Incorporation of Green Tea Extract and Partial Replacement of Fat to Modify the Quality and Lipid Oxidative Stability of Reduced-Fat Pork Sausage

2021-03-01CAOYungangLIYingGUOAnqiXIONGYouling

CAO Yungang, LI Ying, GUO Anqi, XIONG Youling,*

(1.Natural Food Macromolecule Research Center, School of Food and Biological Engineering,Shaanxi University of Science & Technology, Xi’an 710021, China; 2.State Key Laboratory of Food Science and Technology,School of Food Science and Technology, Jiangnan University, Wuxi 214122, China;3.Department of Animal and Food Sciences, University of Kentucky, Lexington 40546, USA)

Abstract: Reduced-fat sausages were manufactured with 50% substitution of pork back-fat by either unpre-emulsified or pre-emulsified commercial canola oil combined with green tea extract (100 and 1 000 mg/kg).Textural properties and lipid oxidative stability (expressed as thiobarbituric acid reactive substances value) of cooked products were analyzed.The partial replacement of animal fat with vegetable oil did not compromise the color (lightness and redness), hardness or deformability,and significantly improved oxidative stability (P < 0.05).However, the oil substitution aggravated cooking loss and markedly decreased the breaking force.Pre-emulsification alleviated the texture deterioration induced by fat replacement.Addition of green tea extract, independent of dosage, almost completely inhibited lipid oxidation in sausages during storage.However,green tea extract at 1 000 mg/kg tended to disrupt the texture properties, although no statistically significant difference (P >0.05) was observed.

Keywords: reduced-fat sausages; color; cooking loss; texture; lipid oxidation

Emulsion-type meat products, such as frankfurters,are the popular and traditional meat products worldwide.However, due to their abundance in animal fat for up to 30%,they are widely considered unhealthy.This is because animal fat contains large amounts of saturated fatty acids (SFAs)and cholesterol[1].Excessive intake of such foods rich in animal fat has been associated with obesity, hypertension,coronary heart diseases and cardiovascular disease[2].Hence,the reduction of fat and/or the replacement of animal fat with vegetable/marine oils and non-meat ingredients in meat products should result in healthier products[3-5].A variety of plant and marine oils have been added to different meat products as partial substitutes for animal fats, including pork back fat[3,6-7].

Vegetable oils are free of cholesterol with a healthier fatty acid profile than animal fats.Among conventional vegetable oils, canola oil contains the lowest levels of SFAs and linolenic acid.It is a relatively rich source of the natural antioxidant tocopherol[8].In addition, canola oil can also be converted to docosahexaenoic acid (DHA) and omega-3 fatty acid eicosapentaenoic (EPA) in the body, both of which are essential for preventing coronary heart diseases[9].Furthermore, phytosterols in canola oil have been reported to be beneficial against colon, breast and prostate cancers[10].

However, the substitution of pork back fat with vegetable oils could cause the changes in the emulsion stability and lipid oxidative stability[11-12].A reduced emulsion stability would result in the reduced product yield and quality.The oxidation of unsaturated fatty acids (UFAs) could develop rancid odors and unpleasant flavors, which deteriorate the quality of meat products[13].The reduced-fat meat products are often rejected by the consumer due to their unfavorable flavor and texture as compared to those of traditional meat products[14].Pre-emulsification of vegetable oils with proteins could be a solution to obtain a stable meat emulsion system and a desirable product with good quality[12,15].Incorporation of natural botanical antioxidants, such as green tea extracts,has been proven to be a very effective strategy to inhibit lipid oxidation[16-17].Moreover, plant extracts rich in polyphenols have been reported to be beneficial for human health[18-19].

The objective of this study was to determine the effect of partial replacement of pork back-fat with pre-emulsified canola oil combined with/without green tea extract on the texture properties and lipid oxidative stability of the reducedfat sausages, in terms of cooking loss, texture profile, and secondary lipid oxidation.The experimental results will provide theoretical basis and reference for the production of the reduced-fat sausages with high quality.

1 Materials and Methods

1.1 Materials

Fresh lean shoulder blade pork meat (moisture 72%,fat 8.6%) and pork back-fat (fat 82.6%, moisture 13%) were obtained from University of Kentucky Meat Laboratory.All the visible fat and connective tissues were trimmed from the pork meat.Then the lean meat and back-fat were cut into smaller pieces, vacuum-packaged and stored in a –30 ℃freezer until use.Soy protein isolate (SPI, protein 93.5%,moisture 4%) was donated by Archer Daniels Midland.Whey protein isolate (WPI, protein 97.7%, fat 0.4%, moisture 4.8%) was donated by Davisco Foods International.Green tea extract (Catechins 86.9%, EGCG 50.1%, HPLC), was donated by Chengdu Wagott Bio-tech Co.Ltd..Canola oil and salt were purchased from a local grocery store (Kroger Supermarket, Lexington, KY, USA) and used directly.All the other chemicals used were at least of analytical grade.

1.2 Methods

1.2.1 Preparation of protein-stabilized oil pre-emulsion

Canola oil was used as a pre-emulsion with SPI or WPI.One part of the commercial SPI/WPI was mixed with nine parts of deionized water, homogenized at 17 500 r/min for 2 min(homogenized for 2 times, 1 min each time, time interval was 30 s)and then mixed with 10 parts of canola oil for another 3 min(homogenized for 4 times, 45 s each time, time interval was 30 s) with a Polytron blender (Brinkmann Instruments, Inc.,Westbury, NY, USA)[20].The preparation process was carried out in a 4 ℃ walk-in cooler.

1.2.2 Sausage manufacturing

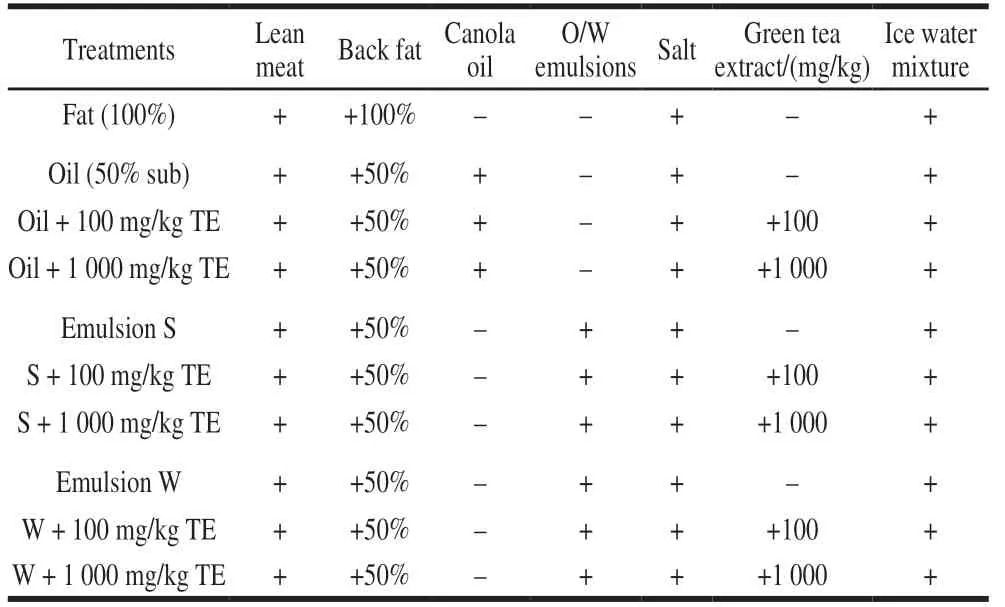

Table 1 Formulation of sausages

Ten treatments of sausages, about 1.5 kg each, were prepared using the formulations shown in Table 1.The control was produced using 60% lean meat, 20% pork backfat, 2.5% salt and 17.5% ice water mixture (ice:water = 1:1).Two levels (100 mg/kg and 1 000 mg/kg) of green tea extract were added in different antioxidant treatments.The partial replacement of back-fat corresponded to weight substitutions of back-fat by 50% with pure or pre-emulsified canola oil was performed.

Lean meat and pork back-fat were separately ground twice through a 4.8 mm orifice plate and subsequently mixed in a food processor (Black & Decker Corporation, Towson,Maryland, USA) with the following common ingredients:salt, ice water mixture, green tea extract (with or without)and pure or pre-emulsified canola oil (with or without).The mixing rate was set to low gear (1st gear), and mixing time was standardized to 7 min (mixed for 7 times, 1 min each time, time interval was 30 seconds).The temperature of the meat batters was below 12 ℃ at the end of the process.They were stuffed into cellulose casings (diameter: 19 mm) and manually tied into 15 cm length rolls with cotton twine.The raw sausage links were held for 16 h at 4 ℃, and then cooked in a water bath from 20 to 80 ℃ at 0.9 ℃/min increments.After cooking, the sausages were taken out and cooled in an ice-water bath.Subsequently, after removing the cellulose casings, the cooked sausages were placed on polystyrene trays and overwrapped with polyvinylchloride films, and then stored in a 4 ℃ refrigerator.

1.2.3 Color measurement

The CIELAB coordinates,L* (lightness),a* (redness),andb* (yellowness), were measured at three to six random locations on the surface of the cross-sections of the sausages using a HunterLab LabScan XE colorimeter with a 0.25 inch port size, illuminant D65 and a 10° standard observer(Hunter Associates Laboratory, Inc., Reston, VA, USA).Before each measurement, the equipment was calibrated with standard black and white plates.Chromaand Hue anglevalues were calculated as follows[21]:

1.2.4 Cooking loss

The weight of each sausage was recorded before and after thermal treatment.Cooking loss was calculated using the following expression: Cooking loss/% = (uncooked weight - cooked weight) / uncooked weight × 100.

1.2.5 Textural profile analysis

The textural properties of sausages were evaluated by uniaxial compression tests with a Instron Universal Testing Machine (Model 4301, Instron Corp., Canton, MA, USA)as described by Xiong Youling et al.[22].Before analysis, the cooked sausage rolls were equilibrated at room temperature(~22 ℃) for 2 h.The slices of 19-mm thickness were carefully cut from the center of the sausages with a sharp knife.Compression and breaking strength analysis were performed using two sets of sausage samples.For the compression test,six sausage samples were compressed to 80% of their original height (20% deformation) in two consecutive cycles as a 1 000 N load cell was used at a crosshead speed of 50 mm/min.To determine the breaking strength, another set of sausage samples was compressed until the structure was disrupted.The values of hardness, deformability,cohesiveness, and breaking force were determined.

1.2.6 Assessment of lipid oxidation

Thiobarbituric acid-reactive substances (TBARS) in cooked sausages stored at 4 ℃ for specific time periods (0, 2,4, 6, 9 and 13 days) were measured to evaluate lipid oxidation as described by Salih et al.[23].Results were expressed as mg malonaldehyde (MDA) equivalent per kilogram sausages.

1.3 Statistical analysis

Two batches of sausages as replicates were done on different days and the randomly selected subsamples(3-6) were taken for analyses.The variance analysis of data was evaluated by the general linear model’s procedure of the Statistix software 9.0 (Analytical Software, Tallahassee,FL, USA).Significant differences (P< 0.05) among the individual means were compared using Tukey’s all-pairwise multiple comparisons procedure.

2 Results and Analysis

2.1 Color parameters of cooked sausages

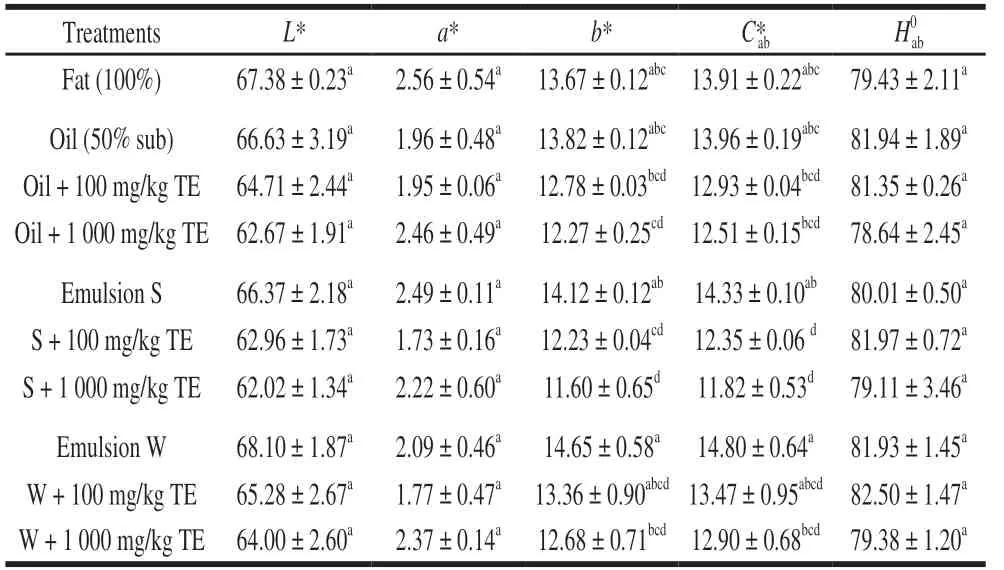

Table 2 Effect of different formulations on color parameters of sausages

The influences of the replacement of pork back fat with canola oil and addition of green tea extract on color attributes of the cooked sausages are shown in Table 2.As can be observed, bothb* andwere significantly(P< 0.05) affected by the formulations, while other color characteristics (L*,a* andwere not significantly(P> 0.05) affected.Replacement of pork back-fat with canola oil tended to depress the lightness and redness, but increased the yellowness, chroma and hue angle, although no significant differences were observed (P> 0.05).Pre-emulsification with SPI increased the redness, while with WPI increased the redness and lightness.Addition of green tea extract tended to reduce values of all the color parameters, especially at high content, except that green tea extract at 1 000 mg/kg showed more redness.These changes were mainly attributed to the typical brown appearance of the green tea extract used in this study.Similarly, the effect of natural pigments in meat emulsion ingredients on the final color of frankfurters has been demonstrated by Estévez et al.[24].Moreover, the observed changes in color might also have been partially due to the chemical interaction of phenolic compounds in green tea extract with myoglobin, since addition of the green tea extract triggered redox change of myoglobin[25].

2.2 Cooking loss

Cooking loss is affected by cooking method, additives,and the type as well as amount of fat in meat products[26].The effects of the partial replacement of pork back fat with canola oil as such or as pre-emulsified mixture with SPI/WPI combined with/without green tea extract on the cooking loss of the reduced-fat sausages are shown in Fig.1.The control(Fat) showed the lowest cooking loss (about 26%), partial replacement of back fat with pure canola oil increased the cooking loss by 42.3%, pre-emulsification with SPI did not inhibit the increase of cooking loss (P> 0.05) caused by fat substitution, and pre-emulsification with WPI appeared to alleviate the cooking loss to a certain extent.It is noteworthy that the addition of green tea extracts appeared to promote juice loss during cooking, especially at high concentrations,although there is no statistically significant difference(P> 0.05).Similar to the results of this study, Jongberg et al.[27]reported that the addition of green tea extract at 1 500 mg/kg increased the cooking loss of pork meat emulsions, while addition of green tea extract at 100 or 500 mg/kg did not show negative effect.Cao et al.[16]found that the addition of epigallocatechin gallate (EGCG) at lower concentrations (< 200 mg/L) caused no negative effect on the cooking loss of MP-emulsion composite gels, while addition of EGCG at higher concentrations (500 and 1 000 mg/L)significantly improved the cooking loss.

Fig.1 Effect of different formulations on cooking loss of sausages

2.3 Texture profiles of cooked sausages

Table 3 Effect of different formulations on textural properties of sausages

The results of the comparative textural profile analysis of sausages in which pork back-fat was partially replaced with canola oil are presented in Table 3.The hardness and deformability of sausages were neither significantly(P> 0.05) affected by the replacement of pork back-fat with canola oil or oil-in-water emulsions nor by the addition of green tea extract used in the formulation.However,the cohesiveness and breaking force were reduced by the treatments.For instance, the partial replacement of back-fat with canola oil reduced the cohesiveness and breaking force by 4.5% and 76.9%, respectively.It was noteworthy that pre-emulsification with proteins tended to prevent textural deterioration induced by the replacement of pork fat with canola oil, while addition of green tea extract at high content(1 000 mg/kg) was found to cause a negative effect on textural parameters, although no significant differences were observed (P> 0.05).Jiménez-Colmenero et al.[28]reported that frankfurters made with oil-in-water emulsions showed greater hardness, cohesiveness and chewiness and poorer adhesiveness than those of all pork fat frankfurters.Álvarez et al.[11]found that replacing pork back-fat with vegetable oils increased the deformability and rupture force, but decreased the hardness and gumminess.These conflicting results suggest that the composition and characteristics of lipid and processing technology are highly influential on the textural properties of meat products.

2.4 Lipid oxidative stability

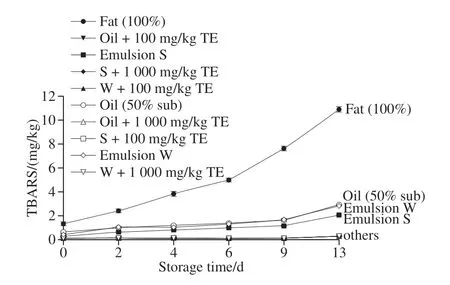

Fig.2 Effect of different formulations on lipid oxidative stability of sausages

The lipid oxidative stability of sausages during refrigerated storage was evaluated by the formation of secondary lipid oxidation products as determined by TBARS(Fig.2).The TBARS value of the control was the largest(1.32 mg/kg) on day 0, the partial replacement of animal fat with canola oil significantly reduced the TBARS value by 51.5%.Pre-emulsification of canola oil with SPI/WPI reduced the TBARS value by 76.5% and 67.4%, respectively.Addition of green tea extract at all levels almost completely inhibited lipid oxidation, as the TBARS values of sausages with green tea extracts were all below 0.14 mg/kg.This is consistent with a previous report on Bologna type sausages prepared from the oxidatively stressed pork with addition of green tea extract[29].The inhibitory effect of green tea extract on lipid oxidation was not dose-dependent in this study since no statistical difference was observed (P> 0.05).

The TBARS value of the control was increased rapidly during the entire storage period and was almost eight-fold higher than the initial level by day 13.In comparison, the TBARS value of the reduced-fat sausages was much lower throughout the storage time and was increased very slowly.Colona oil is rich in UFAs, which are prone to oxidation.This appears to be contradictory to the result of this study.An explanation could be that the commercial canola oil contains antioxidants, such as VE (~100 mg/100 g), which can significantly inhibit lipid oxidation.Similarly, Asumingbediako and colleagues noted that the TBARS values of the sausages prepared using the vegetable oil emulsions were significantly lower than that of those made with pork backfat emulsions, despite the higher amount of polyunsaturated fatty acids (PUFAs) in the vegetable oils[21].Lipid oxidation(TBARS and hexanal content) of dry fermented sausages was found to decrease with the substation of pork back-fat by soy oil in a dose-dependent manner.This could be attributed to the VE (16 mg/100 g) present in the added soy oil[4].Overall, preemulsification with WPI did not further inhibit lipid oxidation,while the TBARS value of sausages made with SPI preemulsified canola oil was lower during the entire storage period.This may be attributed to the isoflavones present in SPI[30].

3 Conclusions

Viewed as a whole, partial replacement of pork back fat with pure canola oil significantly increased the cooking loss and obviously decreased the breaking force, but remarkably improved the lipid oxidative stability of sausages due to canola oil which is rich in natural antioxidants, such as VE.Pre-emulsification of canola oil with SPI/WPI tended to mitigate the textural deterioration caused by fat substitution,and further improved the lipid oxidative stability where SPI showed a stronger influence than WPI.Green tea extract exhibited a dose-dependent effect on textural stability: at low content (100 mg/kg), it had no negative effect, however, at high dose (1 000 mg/kg), it appeared to be detrimental to the textural properties of sausages.At both concentration levels studied (100 and 1 000 mg/kg), green tea extract significantly improved the lipid oxidative stability in the cooked sausages.Overall, compared with partial replacement of pork back fat with pure canola oil, pre-emulsification of canola oil with SPI/WPI associated with green tea extract (at 100 mg/kg) was favorable to improve both the textural properties and lipid oxidative stability of fat-reduced sausages.