Light-Induced Noise Reduction of Lightly Doped Silicon-based Neural Electrode

2020-12-23ChunrongWeiFeiWangWeihuaPeiZhiduoLiuXuruiMaoHongzeZhaoSikaiWangYijunWangXiaoweiYangYuanyuanLiuShanshanZhaoQiangGuiHongdaChen

Chunrong Wei ,Fei Wang ,Weihua Pei ,*,Zhiduo Liu ,Xurui Mao ,Hongze Zhao ,Sikai Wang ,Yijun Wang ,Xiaowei Yang ,Yuanyuan Liu ,Shanshan Zhao ,Qiang Gui ,Hongda Chen ,2

1 The State Key Laboratory on Integrated Optoelectronics,Institute of Semiconductors,Chinese Academy of Sciences,Beijing 100083,P.R.China.

2 CAS Center for Excellence in Brain Science and Intelligence Technology,Beijing 100083,P.R.China.

3 Engineering Research Center for Semiconductor Integrated Technology,Beijing 100083,P.R.China.

4 University of Chinese Academy of Sciences,Beijing 100049,P.R.China.

5 School of Information Technology and Engineering,Tianjin University of Technology and Education,Tianjin 300222,P.R.China.

Abstract:Silicon-based neural probes are practical tools for recording neural cell firing.A single siliconbased needle with a width of only 70 μm,prepared using the standard complementary metal-oxidesemiconductor (CMOS)process technology,can contain thousands of electrode-recording sites.Optogenetics has made control over neuronal activity more precise.By recording the electrical activity of neurons stimulated by light,more information about brain activity can be recorded and analyzed.When yellow light or blue light is used to stimulate neurons,the photon energy is greater than the forbidden bandwidth of the silicon substrate,and the valence-band electrons are excited to the conduction band,generating electron-hole pairs.The photoinduced carrier in the silicon substrate severely disrupts the probe's signal-to-noise ratio.Decreasing the disturbance caused by light is a pragmatic way to execute recording and stimulating simultaneously.The traditional noise reduction method involves using heavily doped silicon as the substrate,reducing the carrier life by increasing the impurity concentration,and then reducing the noise of the silicon electrode under illumination.However,the heavily doped silicon substrate has more lattice defects than its lightly doped counterparts,which makes the silicon electrode fragile,and this method is not compatible with the standard CMOS process technology.On analyzing the photoinduced noise mechanism of manufacturing electrodes on lightly doped silicon substrates,we found that the inhomogeneous distribution of carriers generated by light excitation polarizes lightly doped silicon substrates.The potential caused by photoinduced polarization will affect the electrodes fabricated on it.Metalizing and grounding the lightly doped silicon substrate will effectively decrease the polarization potential.On using this method,the noise amplitude caused by the illumination can drop to 0.87% of the original value.To ensure an appropriate firing rate of neurons,the photo-stimulation frequency was chosen to be 20 Hz.Under the illumination of 1 mW·mm-2,the background noise of the electrode could be controlled below 45 μV,which meets the needs for general optogenetics applications.Modification of the lightly doped silicon substrate will meet the requirements of the neural electrode for optogenetics applications.Unlike the traditional method of reducing light-induced noise by heavily doping the entire substrate,the noise reduction method of lightly doped silicon substrate is compatible with the standard CMOS process technology.It provides a noise cancellation method for the preparation of silicon-based neural microelectrodes with dense recording sites and high channel count using standard CMOS processes.

Key Words:Light-induced noise; Photoinduced carrier; Optogenetics; Lightly doped; Silicon-based neural probe

1 Introduction

A neural probe is a key tool in electrophysiological research.Hundreds of or more electrodes are required to record as much as possible neural cells.The neural probes with multi-electrodes are designed and fabricated with the help of microelectromechanical systems (MEMS)technology to minimize the volume of the probe.Among these multi-channel electrode arrays,the silicon-based electrode array plays an important role.There are plenty of mature processing technologies that can be adapted to custom silicon into the desired shape and size.A silicon-based electrode array can be conveniently integrated with amplifying circuits1.Michigan electrode array,which is made from the heavily boron-doped silicon substrate,is a deputy of thin-film electrode2.As the number requirement of electrodes on one neural probe raising,fabricating high density and multichannel probe integrated circuits utilizing standard complementary metal-oxide-semiconductor (CMOS)process is becoming an economy and feasible method.

At the same time,optogenetics is another important tool to adjust or control neural circuits by optical stimulation or inhibition3-5.Neural probes are often used to monitor the reaction of neurons during light stimulation.For ease of use,a variety of silicon-based optical electrodes are developed1,6,7.Light commonly used in optogenetics is lying in the visible range (400-760 nm).The band is right in the absorption band of silicon.If light-generating potential occurs in the silicon substrate,it will affect the electrodes on the silicon by capacitive coupling.Many studies use heavily doped silicon as the support substrate of the electrode to avoid noise from light2,8,9.The minority carrier lifetime of a silicon substrate with a doping concentration of 1019cm-3is in the order of 10 ns10.The drift of photo-generated carriers is nearly impossible in the heavily doped silicon.From the equivalent circuit,it means that the photodiode does not exist.Thus,light sensitivity is not a problem for heavily doped silicon-based electrode9.

To avoid light sensitivity,heavy doping the whole substrate is a commonly used method11,but such highly doped silicon is not suitable for integrating circuit processing.Therefore,the electrode and the circuit must be fabricated separately on the heavily doped silicon substrate and lightly doped silicon substrate12.If the electrode can be integrated on a lightly-doped silicon substrate with an amplifier circuit,the volume of the electrode can be further minimized.However,light sensitivity will produce extra noise on the lightly-doped silicon substrate.

In this paper,using a lightly doped silicon substrate,a method compatible with standard CMOS is proposed to eliminate the electrode noise caused by light through metalizing and grounding the light-doped silicon substrate.

2 Methods

2.1 Equivalent circuit model

The thin-film silicon electrode used in this paper is fabricated on light-doped silicon film13(n-type with a doping concentration of 1015cm-3).Commonly,silicon based-electrode is composed of four layers.From down to up,they are silicon substrate,lower dielectrics layer,metal wire layer and upper dielectrics layer,as shown in Fig.1a.The silicon substrate mainly provides mechanical support for the electrodes.The lower dielectrics layer electrically insulates the silicon substrate from the metal layer.Because the carrier life in lightly doped silicon material is long enough,photo-generated nonequilibrium carriers located the space charge region T1will generate directional movement when the lightly doped siliconelectrode (LD Si-electrode)is illuminated10.If the carrier life is long enough,a considerable photovoltaic voltage will be built up.The fluctuating voltage will couple into the electrode through the lower dielectric layer,forming a voltage noise eventually.

The equivalent circuit of LD Si-electrode is shown in Fig.1b.Reis the charge transfer resistance,and Ceis the double-layer capacitance14.D0 is an ideal photodiode.C0 is the capacitance which consists of the silicon substrate and the metal layer on two sides of the lower dielectrics.R0is a drain resistance corresponding to the internal resistance of the photodiode.When the electrode is placed in the dark,there is no potential difference across the capacitor C0.The circuit device in the dashed box can be ignored.At this time,the equivalent circuit can be simplified as a double-layer capacitance parallel with a charge transfer resistance,which is an ideal equivalent circuit of the electrodesolution interface.Once the electrode is irradiated,the directional flow of photo-generated carriers in the silicon substrate will charge C0immediately.It,in turn,changes the voltage of Ce and causes a voltage raising or decreasing,which depends on the polarity of the photodiode.When the light is turned off,the capacitor C0and Cewill discharge through the circuit by R0and Re.The voltage of the electrode will recover.

Fig.1 (a)Structural schematic diagram of the LD Si-electrode.Space charge region T1 forms for cause of Si-SiO2 interface state as shown in the inset; (b)light-induced noise equivalent circuit of the LD Si-electrode,Re and Ce are the electrode-solution interface resistance and double-layer capacitance,D0 is an ideal photodiode,C0 is the capacitance (lumped parameter)between the silicon substrate and the electrodes as well as capacitance in the substrate,R0 is drain resistance; (c)structural schematic diagram of the SG Si-electrode; (d)the SG Si-electrode test circuit model,R1 is the grounded resistance formed between the substrate and ground,very small,approximately a wire resistance ideally.

2.2 Method for decrease light noise

In order to solve this problem,an improved structure is proposed,as is shown in Fig.1c.Underneath the lower dielectrics,the low-doped substrate is ohmic metallization and ground-connection.Grounding will eliminate the accumulation of photo-generated carriers.The new equivalent circuit is shown in Fig.1d.R0',D0',and C0' represent the same circuit but with a different value from that of the LD Si-electrode.By grounding the silicon substrate,both ends of the capacitor C0' and the photodiode D0' are short-circuited.This method enables photogenerated carrier recombination.The improved electrode is named as Substrate Grounded silicon electrode (SG Sielectrode).

3 Validation

3.1 Fabrication

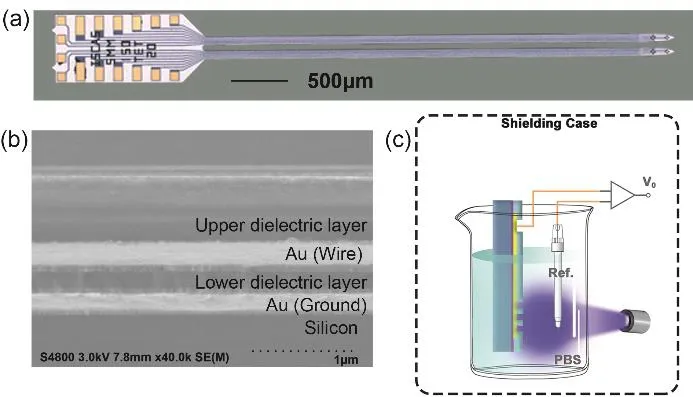

In order to verify the elimination methods,the SG Sielectrodes is fabricated to decrease the noise caused by light,as is shown in Fig.2a.The fabricating process of SG-electrode is identical with that of LD Si-electrode except for substrate processing15.Compared to LD Si-electrode,there are three additional steps.First,the outmost surface (about 300 nm)of the silicon substrate is heavily N+doped to form the ohmic contact layer.Second,Cr/Au/Cr (12 nm/150 nm/12 nm)is deposited for grounding.Since then,the electrode fabrication process is as same as that of the LD Si-electrode.The last process added is exposing the ground pad by etching the upper and lower dielectric layer,as is shown in Fig.2b.

3.2 Testing

In order to study the interference of light illuminating on silicon-based microelectrodes,a simulation test is set up,as shown in Fig.2c.A commercial Ag/AgCl electrode is used as a reference electrode.Both silicon-based electrodes (after being wire-bonded on a customized printed circuit board)and the reference electrode are immersed in 0.1 mol·L-1phosphate buffer saline (PBS)solution (36 °C,pH=7.3)and connect to the corresponding port of a multi-channel recording system.(Blackrock,128-channel multi-channel Neural Signal Processing System,AC coupling,Bandwidth 0.3-7.5 kHz,the sampling frequency is set to 30 k·s-1.)

Blue (460 nm)LED and yellow (620 nm)LED are used as light sources (PlexBright,a commercial optogenetics apparatus provided by Plexon company).The output of the LED is modulated into a square wave.The width,repetition frequency,as well as intensity of the pulse,can be adjusted.A multi-mode fiber with a diameter of 200 μm is used to guide light to the electrode.The fiber end is set 1 mm away from the surface of the silicon electrode.The optical power density of the irradiation on the silicon electrode can be adjusted from 0.1 to 2 mW·mm-2.0.1 mW·mm-2is sufficient to activate ChR2-expressing neurons in vivo16.The test system is in an electromagnetic shield to minimize the interference from the LED driver or other electronic equipment.

Fig.2 (a)Image of the SG Si-electrode from Olympus OLS4100; (b)scanning electron microscope (SEM)image of the SG Si-electrode;(c)simulating testing setup of light sensitivity in 0.1 mol·L-1 phosphate buffered saline (PBS,pH 7.3).

Fig.3 (a)Comparison of the optical noise of the LD Si-electrode and the SG Si-electrode under different light intensities;(b)multi-sample (N=45,each sample noise-level is the average of 10 s)statistical average noise-level of the SG Si-electrode and the LD Si-electrode under different optical power densities.

When the LD Si-electrode is placed in a dark environment,the noise voltage (peak-to-peak)is around 30 μV,as shown in Fig.3.This noise mainly consists of two components:thermal noise,Vt,from the electrode,and the bottom noise,Vb,from the amplifier.For electrodes with the typical impedance of 1 MΩ @1 kHz,the value of Vt is about 14 μV,and Vb is 14 μV bandwidth 0.3-7.5 kHz17.In order to determine the photosensitive portion of the probe,electrodes having the same dielectric and metal layer on the glass substrate have been fabricated and tested.The results show that either under the illumination or in the dark,the bottom noise is around 30 μV.The noise caused by light must come from the silicon substrate.

4 Results and discussion

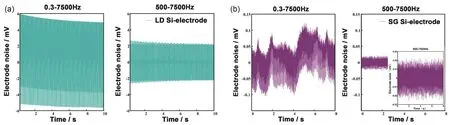

The proposed electrode is tested in the same environment as that of LD Si-electrode.LD Si-electrodes with the same electrode area (20 μm in diameter)and similar impedance (0.5-1 MΩ @ 1 kHz)are tested simultaneously as control groups.The test results are shown in Fig.3a.Two groups of electrodes perform the same noise level in a dark environment.When the LD Si-electrode is illuminated by the blue light,with a repetition frequency of 20 Hz and a pulse width of 10 ms,a large noise occurs as soon as the light shines.As shown in Fig.3b,light pulse illumination will cause ten millivolts level noise on the LD Si-electrode.When the light is turned off,the high noise disappears,and the amplifier output regains its original noise amplitude.Compared with LD Si-electrode,the SG Si-electrode has a significant reduction in noise when irradiated with light pulses.

Taking peak-to-peak noise level for contrast,when the irradiated power density is 0.1 mW·mm-2,the noise of the LD Si-electrode is around 10 mV,whereas the value of the SG Sielectrode has a magnitude of only 38 μV.As the light power increase,the noise value of both electrodes will increase at a low power density range.When the light power density is higher than 0.5 mW·mm-2,the noise level of the LD Si-electrode will tend to be saturation and stay around 12-13 mV.After this point,even if the light power is increased,the noise-level maintains in this value.It means that the light-induced potential reaches the maximum open-circuit voltage of the photodiode.Whereas for the SG Si-electrode,the noise value keeps increasing until light power density increases to 1 mW·mm-2.This phenomenon proves:First,there is still a photo-voltage effect on the proposed device.Second,taking the distribution resister inside the silicon into consideration,grounding is not ideal.Therefore,the value of R1is not zero.So the light-induced carriers will accumulate and establish potential on C0'.The potential will remain at a value when charging from the photodiode D0' reach balance with discharging by R1.When the light-induced current from D0'increase,the potential across R1 increases too to form a new balance.However,the noise of the novel electrode is only 110 μV,even when the optical power irradiated on the silicon electrode increases to 1 mW·mm-2.Multi-sample (N=45,each sample noise level is the average of 10 s)statistical average noise level of the SG Si-electrode and the LD Si-electrode under different optical power densities are shown in Fig.3b.Compared with the noise-level of LD Si-electrode (12.63 ± 0.14 mV),that of SG Si-electrode (110 ± 40 μV)decreases by 99.13%.

Fig.4 shows the noise spectra of two kinds of electrodes irradiated by light pulse with a power density of 1 mW·mm-2.The main energy of the noise is concentrated in the lowfrequency range,especially at 20 Hz and its harmonic waves.It means high-frequency neural signals,such as a spike or action potential,are influenced less than that of low frequency.After high-pass filtered (> 500 Hz),the noise amplitude of both electrodes decreases,as shown in Fig.5.For example,the noise level of the SG silicon electrode is decreased to 40 μV at the highest irradiating power density.It is nearly the noise value in the dark.It means with this method,the light sensitivity of the light-doped silicon-based electrode is reduced dramatically,and light stimulating spike can be recorded without interference.

Fig.4 Noise spectra analysis of two types of electrodes in frequency band 0-1500 Hz,light was applied a square pulse (10 ms)train with the power density of 1 mW·mm-2 at 20 Hz.

We also compared the noise of SG Si-electrode with that of LD Si-electrode under the irradiation of yellow light (620 nm)with the same pulse mode.Studies prove that yellow light will cause higher noise on either LD or SG Si-electrode under the same optical power density.The average noise level in yellow light is 13.06 mV for LD Si-electrode and 0.13 mV for SG Sielectrode.The corresponding values in blue light are 12.63 mV and 0.11 mV.Compared with blue light,yellow light travels deeper into the silicon,we guess,there are more light-induced carriers contribute to the voltage.Even so,the noise level after high pass filter (> 500 Hz)is 0.045 mV for the SG Si-electrode.The light-induced noise on the proposed device has little effect on spike recording.

Fig.5 (a)Noise performance of the LD Si-electrode at 0.3-7500 Hz and after 500-7500 Hz filtering;(b)the SGSi-electrode noise at 0.3-7500 Hz and after 500-7500 Hz filtering.

Compared with the silicon microelectrodes fabricated with heavily doped silicon substrates,the carriers in lightly doped silicon have a longer lifetime.It is difficult to eliminate light interference completely.However,the proposed method can eliminate the overwhelming majority of (> 99%)light noise.On most occasions,the waveguide or fiber is set parallel with the surface of the silicon film electrode.From the experiment,we find that the actual power incident parallel with the silicon substrate is only about 1/6 of the power incident at the simulation set up.1 mW·mm-2irradiation is corresponding to 0.17 mW·mm-2when a fiber is parallel placed on the surface of the silicon-based electrode.In this light power density,the optical noise (including the noise baseline in the dark)generated by the SG Si-electrode is about 40 μV,since the noise mainly concentrates on the frequency under 500 Hz.Spike signals can be recorded nearly without interference.

Metalizing and grounding the lightly doped silicon substrate will effectively decrease the noise,but it needs a high pass filter(> 500 Hz)to get the clean spike.That's not suitable for extracting the local field potential (LFP),because the square wave used in optogenetics contains rich low-frequency harmonic waves and the frequency of these harmonic waves is exactly included in the LFP frequency range.Recording the LFP with sufficient signal-to-noise ratio under light stimulation is still to be studied.

5 Conclusions

A silicon-based photoelectrode is an important tool in the study of optogenetics.An electrode made from lightly doped silicon has more advantages in electrodes-circuit integration and better mechanical characteristics.However,light caused potential fluctuation in the lightly doped silicon substrate severely disturbs the electrode's signal.To decrease the light sensitivity of the LD Si-electrode,the silicon substrate is ohmic metalized and grounded.The novel electrode in this method is fabricated and tested.The results show that the proposed method can reduce the noise generated by photo-excitation by more than 99%.With the help of a high pass digital filter (> 500 Hz),the optical noise of the novel electrode can be controlled below 45 μV under a light intensity of 1 mW·mm-2.This method allows the photo-stimulation and the spike recording to be performed simultaneously.Nevertheless,the lightly doped silicon substrate and the fabricating process is compatible with the process of standard CMOS technology.With the help of this method,high density and high throughput microelectrode array without light sensitivity can be developed by standard CMOS technology.