and production of water-flooded sandstone underground gas storage, 11 (2): 272. Wang, J. X., Yang, P. H., Liu, Q. J., and Guo, H. K., 2003. Determination of relative permeability curves using data mea- sured with rate-controlled mercury penetration., 27 (4): 66-69. Wang, R. F., Chi, Y. G., Zhang, L., He, R. H., Tang, Z. X., and Liu, Z., 2018. Comparative studies of microscopic pore throat characteristics of unconventional super-low permeability sand- stone reservoirs: Examples of Chang 6 and Chang 8 reservoirs of Yanchang formation in Ordos Basin, China., 160: 72-90. Xi, K. L., Cao, Y. C., Wang, Y. Z., Beyene, G. H., Zhang, X. X., Zhang, J. H., and Jin, J. H., 2015. Diagenesis and porosity- permeability evolution of low permeability reservoirs: A case study of Jurassic Sangonghe formation in Block 1, central Jung- gar Basin, NW China., 42 (4): 475-485. Xiao, D. S., Lu, S. F., Lu, Z. Y., Huang, W. B., and Gu, M. W., 2016. Combining nuclear magnetic resonance and rate-con- trolled porosimetry to probe the pore-throat structure of tight sandstones., 43 (6): 1049-1059. Yang, Z. M., Zhang, Y. Z., Hao, M. Q., Liu, X. G., and Shan, W. W., 2006. Comprehensive evaluation of reservoir in low-per- meability oilfields., 27 (2): 64-67. Zhang, J. L., Liu, S. S., Li, J. Z., Liu, L. L., Liu, H. M., and Sun, Z. Q., 2017. Identification of sedimentary facies with well logs: An indirect approach with multinomial logistic regression and artificial neural network., 10 (11): 247. Zhang, M. Q., Huang, S. J., Wu, Z. X., Wu, S. J., and Hu, Z. W., 2007. Carbonate cements and their formation mechanism in Palaeogene sandstones of Lishui Sag, East China Sea Basin., 34 (3): 259-266. Zhang, P. H., Zhang, J. L., Wang, J. K., Li, M., Liang, J., and Wu, Y. L., 2018. Flow units classification for geostatisitical three-dimensional modeling of a non-marine sandstone re- servoir: A case study from the Paleocene Funing formation of the Gaoji Oilfield, East China., 10 (1): 113- 120. Zhang, Z. Q., and Zheng, J. W., 2009. Advances in exploration and exploitation technologies of low-permeability oil and gas., 24 (8): 854-864. Zhu, H. Y., An, L. Z., and Jiao, C. Y., 2015. The difference between constant-rate mercury injection and constant-pressure mercury injection and the application., 26 (7): 1316-1322. Zou, C. N., Yang, Z., Zhu, R. K., Zhang, G. S., Hou, L. H., Wu, S. T., Tao, S. Z., Yuan, X. J., Dong, D. Z., Wang, Y. M., Wang, L., Huang, J. L., and Wang, S. F., 2015. Progress in China’s unconventional oil and gas exploration and development and theoretical technologies.–, 89 (3): 938-971. January 16, 2020; June 1, 2020; July 15, 2020 © Ocean University of China, Science Press and Springer-Verlag GmbH Germany 2021 . E-mail: jinliang@bnu.edu.cn (Edited by Chen Wenwen)4 Results

4.1 Basic Physical Properties of Rock Samples

4.2 Comparison of the Laryngeal Radius

4.3 Comparison of the Pore Radius

4.4 Comparison of the Pore-Throat Ratio Between the East and West Subsags

4.5 Characteristic Analysis of the Capillary Pressure Curve

5 Discussion

5.1 Analysis of the Influence of Sedimentation on the Reservoir Pore Structure

5.2 Influence of the Diagenetic Factors of the Reservoir on the Difference of Pore Structure

5.3 Controlling Degree Analysis of the Various Factors

6 Conclusions

Acknowledgements

杂志排行

Journal of Ocean University of China的其它文章

- Elevated Ducts and Low Clouds over the Central Western Pacific Ocean in Winter Based on GPS Soundings and Satellite Observation

- Control System Design and Implementation at Flexible, Distributed Offshore Sensor Test Sites in the Yangtze Estuary Area

- Global-Scale Diversity and Distribution Characteristics of Reef-Associated Symbiodiniaceae via the Cluster-Based Parsimony of Internal Transcribed Spacer 2 Sequences

- A Preliminary Investigation of Arctic Sea Ice Negative Freeboard from in-situ Observations and Radar Altimetry

- The Stable Carbon Isotopic Compositions of n-Alkanes in Sediments of the Bohai and North Yellow Seas: Implications for Sources of Sedimentary Organic Matter

- Composition and Distributions of Nitrogen and Phosphorus and Assessment of Eutrophication Status in the Maowei Sea